Recirculation of hot water through the boiler.

The water pressure in the boiler itself may be insufficient to provide the cottage with hot water. To recirculate hot water through the boiler, it is necessary to properly install the DHW system with the installation of a circulation pump.

In large country houses, experts recommend installing a hot water supply (DHW) system using a centralized method of heating water, through a gas and electric water heater (you can also use a single-circuit gas boiler). In this case, in order to provide the necessary supply of hot water, an indirect heating boiler must be installed in this system.

The volume of the boiler is calculated taking into account all the people living in the house (for a family of 4 people, a boiler of 100-150 liters will be enough). The water in the DHW system is heated using a heat exchanger, which is connected to a heating source (boiler, water heater).

The DHW system boiler has several inputs and outputs. The design feature of indirect heating boilers is that a coil in the form of a spiral-shaped metal tube is mounted into it, through which hot water from the boiler passes. Due to heat exchange between hot water in the coil and cold water in the boiler, the liquid inside the boiler is heated. This creates a preliminary supply of hot water for human needs.

The entire DHW system has a closed operating cycle. If hot water is not used for a long time, it begins to cool down. When a person wants to use hot water, he will probably face the problem of initial lack. When you turn on the tap, the system itself is activated and water heating begins. But it may take several minutes until it heats up to the desired temperature.

In order to be able to use hot water immediately after opening the tap, a circulation pump is installed in the system, which ensures water recirculation throughout the circuit constantly, regardless of whether a person uses hot water or not.

Uninterrupted recirculation of water through the boiler is carried out by installing additional equipment: an expansion tank, check and safety valves, and an air drain valve.

Thus, hot water is recirculated through the boiler using a circulation pump, a heat exchanger and additional equipment, which is mounted into a single DHW system. As a result, a person will not have to wait for the water to heat up by running water for some time.

Using what criteria to choose

There are 3 main criteria for this process:

- Volume. You should not set the device to the maximum value for this value. This may lead to financial difficulties in the future. Since a container of sufficient volume will use more water, the bill for its consumption will be higher. It is worth remembering that the larger the volume of the installation, the more it will come into contact with the coil, which can lead to heating of the coolant.

- Power. This criterion affects water heating. For a full heating process, a water heater with an indicator of 8-12 kW is suitable.

- Diameter. This criterion depends on the area of the room where the device is installed.

How to refuse water meters?

So how can you get rid of unnecessary water meters? You need to write an application to the Housing and Communal Services (Housing and Communal Services) or management company; the details and address are written in the receipt that arrives every month in your mailbox, so it won’t be difficult to find them.

Interesting materials:

How are the houses on the street numbered? How should you care for small snails? How about a proposal against a wall? How to combine graphs in Excel? How to merge calls on iPhone? How to explain patience and labor will grind everything down? How to declare a variable in VBA? How to exchange points for Beeline minutes? How to exchange Tele2 minutes? How to exchange a skin for CS money?

Installation and operation of a heating boiler

Boiler in the heating system

After completing all the necessary calculations of the boiler power and its volume, you can begin to integrate the device into the heating system

An important task is to determine the installation location. Having decided on the purpose of the boiler in the heating system, you need to read the instructions for its installation

The best option would be installation in close proximity to the boiler. In this case, the transfer of thermal energy from the coolant to water is most effective.

But at the same time, you may encounter the following difficulties in organizing heating using a boiler:

- DHW system supply. In a heating system with a solid fuel boiler, it is most convenient to place the boiler directly in the boiler room. But then to supply heated water to the premises you will need a separate pump and control devices for it;

- Large capacity capacity. if heating through a boiler is planned for large residential areas. There is a problem with the placement of the heating element;

- Electrical supply to ensure the operation of the heating element. For the normal functioning of the boiler for heating a private house, it is also recommended to install an autonomous source of electricity.

Having resolved these issues, you can proceed directly to installation.

The heating water temperature through the boiler is controlled using an installed thermometer. It is not included in the standard package and therefore must be purchased separately.

Installation of a heating storage tank

To install the heat accumulator, it is necessary to prepare a flat area in advance. Its heavy weight should be taken into account - if necessary, a separate foundation is made or the floors are reinforced.

The optimal installation option is on a separate platform. This way you can avoid contact of the housing with the concrete surface, which will reduce heat losses in the electric heating boiler. Almost all manufacturers make containers with special legs. If they are missing, it is recommended to install insulation on the floor.

The procedure for connecting the boiler to the heating system is to perform the following steps:

After installing the container, you need to check its position relative to the horizon. No deviations are allowed. Connect to heating

It is important that the diameter of the pipes is equal. Otherwise, after connecting the boiler to the heating system, excess hydraulic resistance will appear. If installation is carried out in an unheated room, the boiler body is insulated. A connection to the hot water supply is made so that the boiler works not only for heating, but also for hot water supply.

Upon completion of this work, you need to check the tightness of all connections and start the heating system. It is recommended to measure the temperature of the water in the tank and the coolant in the pipes within 2-3 weeks after the boiler is turned off. This way you can determine the actual time of maintaining the required heating level in the heating circuit from the boiler.

In order to make full heating from a boiler, it is not recommended to use antifreeze. It is characterized by a relatively low heat capacity, which will affect the transfer of heat to water and back to the coolant.

Conditions for proper operation of the boiler

Scale on the heating element of the boiler

Servicing a storage tank is practically no different from carrying out the necessary procedures to maintain the functionality of any electric boiler with heating elements. And in this case, in order for the boiler to work normally in the heating system of a private home, you must follow the manufacturer’s recommendations.

This can be ensured even before the heat supply from the boiler is made. It is best to purchase models with the so-called “dry heating element”. On it, scale formation occurs much more slowly. You should also pre-filter the water before feeding it into the storage tank.

In addition to these procedures, you must do the following:

- Once a month, check the integrity of the thermal insulation of the structure;

- Monitor the duration of maintaining the coolant temperature during the heat supply mode through the boiler. The difference between calculated and actual indicators should not exceed 15%;

- Checking the tightness of connections. It is recommended to replace the gaskets before each heating season. This way you can achieve more reliable heating of a private home using a boiler.

The control unit of some models is sensitive to voltage changes. To avoid damage to this expensive device, you should connect a stabilizer for the boiler in the heating system.

To clean the heating element from scale, you must dismantle it. But before that, you need to find out from the seller whether the factory warranty is still valid.

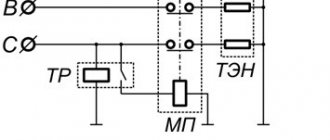

DHW and heat supply diagram

The hot water supply scheme in an apartment building can be implemented in two fundamentally different ways:

- It uses water from the cold water supply and heats it with heat from an autonomous source. This could be a boiler installed in the apartment, a gas water heater or a heat exchanger that uses coolant from a local boiler house or thermal power plant for heating;

DHW system with a closed heat supply circuit (without taking water from the heating main)

Please note: the advantage of this scheme is higher water quality. It must comply with the requirements of GOST R 51232-98 (“Drinking water”). In addition, hot water supply parameters (temperature and pressure) extremely rarely deviate from nominal values; in particular, the DHW pressure is always equal to the cold water pressure, taking into account the pressure loss during water withdrawal.

- It supplies water to the consumer directly from the heating main. It is precisely this scheme of water supply for a multi-storey building that is implemented in the vast majority of residential and administrative buildings of Soviet construction, constituting 90% of the housing stock in the vast expanses of our great and vast land. In the future we will focus our attention on it.

Elevator unit with hot water supply (black inserts)

Dear reader can find additional information in the video in this article.

Preparatory work before installing the boiler

Self-installation of an electric water heater will cost you less than the services of specialists. On average, the work will take about two hours. But when preparing for installation and directly during the work process, safety regulations must be observed.

- First of all, you should decide on the boiler model: what kind of system it should be - flow-through or storage, how many liters it is designed for, how it will be mounted - horizontally or vertically, on the wall or under the sink, etc.

- The next step is to create a connection diagram for the device on paper indicating the connection of hot and cold water. Then you need to do the following:

- make room for the water heater and work;

- check the strength of the wall for the ability to withstand the weight with a double margin (for example, if the boiler has a volume of 50 liters, then fasteners with a weight equal to 100 kg plus the weight of the empty boiler are required);

- since the water heater is a very powerful consumer of energy, it is necessary to determine in advance the type of wiring (aluminum or copper) and the cross-section of the cable laid in the walls, and also evaluate the ability of the wiring to withstand the load of an electric boiler (for example, to connect a 2 kW boiler, a copper cable with a cross-section of from 2.5 mm2);

- check the condition of water pipes and risers (especially for old houses) - they must be in good condition and have points for connecting a water heater.

- Before you start installing the boiler, you need to read the instructions to understand the features of the model, then turn off the electricity and shut off the pipes supplying hot water. It should be remembered that if you live in a multi-storey building, this will temporarily deprive residents of other apartments of hot water, so you need to carefully prepare for the work in order to complete it quickly.

You can check the strength of the wall in the following way: mount the fasteners that come with the boiler and hang two bags of cement on it. If the mount can cope with such a load, then it will be able to withstand a water heater that weighs half as much.

Particular attention should be paid to checking the wall for strength when installing a large 150-liter boiler. Such a unit is fastened using expansion metal anchor bolts or special durable hooks

It is recommended to use anchors with a length of 100 mm and a diameter of 10 mm.

It should be borne in mind that installing the water heater will require the efforts of two people, since this process is quite labor-intensive. Typically, the boiler is mounted in the bathroom or toilet directly above the toilet. As a rule, this place is not used in any way. At the same time, a free approach to it must be ensured.

In a small room, to save useful space, the boiler is usually placed horizontally. A small-volume water heater is attached to the wall, and units with a volume of 200 liters or more are installed on the floor.

Is it possible to install a water heater in the basement? Why are boilers needed in basements?

Management companies are in full swing installing boilers in the basements of houses, fulfilling the city program. And in apartments, on landings and in courtyards, residents are discussing what this reorganization of hot water supply will give them, if once again changes come “from above,” that is, from the executive committee, and not “from below” from the owners of the houses.

“The residents of our house are categorically against the installation, because there are examples of only worsening the situation with these boilers. Now we are collecting signatures from all residents against the installation of water heaters. The director of our management company does not hide that the boiler will only get worse,” writes Nadezhda, the house manager, in the housing and communal services blog on our website. “A boiler is a boiler in which cold water is heated using hot water, like a large cauldron. As soon as everyone opens the taps for DHW consumption, that’s when the problems will begin, i.e. shortage and low water temperature. All this is nonsense, as we tried in one organization, it is of little use, there is almost no savings, when you open the hot water tap, warm water will flow, but for the water to become hot, you have to wait. The water drains, and the meter counts the volume of hot water,” a certain “Veteran” gives his explanation to Nadezhda in the same blog. People are extremely interested in the cost of installing boilers, and how much water will flow from these boilers in rubles.

We contacted specialists from several management companies. It turned out that the price of one boiler, including installation and preparation for operation, ranges from 200 to 850 thousand rubles. The amount depends on the power of the boiler, and the power depends on how many residents will consume water.

“Therefore, it is a big misconception to think that at times of “peak” load someone will have to open the tap and wait for the water to turn from cold to warm. Even if all residents open all the taps in the bathroom and kitchen. This is guaranteed by the technical parameters of the boiler,” says Zamfir Khazivaliev, chief engineer of Paritet Management Company.

— I live in a house where a boiler was installed. No problems, normal water supply, normal temperature,” Lilia Skryabina, head of the planning department of the Chelnystroyremont Management Company, confirms what Khazivaliev said.

The management company takes money for the installation of boilers from various sources, but all of this comes from rent. As a rule, these are funds for current or major repairs. Therefore, boilers are already the property of the owners of apartments and houses, and there is no need to buy them back (as we buy common household metering devices).

Nadezhda is very interested in whether residents can refuse to install a boiler? Is it not in vain that she is collecting signatures for apartments? Lawyers say that home owners, of course, have the right to refuse a boiler. But there are nuances. If the owners hold a quorum general meeting and make such a decision by a majority vote under the minutes, then for both the management company and the executive committee this will be tantamount to an order that is not discussed. If you submit a collective letter to the Management Committee, in which the majority of residents speak out against installing a boiler, then the Management Committee will be forced to create a working group with the participation of building activists. This group will have to analyze everything (from why the residents are against the boiler, to what the consequences of refusing it will be) and offer their solution to the management company and the building council. Now management companies are firmly convinced that boilers are progress.

— Water heaters are replacing the system that we have been using for 40 years. Under the old system, we take water for household needs from the water that is used for heating. Therefore, the thermal power plant is forced to constantly replenish the heating system, and in addition, we consume the hot water that circulates through forty-year-old pipes. And clean drinking water will flow from the boiler from the Chelnyvodokanal treatment station through pipes modernized by the water utility in recent years. If something happens, this water can be cooled and drunk and cooked in it,” Rif Valeev, director of Paritet Management Company, lays out his arguments.

Along with boilers, fees for their maintenance and repair will appear in our utility bills. But even with this fee, the cost of hot water will decrease significantly. It will be different in different houses, because houses are different. An unequal amount of heat will be used to heat the water. The tariffs will be calculated by management companies. House owners, of course, have the right to participate in this process. It is best, of course, to invite management specialists to a general meeting and discuss and approve this tariff. And not only this one. But you can also act through the advice of your home.

Peculiarities

Unlike conventional water heating devices, this device has an inlet pipe (for cold water) mounted at the bottom of the storage tank, and an outlet pipe (for hot water) at the top.

Thus, the liquid must circulate in a closed heating circuit at a fixed temperature, which is achieved in the upper part of the tank.

Indirect heating boiler with connection to the boiler

The main difference between such a device and a conventional water heater for heating is the presence of an external source of heating the coolant. This could be solar panels, a boiler, central heating.

From such an auxiliary source, a coolant passes through a coil passing through the inside of the boiler, which, in turn, heats the liquid in the tank.

This system is protected by a thermal insulation layer.

We disassemble the boiler “to the bones”

You can understand the principle of operation of a storage water heater only by understanding how it works.

With all the modern variety of boilers, they all consist of the same elements:

Electric boiler device.

- outer casing (can be made of steel or plastic, determines the “appearance” of the device);

- internal tank (it can be made of glass porcelain, stainless steel, and can also be equipped with titanium coating);

- thermal insulation (located between the inside and outside of the boiler; usually made of polyurethane foam);

- heating element (is a heating element that converts electrical energy into heat);

- system for fastening to the wall (plate with holes);

- hot water supply and cold water extraction pipes;

- adjustable thermostat (automatically ensures heating of water and maintaining its temperature);

- thermometer (shows the temperature of the liquid);

- magnesium anode (prevents corrosion of the internal tank);

- indicator light (lights up during active operation of the device).

Depending on the type of water heater, there may be some subtleties in its design. For example, today storage heaters with “dry heating elements” are becoming popular, where the heating element is enclosed in a special flask that prevents the formation of scale. The heating element does not come into contact with water, hence the name of this type of heater. A floor-standing boiler will not have a mounting system, unlike a wall-mounted one.

Electric storage boiler design

Knowledge of the structure and operating principle of the unit will allow you to avoid annoying mistakes during installation and operation, and this will increase the duration and safety of use.

What elements does an electric boiler consist of?

- Bracket for fixing the boiler to the supporting surface. Placed at the top of the device, it ensures reliable fastening of the boiler. It is made of thick sheet steel and welded to the outer casing by contact welding.

- Cold and hot water supply pipes. The cold water pipe has a short length and a jet divider. Due to this design, cold water is evenly distributed in the lower volume and the jet pressure does not mix with heated water. The heated water rises due to the difference in the densities of cold and hot water. The hot water intake pipe has an increased length; the intake occurs in the upper, most heated part of the volume.

- A layer of thermal insulation. A very important element of the boiler; heat saving indicators largely depend on it. It is made from various modifications of polystyrene foam.

- Thermostat. Adjusts temperature values, automatically turns on/off power. It will be placed in the lower part, you need to remember this when adjusting the water heating temperature.

- Internal reservoir. It can be made of stainless steel (expensive models) or ordinary sheet steel with an anti-corrosion coating.

- A heating element. Power 1.5–2.0 kW, can be “wet” or “dry”.

- Magnesium anode. Purpose – to reduce corrosion processes in the internal tank. How does it work? Water contains oxygen, which oxidizes iron. Magnesium is highly active and is the first to react with oxygen, due to this its concentration in water decreases and steel rusts more slowly. The frequency of replacing the magnesium anode depends on the frequency of use of the boiler and averages 5–8 years.

- Thermometer. An ordinary bimetallic thermometer is used, the reading accuracy is ±2–3°C. Some modern models have electronic control units, but this does not affect the quality of operation. But the cost of the boiler increases significantly.

- Indicator light. It turns on when voltage is applied to the heating element and turns off simultaneously with it.

- External body. Coated with durable powder paints that reliably protect the metal from the negative influence of external factors.

- Safety and check valves. Manufactured in one housing, they control the pressure in the boiler and protect against excessive pressure increases during water heating. The check valve performs two functions: it prevents emergency exposure of the heating elements and prevents heated water from getting back into the water supply. In the absence of a valve, heated water flows not only for its intended purpose, but also into the entire water supply system.

- Plastic coupling. Used when connecting the boiler to metal pipes, it reduces the voltage during a short circuit of the heating element. But it cannot completely protect users, we will talk about this in the article below.

Most boilers consist of such elements. Minor technical differences do not affect the installation process.

Choosing a boiler for an apartment - the nuances that are really important

Initially, a boiler is a container connected to a water supply with a built-in heat exchanger through which steam, hot water or other coolant heated outside the container itself circulates. At this time, any storage type water heater is called a boiler. In this case, the source of energy for it can be either electricity, gas or heated coolant of the heating system.

Let's figure out what you should pay attention to when choosing a boiler for an apartment, which design should be preferred based on specific operating conditions, and what determines the speed of heating water in a storage water heater.[contents]

Volume of the tank

Before choosing the type and design of a water heater, it is necessary to determine the volume of its tank. This will directly determine how often you will sit under the boiler with a bath towel in your hands, waiting for the desired number on its thermometer.

A large and powerful boiler is the key to no problems with hot water for the whole family

Different sources give different values for daily hot water consumption per person. When making your choice, do not pay attention to these numbers. Each person is individual, so even average values will be inappropriate. A simple instruction will help you calculate the required amount:

- Determine the required volume of warm water for the shower. To do this, we take an average flow rate of 6 liters per minute. Next, multiply this number by the time required for swimming. For a family of 3 people living in a house, taking a shower for 10 minutes, the required volume of water is 180 liters.

- The average comfortable temperature for swimming is 38°C. Optimal operation of the water heater involves heating the water to a temperature of no more than 60°C.

- The tap water that enters the apartment has different temperatures, depending on the season. Let's take an extreme case: the time of year is winter, the water is no higher than 12°C.

- The volume of the boiler is determined by the formula Vb = Рв × (t° – tт) : (tв – tт) , where:

- Рв – volume of water in the boiler;

- t° is the temperature of the water that is required to be obtained at the point of water collection;

- tt – temperature of water from the pipeline required to dilute the hot water coming from the boiler.

- tв – temperature of water heated by the water heater.

Since 180 × (38-12): (60-12) = 97.5 liters, then the choice of a hundred-liter boiler will be optimal in this case. There is no need to add additional water for washing dishes into the calculation. The hot water accumulated in the device will be enough for all residents of the apartment to take a shower. Washing dishes does not require much liquid compared to this value. Therefore, the volume of the boiler calculated using this method is quite enough for domestic needs.

If you are not only a zealous owner, but also a thrifty person, then make your choice in favor of a water heater with a tank 20-25% larger than the calculated one, just keep in mind that you will have to pay an additional amount for electricity.

Power and heating time

When choosing a boiler for an apartment, you should not throw the heating speed factor off the scale. Typically, the connection of power systems is designed for a load power of up to 7-10 kW in a new apartment building. If your home was built in the last century, then most likely the input fuses will trip at a current of up to 20 Amps. This means that the simultaneously switched on load should not exceed 4.5 kW. Subtract from this value the power of all electrical appliances that can operate at the same time, and you will get the value that your network can provide to the boiler. Don't be discouraged if you get a small amount.

DIY heating boiler

It should be noted that the cost of factory-made boiler models for heating a dacha is quite high - from 7,000 rubles. and more. An alternative option is to make the structure yourself.

You can use any steel container for this.

It is important that its volume corresponds to the calculated one. To organize heat supply circuits from a homemade boiler, you will need the following components:

- Tank. It is best to order a stainless steel structure or make it yourself. The body must have holes for soldering inlet and outlet pipes;

- Coil. The best option is to install a copper structure. This material has optimal parameters for the transfer of thermal energy;

- Fastening pipes for connecting to heating and hot water supply.

To ensure thermal insulation, it is recommended to make a double casing. Glass wool or basalt insulation is installed between the walls. The recommended layer thickness is 5 cm. The installation and commissioning procedure is no different from the factory models.

How effective is the use of a boiler in heating a home? It all depends on the correct calculations of the parameters of the entire system. Only after calculating the optimal characteristics and testing them in practice can we talk about the real efficiency of the boiler installation.

The video shows an example of using a boiler in a heating system.

Using a boiler for a water supply system to heat a house

One of the frequently asked questions regarding the use of a boiler in a heating system is the following: can a boiler, which is designed to simply heat water for domestic needs, be used in a heating system. There is no definite answer to this question - it all depends on how extensive the heating system itself is and what additional equipment is used.

A boiler for a water supply system is different in that it has both holes (both the cold water inlet and the hot water outlet) located at the bottom, and both of these holes have a small diameter (most often it is 0.5 inches or approximately 1.2 cm ).

This arrangement of holes eliminates the possibility of water moving through the heating system on its own, since here cold water will not constantly “drive” hot water out of the tank and force it to move through the pipes. But, in general, such a boiler can be used in a heating system if it is supplemented with a circulation pump, which will be “responsible” for the movement of water through the heating system. The effectiveness of such a system depends on several factors:

- depends on how powerful the boiler itself is. Suitable power is usually determined at the rate of 1 kW per 10 square meters of heated area.

- depending on how powerful the circulation pump is

- depends on how extensive the heating system of the house is. It is best if it does not have many branches.

As for the type of boiler, you can use both instantaneous and storage water heaters.

So, heating a house with a boiler is not a fantasy at all, but a completely viable option for installing a heating system. The main thing when creating such a system is to accurately calculate the required boiler power, based on the size of the house. In some cases (for example, if the house area is large enough), the efficiency of the system can be increased by expanding the water inlet and outlet, as well as by upgrading the boiler itself to increase its power.

07/07/2013 at 20:07

Malfunctions

What problems in the operation of the water supply system can the apartment owner eliminate on his own? Here are some of the most typical situations.

Valves leaking

Description: leakage along the stem of screw valves.

A typical leak location is shown by an arrow.

- Reason: partial wear of the oil seal or wear of the rubber O-ring.

- Solution: open the valve knob all the way. In this case, the thread on the rod will tighten the seal from below, and the leak will stop.

Crane noise

Description: when you open a hot or (less often) cold water tap, you hear a loud noise and feel the vibration of the mixer. Alternatively, your neighbors faucet could be the source of the noise.

A noisy neighbor's faucet can become a source of a lot of negative emotions.

Cause: a deformed and crushed gasket on the screw valve in the half-open position causes a continuous series of water hammers. Its valve closes the seat in the mixer body at intervals of a fraction of a second. In hot water, the pressure is usually noticeably higher, so the effect is more pronounced.

Solution:

- Shut off the water to the apartment;

- Turn out the problematic valve housing;

- Replace the gasket with a new one;

- Use scissors to remove the chamfer from the new gasket. The removed chamfer will prevent the valve from beating in a turbulent stream of water in the future.

Replacing the gasket on the screw valve

By the way: ceramic faucets are fully compatible with screw threaded faucets, and do not have the described problem.

The photo shows a ceramic crane box

Cold heated towel rail

- Description : The heated towel rail in your bathroom has cooled down and is not heating up.

- Reason : if the water supply scheme of a residential apartment building uses continuous circulation of hot water, the air remaining in the jumper between the risers after water is discharged (for example, for inspection and repair of shut-off valves) is to blame.

- Solution : go up to the top floor and ask your neighbors to bleed the air from the jumper between the DHW risers and heated towel rails.

If for some reason this cannot be done, the problem can be solved from the basement:

- Shut off the DHW riser passing through your apartment, to which your connections are connected;

- Go up to the apartment and open the hot water taps all the way;

- After all the air has come out of the riser through them, close the taps and open the tap on the riser.

If a vent is installed on the riser, it can be diverted directly from the basement

A caveat: immediately after the end of the heating season, there may be no pressure difference between the threads of the heating main. In this case, the heated towel rails will be cold even if there are no air pockets in the risers.

Immediately after the end of the heating season, the difference between the lines of the route may be zero

Features of mounting a boiler on a thin wall

Ideally, the water heater should be mounted on strong brick, concrete or block walls, since the device, together with water, has quite a lot of weight. But sometimes the device needs to be hung on a thin plasterboard, frame, wood, aerated concrete or foam block base. In this case, you will need to strengthen the wall and use special fasteners.

The water heater cannot be mounted directly on a wooden wall for fire safety reasons. First, it needs to be well insulated from heat, for example, with profiled iron, which is used for roofing.

In other cases, special fastenings are used:

- spiral nylon dowels;

- metal fasteners for mounting boilers with a capacity of 100 liters or more.

If you plan to hang the water heater on a wall made of foam concrete blocks, you will need metal dowels or special chemical (adhesive) anchors for foam concrete. Chemical anchor is a universal fastener that can withstand high loads. It is environmentally safe and resistant to low temperatures.

Attachment to an adhesive anchor is carried out in the following way:

- A hole is drilled to expand the channel by rotating the drill at an angle in different directions.

- Concrete dust is removed from the hole.

- The hole is filled with a quick-hardening mixture, into which a fastening sleeve or threaded pin is inserted.

The resulting cone-shaped plug provides fairly high fastening strength.

Is it possible to use a hot water boiler in a heating system?

In order to fully understand what kind of device this is, you need to understand all the nuances.

What is the device

Visually, the heating boiler looks like a container of quite large volume. A heat source is located inside or below it.

Design and technical characteristics

On the outer body of the device there is a pressure sensor and an electronic-mechanical system for controlling the boiler. Next, there is a layer of thermal insulation that separates the housing wall and the storage tank, and allows you to retain heat.

Photo 1. Indirect heating boiler model 702.1, capacity - 712 l, Italy.

It is advisable to choose the volume of the storage tank in which water will accumulate and warm up in the range of 200-300 liters. Lower values of tank capacity should not be considered, since this will not be enough to heat even a small area.

Water is heated using a tubular electric heater with a power of at least 8-12 kW.

Attention! It is important to take this indicator into account, since if it is lower, the equipment will not cope with heating, and there will be a need for round-the-clock operation of the device

What is it for?

After the storage tank is filled, the heating elements located inside it begin to heat the water to the set temperature. As the required level in degrees is reached, the liquid begins to flow through the pipes into the pipes of the main heating system.

Although the principle of operation of a heating boiler is quite simple, it is important to remember about the features of the preparatory process:

- create a closed circulation circuit;

- foresee the possibility of adding liquid to the coolant from water supply systems;

- install a pump that regulates the stable movement of water through the pipes, shut-off valves, and an expansion tank;

- establish a water filtration structure, the liquid should circulate along the circuit in a purified form, without impurities.

The heating elements built into the boiler control fluctuations in the temperature of the device. As soon as the user-defined value in degrees is reached, the system automatically turns off. If the water cools down, then the reverse process occurs: it starts heating again.

What is a furnace or boiler room?

It is not difficult to guess that a boiler room is a place where a boiler is installed to heat water. There are special requirements for this room. The finishing must be made of non-combustible material. There must be excellent ventilation. Heating radiators are installed in the boiler room. Connection of devices is carried out only according to the rules, so that safety is observed in all respects.

Electric water boilers are sold in a wide range and it is possible to purchase different equipment, choosing according to parameters such as:

- Dimensions;

- Power;

- Tank capacity;

- Type of location.

Electric types of heaters differ from gas ones. It is designed differently inside and does not work like a gas one. To be more precise, it has a different structure of the heating element, and this is a heating element.

Only he is responsible for how quickly a certain amount of water can heat up and to what temperature.

Tens come in dry and wet types. Dry ones are placed in an additional capsule, and heating by such an element takes much longer. A special temperature sensor must be installed near the heating element, which controls the operation of the electromechanical or electronic thermostat. This ensures that the water temperature is maintained at a given level. When the liquid cools, the temperature sensor is triggered and automatic heating of the contents of the tank begins.

Boiler insulation

In order for the boiler to retain heat better, it must be wrapped in polypropylene foam, polyurethane foam or isolon. The insulating material is fixed with glue or wire. Thermal insulation of the entire surface of the boiler not only helps to retain heat, but also reduces the heating time of water by increasing the efficiency of the coolant. High-quality insulation will not allow the water to cool quickly.

The second way to insulate a boiler is to place a smaller capacity container inside a large tank. The resulting space acts as insulation.

Still, if you realize that you are unable to install the boiler yourself, or there is a need to replace the pipes due to wear, contact a specialist. Their services will not cost you too much: dismantling an old water heater - about 500 rubles, installing and connecting a new device - about 7,000 rubles. At the same time, you will be sure that the equipment is connected correctly and you will not experience an accident or explosion. There is another important point: installing the boiler yourself will usually void the manufacturer’s warranty.

The municipality installed a boiler room in the house and handed it over to the maintenance authority

One of the management organizations of Magnitogorsk found itself in a difficult situation, under a contract it was engaged in the maintenance and repair of common property in an apartment building with direct management. In this house several years ago, the administration installed a boiler room and transferred it under the right of economic management to a heat supply organization.

After 13 years, RSO informed the city administration that it would no longer service the boiler room, and the local government excluded the equipment from the register of municipal property in accordance with Part 2 of Art. 36 Housing Code of the Russian Federation. The compulsory medical insurance department sent copies of the inspection and transfer certificates of the ITP, as well as test reports, and all the technical documentation for the boiler installation to the Administration, considering that this is now part of the property of the owners in the house.

But the owners of the premises at the general meeting refused to accept the equipment as part of the common property, and therefore, to include boiler room maintenance in the fee under the agreement with the management company. The company did not do this, including conducting hydraulic tests of input units and heating systems, flushing them and adjusting the ITP. This was recorded by the State Housing Authority after an unscheduled inspection of the company’s activities and demanded that the violations be eliminated.

The management authority appealed to the court to declare the order of the supervisory department illegal: it cannot service equipment that is not included in the common property of the apartment building and in the agreement with the owners. However, courts of all instances, including the Supreme Court of the Russian Federation, rejected the company’s claim (case No. A76-39409/2019). Let's figure out why.

Is it possible to alienate common property in an apartment building?

161270

Heating a house with a boiler

Good heating is one of the most important factors that distinguishes a comfortable home from a home in which a person cannot feel comfortable. Today there are many traditional heating systems that can be used to heat a country house of any size. One of the most popular systems is gas heating. Natural gas is considered one of the cheapest coolants in our country. But, unfortunately, gas pipelines are not stretched everywhere. Therefore, heating systems that use a different coolant - for example, hot water - are very popular. And the basis of such a system can be an ordinary boiler.

Shell and tube heat exchanger and its features

A shell-and-tube heat exchanger is a bundle of small-diameter pipes, which is placed in a metal casing with network water from the heating system. Structurally, a single-pass shell-and-tube heat exchanger and its multi-pass version are distinguished.

In the single-pass version, heated water enters the input of a bundle of metal tubes, the output of which is connected to the hot water system. A multi-pass shell-and-tube heat exchanger uses the principle of repeatedly passing heated water through the same volume of water from the heating system.

Heat exchange pipes are made of materials with increased heat transfer, which include copper or brass. Stainless steel can also be used as a material for heat exchange pipes. Straight sections are connected to each other by U-shaped pipes, which are commonly called rolls.

Standard shell-and-tube VVP are produced in accordance with GOST 27590-2005. The length of one section is 2 or 4 meters, and the outer diameter ranges from 57 to 530 mm. The maximum operating temperature of the coolant is 150°C. The maximum pressure of the GDP should not exceed 1 MPa.

The main advantages of shell-and-tube water heaters are the reliability of the design, which ensures a long service life, as well as ease of maintenance and easy access to the inner surface of the heat exchange pipes.

Pros and cons of boiler-based heating

There are probably not too many advantages of such heating:

- The main advantage of such a system is simplicity. Almost any craftsman can assemble a structure based on a boiler and connect heating pipes to it, because this does not require any special skills or complex equipment.

- Another advantage is low cost. As a rule, boilers are cheaper than electric boilers, so when designing a low-power system, you can save money.

As for the shortcomings, we talked about them throughout the entire article, so all that remains is to summarize:

- The power of household boiler models is not enough to efficiently heat an apartment. The maximum is heating a country house, and even then, not in winter, but in autumn, when there are no severe frosts.

- The heating element of the device is constantly on, which, together with regular water renewal, leads to accelerated corrosion. Of course, the cost of the heating element is low, but replacing it is a very labor-intensive process.

Replacing a heating element is not only a labor-intensive process, but also dirty

If you assemble a system according to all the rules (i.e., selecting a heater of the required power, correct pipe routing, installing a circulation pump in the heating system), then the savings compared to purchasing a boiler are negligible.

Summarizing all of the above, we can say that electric boilers for heating can only be used in some situations. In all other cases, it is better to use heating devices that are more suitable for this purpose!

How does a boiler differ from an instantaneous water heater?

Comparing it with a flow-through water heater will help you fully understand the operating principle of a storage water heater. If a certain amount of water is heated in a storage device, equal to the volume of the tank, then during operation of the flow-through apparatus, as much water will be heated as the consumer consumes at a time. Water heating occurs in real time.

A boiler, compared to a flow-through device, will consume less electricity to heat the same amount of water. This is the most significant advantage of a storage water heater. Among the advantages of a flow-through water heater, it is worth noting its compactness.

Thus, the essence of the operation of modern boilers is quite simple, which allows them to be quite productive and economical. The newest models have fully electronic controls. This makes it possible to effectively “communicate” with the unit even for people who are far from knowledgeable about technology.