Design work on the creation of heating systems requires a clear understanding of the dimensions of heating elements, including radiators. Considering the significant diversity of the latter, such systematization is a truly important task. There are three large groups of radiator sizes:

- standard for the former USSR;

- low radiators;

- tall and non-standard.

Based on the type of materials, radiators are classified as follows:

- aluminum;

- cast iron;

- steel;

- bimetal

Aluminum battery sizes

In Soviet times, “winged metal” was almost not used in the production of metal structures and household appliances due to its shortage; aluminum radiators appeared only in the 90s. Therefore, they are characterized by a wide variety of sizes. The most common sizes: 80x100x585 mm.

Heat dissipation is up to 200 watts per radiator section. The operating pressure of the coolant in the system is 16 atmospheres. Low aluminum radiators are available in a wide range of sizes: from 150 to 400 mm. The most common are 40x200x180 mm.

As you can see, the short length and height of the section is compensated by its high depth, which is almost twice as high as on Soviet standard radiators. This allows “low” format radiators to have very variable heat output - from 50 to 180 Watts per section. Working pressure - 16-24 atm.

Common types

The most common and oldest models are cast iron. Today they are used less frequently, but there are a sufficient number of buildings that are heated with the help of such batteries. Previously, the size of heating radiators made of cast iron was impressive, they looked unaesthetic.

Today, manufacturers have improved them, and it is also possible to hide the device under a special screen, the design of which is selected to the taste of the homeowner. The advantages of such radiators are unpretentiousness to the chemical composition of the coolant, resistance to corrosion and high temperatures, durability, ease of operation, and no need for constant maintenance.

We advise you to study - What to choose - a bathtub or a shower

But batteries also have disadvantages. The most important of them is considered to be instability to sudden temperature changes, therefore, in the event of system failures in centralized heating, cracks and coolant leaks may appear. Installation is problematic because the structure is heavy.

Transportation of such radiators is also difficult, since careless handling results in defects that make the device unsuitable for use. A significant disadvantage is the inability to properly paint old models, as well as the need to regularly update the coating

Despite the shortcomings, the devices are used in apartments and private houses, as they are considered reliable and durable.

Aluminum heating radiator, how to add, twist sections, extend and unscrew the battery

Aluminum models

Aluminum radiators have become quite popular in the last few years. They have advantages that make the models the most preferable option for installation in a private home:

But there are also some disadvantages. The most important is the impossibility of installing such batteries in apartments, since the devices have a low operating pressure. If central heating is interrupted, local leaks may occur due to structural damage.

Aluminum is a brittle metal that is easily damaged during transportation or installation. Its peculiarity is the ability to interact with the chemical components of water in the system. As a result, corrosion areas form on the inner surface, which gradually lead to the complete destruction of the metal. The service life of such models is slightly lower than that of their cast iron counterparts, and ranges from 5 to 15 years. Some manufacturers have been able to extend this period to 20 years.

Bimetallic and steel

Steel and bimetallic models are considered the most modern and reliable, their service life reaches 25-30 years. The first is a stainless steel structure, which is made in different shapes.

The most affordable option would be a steel panel battery, made in a modern style and having a small size and attractive design. Tubular models are durable and are made in the form of small diameter tubes connected to each other. Their number depends on the area of the room.

Sectional models are also very reliable and durable. They are a structure of several sections connected to each other by spot welding. This method allows you to extend the life of the radiator and eliminate the possibility of leakage.

Bimetallic radiators are also available in several versions and are distinguished by their reliability and long service life. The outer frame of the battery is made of a special alloy of aluminum and silicon called silumin. Inside each section there is a steel pipe that prevents contact of silumin with water. This reduces the likelihood of corrosion areas forming.

Bimetallic and steel radiators are suitable for installation in a private house and apartment with a centralized heating system. The devices can withstand operating pressure differences and high coolant temperatures and are not subject to corrosion. A significant advantage is the unpretentiousness to the chemical composition of the coolant.

The disadvantage of the models is their high cost, which differs from the prices of aluminum analogues

It is also worth considering that these heating devices must be installed and connected to the system carefully, following all instructions

How to choose a bimetallic radiator?

Dimensions of bimetallic batteries

Bimetallic radiators consist of a steel core and an aluminum body. The main change that a steel core brings compared to an aluminum one is an increase in the permissible coolant pressure. Of course, the price also increases. The most common sizes: 80-82x75-100x550-580 mm.

Heat transfer is slightly reduced due to the lower thermal conductivity of steel, but is compensated by greater ribbing in the section area. Heat transfer rates: 160-200 Watts per section. The working pressure can be significantly yours: from 25 to 50 atmospheres.

Bimetallic radiators are characterized by the same range of standard sizes as aluminum ones.

The dimensions of low aluminum radiators are also typical for bimetallic ones. At the same time, the heat transfer characteristics also change slightly: radiators from 40 to 140 watts per section are common.

Bimetallic radiators, due to their higher performance characteristics, are more often used to build non-standard heating systems. In particular, such radiators are often used to stylize heating elements in the form of interior design elements.

It simply doesn’t make sense to somehow evaluate standard sizes - they simply don’t exist. Most European radiator manufacturers have their own series of radiators in a wide variety of, often exotic, sizes.

Calculation of radiator sections depending on real conditions

Once again, please note that the thermal power of one battery section is indicated for ideal conditions. This is how much heat the battery will produce if its coolant temperature at the inlet is +90°C, at the outlet +70°C, and the room is maintained at +20°C. That is, the temperature pressure of the system (also called “delta system”) will be 70°C

What to do if your system does not exceed +70°C at the inlet? or do you need a room temperature of +23°C? Recalculate the declared power.

Formula for calculating the temperature pressure of a heating system

For our case it turns out: (70°C+ 60°C)/2 - 23°C = 42°C. The delta for such conditions is 42°C. Next, we find this value in the conversion table (located below) and multiply the declared power by this coefficient. Let's learn the power that this section can produce for your conditions.

Table of coefficients for heating systems with different temperature deltas

When recalculating, we proceed in the following order. We find in the columns tinted blue a line with a delta of 42°C. It corresponds to a coefficient of 0.51. Now we calculate the thermal power of 1 radiator section for our case. For example, the declared power is 185 W, applying the found coefficient, we get: 185 W * 0.51 = 94.35 W. Almost twice as much. This is the power that needs to be substituted when calculating the radiator sections. Only taking into account individual parameters will the room be warm.

Dimensions of cast iron radiators

The standard cast iron radiator of the MS-140-500-0.9 brand is a long-liver of Soviet “Khrushchev” apartments and panels. It was this model that was most often used in the USSR to equip collective heating systems. Its characteristics: 93x140x588 mm.

Most often, such radiators are 7-10 sections long. Heat dissipation - 160 Watt. The operating pressure of the coolant is 9 atmospheres.

Cast iron radiators, sized for low ceilings, are represented by the Belarusian model MS-140M-300-0.9. Specifications: 93x388x140 mm. The heat output is 106 watts. The operating pressure of the coolant has not changed. There are imported samples with center distances of 150, 200 and even 350 mm, but these are clearly exotic.

Large cast iron radiators are represented almost exclusively by imported, European models. For example, consider the characteristic Demrad Retro line: 76x661-954x203 mm.

Working pressure - 10 atmospheres. Thermal power is impressive: 270 Watts per section. There are also more exclusive models on the market. However, they are used extremely rarely, primarily due to the large weight of the cast iron structure.

Other options

Aluminum radiator in the interior of the room

Weight matters when choosing heater mounts.

The passport indicates the mass of one section. To determine the total weight of an unfilled radiator, this parameter must be multiplied by the number of sections. Depending on the size, the weight of one section can range from 1 to 1.47 kg.

The volume of water in the radiator is also calculated from the parameters of one section, which must be multiplied by the number of sections.

The capacity (internal volume) of a section depends not only on its dimensions, but also on the thickness of the shell. The average capacity of one aluminum section is in the range of 250 – 460 ml. The internal volume of the radiator is taken into account when calculating heating systems and has a direct impact on the volume of coolant required to fill them.

The maximum permissible coolant temperature for aluminum radiators is standard and is 110 degrees.

A large selection of design solutions for vertical heating radiators allows them to be installed even in rooms without windows. Photos of interesting models.

Dimensions of steel radiators

In the USSR, heating radiators were traditionally made from cast iron. Consumer fashion for aluminum, bimetallic and steel radiators appeared relatively recently. Therefore, among these products the most common are products from European manufacturers. Accordingly, such radiators have a European system for classifying dimensions and sizes:

- Type 10 – one row, no fins, like cladding;

- 11 – one row with fins, without cladding;

- 20 – two rows without fins;

- 21 – two rows with fins, cladding and grille;

- 22 – two rows with two fins, panel cladding and grille;

- 30 – three rows without fins and with an upper grille;

- 33 – three rows with three panels and an upper grille.

Currently, the most common radiators are types 11, 22 and 33. These radiators have the following dimensions:

- 11— 30x40 cm;

- 11— 90x40 cm

- 22—50x100 cm

- 22— 90x300 cm

- 33— 30x100 cm

- 33—60x100 cm.

Qualitative characteristics

Before purchasing a heating device, you should study the quality characteristics of various models, showing the design features and manufacturing technology.

Coolants

The technical data sheet for the product must indicate which coolants it can be used with. The permissible range of values of the hydrogen index (pH) of the coolant can also be indicated. If an aluminum radiator is supposed to operate with non-freezing liquids (antifreeze), special intersectional gaskets are used in its design.

Connection diagrams for aluminum radiators.

Connection methods

The standard aluminum radiator section has upper and lower manifolds, allowing for one of the known side connection methods. Some models of heating devices are equipped with a manifold with a lower connecting pipe, allowing for a convenient bottom connection when installing a manifold heating system.

Scheme of coolant flow with bottom connection.

Manufacturing method

Sections can be manufactured by injection molding or extrusion. Extrusion is a forming method that produces a high-density product. Radiators made by this method have higher strength, which allows them to withstand increased pressure.

Aluminum radiators of various sizes.

Aluminum sectional radiators have proven themselves well in individual heating systems, when the homeowner has the opportunity to independently choose the type of coolant and control its quality. Such devices are characterized by high thermal performance, outperforming bimetallic models due to their lower cost. The technical characteristics of aluminum heating radiators give the buyer the opportunity to choose the best model among a number of analogues.

How to calculate the size of radiators for a room

Knowing the basic characteristics of heating equipment and the area of the room, you can easily determine the required radiator power, and subsequently all the characteristics of the system, including the boiler.

Let's look at a similar calculation using a real example:

Let’s say a room with the characteristics of 4x3x2.7 is planned for installation of heating - a standard bedroom in a Soviet Khrushchev-era building.

First, let's calculate the volume of the room that will have to be heated: 4*3*2.7=32.4 m3. It is this volume of air that our radiator will have to heat.

Then you should determine how much heat will need to be spent to heat this volume. Without taking into account measures to increase energy efficiency (energy saving, wall insulation, etc.), the standard for the temperate climate zone of Eastern Europe is the cost of heating one cubic meter of 41 watts.

Accordingly, to heat our room you will need: 32.4 m3 * 31 Watt = 1.3 kV

This is the amount of energy that the air needs to receive from the radiator for heating. Next, knowing the required amount of heat, you can calculate the technical characteristics of the radiator that will be mounted.

Each radiator has a heat transfer characteristic. This is the amount of energy that the equipment is capable of releasing into the atmosphere while maintaining the quality indicators of the heating system. This figure may be underestimated, but cannot be exceeded. The radiator power is always indicated on the packaging, in the passport or certificate.

Heating our room will require 1.3 kW of energy. To prevent force majeure effects during abnormal frosts, the indicator is calculated with a margin of 15-20%. In total we have 1.5 watts.

One fin of a standard bimetallic radiator is capable of delivering up to 150-180 Watts of energy. Total: 1500/150=10. Those. To fully heat our room, we will need to install a 1.5 kW radiator, consisting of 10 fins.

Important! The Soviet heating standard was used in the calculations. In practice today, most older apartment buildings and new buildings under construction use numerous technologies to improve energy efficiency. For the most accurate calculation, you should better study the thermal efficiency indicators of the house, windows, etc.

If the walls are insulated and vacuum metal-plastic windows are installed, the actual energy consumption for heating can be reduced by 2 or more times. Accordingly, there is no point in purchasing a radiator of higher power.

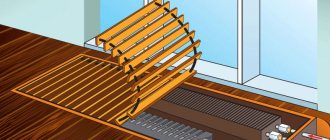

Optimal installation schemes for heating components

If you need to reduce the costs of operations such as installation of 350 mm heating radiators and their further connection, then you can opt for a single-pipe type wiring system. Such a system, however, requires the presence of a bypass line.

Valves will be installed at the highest points through which air will be released. Such a valve will operate automatically, they will release air, and the air inlet will be blocked by water pressure.

Such a valve will also be required during various dismantling works. In the case of a single-pipe distribution system, such a valve is best connected diagonally. In this case, the coolant will flow in the upper left corner and be discharged in the lower right.

The reverse option can also be used. The most important nuance that must be observed is not to connect heating radiators 150 mm high on the same side. In this case, you can lose up to 10% of heat transfer. If small or mini heating radiators are installed, it is best to make a bottom connection.

Dimensions

Radiators

determine the amount of coolant

they can accommodate.

This determines the power of heating batteries.

Which radiator is better to choose?

The choice of radiators depends on what goals you are pursuing. If the number one goal is to save money, then you can find an old Soviet cast-iron radiator in a landfill or scrap metal that will last another hundred years without the slightest breakdown.

If the buyer’s task is to effectively combine an inexpensive product and a good design, modern steel radiators are best suited - they perfectly combine high heat transfer, modern design, durability and maintainability.

If the goal is to achieve maximum thermal efficiency, you should pay attention to bimetallic products with a copper core. This technique provides maximum heat transfer, but the price will make you think.

Today, suppliers are ready to provide any desires of the buyer - from elite European goods to cheap and low-quality Chinese ones. In any case, when purchasing products for such an important thing as heating, you should consult a specialist.

Tall and narrow

Tall radiators, even in their usual design, look unusual. And if you paint it in a non-standard color, give it an unusual shape, and combine it with a mirror or shelf, it generally looks more like a designer item than a banal heating device.

Let us immediately upset cast iron lovers: the tallest cast iron radiator is around a meter. Haven't seen it higher. The same can be said about bimetallic ones - they don’t come above a meter. And in general, all that is in bimetal is 760-860 mm or so.

One of the most attractive models is the Arbonia Entreetherm vertical tubular radiator

Steel panel batteries as standard come in heights of up to 900 mm. But there are also special models that can reach two meters and higher. For example, Kermi has two models Verteo Plan and Verteo Profil - the maximum they can be up to 2.2 m. Purmo also has giants: Kos V, Faros V, Tinos V, Narbonne V and VT, Paros V. They differ in the type of front panel (smooth or profiled) and depth. But they all only have a bottom connection.

Steel tubular radiators are available with a height of up to 3000 mm. Moreover, if necessary, some manufacturers can make it higher. There are tall models from any manufacturer: everyone on the market offers such non-standard options “to order.” Here we will list only the most interesting from a design point of view: Entreetherm, Planterm from Arbonia, Dekor series from Kermi, Harmony from the Russian KZTO, Charleston from Zender.

Other types do not have tall radiators. The choice, it must be said, is considerable. Don't get confused.

Simplified calculation of heat loss compensation

Any calculations are based on certain principles. The calculations of the required thermal power of batteries are based on the understanding that well-functioning heating devices must fully compensate for the heat losses that occur during their operation due to the characteristics of the heated premises.

For living rooms located in a well-insulated house, located, in turn, in a temperate climate zone, in some cases a simplified calculation of compensation for heat leakage is suitable.

For such premises, calculations are based on a standard power of 41 W required to heat 1 cubic meter. living space.

In order for the thermal energy emitted by heating devices to be directed specifically at heating the premises, it is necessary to insulate walls, attics, windows and floors

The formula for determining the thermal power of radiators necessary to maintain optimal living conditions in a room is as follows:

Q = 41 x V,

where V is the volume of the heated room in cubic meters.

The resulting four-digit result can be expressed in kilowatts, reducing it at the rate of 1 kW = 1000 W.