To heat a small living space or a two-story private house, it is not necessary to use complex, expensive technologies. The Leningradka heating system, known since the times of the Soviet Union, is today effectively used to provide heat to small residential buildings.

It remains popular due to its ease of design and economical consumption of materials. After all, you see, more expensive and more complicated does not always mean better.

You can equip the single-pipe Leningradka yourself. We will help you understand the operating principle of the system, provide basic technological diagrams and describe step by step the technology for installing the heating system. Visual photo and video material will help plan the implementation of the project.

Characteristics of Leningradka

When choosing an installation, you should pay attention that it differs in the method of coolant circulation:

- Water is forced to move. Leningradka with a pump increases circulation, but at the same time consumes electricity.

- Water moves by gravity. The process is carried out thanks to physical laws. Cyclicity is ensured by temperature differences and gravity.

The technical characteristics of Leningradka without a pump are inferior to forced ones in terms of the speed of movement of the coolant and the speed of heating.

To improve the properties of the equipment, it is equipped with various devices:

- Ball valves - thanks to them you can regulate the temperature level to heat the room.

- Thermostats direct the coolant to the desired zones.

- Valves are used to regulate water circulation.

The listed additions allow you to upgrade even a previously installed system.

Advantages and disadvantages

The advantages of use include:

- Cost-effective – the cost of the elements is low, installation can be done independently. During operation, energy is saved.

- Availability - parts for assembly are available in any hardware store.

- The heating system of a private house in Leningradka can be easily repaired if it breaks down.

Among the shortcomings are noted:

- Installation features. To equalize heat transfer, it is necessary to add several sections to each radiator located far from the boiler.

- Inability to connect to horizontal installation of heated floors or heated towel rails.

- Since pipes with a large cross-section are used when forming an external network, the equipment looks unaesthetic.

How to install correctly?

Installing Leningradka is quite feasible with your own hands; for this, choose one of the methods:

1. Horizontal. A prerequisite is the installation of a floor covering in the structure or on top of it; this must be chosen at the design stage.

The supply network is installed at a slope to ensure free movement of water. All radiators must be located at the same level.

2. Vertical is used when using forced-type equipment. The advantage of this method is the rapid heating of the coolant, even when installing pipes with a small cross-section. Operation occurs due to the installation of a circulation pump. If you want to do without it, then you should purchase pipes with a large diameter and place them at an angle. The Leningradka vertical water heating system is installed with bypasses, allowing repair of individual equipment elements without shutting it down. The length should not exceed 30 m.

Features of installing the Leningradka heating system come down to following the sequence of work:

- Install the boiler and connect it to the common line. The pipeline must run along the entire perimeter of the building.

- The expansion tank is a mandatory element. To connect it, a vertical pipe is cut in. It should be located close to the heating boiler. The tank is installed above all other elements.

- Radiators are installed into the supply network. They are equipped with bypasses and ball valves.

- The equipment is connected to the heating boiler.

A video review of the Leningradka heating distribution system will help you understand the order of work and follow their sequence.

“Several years ago we moved to live outside the city. We have a single-pipe heating system installed in a two-story house similar to Leningradka. For normal circulation, I connected the equipment to the pump. There is enough pressure to heat the 2nd floor, it is not cold. All rooms are well heated. Easy to install, no expensive materials required.”

Grigory Astapov, Moscow.

“When choosing heating, I studied a lot of information. According to reviews, Leningradka suited us due to the savings in materials. We chose bimetallic radiators. It works uninterruptedly, completely copes with heating a two-story house, but the equipment should be cleaned periodically. After 3 years, our radiators stopped working at full capacity. It turns out that there was debris on the approaches to them. After cleaning, operation resumed.”

Oleg Egorov, St. Petersburg.

“The Leningradka heating distribution system has been working with us for several years now. Overall satisfied, easy installation and easy maintenance. The pipes were polypropylene, 32 mm in diameter, the boiler runs on solid fuel. We use antifreeze diluted with water as a coolant. The equipment completely copes with heating a house of 120 m2.”

Alexey Chizhov, Ekaterinburg.

Overview of basic technological schemes

Each of the Leningrad heating schemes has its own features of practical implementation, advantages and disadvantages, which we will familiarize ourselves with below.

Features of horizontal schemes

In one-story private houses or small premises, Leningradka is usually installed in a horizontal pattern. When implementing horizontal schemes in practice, it should be taken into account that all heating elements (batteries) are located on the same level, and they are installed along the walls along the perimeter of the room being equipped.

Let's consider the simplest classical horizontal open-type scheme with forced circulation.

On the horizontal diagram of "Leningradka": 1 - boiler; 2 - pipe; 3 - tank; 4 - circulation pump; 5 - drain ball valve; 6 — accelerating manifold; 7 — Mayevsky tap; 8 — radiators; 9 - outlet pipeline; 10 - sewerage; 11 - ball valve; 12 - filter; 14 - supply pipeline. The arrows show the direction in which the coolant moves

The diagram shows that the system consists of:

- Heating boiler , which is connected to the water supply system and to the sewerage networks;

- Expansion tank with pipe - due to the presence of this tank, the system is called open. A pipe is connected to it, from which excess water comes out when the circuit is filled, and air, which can appear when the liquid boils in the boiler;

- Circulation pump , which is built into the return pipeline. It ensures water circulation along the circuit;

- Hot water supply pipeline and cooled coolant discharge pipeline;

- Radiators with installed Mayevsky valves through which air is released;

- Filter through which water passes before entering the boiler;

- Two ball valves - when one of them is opened, the system begins to fill with coolant-water up to the nozzle. The second is secret; with its help, water is drained from the system directly into the sewer.

The batteries in the diagram are connected via a pipeline from below, but a diagonal connection can be arranged, which is considered more efficient in terms of heat transfer.

This diagram illustrates the principle of diagonal connection. The coolant enters from above through a pipeline connected to the top of the radiator, and exits from the back of the device at the bottom

The above scheme has significant drawbacks. For example, if a radiator needs to be repaired or replaced, you will have to completely turn off the heating system and drain the water, which is extremely undesirable during the heating season.

Also, the scheme does not provide the ability to regulate the heat transfer of the batteries, reduce the temperature in the rooms or increase it. The improved circuit below solves these problems.

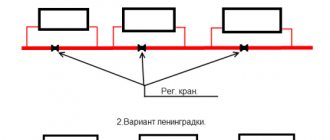

The main difference between the scheme and the previous one is that ball valves were placed on the pipelines on both sides (highlighted in blue), and bypasses with needle valves were introduced into the lower pipe (highlighted in green)

Ball valves installed on both sides of the battery are installed in order to be able to stop the flow of water to the radiator. To remove the battery for repair or replacement without draining water from the system, you can close the ball valves.

Thanks to the presence of bypasses, the battery can be removed without shutting down the system - water will flow through the circuit through the lower pipe.

Bypasses also allow you to regulate the amount of coolant flow. If the needle valve is completely closed, the radiator receives and releases the maximum amount of heat.

If you open the needle valve slightly, part of the coolant will flow through the bypass, and the other part through the ball valve. In this case, the volume of coolant entering the radiator will decrease.

Thus, by adjusting the level of the needle valve, you can control the temperature in a particular room.

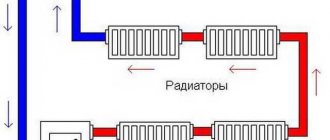

Let's consider a horizontal closed heating circuit with forced circulation.

The figure shows the implementation of the closed Leningradka scheme with forced circulation. The heated coolant is supplied through one collector pipe, which collects cooled water and discharges it to the boiler for further processing

Unlike an open circuit, a closed type system is under pressure due to the presence of a closed expansion tank. The system also includes a control and management panel.

It consists of a housing on which is installed:

- Safety valve. It is selected based on the technical parameters of the boiler, namely, the maximum permissible pressure. If the thermostat breaks down, excess water will escape through the valve, thereby reducing the pressure in the system.

- Air vent. The device removes excess air from the system. If the thermoregulation system fails, then when the liquid boils, excess air will appear in the boiler, which will automatically escape through the air vent;

- Pressure gauge. A device that allows you to control and change the pressure in the system. Typically, the optimal pressure is 1.5 atmospheres, but the figure may be different - it usually depends on the parameters of the boiler.

The closed system is considered the most modern solution due to the automation of some processes.

Image gallery

Photo from

Circulation pump in a single-pipe heating system

Safety group for pump heating

Automatic air vent on the radiator

Balancing fitting with bypass and ball valve

Application of vertical schemes

Vertical installation schemes of "Leningradka" are used in two-story houses with a small area. By analogy, they can be of an open or closed type, represented by circuits with forced circulation and gravity flow.

We have given systems with a circulation pump above. Let's consider a vertical scheme with closed-type natural circulation.

In the diagram, the pipeline is located vertically, and water is supplied from top to bottom through the expansion tank

It is quite difficult to implement a scheme with natural circulation. Here the pipeline is mounted in the upper part of the wall at a certain angle in the direction of water movement. The coolant flows from the boiler into the expansion tank, from where it moves under pressure through pipes and radiators.

For efficient operation of the system, the boiler must be located below the installation level of the radiators.

The scheme may also provide for the possibility of removing radiator batteries without stopping the heating system by installing bypasses with needle valves and ball valves on the pipeline.

Comparison of gravity and pump systems

There is an opinion that organizing a gravity heating system allows you to save on a circulation pump.

To organize the natural movement of the coolant along the circuit, it is necessary to correctly calculate the angles of inclination, diameter and length of the pipes, which is not easy to do. Moreover, a gravity system can operate smoothly and efficiently only in small one-story rooms; in other houses, its operation can cause a number of problems.

Another disadvantage of gravity flow is that its organization requires pipes with a diameter larger than when constructing forced heating circuits. They cost more and spoil the interior.

The diagram shows the implementation of gravity flow for horizontal wiring. Here the boiler is located below the level of the radiators, the coolant rises through a strictly vertically oriented pipe, enters the expansion tank and from there, through the accelerating manifold, enters the radiators

The room must have a basement for the boiler, since the heat source must be located below the level of the radiators. Also, to organize gravity flow, you will need a well-equipped and insulated attic on which the expansion tank will be mounted.

The problem with any gravity flow in a two-story house is that the radiators on the second floor heat up more than on the first. Installing balancing valves and bypasses will help partially solve this problem, but not significantly.

Moreover, the introduction of additional equipment leads to an increase in the price of the system itself, and its operation may remain unstable.

The most rational solution to the issue of the difference in the temperature of the coolant leaving the boiler and reaching distant devices on the ground floor is to install radiators with an increased number of sections.

Increasing the heat transfer area in this way makes it possible to practically equalize the heating characteristics at different tiers of the system.

Gravity-flowing “Leningradka” is not suitable for mansard-type houses, because it is possible to position the pipe evenly only in a house with a full roof. Also, the system cannot be implemented if people do not live in the house permanently.

Image gallery

Photo from

The principle of natural movement

Minimum reinforcement in the diagram

Limitations on the length of systems

Acceleration section of the collector pipe

Horizontal installation

This installation scheme is simple, but it has its own nuances that must be taken into account when performing work. So, the main should be either in the floor structure or on top of it

It is necessary to pay special attention to the thermal insulation of the system, otherwise it will not be possible to avoid high heat transfer

When laid on the floor, the covering will be mounted directly under the system. When using a single-pipe system, the installation procedure can be revised as the work progresses.

The supply line must be installed at an angle to create the required slope for fluid circulation. In this case, the heating batteries are placed on the same level. It is still worth installing Mayevsky taps on the radiators; with their help it will be possible to remove air bubbles from the system.

We lay pipes with our own hands

Before carrying out work, it is necessary to draw up a detailed design of the heating system. At this stage, you should choose one of the two schemes described earlier: vertical or horizontal. You should be guided by your preferences and characteristics of the premises.

Then you need to choose the most suitable type of coolant: antifreeze or water. The first, diluted with water, is best used with vertical decoupling so that it does not freeze in the attic during the cold season. The second one can be safely poured into a highway with a horizontal junction.

Let's get started

First, you need to determine what the heating boiler for the Leningrad heating system will be like and where it is best to locate it. Most often, a gas floor heating unit is installed, which is placed in the basement. It is necessary to take care of safety by reliably protecting the surfaces around and covering the floor with sheet iron.

Then you have to think about the chimney. Its type and design features will depend on the type of boiler selected

It is very important that it provides a sufficient level of draft and at the same time does not let smoke in, removing it out

You should start connecting the main main pipe, which has the largest diameter. Experts recommend choosing one of the following options:

- Metal-plastic (26 mm or more)

- Galvanized (22 mm or more)

- Steel (22 mm or more)

You can use polypropylene pipes. However, they have a significantly higher heat exchange with the environment, so they are not suitable in systems with 3 or more radiators. Distributing branches are made from pipes of smaller diameter.

The expansion tank must be securely fixed above the heating boiler. Its height must be at least 3 m from the heating device.

Next, a pipe creeps throughout the house and each of the heating radiators is cut parallel to it. You should try to make as few bends as possible when laying the highway. It is recommended to place batteries under window openings.

The Leningrad heating system must close at the boiler. At the end, it is recommended to place a filter element that will remove various impurities from the coolant. A node is also provided through which the system will be filled with water or emptied.

Despite the simplicity of Leningradka, no one forbids making some modifications to it to simplify operation and maintenance. By installing taps in front of each heating device and thermostats, the following advantages can be achieved:

- The heating will be controlled, allowing the room temperature to be set, and each radiator will be regulated separately

- It becomes possible to heat only living rooms and block the circulation of coolant through radiators in non-residential premises

In which houses is it beneficial to install single-pipe pumping systems?

A reduction in the length of heating pipes relative to two-pipe schemes is inherent in multi-storey residential buildings and industrial buildings (workshops, warehouses), characterized by heating circuit lengths of hundreds of meters. The use of “one-pipe” in them really saves heating pipes. Widespread use in individual construction is explained by a misunderstanding of the real cost-benefit ratio of this type of heating by customers and practical heating engineers.

In small two-story houses with an area of about 100 sq.m. (50 sq.m. on the first floor, 50 sq.m. on the second floor), a “one-pipe” is often installed, which works well with short circuits containing 4-5 heating devices. Large houses with many radiators are not well suited for single-pipe circuits, although objects with a dozen batteries in a floor circuit actually work, as in the mixed vertical-horizontal single-pipe circuit shown below.

Single-pipe system of mixed (vertical - horizontal) type.

Generalization on the topic

Today we can talk about a boom in the construction of individual housing. Many people prefer to solve the problems that owners of a private home have on their own. Practice shows that by doing heating installation yourself, you can save significantly. To avoid mistakes, simpler schemes are chosen. And the easiest system to assemble is a single-pipe heating option for a private home. Leningradka is an effective and economical heating scheme that is easy to assemble and maintain.

Single-pipe heating system for a two-story house with a circulation pump

Includes floor circuits with horizontal single-pipe distribution, connected by vertical “supply” and “return” risers. The latter are spatially separated or combined into a two-pipe riser. The circulation pump is connected to the return line (“return”) in front of the heating boiler.

The simplest one-pipe heating system for a two-story house, the diagram of which contains two circuits of 3 radiators each, is shown below.

Single-pipe horizontal system of a 2-story house with a pump.

The coolant flow through the horizontal line is N times greater (N is the number of radiators connected in series) required by the two-pipe circuit. The “single-pipe”, which has the same number of heating devices as the “double-pipe”, is equipped with a circulation pump of greater power.

Reviews

- Konstantin, Tula region

“I have a small country house. I often go there in winter, so I installed gas and decided to install heating. The choice was made on the Leningradka. A two-pipe system is too expensive for me, and a single-pipe system is inconvenient - it is difficult to maintain radiators, and you cannot turn off a separate battery. I didn’t take the pump, I connected the radiators diagonally. I’ve been using it for almost the whole winter now, so far there have been no complaints - I’m happy with everything. I can say one thing: “Leningradka” fully met my expectations.”

- Ivan, Novgorod region

“We brought gas to my parents’ village house. The question arose about installing a heating system. We decided to make “Leningradka”. The house is small - there are only 6 radiators. There is no point in a two-pipe system. So far everyone is happy. It heats quite well (I connected the batteries vertically). It works great without a pump, although many say it is necessary. Separately, I would like to say about savings - the expenses turned out to be very small.”

Pros and cons of this heating system

It’s not for nothing that Leningradka is very popular, because it has many important advantages:

- Possibility of laying the supply pipeline under the door opening;

- Low cost of setting up the system;

- Simple and inexpensive installation that you can do even with your own hands;

- Leningradka provides a minimum number of pipes on the surface, so communications will not spoil the interior of the room;

- The system can even be connected to two heating devices;

- If necessary, the system can be repaired;

- There are separate elements for Leningrad on the market, which will help you easily replace failed components;

- The system allows you to create a “warm floor” in the house.

Using one ring at the outer walls you will go around your entire home. With this installation method, the supply pipe comes from the center of the Leningradskaya, passes throughout the room and goes back.

It would be unfair not to talk about the shortcomings. This system also has them, but there are not many of them, and with proper planning and installation of disadvantages you can avoid:

The radiators that go at the end of the system must have a large number of sections. This solution will allow for uniform heat transfer from all batteries in the house;

The layout of a horizontal Leningradka is quite complex, and it is almost impossible to install heated floors and heated towel rails. Therefore, if you need such elements, it is better to use a vertical layout;

The single-pipe version of Leningrad will work effectively only at high pressure of the heat source.

Difference from the usual one-pipe scheme

In fact, one could consider the Leningradka a standard single-pipe heating system, if not for one “but” - jumpers under the radiators. Let's look at the diagrams of the Leningrad and standard single-pipe heating systems.

It is clearly seen that in the usual version, the heated coolant passes through the radiator and transfers heat to the next one to the extent that it remains after heating the previous battery. In Leningrad the situation is a little different. The heated water goes through the radiator and through the jumper, that is, it enters the next battery a little warmer than if it passes only through the radiator - this effect occurs due to the mixing of liquid in the section of pipe running from the jumper to the next element of the system. The circuit in both cases is shown on six components, and the difference in the latter is only five degrees, but even this difference is worth the additional effort and expense of creating bypasses.

Operating principle

Leningradka - classic heating scheme

The classic Leningradka system is a set of heating devices that are connected by a single pipeline. A coolant, which is water or antifreeze, circulates throughout the circuit. With the advent of new heating equipment, the system was improved, made controllable and expanded in functionality.

Depending on how the pipeline is located, the heating circuit is divided into two groups:

- horizontal;

- vertical.

The location of the pipes can be upper or lower. In the first case, the heat transfer efficiency is higher, but installation is more complicated. Bottom installation of the system is easier, but it is necessary to install a pump.

The circulation of the coolant in the circuit can be carried out in two ways - natural and forced using a pump. There are also closed and open systems.

The recommended number of heating devices when installing the Leningradka system is 5. This value can be increased to 6-7 by first performing the appropriate calculations. Installing more radiators will not be effective, and its cost will be unreasonably high.

To make the boiler work longer: advice from professionals

Some simple rules will help extend the life of your heating equipment.

It is necessary to provide:

- softened coolant without oxygen, even just boiled water;

- water softening station or polyphosphate filter;

- an oblique filter on the return, installed in a horizontal position so that it can be twisted to remove air from the expansion tank;

- compliance of the gas supply diameter with that recommended by the boiler manufacturer;

- grounding in the boiler room, voltage stabilizer to avoid the destructive effects of stray currents.

How to even out uneven heating of radiators

The usual way to equalize their heat transfer during unequal heating is to gradually increase the thermal power (or, equivalently, the number of sections) of the radiators as the coolant moves in the circuit. If the power of the first heating device in the circuit is taken as 100%, then the next one has it 110%, and so on up to 150-200% of the power of the last one (depending on the number of serial radiators).

When implementing a single-pipe heating system for a two-story house, the diagram of which includes a main pipe, the diameter of the latter is taken to be large. So, when making connections to radiators with a DN16 metal-plastic pipe, for eight or nine heating devices in a floor circuit, you should take a “main line” with DN40. The DN32 pipe will work, but the stability of the system will decrease. This means that any change in coolant temperature will lead to its imbalance, i.e. a noticeable change in the heating temperature difference between adjacent radiators in the circuit.

“Single-pipe” schemes with so-called radiator piping are common. "bypasses", as shown in the photo below.

Connecting a radiator in the “Leningrad” circuit with a bypass.

These are sections of smaller diameter included in the breaks in the line under the radiators, sometimes with a flow control device installed (needle valve or others). Control valves are also installed in one (or both!) connections to the radiators. It turns out that instead of a continuous line of one diameter, there is a pipe of variable diameter. At the same time, practical installers mistakenly believe that in order to branch the coolant flow into two components in the tee for supplying the radiator, it is necessary to narrow the main passage for it. This is incorrect because a liquid under pressure will fill any free volume encountered in its flow path.

Of course, if in such a scheme with many flow control devices you constantly manually control the heating of each device, then you can still, spending a lot of time, constantly achieve their uniform heating. But is the “game” worth the candle? If you make a “single-pipe”, then the radiators should be connected to a line with a constant large diameter, ensuring their stable operation with a slight decrease in the heating of devices along the circuit.

Conclusion

If radiators in a single-pipe circuit are connected to a main pipe with a diameter at least twice the diameter of the connections to them (with the appropriate size of fittings), then at the cost of such materials costs it is possible to reduce the temperature in the chain to 8-10 devices. In a two-pipe scheme, the same result is achieved with a small diameter of all heating pipes.

How to implement alternative heating for a private home

Two-pipe heating system for a private house - classification, types and practical design skills

Single-pipe and two-pipe heating distribution in a private house

Let's look at the Leningradka even closer - video ↑

For a clearer understanding of the operating features of this heating system, we recommend watching this video. It describes in detail and clearly all the subtleties and nuances of the system, as well as ways to solve possible difficulties during its arrangement.

A modern one-pipe system, if desired, can be equipped with all sorts of radiator regulators, balancing valves, thermostatic valves, ball valves - this will make it more balanced, making it possible to slightly lower the temperature in a particular heating device without a critical (significant) decrease in it in all subsequent ones. When designing and installing the Leningradka on your own, do not forget that the taps installed on the bypass and radiator connections will allow you to repair these devices without shutting down the entire system. Which, you see, is very convenient.

Building your own home is a responsible undertaking. The owner of the site will have to solve many important problems, one of which is the organization of autonomous heating. You can do it in different ways. But most often, a single-pipe heating system “Leningradka” is used for these purposes. Having installed it during the construction stage, you can subsequently independently create a comfortable microclimate in the house by controlling the heating temperature.

Selection of pipes by diameter

How to choose the materials that make up the Leningrad heating system

Pipe diameters are one of the main characteristics that is important to choose correctly. In general, the diameter used depends on many factors, including the area of the house, the cooling rate of the coolant, heat loss, circulation speed, etc.

All this is quite difficult to calculate, so it is better to determine which pipes are needed based on the nominal pressure. So, if 10 atmospheres is enough for the system to operate, then 25 mm pipes can be used. When the pressure is at 20-25 atmospheres, it is better to install pipes at 32 millimeters.

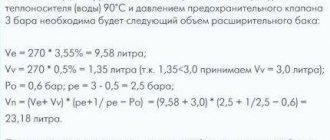

Thermal calculation

An individual calculation will allow you to determine the power of the boiler, the number of radiators, additional devices for the type of building and will save you from unnecessary expenses.

Calculation of boiler power depending on area

According to SNiP, for rooms with a ceiling height of 2.5 m, 1 kW per 10 m2 is provided, taking into account the correction factor.

Heating boiler power = (S x Wsp.)/10 m2,

where S is the total area of all premises;

Wud. (kW) - specific power, which is determined by the climatic zone:

- for Moscow and the region - 1.5;

- Middle band - from 1.2 to 1.3;

- Far north - from 1.5 to 2;

- Southern regions of Russia - from 0.7 to 0.9.

The choice of boiler is influenced by the volume of the room, the location of the rooms, the thickness of the external walls, the type of glazing, etc.

Number of radiators

The calculations are based on the ability of the system to maintain the required temperature, including in sections of the circuit. The number of sections is obtained taking into account the material of construction, the size of the device, and the volume of the room.

Standard section power (W):

- bimetallic - from 100 to 180;

- cast iron - from 120 to 160;

- aluminum - from 180 to 205.

The heat transfer losses of the heating system are taken into account. For radiators, it depends on the material and method of connection to the main line:

- with lower eyeliner - 12-13%;

- diagonal - 2%;

- single-pipe - 19-20%.

The Leningrad heating system with a natural circulation scheme allows the use of approximate data, but for designs with a pump it is necessary to carry out calculations more carefully. Laying out the pipeline with a polypropylene pipe in the drawing will help determine the length and required number of pipes to purchase.

Automatic control of heating system parameters

A servo drive is an automatic mechanism that provides the specified parameters of the coolant by sending a control signal to the mixer. The servo drive for heating works as follows. From a room thermostat or other sensors that record the temperature of the floor, coolant or air in the room, a signal is sent to the servo drive, which sets the mixer damper (three-way or four-way) to a position corresponding to the temperatures set on the sensors. The floor temperature is adjusted, for example, by moving the mixer damper. This movement bypasses the heated floor circuit and redirects part of the coolant to the return line. Thus, the floor temperature decreases and when the minimum permissible temperature is reached, the servo drive turns on again, but this time it closes the damper, more coolant enters the circuit and the temperature increases to the set temperature on the sensor. The cycle repeats periodically.

- How to fill water into an open and closed heating system?

- Popular floor-standing gas boiler made in Russia

- How to properly bleed air from a heating radiator?

- Expansion tank for closed heating: device and principle of operation

- Gas double-circuit wall-mounted boiler Navien: error codes for malfunctions

Recommended reading

Which batteries are best to choose for heating a private home? Heating project for a two-story house: choosing a scheme and connection method What does the heating scheme for a one-story house with forced circulation look like? Heating of greenhouses - types of systems and heating sources

2016–2017 — Leading heating portal. All rights reserved and protected by law

Copying site materials is prohibited. Any copyright infringement will result in legal liability. Contacts

Using a heat accumulator

The heat accumulator is a container connected to the heating system, filled with coolant. The coolant in such a container is heated using a coil connected to the heating.

The main task of the heat accumulator is to smooth out peak heat consumption in the system. The use of such containers is justified in the following cases:

- Using a solid fuel boiler. Such boilers require constant fuel supply. This is easy to do during the day, but at night the fire goes out and the system stops working. In such cases, the energy accumulated during the day in the heat accumulator will be spent at night, maintaining the temperature in the house.

- Use of alternative energy sources: solar panels, solar panels. During the day, this energy is spent to increase the energy of the coolant in the buffer tank. And when using gas or electric boilers, the load on the main heat sources is reduced. Significant savings are made on space heating costs.

Schemes and principle of operation

The Leningrad heating system for a private house provides for sequential installation and connection of heating devices. The coolant in the form of ordinary water or non-freezing liquid moves through all batteries, and along this path its temperature drops. As a result, the water inside the batteries farthest from the boiler will not be as hot. As already mentioned, this problem is solved by increasing the number of sections.

For heating a small house on 1-2 floors, a single-pipe system is perfect. If the scheme involves laying pipes under the floor level, then care should be taken to insulate them; for this, roll materials are used. If this is not done, there will be large heat losses.

The operation scheme of a single-pipe system for a two-story building is quite simple: the coolant enters the batteries and begins to move to the top point. When the liquid cools, it will begin to descend to the bottom. At the same time, the heating and cooling processes take place simultaneously, so the Leningrad machine works without interruptions.

Heating installation requirements

When building a Leningradka with your own hands, you must follow the rules:

- A boiler operating on flammable or explosive fuel is installed in a special room with a separate exit and a window to the street. The requirements for the boiler room are described in the instructions MDS 41.2-2000 and building regulations.

- The start of installation of the heating system is preceded by power calculations and project development in accordance with SP 60.13330.2016.

- The pipeline must contain a minimum number of bends and turns. It is also recommended to use taps, fittings, and pipe narrowings to a minimum, which increase hydraulic losses.

- The slope of the liner is 5-10 mm per 1 meter, except for areas up to 50 cm long, where it is not provided.

121LO

5-, 10- and 9-story buildings of the 121LO series are still being built. The ceilings here reach 280 cm. There are balconies even on the ground floor.

Five-story panel building 121 series

The layout of the house is comfortable. Few people change them. Yes, this is practically impossible, since the interior walls here are load-bearing.

Layout of a typical section

The maximum that can be done is to use the balcony as a living space. Usually there is a relaxation area or a desktop with a computer.

Several design options for such balconies:

All series have a problem with poor sound insulation. But in new houses the issue has been partly resolved by sealing the internal joints of the panels with silicone.

In any case, when buying an apartment in a Leningrad-style building, you will have to think about soundproofing the walls, ceiling and floor.

Adblock detector

Installation of the heating structure "Leningradka"

Before you start building a heating system for a private house with your own hands, you need to perform a competent and accurate calculation. It will be problematic to do this on your own, so it is better to turn to professionals in this industry. Using calculations, you can determine the list of equipment and materials needed for the work.

The main elements of the “Leningradka” include the following:

- boiler for heating the coolant;

- metal or polypropylene pipeline;

- radiators (batteries);

- expansion tank or tank with valve (for an open system);

- tees;

- a pump to ensure coolant circulation (in the case of a forced design);

- Ball Valves;

- bypasses with needle valve.

In addition to calculations and purchasing materials, you should also take into account the location of the pipeline. If you plan to install it in a wall or floor, you will need to prepare special niches - grooves, which should be located along the entire perimeter of the contours. In addition, all pipes must be wrapped in thermal insulation material in order to prevent the temperature of the liquid from dropping before entering the radiators.

What is the best material to choose for the pipeline?

Most often, polypropylene is used as a pipeline for installing Leningradka in a private house. This material is quite simple to install and inexpensive. However, experts do not recommend installing polypropylene pipes in regions where the air temperature drops too low, meaning the Northern Territories.

Polypropylene begins to melt if the coolant temperature rises above 95 degrees, which can lead to pipe ruptures. In such cases, it is more advisable to use metal analogues, which are rightfully considered the most reliable and durable.

In addition to the material, when choosing a pipeline, it is important to choose the correct cross-section. In this case, the number of radiators used in the circuit is of no small importance. For example, if the circuit is supposed to have 4–5 elements, then the diameter of the pipes for the main should be 25 mm, and for the bypass this value changes to 20 mm

Thus, the more radiators in the system, the larger the cross-section of the pipes. This will make it easier to carry out balancing when starting the heating structure

For example, if there are supposed to be 4-5 elements in the circuit, then the diameter of the pipes for the main should be 25 mm, and for the bypass this value changes to 20 mm. Thus, the more radiators in the system, the larger the cross-section of the pipes. This will make it easier to carry out balancing when starting up the heating structure.

Connection of radiators and pipes

Installation of Mayevsky crane.

Bypasses are manufactured together with bends and then installed into the main line. In this case, the distance maintained when installing the taps must have an error of 2 mm so that the battery fits when connecting the structural elements.

The play that is allowed when pulling up an American woman is usually 1–2 mm. The main thing is to stick to this value and not exceed it, otherwise it may go downhill and a leak will appear. To obtain more accurate dimensions, you will need to unscrew the valves located in the corners of the radiator and measure the distance between the couplings.

Starting a heating structure

Before starting the Leningradka heating system, it is necessary to open the Mayevsky taps installed on the radiators and release the air. After which a control inspection of the structure is carried out for the presence of flaws. If they are found, they should be eliminated.

After starting the equipment, all connections and components are checked, and then the system is balanced. This procedure means equalizing the temperature in all radiators, which is regulated using needle valves. If there are no leaks in the structure, no unnecessary noise and the rooms heat up quickly enough, the equipment is installed correctly.

The Leningrad heating system for a private house, although outdated over time, has changed, but is still widespread, especially in buildings with small dimensions. It is easy to install it yourself, while saving money on hiring specialists and the equipment necessary for construction.

Advantages and disadvantages

The system is best suited for one-story houses with a small area.

The Leningradka heating system has its positive and negative sides. The advantages include:

Simplicity of wiring and installation. The amount of installation work has been significantly reduced. You can install it without the help of specialists. High efficiency. Economical. Pipe consumption is 30% lower than other heating systems. In addition, there is no need to purchase expensive equipment. The introduction of control elements (bypasses, ball valves) made it possible to improve the circuit and regulate the temperature conditions in different rooms. Adding new elements makes it easier to make repairs and replacements without shutting down the entire heating system in the house. Versatility. The system can be used in one- and two-story houses. The difference in the schemes will be small. Reliability. The heating system will function without failure. With a lower location in a building with one floor, you can hide the pipes in the thickness of the floor

It is important to observe measures of thermal insulation and tightness of connections.

“Leningradka” has proven itself well in one-story buildings with a small area.

The main disadvantages include the complexity of calculations. The number of sections and pipe diameters depend on many parameters, including the individual characteristics of the house, so problems may arise with the correct determination of the parameters. Difficulties also arise when balancing the system. This may require additional equipment and repair work. The system cannot be implemented in large apartment buildings due to its inefficiency.

System modernization

The use of 21st century technologies, taking into account all the pros and cons of the schemes, increases the efficiency of single-pipe heating by 30% compared to two-pipe heating, while financial costs are reduced by 15%. Modern equipment ensures stability, operational safety, and convenient temperature control of both the entire system and its individual sections.

Modernization elements include:

- Thermostatic balancers are sensors, valves, valves that regulate the flow of coolant and, if necessary, completely block the flow of liquid into the radiator.

- Ball valves are installed on the inlet and outlet of heating devices, which allows them to be turned off without interrupting the operation of the entire system.

- Mayevsky crane - crashes into batteries to extract air manually. There are automatic systems to perform this task.

Series 1LG

The houses in this series are panel.

1LG 502

Brezhnevki 1LG 502 were built from 1963 to 1972. These are five-story buildings with two or more entrances and a ceiling height of 250 cm.

Balconies and loggias are not available in all apartments. Houses without a garbage disposal with four apartments per floor.

Most apartments in the 502 series do not have balconies

House structure:

- The external walls are made of expanded clay concrete panels 303 mm thick in three layers with ceramic mosaic cladding. Internal – single-layer 140 mm.

- The ceilings are solid, 120 mm thick. The covering of the last floor is ribbed.

- Flights of stairs on the central stringer.

- The bathrooms are made from solid reinforced concrete cabins, separate and spacious.

Layout of house section 1LG 502

1LG 504D-MK

In 1975, the 502 series from Lenproekt was replaced by another standard version of panel apartment buildings - 1LG-504D-MK. They were built before 1989. These were two to eight entrance 12-story buildings. Some have two non-residential floors below.

12-storey building 504 series

All apartments, starting from the 2nd floor, have balconies. The height of the premises increased to 270 cm.

Standard layout of sections and apartments:

1LG 600

Houses of the six hundredth series were built in the Leningrad, Tyumen, Pskov and Chelyabinsk regions for 22 years, from 1967 to 1989. They featured curved brick inserts designed to dampen gusts of wind in coastal areas. Because of this, they are called "ships".

House 600 series

Houses with Leningrad layouts are the most in demand on the secondary housing market.

They were built in old neighborhoods with good infrastructure. They have an elevator and a garbage chute.

Disadvantages: poor sound insulation and small six-meter kitchens in the first houses. Later, this omission was improved and the kitchen area was increased.

In the northern regions, many hotel-type houses of the 1LG-600A/UR-25 modification were built for small-family hostels. These are 108-apartment nine-story buildings that have little in common with the main series.

Houses with three sections connected perpendicularly are called “three-leaf houses.”

In addition to them there were several modifications:

- 9-storey buildings with 54, 180, 252, 322 apartments;

- 12-storey buildings with 54 and 72 apartments;

- 15-storey buildings with 90 apartments.

Section plan and most common layouts:

1LG-602

The standard design went into production in 1966. Five- and nine-story buildings with 216, 252, 288 and 324 apartments without a technical floor were built until 1982. There were 6-9 entrances. Loggias appeared at the ends. The windows became three-frame.

Five-story building 602 series

In 1972, rotating and corner sections appeared in the houses of this series. In 1975, experiments were carried out with the front cladding of wall panels. The shape of the canopies over the entrance to the entrance, the design of the ventilation ducts, and the layout of the bathrooms have changed.

Typical floor plan

The soundproofing of the apartments has become better than in the houses of previous series. The disadvantage is the impossibility of redevelopment of apartments.

Execution options

Depending on the orientation of the Leningradka highway, it can be:

- vertical;

- horizontal.

Vertical

Suitable for multi-storey buildings. Each contour is a vertical riser running from the attic to the basement along all floors. Radiators are connected sideways parallel to the main line and in series on each floor.

The effective height of the vertical type Leningradka is up to 30 meters. If this threshold is exceeded, the distribution of the coolant is disrupted. It is not advisable to use such a connection for a private home.

Horizontal

The best option for an autonomous heating system for a private house with one or two floors. The main goes around the building and closes to the boiler. Radiators are installed with a bottom or diagonal connection, with the top point oriented towards the hot end of the line, and the bottom point towards the cold end. The radiators are equipped with a Mayevsky valve for bleeding air.

Coolant circulation can be:

- natural;

- forced.

In the first case, the pipes are distributed along the contour with a mandatory slope of 1–2 degrees. The hot outlet from the boiler is located at the top point of the system, the cold outlet at the bottom. To increase circulation, the section of the line from the boiler to the first radiator or the switching point of the open expansion tank is laid with an upward slope, and then evenly downward, closing the circuit.

- boiler (hot outlet);

- open type expansion tank (highest point of the system);

- heating circuit;

- pipe with a ball valve for draining and filling the system (lowest point of the system);

- ball valve;

- boiler (cold input).

1 - heating boiler;

2 — open type expansion tank; 3 — radiators with bottom connection; 4 — Mayevsky crane; 5 - heating circuit; 6 - valve for draining and filling the system; 7 - ball valve For a one-story house there is no need to make upper and lower wiring of the main line; a lower wiring with a slope is sufficient. The coolant circulates mainly along the circuit of the common pipe and boiler. The hot coolant enters the radiators due to the pressure difference caused by the change in water temperature.

The expansion tank provides the required coolant pressure in the system. An open-type container is installed under the ceiling or in the attic. A membrane-type tank for a closed heating system is installed on the return line after connecting the parallel circuits, but before the boiler and pump.

Forced circulation is preferable. There is no need to maintain a slope; you can install the main pipe hidden. A membrane-type expansion tank allows you to accurately set the pressure in the system.

- boiler (hot outlet);

- five-pin fitting for connecting a pressure gauge, air vent and explosion valve;

- heating circuit;

- pipe with a ball valve for draining and filling the system (lowest point of the system);

- expansion tank;

- pump;

- ball valve;

- boiler (cold input).

1 - heating boiler; 2 - security group; 3 — radiators with diagonal connections; 4 — Mayevsky crane; 5 — membrane-type expansion tank; 6 - valve for draining and filling the system; 7 - pump

Heating Leningradka open wiring diagram

The open scheme of water heating "Leningradka" has an interesting feature - the sequential placement of all structural elements along the outer contour of the walls.

The central unit of such a single-pipe system is the heating boiler, which is connected to the first battery through a supply riser. Then, from the first radiator, hot water flows into the next element and so on until it passes through all the heating units in the entire house. Having passed through all the batteries, the cooled water returns through the return pipe to the boiler for reheating and everything repeats again, forming a closed cycle. Due to the heating of water in the heating system, according to the laws of physics, it expands in volume. Therefore, to remove its excess, an expansion tank is installed in the circuit. Moreover, in an open heating system, such a structural element is connected to the air in the room through a special pipe. After the coolant has cooled, it enters the system again from the expansion tank.

Very often, to increase heating efficiency, a single-pipe system is equipped with a circulation pump. which is installed in front of the boiler on the return pipe. Thanks to this addition, the heating rate of a private house, both one-story and two-story, increases significantly, since the coolant begins to circulate according to the forced principle.

To make it easier to fill the heating system with water, a cold water supply pipeline is connected where the return pipe passes through a locking mechanism and a cleaning filter. Also, a drain pipe with a tap at the end is mounted at the lowest point of the system. This device allows, if necessary, to drain all the coolant from the system.

In private housing construction, standard radiators with a lower connection diagram are usually used. Moreover, each battery is equipped with a Mayevsky tap to remove air locks. In addition, in private houses for Leningradka they often use a sequential diagonal method of connecting batteries.

But, despite the popularity of such heating distribution schemes, they have a common significant drawback - they do not provide for adjustment of the heat transfer level of each individual battery. To solve this problem, there is a radically different way to connect radiators.

To improve the operation of the heating system by adjusting the heat of each radiator, a parallel connection of all batteries to the riser is used. In this case, each heating device at the inlet and outlet pipes is equipped with shut-off valves. Also, in a section of the riser parallel to the battery, which in such a situation acts as a bypass, a needle valve is mounted to regulate the intensity of the water flow through the heating battery. This was achieved thanks to the laws of physics, because when the locking mechanism is fully opened, the coolant will not flow up the battery, overcoming the force of gravity. This leads to the fact that as the valve opening degree increases, the temperature in the battery decreases.

Questions and answers

Does it make sense to install a needle valve to regulate the temperature?

Yes, since the first radiator often gets too hot. The latter does not require a tap.

Is a pump required?

With a vertical connection - no. But if you incorrectly determine the angle of inclination of the upper circuit, water will not circulate normally through the system.

Is the temperature at the boiler outlet very different from the temperature at the last battery?

Yes. The difference can reach 45% - 50%. This is why it is so important to ensure proper coolant circulation.

Is it necessary to insulate the expansion tank?

Only if it's open. A closed one can work without insulation in an unheated attic.

Fundamental features of the functioning of Leningradskaya

As already mentioned, the Leningrad heating system wiring diagram involves the sequential connection of all devices starting from the boiler.

Therefore, the temperature at the inlet of the coolant return pipe will be much lower than at the outlet of the supply pipeline. It is thanks to this temperature difference that water naturally, according to the laws of physics, circulates along the circuit of the heating system. At the same time, the single-pipe “Leningradka” scheme, despite all its apparent simplicity, can be used even in two-story buildings. Since in the provided scheme it is possible to lay the pipeline below the level of the floor surface, it is necessary to worry about high-quality thermal insulation. If this issue is neglected, then the efficiency of the Leningrad heating system will significantly decrease and, in addition, the structural elements of the floor will overheat greatly, since the temperature of the coolant in the pipe is quite high.

How to install a heated floor system in Leningrad: possible limitations

Many homeowners have long appreciated the benefits of using heated floors. Rooms equipped with such systems receive the same heating, and a warm surface is much more desirable to walk on. The use of TP in the bathroom, kitchens and corridors is very popular.

Connecting heated floors

A situation often arises when a hydraulic floor system is installed in a small area. In this option, it is absolutely inappropriate to use a separate source of warm water for it. Thanks to this, the heated floor is connected to the existing heating distribution.

There are several heating system schemes:

- two-pipe - in this option, the supply goes through one pipe, and the return goes back to the boiler through the second;

- single-pipe - this scheme is called a single-pipe wiring system; only one pipe is used for it;

- gravity - for heating, large-diameter pipes are used, which are located along the perimeter of the building at a slight slope. Thanks to this, the water actually moves through them.

Under any circumstances, before connecting the TP, you need to accurately calculate the system, otherwise it will not work well.

Connecting the TP to a heating system with one pipe

The TP is connected to a circuit with one pipe in the same way as an additional radiator. But such a heating scheme imposes some restrictions:

- The TP supply is connected before the pump, and the return after.

- The length of one heated floor circuit should not exceed 30 meters. If it comes out longer, it must be divided into two equal parts: for example, if the length is 40 meters, then 2 circuits of 20 m each are made. This is necessary so that suitable pressure is maintained in the system.

- The pipe diameter for the floor must be no more than 20 mm.

- The temperature of the hot coolant should not be more than 55 degrees, thanks to this it is much better to install the TP after the radiator.

- It won’t be difficult to set up heated floors using a specialized floor connection module.

If it is intended to lay complex heating wiring for heating using several TP circuits, this circuit must include a collector.

Seamless polymer ethylene will be most suitable for heating pipes. These pipes allow you to organize the circuit in one single pipe, which virtually completely eliminates the risk of leaks. Moreover, plastic does not rust, and plaque does not appear on the surface inside the pipes.

Another plus is that it is quite easy to install such material. However, it must be remembered that the bend of the pipe does not have to be less than its thickness multiplied by 5. For example, for a diameter of 2 cm, a very small radius will be 10 cm.

TP module

This is a rather necessary device through which the operation of heated floors is adjusted. Its main role is to turn the heat supply on and off. This occurs thanks to thermal, which reacts to temperature. The module itself consists of:

- plastic box for hidden installation;

- thermal;

- shut-off valve;

- air release machine.

In this case, the device is installed on the return line from the heated floor circuit. And the height of its installation should not be more than 1 meter.

If it is not possible to install a heating module for the TP, you can use an ordinary ball valve to regulate the operation of the heat supply. But such a scheme is justified only for small TPs that consist of a single circuit.

In general, there are these types of connections:

- unregulated circuit - suitable for small circuits;

- application of balancing adjustment;

- use of a three-way valve;

- use of a flow meter.

Main! When using an unregulated scheme, heat supply costs can significantly increase.

Installation features

For hidden installation, thermal insulation of the walls is required.

The installation of the Leningradka single-pipe system requires care in calculations and execution. To implement it, it is necessary to calculate in advance the dimensions of the pipes, the number of sections in the radiator, prepare the premises and do a number of other works.

The system consists of the following mandatory elements:

- boiler;

- pipeline;

- heating battery sections;

- expansion barrel;

- tees.

If the Leningradka heating system with forced circulation is organized, another pump will be required. To improve the capabilities, ball valves (2 pieces per battery) and bypasses with a needle valve are used.

The main line can be mounted in the plane of the wall or along its surface

When located inside walls, floors or ceilings, it is important to make high-quality thermal insulation. Otherwise, heat losses will increase and the temperature in the radiators will be lower

This is due to microcracks that form during the wall gating process.

The installation location of the expansion tank and boiler is selected in advance. The tank should be placed above the level of the radiators - for example, in the attic. The boiler is usually installed in the basement.

Selection of materials

Pipes are selected taking into account the length of the pipeline, coolant temperature, installation method

The amount of heat in the radiator depends on the material of the pipes. Typically polypropylene or metal products are used.

Heating in a private house from Leningradka polypropylene pipes can be easily done with your own hands

It is important to note that such pipes are not suitable for installation in houses located in the northern regions. This is due to the properties of the material

Polypropylene melts when it reaches +95°C, which increases the risk of pipe rupture at maximum heat transfer of the system.

Metal products are more difficult to install, as welding of components is required, but their quality and reliability are at a high level. They are ways to withstand high temperatures. They are durable.

The diameter of the pipe depends on the number of heaters. If 4-5 radiators are installed in the house, pipes with a diameter of 25 mm and a bypass of 20 mm are needed. When the number of batteries is 6-8, a 32 mm main line and a 25 mm bypass are selected. In the case of creating a gravity system, pipes with a diameter of 40 mm or more are purchased. The size also depends on the number of batteries in the circuit.

Connecting elements and pipes to each other

The bypass serves for uninterrupted operation of the heating system

Bypasses are built into the assembled main line. They are manufactured separately with bends, the distance between which is calculated with an error of 2 mm. A backlash for trimming of 1-2 mm is allowed. If this distance is increased, the system may leak. To determine the exact dimensions, the corner valves in the radiator are turned out, and the distance between the centers of the couplings is measured.

Tees must be welded or connected to the bends. One hole should be allocated for bypasses. The second is selected according to the distance between the central axes of the bends.

Welding parts

Metal pipes are connected by welding. To do this, the master must have special equipment and skills to work with it. Otherwise, installation should be entrusted to professionals.

When welding, it is important to ensure that internal beads do not form. This will lead to a decrease in the amount of coolant that enters the radiator

If nodules form, the work should be redone.

After welding all parts, the radiators are placed on the wall using corner valves and couplings. Bypasses with outlets are placed in the grooves. Their length is measured and the excess is cut off.

Nuances of the work

If the system does not have a pump, the upper circuit should be positioned with a slight slope

While working, you need to remember the following features:

- If metal pipes are used, internal beads must be avoided when welding. They reduce the internal clearance and interfere with the normal movement of the coolant. If there are swells, the system will not work normally.

- After filling the system, you should not immediately conduct a test run. Before it, you need to wait 3 - 4 hours and check all sections of the pipe, its connections with radiators, boiler, tank. This will allow the leak to be identified and repaired in a timely manner.

- Before a test run, it is necessary to remove air from the system using Mayevsky valves located in the radiators. Otherwise, it will only partially warm up (in the area up to the air bubble).

If the system does not have a pump, the upper circuit should be located with a slight slope (approximately 5 - 10o). This will facilitate the flow of coolant and prevent the problem of water stagnation in a certain section of the pipe.