Autonomous heating will never go out of demand: country houses, dachas, geological expeditions, hikes and other options for people staying away from heating plants will force them to use this method of heating the room. One of the simple options for making an autonomous wood-burning stove is a boiler from a cylinder (gas, or used).

Features of a long-burning stove

The first step is to understand what happens when wood burns. For a flame to appear, the temperature of the wood must be brought to approximately +150 degrees, using an external heating source. Usually, a piece of paper lit from an ordinary match is enough for this. After this, the process of slow charring of the material begins, which, after reaching +250 degrees, begins to decompose into simple chemical elements. The white smoke that appears when a flame is ignited includes gas and water vapor: they are emitted by heated wood. Ignition of the released gaseous components is observed when heating reaches +300 degrees: as a result of this, the thermochemical reaction is significantly accelerated.

The breakdown of organic matter into simple elements is called pyrolysis. Practice shows that during the combustion of wood, part of the energy potential inherent in it remains unused. This is reflected in a significant amount of waste remaining after the flame goes out. In pyrolysis furnaces, fuel is used much more efficiently, which is achieved by separate combustion of gases released during fuel combustion. At the same time, the rate of smoldering of the wood itself is very low, which helps to increase the operating time of the stove on one stack. The Bubafonya stove, which is a type of pyrolysis heater, guarantees almost complete combustion of all fuel.

The main advantages of pyrolysis ovens

- High efficiency - from 90% or more.

- Fuel efficiency - one bookmark is enough for 12-24 hours.

- Modern models of factory-produced pyrope stoves operate on one fuel fill for more than 48 hours.

- Minimum human intervention, simplified operation. Night shifts are excluded.

- From an environmental point of view, the fewer combustion products released into the atmosphere, the better. A pyrolysis oven produces a minimum of carbon monoxide and particulate matter. Almost all CO burns out.

- If you have competent drawings for making a pyrope stove with your own hands and high-quality, precise execution, it is possible to obtain a unit that operates with almost complete combustion of dry fuel. There is very little ash and soot, everything burns without a residue, and there is no need to clean the stove and chimney.

- You can use cheap fuel - dried wood waste, light plant biomass, leaves, branches, straw, etc.

A little history

The development of the Bubafonya stove is attributed to folk craftsman Afanasy Bubyakin from Kolyma. Subsequently, a new invention was named in his honor. During his experiments, Afanasy relied on the design of the Lithuanian-made Stropuva pyrolysis boiler.

The domestic inventor tried to simplify the design as much as possible so that it could be built with your own hands. This specificity of Bubafoni explains its high popularity. Considering that the material for the manufacture of this device is mainly improvised means, it cannot boast of external aesthetics. The strengths of the stove are its simplicity, efficiency and reliability.

Pyrolysis oven made from cans

Camping stove made from tin cans (bottom view).

Who needs a pyrolysis oven made from cans? Obviously, a person who spends a lot of time in nature. These are tourists, fishermen, hunters and travelers. Considering the fact that factory models are quite expensive and weigh a little more than 300 grams, it is best to start making them yourself. Let us immediately note that for work you will need:

- metal scissors;

- drill.

If you can still use a knife instead of metal scissors, then nothing can replace a drill. Therefore, it is hardly possible to make this device in the field. And there’s no need for this; it’s easier to heat up everything you need over a regular fire. As they say: “Get your sleigh ready in the summer.” In order to make a simple pyrolysis oven with your own hands from cans, you will need just two cans of different diameters. No other materials are needed. Sequence of work:

- in a thicker jar, cut the bottom to the diameter of the thinner jar. The latter should fit very tightly;

- in a thin jar we make holes along the top and bottom edges, as well as in the bottom;

- in a thick jar we make holes only along the top edge, where we did not cut a hole;

- connect two banks. The small one is inserted into the cut hole in the large jar until it stops.

The drilled holes must be wide enough to provide good traction. After you have succeeded in making a pyrolysis oven, all that remains is to check the product. Place it on the ground and put small sticks and paper inside. Since this device is used in field conditions, it is very likely that it will have to be lit with a flint. Matches and paper may get wet. What to do in this case?

A useful life hack for tourists is tinder made from a cotton pad. Tinder is a means of starting a fire. To make waterproof tinder from a cotton pad, simply dip it in melted paraffin. This disc repels moisture and is easily ignited with both matches and flint. To ignite it using only sparks, the cotton wool needs to be torn into small pieces. Once the disk has flared up, it can only be extinguished with water; gusts of wind will not extinguish it.

Read how to choose pipes for heating boilers here.

Design

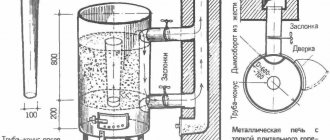

The Bubafonya long-burning stove includes the following components:

- Frame . The main element of the device, usually shaped like a cylinder. It is most often made from cylinders, barrels, large fire extinguishers, thick welded pipes, etc.

- Chimney through which combustion products are discharged. The material for its manufacture is usually a metal pipe with a diameter of 110-250 mm. It is fixed by welding to the upper part of the furnace.

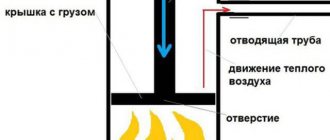

- Piston . Ribs are welded onto the lower part of the metal circle: the air duct pipe is fixed in its central part. Due to the ribs, an additional layer of air is created that separates the fuel and the piston. This makes the smoldering process more efficient and stimulates the active release of pyrolysis gases.

- Regulator . Thanks to this valve, oxygen is supplied inside the firebox.

- Lid . It has holes for the air duct, forming, in combination with the piston, a secondary combustion chamber. Inside this compartment combustion of pyrolysis gases occurs.

What is a pyrolysis boiler for and how does it work?

The scope of application of this device is space heating. The cylinder unit can be used:

- in residential premises (dacha, small cottage, etc.);

- in industrial buildings (cabin, geological exploration temporary hut, warehouse, etc.);

- in garages (private and industrial);

- in outbuildings (greenhouse, greenhouse, barn with pets, etc.).

The operating principle of the device is based on the complete combustion of all components of the energy source. In this case, wood material.

It can be:

- firewood:

- pressed (from sawdust or shavings) briquettes;

- wood chips

If, when burning them in a traditional furnace, ash, coal, and flammable gas remain (removed along with the smoke), then during a thermochemical reaction - pyrolysis (the principle of operation of a furnace from a cylinder) - all components undergo almost complete decomposition (to an ash-like state) with the release of thermal energy .

Strengths and weaknesses of Bubafoni

The pyrolysis stove has a number of positive qualities:

- Simplicity of design . Having welding skills and experience working with metal, building a stove will not be difficult.

- Universalism . Bubafonya is very unpretentious in terms of fuel: you can throw firewood, coal, sawdust, chips and other types of wood waste into it. The stove also copes well with pellets – inexpensive, environmentally friendly granules.

- Duration of work . The time it takes for one stack of firewood to burn out is almost a day: during this time, the stove regularly generates heat. This indicator may vary depending on the modification of the device, the volume of its firebox, the oxygen circulation rate, etc.

It is also worth mentioning the main disadvantages of Bubafoni:

- Low efficiency . The reason for this is uneven heating of the device body with sufficiently low heat transfer. More “advanced” pyrolysis furnaces are much more efficient in this regard: their efficiency often exceeds 90%.

- Inconvenient to clean . There is no ash pan as such in the design, so the remaining combustion products are removed through the top. Some modifications of the stove are equipped with a door at the bottom, which facilitates the procedure for removing ash and ash.

- Low aesthetics . The appearance of Bubafoni can hardly be called beautiful, so it is mainly used for heating utility rooms.

Range of gas stoves on the market

Today you can buy similar equipment for a bathhouse to suit any request. A Russian company from Novosibirsk, which produces heating units under the Teplodar brand, has worthily declared itself in the domestic and foreign markets with high-quality certified products that meet international standards. The great popularity of gas stoves for baths "Teplodar" is caused by their ability to quickly heat up and high efficiency. Thanks to the special design of the stove, the steam room is evenly heated and filled with high-quality steam.

The popularity of Termofor gas units, which are also installed in bathhouses, has also been deserved.

The first thing that attracts the consumer’s attention to such products is their rather original appearance. In their reviews of the Termofor gas bath stove, numerous fans note ease of use, high efficiency and excellent performance characteristics

Such a stove fits harmoniously into the interior of any bathhouse, adding special comfort to the room and creating a warm atmosphere. All of its internal technical components are hidden behind the translucent glass on the device's door. The price of a gas stove for a Termofor bath ranges between 10-12 thousand rubles.

The main competition for the products of domestic companies is the German gas furnace Kusatek. This device for heating baths has many advantages. These are, first of all, compactness, which simplifies installation, ease of use and rapid heating, ensuring the achievement of the optimal temperature in a short time. Adjustment of operating modes is achieved by slightly turning the valve. There is no need to remove ash from the stove, since there is simply none. In addition, the internal surface of the device does not require regular cleaning.

German products are distinguished by a high degree of safety, which is why manufacturers confidently recommend installing such a stove in bathhouses. The risk of emergency situations is also eliminated due to the built-in control system, which is responsible for the quality of combustion and fuel pressure indicators.

Drawing up a drawing

The main proportion in the process of making a homemade Bubafonya stove from a gas cylinder is the mathematical ratio of the parameter of the internal diameter of the body and its height. It should be between three and five to one. The optimal diameter is from 30 to 80 cm.

Making the diameter of the stove body less than 30 cm is not effective, since oxygen will circulate too quickly through the combustion chamber without fully reacting with the wood. This leads to a noticeable decrease in the efficiency of the device. In chambers with a diameter of more than 80 cm, another problem arises - in it, the firewood on the edge burns very slowly, and in the center - faster. As the fuel burns out, a hole appears into which the piston descends. As a result, the flame gradually fades away. In the drawing, it is more convenient to denote the diameter by the letter D, and the height by H.

The manufacturing process of an atmospheric gas burner

An atmospheric burner is easier to build, since it is structurally much simpler than its fan counterpart. The most typical example known to most Russians is the burner block in old-style geysers. There are no energy-dependent elements in its design that force gas and air to mix in the required proportions.

Air is drawn into the chamber with the atmospheric burner module spontaneously as needed. Blue fuel processing products are discharged naturally through a standard chimney due to the presence of draft. All the work consists of constructing a manifold with gas nozzles through which gas will flow at the required speed.

If you want to build a gas burner with your own hands, it is better to take a factory-made product as a basis, or rather, the drawing available in its technical passport with the dimensions and designation of structural elements

To make a burner with your own hands to equip a gas heating boiler, you will need:

- Valve series VK-74. Typically used on oxygen cylinders, designed for a maximum pressure of 20 mPa. The package should include a 3/4″ union nut, with which you can tightly connect to the gas supply pipe or hose. The valve will serve as a support base for fixing the nozzle.

- Nozzle cap. The device will hold the gas supply dispenser and form a narrowly directed jet. A hole is drilled at the top of the cap into which the nozzle is to be placed. The base screws onto the valve.

- Nozzle. It is better to buy it ready-made with the expectation of supplying main gas or a liquefied gas mixture. The injectors have different outlet diameters. Instead of nozzles for boilers, you can use a jet from a gas burner.

- Homemade injector. It is constructed from a steel tube with a wall thickness of up to 2 mm. You will need a piece of pipe approximately 10 cm long.

- Piezo element. It is installed at will, although you can do without it. Homemade products can be set on fire with matches.

All of the above elements are assembled mainly by welding. Therefore, skills and minimal knowledge in welding will be very useful for an enterprising “do-it-yourselfer”. However, where it is possible to use threads, it should remain a priority.

The gas supply channel must be impeccable and sealed, because safety depends on its condition. A distance of 10 cm must be maintained between the gas inlet into the device and the nozzle, which is necessary for mixing fuel with air.

Image gallery

Photo from

Large gas burner

Gas burner combustion process

Ignition of the atmospheric burner block

Burning oxygen indoors

The home craftsman just has to figure out how to secure a homemade gas burner in the combustion chamber of a used water heater or in the firebox of a former wood-burning boiler. Please note that you need to leave room for air flow. Air must be regularly supplied to the chamber, for which round or longitudinal holes must be cut in the door.

Do not forget that the above option can hardly be called a safe gas supply device. The design does not have automatic equipment that interrupts the operation of the boiler in case of blowing out or unstable flame. Owners will not have the opportunity to adjust the pressure and gas flow, so there can be no talk of either convenience or savings.

Piston pressing block

The distance from the piston to the inner surface of the piston is calculated using the formula 0.5xD. To calculate the diameter of the pancake, accordingly, the formula d = D – 2xH is used. Calculating the height of the pressing ribs from a metal profile is more difficult, because The relationship between the parameter values is nonlinear. Theoretically, for a furnace body with a diameter of 60-80 cm, this parameter is taken as a number of 0.1xD. The Bubafonya stove from a smaller gas cylinder is calculated using a proportional equation, taking into account that with D0 = 30 cm h0 = 4 cm.

Advantages and disadvantages of equipment

Such wood-burning stoves have a number of advantages compared to other devices for heating a private home:

- high efficiency rate - from 80% to 93%;

- the economy of this type of heating, since the cost of firewood is much lower than gas or electrics;

- You can use not only firewood, but also waste from the wood industry - shavings, sawdust;

- gradual heating of the room;

- When installing the unit, there is no need to further equip the foundation;

- it is possible to connect to the water heating system of a private house;

- environmental friendliness of the device;

- unit safety;

- does not require professional maintenance.

Two schemes of pyrolysis boilers

In addition to significant advantages, the process of heating a private house with wood can cause some difficulties, especially if it is not possible to constantly be near the device. As the wood burns, you need to add new logs. This system requires constant cleaning, since a lot of soot accumulates on the walls of the device and the inner surface of the chimney.

It is also important to provide a place to store a large volume of firewood, which must be dry.

Pancake thickness

This value is in inverse proportion to the internal diameter D. It is necessary to achieve optimal piston pressure on the fuel filler. If the pressure is insufficient, this will lead to a decrease in the reverse action coefficient. As a result, the firebox may backfire with further smoke escaping through the chimney. If the piston is very heavy, this will significantly reduce the air gap necessary for high-quality combustion: as a result, the flame will die out.

The relationship between the internal diameter and thickness of the pancakes is approximately as follows:

- 30 cm – 6-10 mm.

- 40 cm – 6-8 mm.

- 60 cm – 4-6 mm.

- 80 cm – 2.5-4 mm.

Drawings, dimensions and calculations

You can make a small stove with your own hands to heat a garage or other space using scrap materials.

It’s easy to create a sketch plan and drawing of a small metal stove-stove yourself

An obligatory step is the creation of a drawing or diagram of the future structure. To do this, you need to determine the shape and dimensions of the case, the location of the cameras. After this, the power sufficient to heat the room is calculated. The parameters are determined as follows:

- Let's assume that 10 kW of heat is required to heat the room at the lowest outside temperature. We determine the required power of the furnace in normal combustion mode. It is known that in the gas generation mode the furnace power is 10-30% of that which develops in the flame combustion mode. Consequently, to obtain 10 kW with gas generation, the unit, when burning with a flame, must develop a power of W = 10 / 0.3 = 33.3 kW (we assume a 30 percent power ratio);

- We choose the least energy-intensive fuel. For example, dry beech is optimal;

- We calculate the volume of fuel that can provide the required power. A portion of firewood burns in flame mode in approximately 4500 s. Therefore, during this time it should provide the following amount of heat: Q = 33.3*1000*4500 = 149.85 MJ. Let's calculate the required mass of fuel, taking into account that it burns only 80% completely, and the efficiency of a homemade stove is approximately 50%: M = 149.85 / (15.5*0.8*0.5) = 24.17 kg. Knowing that the density of dry beech is 620 kg/m3, let’s convert the resulting mass value into volume: V = 24.17 / 620 = 0.039 m3 = 39 l;

- We calculate the volume of the firebox. The average furnace load factor is 0.63. It should have a volume: Vt = 39/0.63 = 61.9 l.

You can make a drawing or technical drawing of the product yourself, taking into account the shape and features of the stove. A ready-made image of a suitable unit is taken as a basis.

Tools and materials

List of required consumables and working tools:

- sheet steel grade St20, thickness 3–4 mm;

- steel equal angle angle 4x50 mm;

- pipe with a diameter of 50–60 mm;

- steel reinforcement with a cross section of 8 mm;

- steel pipes with a diameter of 110 or 120 mm for the chimney;

- bricks in the amount of 15 pieces;

- electric welding machine and several packages of electrodes;

- drill and metal drills, grinder with 230 mm circles;

- building level, tape measure, pencil, hammer.

Choose consumables that are high-quality and reliable. Not only the operation of the pyrolysis furnace, but also the safety of the surrounding area during the heating process depends on this.

Preparation and selection of installation site

The assembly of the structure is carried out directly in the room where the stove will be installed. It is best to order sheet cutting into blanks from specialists in the store. This will ensure a good quality base for the product.

The space around any stove must be safe and heat-resistant, and the floors must be level.

The site for installing the unit must be prepared.

- a base of bricks or other non-combustible material is laid on the floor;

- the base area should be larger than the dimensions of the oven;

- install the unit at a distance of at least 80 cm from the nearest walls;

- the floor within a radius of 1.2 m in front of the heating device must have a fireproof coating (iron sheet 1.5 mm thick).

Calculation of the optimal chimney area

When determining the smallest permissible area S, the pipes are based on the maximum energy release per hour. S(cm2) = 1.75 x E (kW/hour). Here E = m x q where m is the weight of one portion of fuel: it is calculated by multiplying the maximum volume of the load V by its density. The coefficient q denotes the specific energy of combustion of a unit volume of fuel in 1 hour.

Positive and negative parameters

Using a gas cylinder to form this design has certain advantages:

- You can get a long-burning stove without spending a lot of money, since you will need standard and inexpensive elements and materials.

- You can do all the processes yourself.

- The resulting equipment can be used for a home, bathhouse or other structures.

- On the Internet you can find video instructions for creating the structure.

- These stoves are easy to use and there is no danger involved.

- You can make different types of ovens.

The disadvantages of this equipment include the fact that all work must be carried out according to the drawings. Without them, you can violate the basic principles of stove design and make serious mistakes.

Preparatory activities

Since constructing a Bubafonya stove from a gas cylinder will require a welding machine, it is necessary to find a suitable room for the work in advance. It must be equipped with effective ventilation, uninterrupted power supply and reliable wiring (as a rule, the use of welding provokes power surges in the network). The workroom must be well protected from climatic influences and have sufficient space. It is also desirable to have good sound insulation, since the grinder and welding machine are quite noisy tools.

You also need to prepare the following materials:

- Old gas cylinder. This is the basis for a pyrolysis oven. Also suitable for this role is a steel or cast iron barrel with a volume of approximately 200 liters, which has strong, rust-free walls. Often, large fire extinguishers or metal pipes with welded bottoms are used for this.

- Pieces of reinforcement. They will be needed to make handles, which are usually installed on the sides of the case and on top of the lid. This significantly simplifies the procedure for cleaning the stove from combustion residues and moving it from place to place.

- Steel sheet for piston.

- A pair of metal pipes. They are needed for the manufacture of a chimney and air duct. The optimal cross-section for the air pipe is 85-100 mm. Moreover, it is approximately 150 mm higher than the height of the cylinder. For the chimney you will need a wider pipe: its diameter must be at least 150 mm. The length of the smoke channel should not be less than the cross section of the cylinder.

- Channel.

- Material for laying the foundation for the stove.

List of tools required for work:

- Hammer.

- Vise.

- Shovel.

- Master OK.

- Portable welding machine with a set of electrodes.

- Grinder for cutting blanks.

- Tape measure, pencil, plumb line and level.

How to increase the efficiency of a pyrolysis furnace

Basically, the efficiency of Bubafoni decreases due to uneven heating of its body; this leads to a deterioration in the efficiency of heat exchange between the device and the surrounding space. There is a fairly simple way to optimize the process using corrugated metal sheet. An improvised jacket for the body is made from it: it is fixed over the cylinder by welding or twisting.

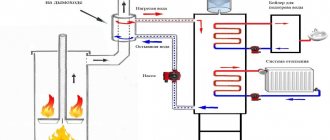

Another popular option for increasing the efficiency of a pyrolysis furnace is the Bubafonya boiler with a water jacket. Most often, the water circuit is made from a metal barrel or box, pouring water into it. By placing red-hot Bubafonya inside the manufactured structure, you can heat the water and let it go inside the heating system. In this way, it is possible to acquire a kind of boiler for heating a large room.

When creating a water jacket, you must take all necessary measures to make it as reliable as possible. If a box is used for these purposes, it must be well welded to avoid leaks. It is advisable to seal all seams with heat-resistant sealant. The recommended thickness of the steel sheet for making a water circuit is at least 3 mm. It is best to close the top of the box with a lid with handles. The Bubafonya long-burning stove with a water jacket can be additionally equipped with a heat exchanger consisting of thin tubes.

There are several useful tips for better and safer operation of a long-burning gas cylinder stove:

- It is best to install the device indoors on a sheet of metal.

- The space around the stove must be cleared of any flammable objects.

- When igniting fuel, it is not recommended to abuse flammable liquid.

- The body of the product gets quite hot, so when servicing the heater you need to wear thick gloves.

- To extinguish the flame, the damper on the air pipe is closed.

- Painting parts of Bubafoni is strictly prohibited.

How to assemble a structure with a water jacket

The manufacture of the chimney is carried out in the following sequence of operations:

- Carefully cut the balloon at the top. The resulting cap is subsequently used to make a lid for the boiler.

- The bottom of the cylinder is equipped with homemade legs. Each of them must be exactly level before fixing.

The piston is constructed in three stages:

- A steel circle is cut out: in cross section it should be approximately 35-45 mm smaller than the internal diameter of the cylinder. Thanks to the side gaps, pyrolysis gases will leak into the secondary chamber without interference. A hole is made in the center of the circle for the air duct: this pipe should be inserted into it quite tightly.

- Next, the metal circle and pipe are welded to each other.

- A piece of channel is welded on top of the piston base.

To make a furnace lid, you can use the upper cut part of the cylinder. On its surface, markings are applied for the air duct pipe with a fixed supply piston. In this case, it is necessary to provide a certain margin for the free movement of the pipe. Cutting is done along the drawn lines. On the side, the homemade lid is decorated with handles, for which fittings bent in a vice are used. Now you can begin installing the chimney at the top of the improvised pyrolysis oven. Using a grinder, a cutout is made for the pipe blank: welding is also used to fasten the parts.

To increase the quality of chimney draft, it is recommended to make it from two elbows perpendicular to each other. To do this, a cut is made at the end of the pipe section leaving the furnace at an angle of 45 degrees, after which it is connected by welding to a piece of pipe of the same diameter. It would not be superfluous to take care of additional protection for the chimney from the ingress of debris and climatic precipitation - a reflective cap is usually made for these purposes.

At this point, the main part of the work on the construction of Bubafoni is considered completed: it can be put into operation. It is advisable to install the stove on a pre-arranged foundation.

Homemade pyrolysis oven from a gas cylinder

Design and operating principle of a gas cylinder stove.

You can make a pyrolysis oven with your own hands according to the drawing from an ordinary gas cylinder; it is also called the Bubafonya oven. Pyrolysis is the separation of organics from inorganics in the absence or deficiency of oxygen. During pyrolysis combustion, temperatures up to 500 degrees are reached. This is a necessary condition for the released pyrolysis gases from wood to burn out.

A pyrolysis furnace from a gas cylinder can operate on any solid fuel, and the fuel moisture level can reach 70%. The cylinders are made of ferrous metal, 3–4 mm thick. The upper part is made in the form of a dome and welded to a cylindrical base. Let's consider what manipulations need to be carried out to make a pyrolysis oven from a gas cylinder:

- cut off the upper convex part;

- in its central part we make a hole for the air duct;

- in the upper part of the conical body we make a hole for the smoke exhaust;

- we manufacture a gas divider with a pipe for supplying oxygen;

- We weld the chimney.

In principle, a homemade pyrolysis oven from a cylinder has a fairly simple design. In your work you may encounter various nuances.

Gas diffuser at the end of the air supply pipe.

The hole in the lid should almost coincide with the diameter of the air supply pipe, and the latter should move easily. The diameter of the gas divider must also be matched to the size of the tank. At the bottom of the gas divider, ribs are welded to direct gas flows. It is better to make them curved so that the flow swirls. Remember, the fewer extra gaps, the higher the efficiency of the unit.

To protect yourself, before starting cutting, you need to fill the cylinder to the top with water, in case gas vapor remains inside. Even if there was liquid in the cylinder before, and there are definitely no gas vapors, a characteristic smell of propane may appear during cutting. Don't worry, it's the additives that are added to the gas that smell. They tend to settle on the inner walls. Additives are a necessary warning measure, since the gas itself has no odor.

The operating principle of a homemade pyrolysis oven from a cylinder:

- Fuel is placed in a cylindrical tank and ignited;

- a pipe with a gas divider at the end is installed on top (the latter should press the fuel);

- the lid is put on top;

- combustion occurs from top to bottom; as the fuel burns out, the pipe with the gas divider lowers.

A feature of this fuel combustion method is the minimum amount of smoke and soot. There is really very little ash. After the first burning, a sharp smell will appear - this is the burning paint that covers the cylinder. There is no point in removing it mechanically, as it is ineffective. It’s easier to burn out everything unnecessary by testing kindling.

To make long-burning pyrolysis stoves with your own hands, you will need the following equipment:

- Bulgarian;

- hammer;

- pliers or pliers;

- welding machine.

To carefully cut a round hole with a grinder in a blank for a pyrolysis oven from a gas cylinder with your own hands, you need to take a small, already erased circle and make a 1 mm indentation along the cutting line. Then, using a large, new circle, cut a square in the center of the marked hole and make slits from it to the edges with an indentation of 1–2 cm, like the petals of a flower. Then the petals are bent inward with a hammer. The bend line will run exactly along the intended perimeter with a depth of 1 mm. The petals can then be broken off with pliers.

As a result, we get a neat hole. If you immediately use a large circle, then the cuts will inevitably go beyond the boundaries of the markings. After this they will need to be brewed. As you know, no welding seam can compare in strength to solid metal.

You can read about how to lay heating pipes in the floor here.

Foundation construction

The foundation for the Bubafonya stove is laid in this way:

- The first step is to dig a square hole. Its approximate dimensions are 150x150 cm, with a depth of 20-30 cm.

- The bottom of the trench is covered with a cushion of crushed stone and filled with concrete solution. A trowel is useful to level its surface. When the filled area has set, it is necessary to check the horizontalness of its surface using a building level. If necessary, additional adjustments are made.

- Refractory bricks are laid in several rows on top of a completely dry concrete base. Usually 2-3 layers are enough.

Simple and convenient “ash pan”

In a long-burning potbelly stove, an ash pan is not needed; a small amount of light ash after combustion remains directly in the firebox. But you can still adapt the stove for easier cleaning, especially if you plan to add coal to the firewood.

1. Stops from the corner. 2. Grate over the ash pan

If the potbelly stove is positioned horizontally, you need to cut out the same plate that was used to form the upper chamber. Instead of a partition, it has a regular 35 mm corner welded transversely. In the front part, a handle is made from a thin rod. The plate is installed on two guide angles welded along the body. To ensure a tight fit of the plate and avoid strong air leaks, it is recommended to do the following:

- weld the corners under the bottom of the plate with the shelves up on small tacks that are easy to break off;

- insert the plate into the body and weld the corners to the walls, filling the thick weld seam well;

- insert a crowbar into the lower chamber and undermine the plate, if possible, clean out the weld marks.

Through small cracks, the minimum amount of oxygen required for combustion will enter the chamber.

1. Disc. 2. Holder made of reinforcement. 3. Side of the “ash pan”

For a vertical potbelly stove, you need to cut out another flat disk and weld a piece of thick steel reinforcement to it in the center. A side made of steel strip is bent and welded along the perimeter of the circle. In both cases, ash removal is carried out after the potbelly stove has cooled: the ash pan is removed, cleaned and replaced before a new filling.

Oven operation

Before igniting the Bubafoni, it is necessary to remove the welded air duct from inside the housing, first removing the top cap. Wood logs are placed inside the stove in a horizontal position, close to each other. When stacking vertically, some obstacles may arise in the path of the piston movement: this usually happens in cases where the logs are not completely burned. As a result, smoldering in the primary chamber will develop into full-fledged combustion, which seriously impairs the proper functioning of the stove. In this case, firewood is consumed much faster, and smoke begins to seep out of the air duct. When laying logs, it is prohibited to block the area where the chimney is welded.

A layer of chips, sawdust or chopped branches is poured onto the firewood. On top of them you need to put old cloth or paper soaked in kerosene. A piston is installed end-to-end on the fuel filler and a cap is put on. To light firewood, you need to light a piece of rags or paper and throw it inside through the air pipe. Matches are ineffective in this case, since they go out before they can reach the fuel. After lighting the firewood, pause for 15-20 minutes, allowing it to flare up well. When the flame gains strength, the valve on the air pipe should be closed: thus, Bubafonya is transferred to the main operating mode.

Features of operation and rules of safety regulations

It is very easy to operate such a sauna stove:

- collected thick and long firewood;

- they filled the entire volume of the firebox;

- They opened the damper and ash pan, made sure there was good draft and lit the wood.

Everything, as the wood burns, the stones heat up, the water heats up. You can call your friends, take brooms and a supply of herbal decoction or just kvass and, after throwing a few shakes on the stones, enjoy the fragrant and hot steam and conversation with loved ones.

When operating, it is important to follow the rules for safe use of the oven. There are few of them and they are very simple:

- Be sure to monitor the condition of the chimney. At the first sign of its malfunction or decrease in traction, all problems will need to be corrected immediately. It is recommended to clean the chimney at least once a month;

- after the wood starts burning, the ash pan door must be closed;

- The firebox door opens only to add firewood and control its combustion. The rest of the time, when the fuel is burning, the door must be securely locked;

- You should not try to heat the oven by touching the sides with your bare hands - this will lead to burns on your hands. The level of heating can be felt by the amount of steam from the stones when water is splashed on them from a ladle.

Top-loading oven – “Bubafonya”

Before using a top-loading oven, you should know its benefits. In this article we will explain in detail how they differ from conventional analogues, and why it is better to use them. Experts highlight the following advantages of the design: · These furnaces have a compact combustion chamber, which is convenient to use. · It is possible to use gravity in the operation of the furnace; · Fuel is consumed in minimal quantities, i.e. A top-loading stove helps save wood. · The above design has a low discharge temperature. Those. you do not need to insulate the chimney using additional technologies. · Smokeless emission will not pollute the atmosphere. A distinctive feature of vertical loading stoves is that the fuel is gradually burned. This means that the heat in the room will be distributed evenly, i.e. The body will have time to get used to the increase in temperature. As for potbelly stoves and the like, the fuel immediately ignites. The most popular are “Bubafonya” and “Rocket”

Bubafonya oven, why is it called that?

The stove received this name from its creator. The peculiarity of this type of LDG (long-burning furnace) is that there is constant piston pressure. The heel of this piston maintains the optimal temperature in the room for a long time. As a result, certain areas of the room will not overheat, and some will not be too cold.

How to assemble a stove

To assemble the stove, you must follow the instructions below: · Initially, we will need a barrel. We cut off the top part (it can be used as a stove lid in the future). If you used a gas cylinder instead of a barrel, you should cut off the upper part along the solder boundary. Do not forget that the cylinder is a flammable structure. Therefore, you should make sure that there is no gas left in it. To do this, pour water into it, and after that you can use it without fear. · A hole for the chimney should be located slightly below the cut part. Then we weld a channel from a pipe, the diameter of which should be about 120 millimeters. · Let's start building the air duct. The internal diameter of the air duct should be 75 millimeters. Length – about 30 millimeters. · We use a sheet (6 millimeters) on the heel. We cut out the structure in the form of a circle, the diameter of which should be 4 centimeters less than the combustion chamber. · Next, cut a special hole about 3 millimeters in the center of the heel. · Then you should weld 30x30 or 40x40 corners in the form of rays from the center onto the working surface of the heel.

How to choose a cylinder

A 5 liter household gas cylinder is too small to heat the room. And fuel can only fit in it in the form of briquettes or wood chips. A 12-liter cylinder will allow you to develop thermal power up to 3 kW. This stove can warm a small lodge or tent. Gas cylinders of 27 liters provide up to 7 kW, we can talk about heating a small garden house, greenhouse or garage.

Gas cylinder options

And finally, the king of household gas cylinders is the 50-liter giant. This is the best option for creating a potbelly stove with your own hands, suitable for heating a country house. 40-liter industrial gas cylinders have too small a diameter and thick walls. It is better to cut and shorten them. Thick walls will take longer to warm up and retain heat longer. Such a stove will also last significantly longer.

Assembly of bubafoni with top combustion

There is absolutely nothing difficult about making bubafoni yourself. Prepare all the required equipment for work and get started.

Manufacturing Guide

Furnace making kit

First step. Carefully cut off the top of the barrel. If there is no barrel of suitable volume, the furnace body can be made from a welded sheet or an empty gas cylinder.

Second step. Cut a 100mm hole in the center of the cut top circle.

Third step. Weld a pipe of the same diameter to the hole prepared in the previous step.

Fourth step. Weld four pieces of metal channel crosswise to each side of the circle. The resulting pressure circle will press down the loaded fuel and also facilitate the flow of the required volume of oxygen into the combustion chamber.

Pressure circle

Pressure circle

Pressure circle

Fifth step. Prepare a fuel loading door at the bottom of the housing. To do this, cut a rectangular hole with a grinder, weld the canopies to the resulting piece of metal and place the door in its proper place.

Sixth step. Using a similar scheme, arrange a hole below the firebox to clean the stove from ash.

Cutting out the door

Seventh step. Cut a hole with a diameter of 100-150 mm in the upper side of the case. You will connect a pipe to it to remove gases and provide the required level of draft in the unit.

Long burning stove (bubafonya)

Eighth step. Make an elbow out of a chimney. To do this, cut a piece of pipe at approximately 45 degrees, turn the resulting pieces over along the cut and weld at the joint to form a strictly right angle.

Ninth step. Weld one side of the created elbow to the body. On the other side of the elbow, weld a long (4-5 m) pipe to remove flue gases from the room.

At this point the stove is ready. All that remains is to install it correctly.

Bubafonya stove

Do-it-yourself bubafonya oven

Tenth step. Prepare the foundation for installing bubafoni. To do this, dig a hole with dimensions of about 100x100x20 cm, fill the bottom of the pit with a layer of crushed stone and fill it with liquid solution. Let the poured mortar dry, and then lay a couple of rows of brickwork over it.

After the masonry has completely dried, install the stove.

Bubafonya stove from the inside

Eleventh step. Place a reflector near the bubafoni. During operation, the stove gets quite hot, and the reflector will provide additional fire safety.

The reflector will also contribute to a more uniform and high-quality distribution of heat throughout the heated room.

To make such a reflector, use heat-resistant materials available to you. For example, quite often such screens are built from brick.

Bubafonya

Reviews about the stove on the forum pages

The craftsmen who have made and use a top-burning stove speak mostly positively about it, but with caution. Here are some reviews from real participants of the famous forum:

Andrey, Naberezhnye Chelny, Russian Federation.

I made such a stove to heat a 6 x 6 m box in 2 days. I'm happy with the result; it burns on waste chipboard for 6 hours. What improvements are needed: an air casing and a blower, then the room warms up completely and quickly. Second: you need an ash unloading hatch; turning the body over is very inconvenient.

Valentin, Saransk, Russian Federation.

Bubafonya is good for garages and other similar premises; it cannot be placed in a house. It smokes when there are gusts of wind outside and when reloading with firewood, and with a water jacket it quickly becomes clogged with soot due to the drop in temperature. I made conclusions after a year of testing and modifications to the design. You can also heat with damp wood, but then the heat is much less, which is natural.

Yuri, Vytegra, Russian Federation

I made Bubafonya from an old sauna stove - 500 mm pipe and 8 mm wall, height - 1 m. After launch, the result was pleasantly surprising; it burned on birch logs for almost 9 hours. Only it takes too long to warm up, but in my case the reason is clear - the metal is too thick, you need twice as thin, then the efficiency will increase.

Vitaly, Grodno, Republic of Belarus.

This device was installed at the dacha, the initial goal was to heat at least one large room. Everything turned out better than I expected, the room is very warm, and you load firewood twice a day. Next winter I want to do it with the water circuit and connect the old batteries in the adjacent rooms.

Do-it-yourself Bubafonya stove

The best material for the stove is an industrial cylinder or a piece of pipe. When using a cylinder, there is no need to cook the bottom.

Since when making homemade boilers you usually have to start not from the proposed dimensions, but from what is available, the calculations will look like this:

- The diameter of the loading tank is from 30 to 80 cm. (If you make it smaller, the air will come out too quickly, but a larger diameter will lead to uneven heating).

- Diameter to height ratio 3:1 or 5:1. For example, with a diameter of 30 cm, you can take a height of 90 cm.

- To calculate the diameter of the internal heavy piston you need to know that the gap between the wall and the piston should be equal to 0.05 D. If, for example, D = 30 cm, then the gap = 15 mm on both sides. Accordingly, the diameter of the cargo pancake remains 27 cm.

- The height of the ribs for small ovens (with a diameter of 30 cm) can be approx. 4 cm, if the diameter of the boiler is 60 - 80 cm, the ribs are made approx. 6 cm.

- The thickness of the pressure piston is inversely proportional to the diameter of the furnace. For a 30 cm structure = 6-10 mm, for a 60 cm = 4-6 mm, and for an 80 cm oven, the bend thickness = 2.5 – 4 mm.

- The ribs on a piston of small diameters are made straight, but for tall stoves it would be better to bend the ribs, as if twisting them clockwise.

- The air duct should protrude from the pressure piston, its edge ending at the level with the edge of the ribs.

- The diameter of the chimney (for a 30 cm stove) is 15 cm.

- Diameter of the air duct pipe = 7.5 – 8 cm.

- The gap between the cover and the air duct is no more than 2.5 mm.

- A small collar is welded onto the furnace lid, in the place where it passes the air duct pipe. This is a very important detail in order to prevent a decrease in efficiency! Its height will depend on the resulting gap and will be 80 times larger than it.

- You also need to decide on the length of the air duct. To calculate it, it is taken into account that, at a minimum, the pipe should rise 15 cm above the collar.

Stages of furnace assembly with dimensions of parts

The wall thickness of Bubafoni needs to be greater than that of factory models. There they are made of heat-resistant steel (thermal conductivity is higher), and the gases do not contact the wall as tightly as in a homemade model. If you make the walls 2.5 mm thick, like factory boilers, a thick layer of soot will quickly accumulate on them, and the chimney will accumulate a large amount of condensate. The wall thickness of Bubafoni should be 4-6 mm!

If you need to bend a boiler made of sheet steel, then a dilemma arises: sheet bending machines in small enterprises do not bend steel thicker than 2.5 mm.

Thin steel can still be used for low-power furnaces, but only without a water jacket!

Furnace design and its elements

Bubafonya stove - structure diagram

How to make a bubafonya stove with your own hands? To answer this question, you need to study the structural design of the unit. The overall design consists of several main elements:

- Cylindrical body with chimney pipe;

- Top removable cover;

- Pressure piston device with air duct;

- Additional elements - damper, handles, doors.

Solid fuel is loaded into the housing. The height of the body is selected in the range of 3 – 5 diameters of the cylindrical part. The piston (a steel circle with a through hole) closes the fuel and divides the internal volume into two combustion zones. The diameter of the pressing element is 0.95D, where D is the internal diameter of the firebox. The thickness of the piston metal has values depending on the internal diameter of the furnace: at 300 mm - 9 mm, 400 mm - 7 mm, 600 mm - 5 mm, 800 mm - 3 mm. Fuel smolders in the main firebox, and pyrolysis gas burns in the upper hollow part of the cylinder. Air for the combustion process passes through the pyrolysis combustion zone through an air duct (steel pipe). The products of the process leave the firebox through a chimney pipe connected to the chimney.

The surface (pressure) of the steel circle is optimized by installing air channels - corners, channels or bent steel strips are welded to the lower plane, improving the aerodynamic movement of air and pyrolysis components. The height of the channels ranges from 10 to 12% of D. A fender with a hole is welded to the outlet hole - it distributes air over the surface of the smoldering filling. The diameter of the air supply channel is taken at the rate of 0.5 of the chimney diameter.

Calculation of the chimney diameter is mandatory due to the complex aerodynamics visible in the drawings of the bubafonya stove. Drawings of the Bubafonya stove are easy to find on the Internet. If there is no calculation, the combustion process will be disrupted and the stove will stop working.

The cross-sectional area of the smoke pipe is 1.75Q, where Q is the thermal power of the furnace, kW/hour. Thermal power is the product of the mass of a unit load of fuel and its specific calorific value, M x A. The calorific value A depends on the substance of the fuel and is determined from reference books.

The fuel mass is calculated from the product of the furnace volume V (cubic dm) by the bulk loading density N. The bulk density of the fuel is also determined from reference materials. The volume of the firebox is taken with a coefficient of 0.65 from the height of the furnace and is calculated by the formula V = πD2/4xB, where B is the height of the device.

Having received all the calculated data, its diameter is calculated from the cross-sectional area of the smoke pipe.

The amount of heat produced by the unit is determined by the magnitude of the thermal power, depending on the mass of a unit load of fuel. As a rule, furnaces are designed with a loading cycle of 12 hours. Then the hourly power is Q/12. When generating 50 kW of heat, the hourly power will be 50/12 - 4.16 kW. The aggregated value of the heat required for heating rooms with a ceiling height of up to 2.7 meters and average thermal insulation is 80 - 120 W per square meter of area. The calculated value of 4.16 kW provides high-quality heating of a room of about 40 square meters.