There are several types of long-burning stoves. This allows you to choose the best option for a particular building. For example, in residential buildings and cottages, “Buleryan” stoves with warm air heating can be used, as well as long-burning stoves with water circulation through pipes, which are also suitable for arranging bathhouses on the site.

There are some general points in installing these furnaces, but it is better to consider them separately in order to understand all the nuances.

Buleryan

Initially, this type of stove was intended to heat the temporary homes of lumberjacks in Canada. Therefore, the requirements for heating speed, ease of adjustment and safety were increased. It is this factor that has made such stoves not only of high quality, but also in demand for various types of premises, including permanent residences.

The impeccable heating design ensures optimal heat transfer. There are different types of power of this unit, but on average up to 6 cubic meters of air are heated in 1 minute. Active combustion, as in other types of long-burning stoves, is observed only at the beginning, then the stove functions due to afterburning and self-ignition.

The advantage of this design is safety for humans. If the door is not closed, the occupants will not get burned, and contact with the body will not cause a burn.

The only “disadvantage” is that such stoves cannot be heated with coal and coke. There will be no heating effect, and the oven will fail.

Type of fuel

Most fireplace stoves are designed to use wood. The type of firewood does not matter much - coniferous or deciduous, it is not so important. It is important that the firewood is dry. For this purpose, many models have a shelf for storing firewood. After lighting the fireplace, a new portion is placed on the shelf, which dries at an accelerated pace, since the temperature is higher.

When choosing a metal or cast iron fireplace stove, pay attention to the type of fuel for which the unit is intended

There are metal fireplaces that can be burned with coal. This type of fuel provides more heat with less consumption. But when burning coal, the temperature in the firebox is much higher than when burning wood. Therefore, it is not recommended to heat a wood-burning stove-fireplace with coal. No, you can add coal and it will burn well. But after a short period of time, the fireplace insert will burn out. This will happen due to the fact that the combustion temperature was much higher than “planned”. If you plan to periodically use coal, you need to look for a long-burning stove-fireplace for a summer house or home, whose characteristics indicate the ability to burn with coal (black or brown also makes a difference).

Wood-burning stove-fireplace Moscow 12 (manufacturer Meta)

Okhta fireplace stove for wood and brown coal

A budget option for a cast iron stove-fireplace for coal - Torn (Torn) manufacturer Eurokom

French stove fireplace for pellets and wood INVICTA MIX

Pellet stove fireplace NOLA 7 Invicta (made in France Invicta)

Beautiful cast iron stoves and fireplaces for pellets Castelmonte

When choosing pellet stoves, pay attention to the size of the loading box

The famous heating stove Professor Butakov from Termofor can be equipped with a fireplace door

You can also heat a metal fireplace stove with fuel briquettes of various types; there are those that can run on fuel granules (pellets). In general, when choosing, pay attention to the type of fuel used. It is important.

Preparing to install the Buleryan stove

The first stage is to find the optimal location in the house in relation to the walls. There are special standards:

• from wooden unplastered walls – 1 m;

• from walls with non-flammable 25 mm plaster with ceramic tiles – 0.7 m;

• from surfaces with 7 mm thermal insulation and 1 mm metal layer, as well as single 55 mm brickwork – 0.5 m;

• double brickwork of 110 mm, as well as walls of 2 metal sheets of 1 mm with a 30 mm insert between them - 0.3 m.

The base must also be non-flammable. It is usually made from 4 rows of brick and clay masonry. To save money, the first two rows can be done with skips. But you should accurately measure the length and width of the stove and make the base 30 cm wider in all directions.

Also, a non-flammable base can be made from metal pipes 15-30 cm long. But the main thing is not to forget the safety requirement - lay a half-meter sheet of metal in front of the stove, the length of which is 0.7 m.

Operation and care

To ensure maximum efficiency, keep the stove in good condition, use only dry fuel, load it correctly and monitor the formation of condensation. Before starting the fire, the ash pan must be cleaned. Complete cleaning should be done every six months.

Conditions for correct use:

- The chimney must be of sufficient height to provide draft.

- The diameter of the chimney must be chosen equal to the diameter of the boiler damper (throttle).

- The pipe must have a straight vertical section at a distance of 2 or more meters from the gate.

- The entire chimney located above the damper must be insulated and the tightness of its joints must be monitored.

- The boiler is installed clearly horizontally without tilting in any direction.

- You need to place a metal sheet in front of the heating device.

- Do not extinguish a burning or smoldering substance with water. If necessary, you need to use sand or completely block the air supply hole.

An important factor in heating a stove is the moisture content of the wood. The use of poorly dried wood material leads to the formation of a large amount of soot on the walls of the firebox and condensation. The mixture of moisture and soot is a very aggressive environment that quickly destroys the walls of the fuel compartment, so constant cleaning will be required.

How to increase combustion time and efficiency

In most cases, boilers from manufacturers are already supplied with factory settings, which are not always correctly correlated with operating conditions and the fuel used. Because of this, a situation may arise when the potential inherent in the device is not fully revealed. In this case, you will need to change the initial settings.

Clear signs of the need for reconfiguration are:

- The filling ends after 3-4 hours at optimal fuel moisture content.

- The firewood does not burn completely; large fragments remain.

If the boiler needs retuning, it is better to contact a specialist. Trying on your own can lead to even more disastrous results.

How to load fuel correctly

When installed correctly, even small units can heat a house for 6–12 hours. But there are models that require adding fuel once a day. Let's look at this process in detail using firewood as an example; with other types of fuel everything happens similarly.

Procedure:

- The entire volume of the fuel chamber must be filled tightly. Wood chips and paper should be placed on top of large fragments.

- Then you need to ignite. Unlike conventional furnaces, in pyrolysis boilers the filling is ignited from above, and not from below.

- During ignition, the combustion and ash doors must be fully open. After the firewood has ignited, you need to completely close the firebox and install the valve so that smoldering begins.

- Then the second valve in the afterburning chamber of the pyrolysis gases opens, which leads to their spontaneous combustion.

Firewood must be dry, and using wet firewood will lead to a long combustion and low heat transfer.

Chimney

The variability of this design lies both in the type of construction and in the materials used. Suitable for a chimney under Buleryan:

• 12 cm bricks;

• concrete (6 cm wall);

• metal.

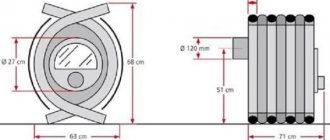

The exact dimensions of the chimney are determined by the size of the buleryan:

• models 00 and 01 – height 4 m and cross-section 12 cm;

• products of type 02 – 04 – 5 m and 15 cm, respectively.

The tightness of the chimney is largely determined by the use of a special heat-resistant sealant.

Technically, it is allowed to exhaust the chimney in residential buildings for permanent or seasonal residence, both through the ceiling and through the wall. The second option is easier to implement with your own hands. The passage through the ceiling and roof will require knowledge of fire safety fundamentals. But the height of the pipe above the ridge in both cases is at least 50 cm.

We make “bubafonya”

If you are making a stove for heating premises for household or technical purposes, you should pay attention to the stove under the slightly funny name “bubafonya”.

It has a simple but original design that provides a lot of thermal energy. It works as follows:

- The lid is removed, firewood is loaded (small chips are placed on top);

- Kerosene-soaked rags are placed on top of the firewood and in the spaces between them;

- The rags are set on fire and the wood is set on fire;

- A piston is installed in the oven, the lid is closed - the unit begins to generate heat.

In order to understand the essence of this unusual long-burning stove, you just need to look at its diagram. The unit consists of three main parts - a body, a chimney, a heavy piston and a cover.

This picture clearly demonstrates the scheme and principle of operation of the “bubafoni”.

“Bubafonya” is simple to make; the easiest way is to build it from two whole metal barrels (without holes) with a volume of 150-200 liters. Thick steel is not particularly needed here, since due to the limited supply of oxygen, combustion will be slow and low-temperature. Let's see how to make such a long-burning stove with your own hands. Here are step-by-step instructions:

- We cut off the lid from the main barrel and prepare the combustion chamber;

- We weld a piece of pipe with a diameter of 100-150 mm into the side wall of the combustion chamber (in the upper part, according to the figure) - this will be the chimney;

- We prepare the top cover - we make a hole 40-50 mm wide in it, through which the piston pipe will pass. Bend the edges of the lid outward with gentle blows of the blade, tamp the edges of the barrel (combustion chamber) inward - the lid should fit tightly onto our barrel;

- We are preparing the piston of our long-burning furnace - we take a pipe with a diameter of about 40-50 mm (it should fit into the hole in the lid), weld the lid from the second barrel to it from below, and you cannot weld the pipe itself - air will pass through it. We weld pieces of a thick L-shaped channel to the bottom of the piston cover so that the piston itself is as massive as possible. The diameter of the piston itself must be such that it can be easily inserted into the combustion chamber (there should be gaps about 5 mm wide between the walls and the piston, through which combustion products will escape).

Our self-made long-burning stove is ready - all that remains is to install it on a non-combustible base and test it. How this stove is set on fire is described a little higher.

Some models of these long-burning stoves operate on one load of firewood for up to 20-24 hours or more, generating a large amount of heat.

Water heat supply for long-burning stoves

You can set up such a system using a pyrolysis boiler or a long-burning unit like a sauna. It is the latter that is most often chosen for reasons of economy and due to the relative ease of its installation. It allows you to both heat living rooms and attach a bathhouse to the house and get a full-fledged hygienic and relaxation room. For a striking example, you can take the Siberia stove with a firebox wall thickness of 6 mm, a cast iron door, an ash drawer in a metal channel and a weight of about 100 kg.

Review of popular models

Table 2. Overview of popular models and their characteristics

| Appearance of models | Characteristics |

| Bavaria series stove from EcoKamin | This Russian manufacturer has been presenting its products for only a decade and a half, but this was enough to establish its high-quality and aesthetic products on the market. In particular, steel and combined stove-fireplaces from the Bavaria series with a power of 9-11 kW are very popular. The photo shows an option with a steel body, cast iron stove and tiled cladding, which is capable of heating 110 m³ of premises. Burning duration is 5 hours, firewood consumption during this time will be 7-7.5 kg. |

| Fairway Gunther | Another Russian manufacturer specializing in the production of compact cast iron fireplaces and stoves, which are ideal for country use. In particular, the GUNTER model is presented here, capable of heating a house with an area of 140 m² with very modest dimensions of 750*750*560 mm. Its power is 14 kW and can operate on both wood and wood briquettes. |

| JOTUL oven, model F 3TD BP | Fireplace stoves from the Norwegian company Jotul (which has been in this market for 150 years) are known and loved all over the world. A huge range of models covers a variety of consumer needs. The rating presents a modest power (7 kW) and very compact (dimensions 577*707*484 mm and weighing only 106 kg) cast iron model for a summer residence. It provides secondary combustion of fuel, self-cleaning glass and the ability to connect a chimney both from above and from behind. Can heat a room with a volume of 60 m³. On a note! This manufacturer gives a 10-year warranty on its stoves, while Russian-made models have a maximum of 5 years. |

| Tim Sistem, model Alma Mons | The Serbian manufacturer of metal furnaces Tim Sistem is well known not only in Europe, but also beyond its borders. In our rating, we present the ALMA MONS model (R - with red lining, but there are options with black and white design), capable of heating up to 180 m³ of living space. It has not only a hob, but also an oven. The top and door of the firebox are cast iron, but the body is made of sheet steel painted with heat-resistant enamel. The hob has three burners and a convenient drawer below for storing firewood. By removing or installing an additional grate, the volume of the firebox can increase or decrease accordingly. This stove is intended not so much for heating as for cooking, therefore it has increased dimensions of 925 * 800 * 550 mm with a power of 6 kW. Weighs only 80 kg. |

| GreiVari, model 1.100 Screen | Another model from a Russian manufacturer, designed not only for heating, but also for cooking and heating food. Made of steel, it has a power of 10 kW, which makes it possible to heat up to 130 m³ of room air. It provides different heat transfer modes - not only intensive, but also economical. It can operate on all types of wood fuel, and if the firebox is fully loaded, it operates continuously for up to 5 hours. |

| Termofor Germa | The Germa steel stove from the Russian manufacturer Termofor, with dimensions of 450*645*1080 mm, is capable of heating at least 250 m³ of air volume. The hob is small in size, but there is a recess in the form of an open oven, in which a kettle or dishes with food can remain hot for a long time. The stove has a large, spacious firebox with a volume of 125 liters and an impressive power of 13 kW. |

Here is a far from complete list of manufacturers of fireplace stoves whose products are present on the Russian market. Among them there are many domestic brands that produce models that are quite worthy in terms of characteristics and external design. And everything would be fine. But buyers are alarmed by the ridiculously short warranty period of one year, which is determined by some of our manufacturers. For Chinese teapots there is a longer guarantee.

What to look for when choosing

Before purchasing a stove, you should determine for yourself what functions the device should have. Your choice depends on whether this unit will be the main source of heat or will serve as an assistant for a gas or electric boiler. Decide whether you are attracted by the cooking function available on some stoves, and how this can be useful in a country house.

Don't forget to also consider the size and features of your space. Taking into account the parameters of the room, decide on the required power, efficiency and heat transfer of the purchased equipment. Depending on the area of the allocated space for installing the furnace, the dimensions of the unit are selected.

If you periodically need to heat a living space in a short time, you need to purchase a model whose body is made of steel. This material has the property of releasing heat into the space immediately after heating. Under the described conditions, a potbelly stove is perfect.

Sip panel finishing

Construction of houses from sip panels is pleasant not only because of the quick installation time and ease of construction - finishing such structures is a real pleasure! Since the surface of the panels is perfectly flat and smooth, you do not have to spend money on plaster or screed and spend hours leveling walls, floors and ceilings to achieve the desired result for the finishing cladding. Let's consider how you can improve the exterior of a frame house and how to carry out interior decoration.

Interior finishing

Before proceeding with the interior finishing, it is necessary to seal the joints with paint mesh, sand and polish them. Since the panels are monolithic, immediately think about where the communications will be located and make holes for them. In the bathroom, preparation follows a different scenario - the joints are closed not with a mesh, but with a sealant based on silicone or acrylic. The panels on the floor should be completely covered and overlap the walls by about 20 cm, so that if water spills, the wall materials will not get wet.

Any materials can be used for finishing a house made of sip panels. It is recommended to pre-cover the walls with plasterboard. This is necessary not so much for aesthetics (the panels are already smooth), but to enhance the fire safety of the building (we wrote about this above).

Since the floors in such houses do not need leveling and insulation, they can be covered with even the most demanding coverings - laminate, tiles, parquet. In the bathroom and kitchen it is better to make self-leveling acrylic floors to provide additional waterproofing.

Exterior finishing

Some owners prefer not to resort to exterior finishing of houses made of sandwich panels at all - they already look quite beautiful. But to protect the material from dampness, it is recommended to cover it with something.

The most popular options for exterior finishing of panel houses:

- Siding – vinyl siding panels are made of thin plastic. The coloring often imitates natural wood, the surface does not fade, protects well from moisture and is not susceptible to rotting. Basement siding is slightly thicker than classic vinyl panels (3 mm) and can even be used for interior decoration. The coloring imitates not only wood, but also natural stone, which allows you to create interesting exteriors. There is also steel and metal siding. The first is made of galvanized steel and a thin polymer coating. It can withstand strong temperature changes, mechanical stress, and direct contact with fire. Metal panels appeared on the market relatively recently. They have all the characteristics of steel, but their cost is much lower than that of galvanized products.

- Facade plaster is the most common option for exterior finishing of houses. Decorative compositions allow you to achieve an interesting effect and protect the panels well from the negative influence of the environment.

- Corrugated sheeting - a metal profile is chosen for its high strength, durability, corrosion resistance and easy installation. A wide color palette allows you to choose an option for every taste. Light weight does not create a strong load on the walls and foundation.

- Fiber cement - slabs are made from environmentally friendly materials (90% cement, 10% cellulose) by pressing. They reliably protect the house from cold, rain and wind; service life can be calculated for decades.

- Clinker facade tiles give the house a cozy and respectable look. Despite the high cost, it is chosen because of its beauty, durability (can last 100 years or longer) and environmental friendliness.

- Facade tiles are a cheaper option compared to clinker finishing. The tiles are made of concrete with modifying additives and allow you to create a convincing imitation of natural stone and brickwork.

As described in detail in the video, houses made of sip panels are becoming increasingly popular every year. This is explained not so much by fashion as by tangible savings - housing is constantly becoming more expensive, apartments in cities cost more and more, and it is becoming more and more difficult to find your own home.

Why spend crazy money on an apartment with a modest square footage, noisy neighbors and a smoky highway outside the window, when you can build your own spacious and warm house from sip panels for much less?

What types of wood are suitable for heating

Pyrolysis boilers are universal regarding the fuel used. They can work on wood, coal, pellets and peat briquettes. Only dry fuel should be used for stowage.

Common types of wood:

- The best firewood is oak firewood. Birch and pine burn quickly, but contain a lot of resin. Aspen, alder and linden do not light up well, but then they smolder for a long time.

- Pellets. They are compressed granules. They are made from agricultural waste (straw, sunflower husks) or lumber waste (chips, sawdust, shavings).

- Fuel briquettes. The main filling material is the same as in pellets. But they are pressed in the form of briquettes up to 45 cm long.

- Coal. It cannot be used in steel structures; only cast iron ones are suitable for it. When burned, coal releases a lot of heat, which causes destruction of the chamber walls.

The key point when choosing fuel for a pyrolysis boiler is the equipment data sheet, which indicates the possible types and consumption of fuel for each specific model.

Wood-burning stove-fireplace META Marseille 14

RUR 74,900 Rating 4.5

1 reviews

This is a fireplace stove from a Russian manufacturer. It is made of durable cast iron, and its thickness varies from 8 to 14 mm. Some of the components for this stove are supplied directly from France, and the especially heat-resistant glass ceramics are made in Japan.

Thanks to this, the end result is a highly efficient device that is capable of heating a room of up to 250 square meters.

The fireplace is heated with both wood and regular coal burners. However, you should not use coal. The fireplace stove is capable of producing an even supply of heat throughout the house. There is also a convenient handle that allows you to open the doors with ease.

Advantages:

Quality materials; High heating power; There is a system that allows wood to burn for a long time; Affordable price;

Flaws:

There is no special compartment for firewood;

Power 14 kW Type closed Chimney yes Fuel wood Burning time 8 hours "clean glass" system yes Long burning system yes Ash box yes External body material cast iron Door material glass Lining fireclay Chimney diameter 15 cm Top connection to the chimney Dimensions (WxHxD) 55x113x43. 90 cm Weight 130 kg

4.5/ 5 rating