Stoves in the house have not lost their relevance to this day; they successfully solve the problem of heating a home. If the house is too large, then using only one furnace device it is difficult to achieve a comfortable temperature in all rooms. In such cases, it is impossible to do without installing an effective heat exchanger and multiple radiators. The coolant is usually water or steam. As a result, the air, walls and floor are heated evenly throughout the building, creating a microclimate quite comfortable for people.

High efficiency of steam heating is possible only if high-quality equipment that meets all standards and requirements is used for its installation. Source plasportal.com

Principle of operation

When installing steam heating in a dacha, a stove or boiler is used as a heat source. With their help, water is heated to boiling point, then the evaporation process begins. The steam penetrates the batteries through the pipeline, gives off heat, and gradually condenses. The resulting water flows into the heat exchanger through the return pipe.

Steam boiler

When choosing a water heater, it is extremely important to pay attention to the performance of the unit. The larger the area of the heated premises, the more powerful the heating device should be.

In houses with steam heating, a solid fuel boiler is often used. A modern gas heat generator is comparatively more efficient. Using an electric device to heat a home is not economically profitable, which is associated with high costs for electricity.

Household steam boilers are used as a heat source for heating a house: they heat a container of water and drive the resulting steam into heating pipes Source eurosantehnik.ru

Bake

If the house has a stove, it can serve as a heat source when installing steam heating. This will save you from additional waste on dismantling the device and repairing the premises. It’s also worth remembering: coal and firewood are inexpensive fuels. When using it, there is no dependence on centralized electricity and gas supplies.

The steam generator is a heat exchanger; you can make it yourself or order it. The design itself is quite simple, consisting of interconnected metal pipes.

If you plan to use a wood stove as a heat source, you should immediately calculate and design a special heat exchanger Source 1-teplodom.ru

How to do it yourself

If you have plumbing knowledge and skills, as well as confident handling of power tools, you can provide steam heating for your home yourself.

To complete the work you will need:

- pipes for heating mains;

- fittings, adapters, Mayevsky taps;

- heating device;

- steam generator;

- control devices.

Attention! In order for the project to be thoughtful, it is worth writing down ideas for the placement of elements, their types and sizes. This can be done directly on the diagram.

The process consists of several stages. In order to start work correctly, and most importantly, to complete it safely, you should design the structure. This means thinking through every meter of the heating circuit taking into account the high temperatures of the pipes.

Boiler

First, the power of the steam boiler is calculated. For a small house, take a capacity of 25 kW; an area of more than 200 square meters will require 30 .

If the heated area is 300 sq. m and more , then you should choose tanks from 35 kW. The boiler power ratio is on average 1 kW per 10 sq. m , if the ceiling is not higher than 2.7 m.

In addition to power, attention is paid to the possibility of heating water for home use.

Important! The boiler must be tested and have a certificate . This is necessary to reduce the risk of accidents.

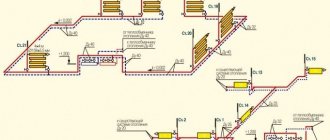

Heating scheme

After determining the type of boiler, the design operation schemes are selected:

- two-wire with top wiring (the equipment warms up more evenly, condensate goes into the boiler through a separate pipe installed with a slope);

- single-wire with bottom wiring (the part of the line distant from the tank will be heated with hot water).

The choice of scheme is determined by several factors:

- heated area ;

- boiler installation location;

- number of installed pipes and radiators;

- convenient and safe arrangement of pipes and installation of a heat exchanger.

This is a complex process that will require time and careful analysis of the existing conditions.

Materials for lines and radiators

Conventional pipes that are used to supply water will not work. Consumers are offered the following options:

- steel - can withstand high temperatures, however, they rust over time;

- copper - good thermal conductivity, durability and cost;

- galvanized steel - not subject to corrosion, inexpensive.

The last option is considered optimal.

cast iron are primarily considered . They are durable, resistant to aggressive environments and corrosion. Steel ones with ribs are also suitable - for increased heat transfer.

Photo 1. Cast iron radiator with fins, model Prince 640, heat output - 399 W, .

Control devices

The control block is a necessary element, since hot steam is a poorly controlled element. The reducer regulates the pressure, and when it increases, the valve is activated.

The project should have:

- total length of pipes;

- radiator installation locations;

- pipeline branch points;

- necessary adapters.

This is put on paper, a diagram is drawn taking into account the characteristics of the home. All details and dimensions are written directly on the drawing. With the finished model of the future design, they plan and carry out the purchase of the necessary equipment and tools.

Homemade schemes that are easy to repeat

If we consider in detail the materials on the installation of steam heating, it becomes clear that it is quite possible to make a house warm on your own .

Monotube

The simplest scheme is a series connection of radiators , which are connected to the output and input of the boiler. The steam, gradually cooling, moves from the beginning of the circuit back into the boiler. Part of the mechanism is no longer heated by steam, but by hot water.

Reference! The pipes are placed low , and the temperature in the first and last radiators is equalized by connecting the circulation pump.

Horizontal

This simple design is suitable for a small home . If there are many rooms, you will have to speed up the movement of the coolant with a pump . To turn on radiators variably, they complicate the circuit by integrating bypasses (adapters that exclude some sections).

Vertical version of a single-pipe scheme

Provides heat to a house with two or more floors . For a small home with a heated attic or a warm underground floor, this is a suitable type of circuit. Few materials are required, and the design itself is inexpensive.

For each floor a chain of radiators , the required amount of material is calculated, taking into account jumpers with bypasses (this will help make the temperature in the rooms more even).

Leningradka

This is a complicated previous scheme that provides for maximum equalization of coolant temperature along the entire length of the circuit.

The principle of operation is to distribute the coolant in such a way that part of it moves, bypassing the radiators (using bypasses). To do this, a pipe is laid under them, from which there are branches to the inlet and outlet of the battery. The section between the taps is a jumper that will help control the temperature in the room. The coolant goes directly to the next part of the circuit without cooling down.

Advantages and disadvantages

Equipped steam heating at the dacha has the following advantages:

- provides intensive heating of rooms;

- steam instantly reaches all areas of the heating system, regardless of its complexity or the size of the building;

- pipes never freeze;

- does not require large expenses for the device;

- can be used in buildings for seasonal residence, for heating several floors;

- maximum heat transfer coefficient;

- Can be used together with heated floors.

Flaws:

- circulating along the circuit, steam creates a lot of noise;

- pipes and batteries can heat up above 100°C, which creates a risk of burns upon contact;

- it is difficult to regulate the indoor air temperature;

- the system is susceptible to corrosion, so it does not last very long;

- in the event of a pipeline breakthrough, a dangerous emergency situation is created (the coolant temperature reaches high values).

Important! Steam heating can be used to heat a house with several floors. The steam rises independently to any height, cools, and returns as condensate. Moreover, the installation of expensive pumps is not required at all.

Russian stove

A beautifully laid brick stove will be an excellent decoration for your home. If working with brick is not new to you, installing a water-heated stove in your home will not be difficult. Any construction work begins with a project, which indicates all the parameters of the future structure. After a carefully developed project and drawing up an order, you need to purchase building materials. The main materials used in the construction of the furnace are red ceramic bricks.

For masonry, only the highest quality brick is needed. You cannot start work if you have pale pink unburned brick or burnt brick with a glassy surface.

Good quality building material makes a metallic sound when tapped and has a uniform red color over the entire surface.

To make a firebox you will need a refractory refractory brick. If the firebox is needed for coal, it is advisable to use fireclay bricks. For a firebox that runs on wood or peat briquettes, white brick from the Gzhel or Borovichi plant is suitable.

The mortar plays an equally important role in the quality of the masonry. On the construction market you can buy dry special mixtures, which are simply mixed with water before use, but kiln masters prefer to use a solution.

Popular publications:

The basis for heat preservationBefore you properly insulate the floor in a wooden house, you need to study the diagram...

How to make a window sill: materials and methods Before starting work on the manufacture of a window sill, you must carefully take the dimensions...

Plastic or wood? Plastic window with wooden window sill We definitely recommend one or another type of material for manufacturing...

Autonomous heating in an apartment building. Is it possible to install autonomous heating in an apartment with your own hands? Although legislative...

Scheme

The heating system operates thanks to natural circulation. Therefore, the heat exchanger must be installed below the level of the radiators. The circulation pump ensures constant operation of the thermal circuit.

There are open and closed steam heating circuits: in the first case, the system is connected to the atmosphere (open), in the second, it is completely isolated from the effects of atmospheric pressure Source s-proms.ru

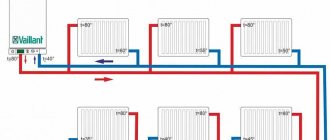

Steam heating in a house involves the installation of a one- or two-pipe heating system. The optimal choice of the latter depends on the area of the building that is planned to be heated.

Single-pipe

With single-line wiring, radiators are connected in series. The resulting steam passes through a pipeline from one battery to the next. As a result, the first radiator is always the hottest, the last one is almost cold. The single-pipe system is suitable only for small-sized rooms (no more than 80 m²).

Two-pipe

If the house has a huge area, a two-line heating option should be used. A constant supply of hot steam is carried out through the upper pipe. The cooled condensate returns to the heating unit through the lower pipeline. Regardless of the distance from the boiler, all heating batteries heat up evenly.

A single-pipe heating system is more suitable for heating a summer house or a small house; for a spacious cottage or two-story building, it is recommended to use a two-pipe system Source gubernia.media

Circulation system type

Steam heating of a house does not always require a pump, since with natural circulation the pipe layout allows water to move in a closed circle according to the law of gravity, without the forced action of electronics.

The location of the radiators and the outgoing pipeline is at the highest point relative to the incoming one. The difference in water temperature causes it to constantly move around the system. The forced heating system operates using a pump.

Forced heating system.

Materials and equipment

To properly equip steam heating, you need to prepare:

- heat exchanger;

- radiators;

- pipes (preferably galvanized steel, copper);

- pressure reducing valve;

- brackets;

- valves;

- clamps, elbows, fasteners;

- welder;

- hydraulic valve;

- reduction-cooling device;

- pump;

- container for collecting condensed steam.

Advice! To minimize the cost of organizing steam heating, expensive equipment can be rented.

Radiators for steam heating are selected in accordance with the characteristics of the material from which they are made, taking into account the operating temperature Source otoplenieblog.ru

Heat exchanger

When building a brick stove, a heat exchange device will have to be ordered or made on your own. To do this you will need a welding machine and metal pipes. The thickness of the walls of the latter should be more than 2.5 mm. By welding they must be connected in the form of a coil. In addition, it is worth taking care of the tightness of the joints. It is important to take into account that 1 m2 of the surface of a curved spiral produces about 9 kW.

After creating the structure, it is important to check for permeability: fill it with kerosene, then outline the seams with chalk. Darkening of the latter will indicate penetration of a flammable liquid into the heat exchanger. Therefore, it is unacceptable to use such a device for heating with steam.

Self-manufacturing of a heat exchanger is only possible for people who have certain skills, tools and knowledge Source heatylab.com

Installation process

Steam heating in a private house from a stove should be installed in this way:

- When building a stove, place the heat exchanger in the combustion chamber. If the stove device is planned to be used for cooking, there should be no pipes left on top.

- Install radiators and connect the pipeline to them. To ensure natural circulation in the future, it is necessary to maintain a slope (3 mm per 1 m).

- All converters must be equipped with valves designed to remove air.

- For safety reasons, install a shut-off valve in front of each battery or one for the entire system.

- At the beginning of the circuit, install a cooling device, a pressure reducing valve.

- Connect a container to collect condensate. From it, water will flow at an angle back into the heat exchanger. It is not advisable to use a membrane expander: it is not designed for temperatures exceeding 85°C.

- When using forced circulation, install a pump directly in front of the stove (in the return circuit).

Important! Heating systems with natural circulation of steam do not require the installation of a tank or pumping equipment. Therefore, their work does not depend on the presence or absence of electricity.

If heating is planned to be done with solid fuel (for example, wood), then metal pipes must be used to install the system Source 1poteply.ru

If you do everything on your own

Furnace steam heat supply can be done independently. Certain knowledge and, very importantly, tools are needed, but acquiring them is not a big problem:

- The stove should be located in a place where it will not be a hindrance to residents. And the point is not that she will ask for free space for herself. Adding firewood or adding coal - sometimes smoke escapes, and then the risk of absorbing a “smoky smell” is very high.

- If you need to choose between a steel and plastic pipe, then it is better to go with the first option. Iron wire pipes for air heating are the most suitable, since the economy in this case cannot be compared if gas or liquid fuel were used. Thanks to this, it is possible to make the pipeline diameter larger, thus increasing the volume of the coolant. But the area of the metal from which heat will emanate also increases. So it makes sense to think about this.

- The stove is made of metal or fireclay brick. Two options worked well. But there are differences, and for some they are fundamental. For example, a metal stove cools down much faster after the last batch of wood or coal has burned out. Brick retains heat longer: even if the stove goes out in the evenings, in the morning you will feel a temperature of about 30-40 degrees on the surface of the brick. For steam heating, this will not play a special role, but if the stove heats a separate room, then it is better to look in the direction of brick.

Water heating system circuits installed in the furnace

Steam heat supply using a furnace is an affordable option, although with characteristic features. However, this option has been tested over time and has proven itself very successfully. So you shouldn’t discard it outright.

Useful tips

When selecting equipment for creating a steam heating system, during its installation it is advisable to take into account the following recommendations:

- You cannot use used heating radiators. They are highly likely to have hidden damage, which will subsequently cause the system to depressurize.

- It is not advisable to use cast iron batteries. Under the influence of large temperature changes, they begin to collapse.

- Installation of the circuit must be carried out by workers with certain knowledge and skills. Otherwise, the created design may be ineffective.

- If you install a steam generator in a conventional wood-burning stove, you can significantly save usable space. In addition, home heating costs will be minimal.

- When using natural circulation, it is recommended to install the stove in the basement of the house. This will ensure that condensation quickly drains to the lowest point.

- For safety reasons and to prevent emergency situations, you cannot refuse to install valves.

The installation of steam boilers in a central heating system is prohibited by law. In private homes, this type of autonomous heating can function for decades without requiring replacement of the main structural elements.

The chimney of a stove with a built-in heat exchanger gets dirty faster than a conventional stove, so it needs to be cleaned more often Source roof-tops.ru

What specifics might there be?

Like any other heating system, steam heat supply using a wood-burning stove has certain disadvantages. It would be correct to use even a word that is not given and change it to specifics that may seem inconvenient to some:

- Sometimes the stove is located in a neighboring building. This is not uncommon, but a solution has been found. It is only necessary to pay great attention to the proper thermal insulation of the pipeline, which will connect the house and the building with the stove. Otherwise, a lot of heat will be lost.

- The coolant in the system can heat up above 100 degrees. This is due to the fact that in a closed space the pressure becomes greater when heated and, based on this, the temperature increases. Stopping the supply of wood or coal does not solve the problem; putting out the stove is also not an option. It will be quite simple to slightly open the combustion chamber of the furnace and completely close the vent so that the temperature from inside the system stabilizes. This is inconvenient, but it is quite possible to learn how to determine the required amount of fuel for a one-time use.

- The lack of automation means the impossibility of independent work. To maintain the desired temperature, you will either need to accept that until the morning the pipes and heating devices cool almost completely, or add a new portion of fuel in the middle of the night. This is also uncomfortable, although not critical.

- The risk of smoke in the room where the stove is located is quite high. Low atmospheric pressure, dirty chimney, damp firewood, poor quality coal - these moments can bring their own share of troubles.

Diagram of the wood stove and heating system

How does steam heating differ from water heating?

In a water heating system, the coolant is often water. It moves inside the pipeline and gradually cools there. In the case of steam heating, the liquid being poured evaporates and hot steam moves through the pipes. After cooling, it condenses and then flows through the return pipeline back to the heating unit.

When the coolant is steam, the thermal output of heating devices is significantly higher, rooms heat up three times faster. Such a system starts up quickly even after a long break in use.

Additionally, it is worth noting the lower cost of materials for steam heating devices. This is explained by the use of compact and ergonomic equipment during installation (for example, pipes of relatively small diameter).

Unlike water heating, steam heating gives greater heat transfer and warms up the room three times faster Source pechiexpert.ru

Features of heating a private house with steam

Heat delivered by steam has a number of advantages that attract the attention of zealous owners:

- installation of the structure will be relatively inexpensive , repair and maintenance also do not require a lot of money and time;

- the equipment does not take up large spaces;

- the room heats up in a matter of minutes;

- there is practically no heat loss ;

- heat is transferred through pipes and distributed not only by convection, but also by radiation ;

- due to efficiency, a small number of radiators and even only pipes are used.

Due to high heat transfer, the area of radiators and the diameter of pipes are reduced.

When choosing a heating design, you should know not only the advantages.

There are a number of disadvantages :

- the equipment itself is noisy ;

- you will have to be careful as the temperature of the pipes can be more than 100 degrees;

- the surfaces of the heating main must be closed , especially if there are children in the family, to avoid serious burns;

- high air circulation in the room , a low level of humidity will be established, which will require measures to purify and humidify the air;

- In the event of an accident, there is a risk of serious injury - hot steam will erupt.

Conclusion

From the article you found out how to make steam heating, and that its use in a private residential house is cheaper than water heating, despite the fact that it is more dangerous to operate. Based on this, you need to strictly adhere to the guidelines and equip the system with special equipment that will increase its safety.

You have the opportunity to order a heat exchanger from experts or make it yourself. Connecting and installing radiators is not difficult. The video in the article will help you find additional information on this topic.

We build a coil from iron sheets

The metal layer must be at least 5 mm for this element. When collecting, a 60*40 mm profile and 5 mm pipes are also used; they are designed to remove water and water mass. The overall size of the device depends on the length of the fuel part of the stove.

The metal layer must be at least 5 mm for this element

If the element is ultimately installed in the heating and cooking system, then the optimal solution would be to ensure that the gas warms the coil shelf and goes into the smoke channels, which will be located in front of the exchanger. With this calculation, it is easy to place a surface for cooking.

The part can also be made in the form of a book if you connect the outer panels with tubes or a profile. But with such a structure, the top shelf will be missing. And for optimal cross-country ability you need to place connecting tubes in the upper part. It is better to organize the inlet and outlet behind the heat exchanger or on its side.

Arguments for"

The steam method quickly heats the air in the house.

It is not necessary to demolish the stove, since in addition to the expenditure of effort and time, major repairs may be required.

Due to the absence of mechanisms, any adjustment is carried out manually, which means that the equipment will not break down or malfunction.

This is an option for a dacha or country house, since the presence there is seasonal, and fuel can be stocked up in advance. The heating will not turn off due to bad weather, non-payment of electricity or gas.

Even if the furnace itself is located in a neighboring building, it is possible to install a steam system. The main thing is to take care of thermal insulation.

How to do this is clearly shown in the following video:

https://youtube.com/watch?v=aB1duN9-N4c

Choosing the best option

It will be difficult to install a massive brick stove in an already built house. In this case, water heating is best organized on the basis of a metal potbelly stove, which can be placed on a reinforced wooden floor without pouring the foundation.

However, if it is possible to make the foundation as it should be, then preference should be given to a more reliable brick stove structure.

The water circuit around the house for a wood-burning stove is best made from thick steel pipes and with natural circulation of coolant

Installing a circulation pump and/or accumulator in the heating circuit in question is a waste of money and zero additional benefit. They will only complicate the installation of the system. And if the lights go out, these devices will create problems. Whereas the heating option without them will continue to calmly heat the house if there are problems in the electrical network.