Even before designing water heating, a decision must be made on the material for the pipes. Currently, in Russia, preference is given to polymer pipes, less often - metal-plastic, and even less often - stainless steel. Abroad, copper pipes are most often used for heating. They are often used for wiring water systems in private homes. Many years of experience have shown that copper analogues have the best ratio in terms of reliability/practicality.

Installation of heating from copper pipes and fittings

There are a number of difficulties associated with the installation of copper products, but all of them are somehow related to the lack of experience of the master. As a rule, after some training you can learn how to solder copper pipes well, which will allow you to efficiently connect them to each other and connect them to fittings for subsequent assembly into a complete system.

The technology for soldering copper pipes includes the following steps:

- First of all, using a pipe cutter, cut a suitable piece of pipe that has the required dimensions. It is advisable to cut off the chamfer on the inside of the pipe - this will reduce the hydraulic resistance in the pipeline.

- When the chamfer is removed, the outer part of the pipe and the inner surface of the fitting are cleaned. A synthetic sponge with hard fibers is excellent for cleaning copper parts. The sponge should not contain metal elements.

- The cleaned areas are coated with soldering flux. Flux is necessary for reliable contact of the surfaces to be joined.

- The fitting is put on the edge of the pipe prepared for work, after which you can directly solder the elements.

- First of all, you need to start heating the joint of the fitting with the pipe using a gas burner. In this state, all elements are held until the flux melts.

- When the required temperature is reached, you need to take a rod of soft solder and apply it to the place where the weld should be.

- If all previous operations were performed correctly and the burner temperature was selected correctly, the solder will begin to melt and flow into the joint, completely filling all the necessary space.

- All you have to do is wait until the solder cools down. You can use water for cooling, but there is no particular need for this - the seam cools well even at room temperature. Once the copper heating pipes and fittings are soldered, you can connect them to the heating system and start it up.

There is nothing complicated in the technology described - all actions are simple, understandable and accessible even to a novice master. Of course, before final soldering you will have to practice so that the installation of heating from copper pipes is not fraught with unexpected difficulties - for example, it is very difficult to correctly determine the heating time of parts before soldering without practice.

Conclusion

Copper pipes are an expensive, but very high-quality material that is excellent for heating installations. Long service life and the ability to withstand most aggressive influences make copper products a profitable long-term purchase. If you approach the issue of installing copper heating correctly and perform all operations correctly, the result will be a most reliable heating system made of copper pipes, which in terms of durability can be compared with the entire building.

Installation instructions using fittings

There are two types of compression fittings - the so-called compression and compression. They create completely different connections, so before starting work you need to decide what kind of connections you would like to see: permanent or conditionally detachable.

Press fittings are similar to solder fittings, but have shallow recesses at the edges with sealing gaskets. Using special press pliers, which have a set of nozzles for different diameters, crimping is carried out.

As a result, it creates a sealed, permanent connection that cannot be repaired, and in the event of an accident can only be replaced.

In the store you can see parts that are identical at first glance, but they differ in characteristics (composition, wall thickness, etc.). Heating fittings are marked with green markings

Pressing creates a strong, reliable connection of parts, while maintaining the geometry of the pipes and does not deform the connecting elements. There is a nuance of pressing “soft” copper products: before the operation, a support sleeve is inserted into the pipe, which resists deformation of the pliable material

The pressing process is simple and does not take much time. The tools required are a standard set for cutting and processing pipes, as well as press pliers with the required attachment.

Image gallery

Photo from

Step 1 - Selecting a Brass or Copper Fitting

Step 2 – connecting the copper pipe and fitting (angle, cross, adapter)

Step 3 - marking the installation location of the fitting

Step 4 – pressing with special press tongs

Pressing is considered a reliable method. If you plan to thermally insulate copper pipes, you can use insulating tubes, which are easy to put on even on curved structures. After pressing, the finished heating network can be masked in grooves, covered with decorative cladding and filled with screed.

The second type of fittings is compression. They differ in design and installation process.

A compression fitting for copper pipes is a prefabricated device consisting of three parts: a brass or copper body, a ferrule, also called a collet, and a nut.

The crimping procedure is as follows:

- a nut is loosely placed on the prepared end of the pipe;

- then the collet is put on;

- last of all, the fitting body is put on until it stops;

- the nut is screwed manually along the thread, while simultaneously pressing the split ring;

- The connection is tightened with an adjustable or sized wrench.

During the compression crimping process, the cutting ring tightly grips the pipe, creating a strong and airtight connection. The nut may become loose over time, so pipelines with this type of installation must be regularly maintained.

The connections are conditionally detachable, since they can be disassembled, however, if necessary, the fragment with the clamped ring will have to be removed and a new fitting installed.

Application areas for smooth flexible and rigid pipes

Inspection sections of pipelines, as a rule, are made of transparent pipes that are not able to withstand high temperatures.

When laying a heating system, it is important to provide a distance of 50 cm or more to protected electrical wiring.

Flexible heating pipes are often made of stainless steel. They are convenient to use for laying a system of warm water floors under laminate. The service life of such products is quite long, and their shape allows them to withstand water hammer with a load of up to 60 atmospheres.

Warm floors with water coolant under laminate can be installed very quickly using a minimum number of fasteners. The maximum operating temperature and pressure for flexible pipes is 150 ℃ and 15 atmospheres.

The depth of installation of such underground communications may vary. As a rule, this indicator is not particularly important. A layer of soil can be poured on top of polymer-protected pipes. But for galvanized products, tunneling will be required.

If an air-type heating circuit is assembled from pipes, then the standard distance must be maintained from the outlet grille to the nearest furniture or household appliances.

So we have decided which pipes are better for central heating. The main condition for the successful operation of any heating system is reliability and safety. The appearance and configuration can be easily selected due to the large selection of products on the market.

Materials and equipment

Welding is considered the most reliable connection of copper pipes. It is recommended to carry out docking using the following devices:

- solders that are chosen for a specific material;

- additional fittings;

- flux in the form of a liquid or paste to clean the joint from oxide deposits;

- for cutting workpieces, a pipe cutter is used, with the help of which workpieces with a smooth edge are prepared;

- chamfer;

- to enlarge the holes, use a flaring tool;

- gas appliances for heating the welding site.

Types of Welding Torches

The choice of equipment directly depends on the volume of work to be done and the diameter of the pipes. To know how to weld copper pipes, you need to understand the characteristics of this metal. For example, you can carry out work using hard solder with a torch that can heat it to a temperature of 430°C - 450°C, while for soft solder it should not exceed 425°C. Among the large assortment on the market, we can highlight the following equipment for welding copper pipes:

- If the volume of work is large enough, then you can purchase an acetylene-oxygen apparatus, which provides uniform distribution of heat at the joint. This type of welding equipment requires skills to work with it, since the oxygen-acetylene mixture is explosive at high pressure. Typically used for working with hard solder.

- Household gas burners are more suitable for a self-taught welder and may differ in the composition of the gas in their cylinder:

- For welding small elements, a machine with a cylinder containing a mixture of gas and air is suitable. The container can be either stationary or removable.

- Mixtures with oxygen in burners are applicable when installing pipes of any diameter and wall thickness. They belong to the category of professional equipment and, as a rule, have stationary containers.

- Small hand tools can help you repair copper pipes and are inexpensive to the owner. They are equipped with a disposable propane or butane cylinder and can work with any type of solder. Typically, such a tool is sold with replaceable nozzles, which allows you to adjust the flame power.

The best equipment for a home craftsman are hand torches, since working with them does not require special knowledge and skills. They are equipped with flame deflectors and a special valve to shut off the gas supply, which provides additional protection for the inexperienced beginner.

- Induction welding of copper pipes is carried out by an inductor connected to a generator and, as a rule, is used by professional welders when installing industrial lines.

Welding copper pipes (the video shows this) with your own hands is quite within the capabilities of an inexperienced craftsman, if he has chosen the right tool for this. The simpler the unit, the easier it is to work with. In this case, an autonomous hand torch is the best choice.

DIY assembly

Before installing the heating with your own hands, carry out assembly work:

- Check the materials for integrity, as it is prohibited to install damaged elements.

- Take measurements of communication intervals, and then cut them to size, taking into account the attachment of fittings, radiators, and shut-off valves to them.

- Connect the communication sections, taking into account the installation features.

Required tools and materials

To carry out heating in a private house, you need to prepare the following tools in advance:

- tape measure, building level;

- cutting tool;

- marker;

- sealant or sealing tape;

- drill or hammer drill;

- welding machine;

- adjustable wrench;

- knife.

In addition, you will need the following materials:

- pipes;

- a set of rotating and connecting elements;

- fasteners;

- shut-off valves.

Installation tool

Calculations

To create a reliable heating system, it is necessary to calculate the following parameters:

- maximum temperature;

- coolant pressure;

- wall thickness, outer diameter of communications;

- determine the distance from the boiler to consumers in order to select its parameters;

- safety factor;

- duration of continuous operation of the heating system.

Work order

The installation of heating pipes must be carried out in the following sequence:

- Walls are marked for hidden installation of communications or for external fastenings, taking into account a pre-developed plan.

- Channels are being prepared for laying or installation of fastenings to the walls.

- Heating is installed using plastic, metal-plastic or metal pipes in accordance with building codes.

- An external inspection of the structure is carried out for defects.

- After installation, the system is tested with operating parameters.

- If leaks or deficiencies are identified, they are eliminated.

Possible mistakes

When installing heating system pipes, the following errors may be made:

- compensation for thermal expansion is not provided, resulting in deformation or depressurization of joints;

- materials are selected incorrectly or have defects;

- leaky connection;

- load-bearing structures cannot support the weight of communications.

It is also worth understanding that it is not always possible to identify all defects in the early stages of assembly and operation. Therefore, it is better to involve specialists who will perform assembly and testing work.

Pipe joining methods

According to docking technology, they are considered universal. Any of several connection methods will do, which is a definite plus.

Depending on your goals, you can choose:

- welding;

- mechanical assembly (pressing, compression connection, clamping with self-locking fittings);

- soldering (hard or soft solder).

For welding, a diameter of 100 mm with a wall thickness of more than 1.5 mm is suitable. Mechanical assembly is only suitable for open areas. If the site is hidden in monoliths or in building structures, then such fittings will be expensive. Domestic heating systems typically use soft soldering. It requires special capillary fittings to operate.

Advantages and disadvantages of copper pipes

Copper elements that are used to make heating systems have strengths and weaknesses. Advantages:

- Service life up to 50 years.

- Withstand pressure over 30 atmospheres.

- The material does not react to ultraviolet radiation and is resistant to corrosion under natural conditions.

- No air leaks through the walls.

- Copper does not emit harmful substances. Has antibacterial properties.

- Light weight.

- It is possible to defrost the system 3 times.

- The material can withstand prolonged exposure to active chemicals and does not release any additional elements.

- Deposits do not accumulate on the inner surface of the products.

- Low rate of thermal expansion, which does not require the installation of expansion joints.

Flaws:

- High price when compared with other materials.

- The connections are permanent, which may cause difficulties during installation.

- Galvanic corrosion can occur if you try to combine copper with other metals.

- If the room has a high level of humidity, corrosion may appear on the surface of the products.

- High electrical conductivity contributes to the deterioration of the walls of products.

- To reduce heat loss in the walls, it is necessary to use additional insulation.

Flaws

Minuses:

- The highest cost among analogues.

- The assembly technique is much more complex than, for example, soldering polypropylene.

- Due to their high thermal conductivity, it is recommended that such pipes be laid in insulating sleeves (foamed), as this will allow heat to be delivered to heating devices with minimal losses.

Production

Seamless copper products are used for the construction of water supply and heating pipelines. They are manufactured using three technologies:

- cold rolling - deformation of the metal workpiece occurs when passing between rotating rolls. A through hole is created by stitching. The sleeve is then calibrated to the required dimensions;

- cold drawing - is based on pulling the workpiece through a drawing tool (drawing die) with a special channel tapering in length. During the drawing process, the metal is compressed to the required geometric parameters and stretched in length;

- hot pressing - producing a pipe by extrusion (extrusion) through the outlet hole of the matrix.

In industrial production, one of these technologies or a combination of them can be used. The composition of the equipment and technological operations may have some differences, but the basic manufacturing process always consists of the following steps:

- preparation of the workpiece;

- cold rolling or drawing, or hot pressing;

- heat treatment;

- lubrication of pipes and tools;

- processing of finished and intermediate products;

- cutting into dimensional pieces or winding into coils;

- quality control of finished products.

How to connect pipes using capillary soldering?

Soldering takes more time, but the connections made are durable and tight. The best option for solving everyday problems is to use soft solder. The operating temperature does not exceed 250 °C.

The use of hard solder increases strength, but the work will require expensive equipment and special conditions, since the soldering process takes place at a temperature of more than 700 ° C.

With the help of soldering, permanent connections are created, which are made either using the socket method or using fittings. With socket technology, one end of the pipe must be expanded so that when the elements are joined, a gap of 0.2-0.3 mm wide is formed between their walls.

It is filled with solder, after which a sealed connection is created. But let’s take a closer look at soldering with fittings, the most popular among installers.

Materials and tools for work

It is necessary to prepare copper pipes and fittings, but not the first type that comes across, but those specially designed for soldering.

Connectors and adapters for soldering are characterized by a smooth surface and the absence of additional grooves, nuts, rings, etc. They can have a straight, angular, cross shape - depending on the purpose

Tools for performing the work:

- gas burner – propane is sufficient;

- pipe expander (calibrator);

- pipe cutter, since metal scissors deform the shape of the pipe;

- chamfer;

- equipment for cleaning and polishing (fine sandpaper, brushes, rags).

When choosing solder, it is better to choose the option with a tin base. In addition to tin, the solder may contain bismuth or silver. This type is good because its melting point is much lower than that of copper products.

You can read more about solders for soldering copper pipes in this material.

During the soldering process, the solder will take on a liquid state and will be able to hermetically fill the connection gap, while the copper elements will not react to high temperatures.

In addition to solder, flux is required. This is a kind of lubricant for parts of elements that need to be joined. Flux is carefully applied with a brush to the surface of pipes and fittings.

For ease of installation work, you can use special fittings for low-temperature soldering. They differ in that at the ends they have a narrow groove filled with solder.

Low-temperature (soft) soldering is typical for household work, while high-temperature (hard) soldering is used in production. The rigid type is also used when connecting pipes of air conditioning systems and refrigeration units.

Description of the soldering process

Copper is a malleable material, it is not difficult to work with it, but if you have no experience, it is better to first practice on unnecessary sections of pipes.

Image galleryPhoto from Using a pipe cutter, a special tool, we cut the elements. It is better to carry out operations directly during installation, in order to adjust the length if necessary. Insert the bevel cutter into the pipe and rotate it until we remove the edge that appeared during the cutting process. This is necessary so that the inside of the pipe does not narrow. First, using the same bevel remover, but its other side, and then with fine sandpaper, we process the outside of the pipe so that there are no scratches and the copper shines. To increase the efficiency of soldering, it is necessary to thoroughly clean the second part - the corner, the adapter . A suitable tool is a screwdriver with an attachment made from a regular brush. An ordinary glue stationery brush is suitable for applying flux. We take the solution in small portions and distribute it in a thin layer over the surface of the pipe. Place the prepared, cleaned corner on the end of the pipe covered with flux. To make the connection tighter, screw the pipe into the corner with light movements. Before starting soldering, you need to remove excess flux or paste. An ordinary rag will be useful for this. When the surface is completely clean, for ease of work we fix the part in a vice. We take solder in one hand, a torch in the other and begin to carefully solder. After heating the pipe, we place the solder at one point, thanks to the capillary principle it will spread over the entire area. Step 1 – cutting the copper pipe into pieces of a given size. Step 2 – removing the edge with a bevel remover. Step 3 – preparing the outer wall for soldering. Step 4 – processing the inner surface of the corner. Step 5 – applying flux or paste on the end of the pipeStep 6 - twisting the end of the pipe into the cornerStep 7 - cleaning the joint with a ragStep 8 - soldering process with soft solder

Corrugated stainless steel pipe

13. Corrugated stainless steel pipe is a new product on the Russian market.

Corrugated stainless pipe is suitable for installation of all types of pipelines for transporting liquids.

These pipes are easy to bend - this is very convenient when installing water heating in confined spaces.

A distinctive feature is the quick installation of pipe-fitting connections. This greatly simplifies the installation of pipelines.

14. Fittings for connecting stainless corrugated pipes.

Corrugated stainless steel pipe is good for installing water heating systems in new buildings. And also in old buildings where pipelines require replacement.

Thanks to its high flexibility, it is possible to install complex routes with a minimum number of connections, which is important when installing pipelines in limited spatial conditions. The corrugated stainless pipe is resistant to high pressure in the system and can withstand water hammer up to 5-6 atm.

Advantages of corrugated stainless pipe:

- durability, does not corrode (unlimited service life);

- O-rings are designed for a service life of at least 30 years;

- is not afraid of both water hammer and external mechanical influences;

- bends easily without any tools, without reducing the internal diameter;

- environmental friendliness, because no sediment or scale forms on the pipe wall;

- not afraid of defrosting;

- the drinking water pipeline does not require special flushing;

- can be embedded in walls under plaster and in concrete floor screeds;

- The corrugation is resistant to linear expansion and contraction due to temperature changes and to water hammer;

- high heat transfer, which is why corrugated stainless pipe is very preferable for the manufacture of warm floors and warm walls;

- you can use the pipe itself as radiators, without installing the actual radiators;

- not afraid of rodents, fungus, mold;

- installation of the pipeline is quite simple;

- due to the flexibility of the pipe, installation of complex routes is possible with a minimum number of connecting nodes;

- applicable for pipelines for any purpose (heating, hot or cold water supply, etc.).

Disadvantages of corrugated stainless pipe

I found only one drawback with corrugated stainless steel pipes: they are not sold in the cities closest to my village. I was “ashamed” to buy online: heating is a responsible thing, so I think you need to touch the materials before purchasing...

Diameter

Previously, it was indicated in inches, but in the latest version of GOST 617 of 2006, the dimensions are given in millimeters. The new document specifies more than 70 standard sizes for outer diameters from 3 to 350 mm only for cold-deformed copper pipes. However, foreign and some Russian manufacturers still mark their products in inches.

To characterize a pipe, the nominal, external, or internal diameter can be indicated. In practice, when selecting connecting elements, they use the concept of conditional passage, meaning the size of the internal clearance. Domestic manufacturers indicate it in millimeters, while foreign manufacturers indicate it in inches.

The throughput of pipelines is calculated based on the internal diameter, and classification is made based on the external size. The nominal diameter is a value approximately equal to the nominal diameter, but with an indication of the exact value.

When converting units of measurement, it should be taken into account that the internal cross-section of an inch pipe (1″) is 33.5 mm, although in the metric system this value is 25.4 mm. The discrepancy is due to the fact that in the document it is indicated by the nominal diameter, and the outer size of imported products is in inches. Therefore, a 1″ pipe inside can be from 25.5 to 27.1 mm. To convert the cross-sectional value from one system to another, use the table:

| Inches | External diameter, mm | Conditional bore, mm |

| 1/4 | 13,5 | 8 |

| 3/8 | 17 | 10 |

| 1/2 | 21,3 | 15 |

| 3/4 | 26,8 | 20 |

| 1 | 33,5 | 25 |

| 1 1/4 | 42,3 | 32 |

| 1 1/2 | 48 | 40 |

| 2 | 60 | 50 |

| 2 1/2 | 75 | 70 |

| 3 | 85,5 | 80 |

| 3 1/2 | 101,3 | 90 |

| 4 | 114 | 100 |

| 5 | 140 | 125 |

When converting inches to millimeters and vice versa, an error is obtained that should be taken into account when choosing pipes of the required diameter. The result is rounded up. Frequently encountered data is shown in the table:

| Inches | Millimeters |

| 1/2 | 20 |

| 1 | 25 |

| 1 1/4 | 32 |

| 1 1/2 | 40 |

| 2 | 50 |

| 2 1/2 | 65 |

| 3 | 89 |

| 4 | 100 |

Labeling and cost

Copper pipes are available in two types: soft and hard. Solid ones are often used for heating. Release form - linear sections of 2-5 m long or coils in which sections of 5-10 m are twisted.

Copper pipes are supplied either in lengths or coils

Dimensions. The outer diameter is indicated in millimeters (usually domestically produced or from the CIS countries) or inches (imported), and the wall thickness is indicated through a fraction or “x”: 22x1 mm (22/1mm) - outer diameter 22mm, wall thickness 1mm, which means inner diameter , according to which heating systems are designed, will be 21mm (22-1=21). For wiring a household heating system, a wall thickness of 0.8-1 mm is sufficient.

The outer diameter of copper pipes is marked, and the wall thickness is indicated after the fraction.

The fittings coming out of the boiler are usually either copper or brass, but in each case, check and remember that other materials cannot be directly connected to copper. In order to avoid a chemical reaction, you will have to use brass or bronze fittings or adapters.

There are also annealed and unannealed pipes. Unheated pipes have a large margin of safety: they can withstand pressures of up to 450 MPa, but do not bend very well: they can only stretch by 6%. To change their characteristics, they are heated to high temperatures and then cooled. The process is called annealing, and the products that come out after it are annealed. The safety factor has become smaller - up to 22 MPa, but the elasticity has increased: the material can stretch by 50-60%. The material has also become more resistant to temperature changes, tolerates ultraviolet radiation without problems and is almost insensitive to high humidity. That’s why annealed copper is used not only in heating, but also in car engines and drives.

One example of soldering copper pipes

The cost of copper pipes for heating is high. We can compare:

- reinforced polypropylene pipes with a diameter of 16 mm - from 40 rubles/m;

- metal-plastic pipes with a diameter of 16 mm – from 47 rubles/m;

- unannealed copper diameter 10mm - from 280rub/m;

- annealed copper diameter 18mm – from 400rub/m.

The picture will be approximately the same in fittings: copper ones are several times more expensive even than those used in metal-plastic systems. As an example, the following are not the most expensive PPR and MP pipes; some are more expensive, many times more expensive, but copper ones are also not the most expensive. So you can roughly imagine the difference.

Reviews and operating experience

Some people consider copper pipes an excellent solution, while others do not accept them. But, in fact, this is typical for any technology and material. The only thing that people pay attention to and what is worth listening to is the fact that in an acidic environment, copper begins to deteriorate. Therefore, fill the system with either coolant with a neutral PH or slightly alkaline. It is also not recommended to use steel, aluminum or cast iron radiators. It is imperative to protect the system from stray currents (grounding and dielectric gaskets are required), otherwise chemical or electrochemical destruction begins. But in central heating systems you will not completely get rid of destruction: the coolant in them is saturated with iron, and if solid particles can be retained by a filter, then there is no escape from those dissolved in it.

Another piece of advice from an experienced installer: copper is very sensitive to contact with concrete (it oxidizes). The rate of destruction depends on the composition of the wall, but in any case it is better to lay the pipe in a PVC sheath or any insulator with similar characteristics.

Copper pipes react actively with concrete, so it is better to lay them in a protective shell

Another tip from the master, but this already concerns soldering: it is important not to overdo it. Firstly, from an overabundance of diligence, you can weld the entire lumen (if a pipe of small diameter is especially important), secondly, when the soft solder overheats, the paste is overheated, which is why it cokes, which leads to the formation of fistulas, and thirdly , do not overdo it with the amount of solder. If you have no experience, practice welding on small pieces of pipe: you can check both the clearance and tightness of the connection. And after gaining at least some experience, you can begin welding the system.

Sequence of actions in case of a pipe breakthrough

It is worth immediately noting that some measures to eliminate burst heating pipes are taken at the installation stage. We are talking about compliance with all building codes - in particular, ensuring unhindered access to areas of the system and maintaining the required distances between the elements of the heating circuit.

The most correct solution to the problem of a broken heating pipe is to call a specialized repair team or plumber - but, unfortunately, this is not always possible. That is why, if the leak is extensive enough and can lead to serious negative consequences, you need to begin neutralizing the problem as quickly as possible.

The first thing to do after a pipe burst is to try to localize the leaking water so that it does not spread throughout the house and does not flood the neighbors below if it happens in an apartment

Everything must be done carefully - the coolant has a fairly high temperature, so the likelihood of a burn in direct contact with the human body is high. To prevent burns, you should use thick rubber gloves.

If the stream is not very intense, the simplest solution is to place any container under it so that the water does not flow directly onto the floor covering. The same laminate, for example, very quickly deforms when in contact with a hot liquid. The next action that needs to be taken is to shut off the heating system riser, the valve of which in a multi-storey building can be located both in the basement and in the apartment. In a private house, it is enough to simply turn off the heating.

Scope of application of copper pipelines

The scope of use of copper pipe products is extensive, but most often it is used for laying:

- heating systems;

- pipelines for water supply;

- highways along which compressed air or gas is transported;

- fuel pipelines;

- condensate drainage systems;

- structures for connecting technological equipment;

- pipelines supplying freon to refrigeration units;

- air conditioning systems, etc.

Which pipe is better to use for heated floors?

When choosing pipes, many people wonder what material is best to buy pipes for heated floors from. The choice of purchase will be influenced not only by price and quality, but also by the ease of installation of the selected product.

It is also worth paying attention to the advantages and disadvantages of one or another type of material from which the coolants are made

When choosing between copper and corrugated stainless steel pipes, you need to compare their positive and negative qualities. For example, copper pipes are durable and reliable. They have good heat conductivity. You can fill the system not only with water, but also with antifreeze or antifreeze. With great strength and temperature resistance, they can be used almost anywhere. The low resistance coefficient of the inner layer allows liquid to circulate freely within the system. This allows you to select coolants with a minimum diameter (16 mm).

Corrugated stainless steel products are also strong, flexible and durable. However, when choosing which pipe is better from these two types, you need to know:

- Copper materials are afraid of acidity and water hardness. These factors significantly reduce the service life.

- The price of copper and stainless steel pipes is quite high.

- Installation of such pipes requires considerable financial costs. You need to hire specialists and have special equipment. True, these costs are recouped through the long-term operation of these systems.

- The main condition when using corrugated stainless steel coolants is that they are not exposed to electric current.

- The combination of copper and steel can lead to negative electrochemical processes.

When choosing between metal materials and metal-plastic, which pipes are better, preference is given to the latter. This is influenced by the lower price of the product.

Layout example

Metal-plastic, also durable in use. Unlike copper and stainless steel, water flows through these pipes almost silently. This material does not react with various chemical elements of water. Metal-plastic pipes are much lighter than copper and stainless steel pipes. Their installation is quite simple and does not require special technical skills. The heating system can be installed independently and quite simply.

The disadvantages of metal-plastic products include

- Short-term maintenance of temperatures above +100°C.

- This material is susceptible to open fire.

- When pressed with a mounting nut, a cut may appear on the pipe and subsequently leak.

- A poor-quality connection of pipes with fittings will result in the formation of a limescale layer at the joints.

You also need to pay attention to the large number of Chinese counterfeits of these products. Polypropylene coolants, although not very expensive, are used less frequently

This is due to the large bending radius (8 - 9 pipe diameters). During installation it is necessary to use additional special connections

Polypropylene coolants, although not very expensive, are used less frequently. This is due to the large bending radius (8 - 9 pipe diameters). During installation it is necessary to use additional special connections.

Their advantage is a fairly simple and reliable connection method (soldering). The joints are strong and monolithic.

Which polyethylene pipes are best to choose for heated floors can be determined by the product labeling, finding out the minimum crosslinking density. The price will depend on the value of this indicator. But it will be significantly lower than for pipes made of metal material.

The main disadvantage of polyethylene products is the need for rigid fixation during installation.

It is also worth paying attention to caution when delivering and installing such coolants. Defects in the anti-diffuser protective layer will lead to a decrease in service life

Having studied all the advantages and disadvantages of various types of material, everyone chooses for themselves which pipes are best used for warm water floors. It is more expedient to carry out a complete re-equipment of the heating system in a private house. Multi-storey buildings will require additional permits, which will entail unnecessary expenses.

Polyethylene consists of hydrocarbon molecules that are not connected to each other. However, new developments have made it possible to connect molecules by interacting carbon and oxygen atoms. Such technologies made it possible to create a new material – cross-linked polyethylene (PEX). With additional processing (under high pressure), it acquires greater strength.

Criterias of choice

Copper models, due to their high cost, must be carefully selected.

In order not to make a mistake, you need to get acquainted with the main selection criteria:

- Compliance with terms of use. The main advantage of the products is their versatility. Suitable for both plumbing and heating systems, because they are immune to constant temperature changes and high pressure. They can withstand loads up to 40 atmospheres and temperatures up to 500 degrees Celsius. They are resistant to ultraviolet radiation and have a low expansion coefficient (7 times less than polymer ones). Also, thanks to the active bactericidal properties of copper, it is absolutely safe for humans. But it is worth paying attention to the fact that copper reacts poorly to chlorine, so interaction with it will quickly render the pipes unusable.

- Cost of material and installation. The cost of copper is several times higher than its analogues (about 4 times higher than the price of plastic). But if we take into account all the work associated with the installation and additional elements, then the final cost of the work is no higher than that of metal-plastic. A press fitting for plastic is much more expensive than a solder fitting for copper. Consequently, the final installation cost directly depends on the footage and the number of fasteners.

- Life time. The trouble-free service life of a copper pipeline is 50 years or more, which is a very good indicator.

- Ease of installation. Pipeline installation takes place in several stages: preparation of the material, its processing and installation. The process itself takes a long time, because it is necessary to cut the pipes, bend them using a pipe bender, and also carry out complete installation of all elements. In the end, everything must be connected using fittings (soldering and crimping).

You should not combine copper with galvanized steel, because due to electrolytic processes the copper will simply be destroyed.

Advantages and disadvantages of different types of heating pipes

Each pipe material has characteristics unique to it, which means advantages and disadvantages.

Metal pipes

Metal pipes are the oldest version of pipeline elements, and are still actively used both for heating private houses and for creating city communications.

Since iron is highly susceptible to corrosion, galvanized pipes or their corrosion-resistant steel grades should be used.

The widespread use of these products at present is partly due to adherence to traditions in the design of heating circuits, but there is also a rational explanation.

The advantages of using metal (steel, cast iron, copper) heating pipes:

- ease of pipeline installation;

- resistance of products to elevated temperatures;

- resistance to mechanical stress of any kind;

- good thermal conductivity;

- the ability to use a minimum of fasteners due to the inherent rigidity of metal;

- plasticity of pipes, which makes it possible to bend products;

- a wide range of fittings - connecting, corner, etc.;

- resistance to high internal pressure in the heating system;

- the ability to use pipes made of different metals;

- durability and reliability of the assembled structure (for steel pipes - up to 50 years, for copper pipes - over 100 years).

Disadvantages of metal products:

- heavy weight, in some cases making it impossible to work alone;

- the need to weld elements, requiring a qualified welder or skills in working with a welding machine;

- installation of a metal pipeline takes more time;

- roughness of the inner surface of the pipes, which means the possibility of sedimentation;

- the threat of corrosion of elements, requiring the avoidance of hidden pipe laying;

- the need to periodically paint products to avoid external damage;

- large heat losses in cold rooms.

Polypropylene pipes

Advantages of pipelines made of polypropylene pipes:

- smooth inner surface, virtually eliminating the possibility of blockages;

- light weight, allowing installation without unnecessary effort, including alone, and in addition, safe for houses built on shifting soils;

- there is no threat of corrosion, so such pipes can be laid in walls in a closed way;

- there is no need to paint products;

- if the required temperature level is maintained, the pipeline will last at least 20 years;

- the structure is easy to wash and clean;

- low cost of production - for the same money you can build a pipeline of much greater length than from metal.

Disadvantages of such pipes:

- you need a special welding machine to connect structural elements;

- pipes cannot be bent, fittings must be used;

- maximum temperature threshold - 70°C (short-term - up to 90°C);

- instability to mechanical stress;

- sagging in extended areas (more fasteners should be used during installation).

Cross-linked polyethylene (PEX) pipes

The advantages of such products:

- high operating temperature threshold for plastic – up to 90°C;

- increased density of the manufacturing material, providing good mechanical stability and protection against leaks;

- pipes made of this material can be bent when heated and unbent in the same way (memory effect);

- smoothness of the inner surface, preventing the formation of blockages;

- small expansion coefficient, which does not require the installation of compensators;

- light weight, making it possible to freely assemble the pipeline;

- ease of installation (press fittings are used);

- durability of products - the service life of such a pipeline is at least 50 years.

Such pipes have no disadvantages; they can be used both for installing the pipeline as a whole and in combination with other materials.

Metal-plastic pipes

Such pipes combine the best properties of metal and polymer products: a smooth inner surface, metal reinforcement that provides strength, and an outer layer that does not require painting.

Disadvantages of products:

- high cost of associated fittings;

- deformation due to freezing - such pipes must be used in houses for permanent residence, otherwise an unused pipeline will become unusable over the winter.

The choice of pipes for the installation of heating systems is practically unlimited, and the quality of the assembled circuit depends primarily on the correct decision of the designer and the conscientious implementation of all stages of system assembly.

Advantages

A distinctive feature of copper pipes is their very low expansion when exposed to high temperatures.

This indicator is up to eight times lower than that of any type of polymer pipe. This type of pipe is not susceptible to ultraviolet radiation, which has a detrimental effect on plastic pipes. Copper pipes have another excellent feature - bactericidal properties. This factor is not so important for heating circuits, but it is of decisive importance when installing drinking water supply systems. It can also be noted that copper is not subject to corrosion, but only oxidizes in water.

The presented type of pipes is not in any way threatened by freezing of water in the system. Their combination with capillary solder fittings makes them 100% oxygen impermeable. This type of pipe can be safely used in “warm floor” floor systems, and can also be hidden in the wall behind a layer of plaster without fear of leakage.

Perhaps the only drawback of this metal is the electrolysis process, which can damage the pipeline. This process is especially rapid if radiators made of aluminum or its alloys are used in parallel in the heating system.

Heating pipes are insulated solely for practical purposes. This is explained by the fact that in the section from the heating boiler house to the client-consumer there is a significant loss of heat temperature. Sometimes this heat consumption ranges from five to twenty percent.

Therefore, thermal insulation of heating pipes is simply necessary. In addition, proper insulation work is needed. This in turn will affect the efficient functioning of the entire heating system as a whole.

Several methods using various materials are used to insulate heating pipes. In order for the thermal insulation of heating pipes to function effectively, it is necessary to use not only the necessary material, but also perform proper installation in accordance with all technological rules.

Pipes made from alternative materials

To figure out when which pipes can be used for heating, you need to compare them according to several parameters and answer a number of questions:

- What kind of heating system will there be - forced or gravity.

- Type of pipe installation - inside or outside the wall, simple or complex system configuration.

- Maximum and operating pressure and temperature in the system.

- Price

After analyzing this data, you can choose your option.

Iron pipes

Today, the market offers a large selection of iron pipes, although their use has been reduced to use in a gravity autonomous heating system using large-sized pipes. The main advantage of these pipes remains their strength; they cannot be damaged mechanically. They are resistant to high temperatures (over 1500˚C) and pressure. Moisture has little effect on metal, since with prolonged circulation of the same coolant in the system, oxygen quickly evaporates from it. The practice of operating iron pipes shows that their service life is more than 20 years.

The disadvantage is the complexity of installation; a qualified welder is needed to connect the pipes, which leads to a significant increase in the cost of the structure, and repairs in an already lived-in room will lead to damage to the wallpaper and furniture if it cannot be moved. Iron pipes are susceptible to corrosion, so it is not advisable to install them inside the wall. Also, iron pipes do not have a very attractive appearance and require painting every year. But high thermal conductivity indoors is an advantage; it increases heat transfer, whereas when passing through unheated areas, it can significantly lose heat and requires insulation. The price of such pipes is not high.

Propylene pipes

Propylene pipes retain their appearance for a long time

Unfortunately, a system made of polypropylene pipes is of little use for repairs. And the entire section will have to be replaced. The low rigidity of the pipes requires additional fastening so that under the influence of temperatures it does not bend too much. The pipes have a low heat resistance of no more than 70˚C, and the climatic conditions of the country require more heating of the pipes to ensure comfort in the home. The price is low.

Metal-plastic pipes

Metal-plastic pipes have become very popular because they combine the best qualities of steel and plastic pipes. The pipe consists of three layers. The base is aluminum foil, 0.2-0.3 mm thick, coated with a layer of plastic that protects the metal from the negative effects of aggressive environmental components, and an inner thin layer applied to the foil to prevent the appearance of various deposits inside the lumen of the pipe. The layers are connected using a special glue with high adhesion to both components - polymer and metal. It is the adhesive composition that gives the pipe strength and elasticity.

The advantages of metal-plastic pipes include a smooth surface, aesthetic appearance, ease of installation, which does not require special equipment. They also include durability - 50 years, savings in cutting and the absence of residues. Metal-plastic pipes do not conduct stray currents, they have no thermal expansion and can be safely mounted into a wall.

The disadvantages include the price of the entire system; the pipes themselves are inexpensive, but the accessories for them are not cheap. The connecting elements have a narrowed cross-section, this reduces the permeability of the pipeline, and at sub-zero temperatures a rupture will occur. They cannot be used in country houses.

Stainless steel pipes

not subject to internal pollution50 years

If we consider heating in an apartment, then in terms of reliability all pipes meet the requirements.

Copper and stainless steel are the most expensive but versatile materials, but still the advantage of metal-plastic pipes for heating in a modern apartment is their low thermal conductivity, it will be possible to avoid heat losses by installing them in the wall or under the baseboard, low price and the ability to install the system yourself heating without special qualifications. Copper pipes, which have high thermal conductivity, must be insulated in order to be laid inside the walls; they are expensive to install in an apartment. But in a country house, copper pipes will be a good solution for those whose finances are not limited. They are aesthetic, reliable and durable. Date: September 25, 2022

Features of copper solder fittings

One of the simplest and most durable connections of pipelines made of copper components is soldering.

Unlike polymer products, copper fittings, like pipes, are considered to have an eternal service life, they last for at least a century, do not deteriorate under the sun, do not melt from high temperatures and do not crack in the cold, therefore they are used where the tightness and strength of pipelines highways are subject to increased requirements.

The popularity of copper fittings is due to the special characteristics of the metal:

- copper is a known antiseptic that protects pipes from the development of bacteria and fungi;

- installation of communications consisting of copper components is simpler than connecting pipeline systems made of cast iron and steel;

- It is possible to damage copper pipes or fittings only under pressure of more than 200 atm, but such pressure simply cannot exist in communication systems.

Boiler room maintenance cost

Technical (service) maintenance of the boiler room

| Name of works | Volume | Price |

| Service contract for floor-standing boiler (gas, diesel) up to 60 kW | with 1st scheduled departure | from 14 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) from 60 to 170 kW | with 1st scheduled departure | from 20 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) up to 60 kW | with 2 scheduled trips | from 22 000 ₽ |

| Service contract for floor-standing boiler (gas, diesel) from 60 to 170 kW | with 2 scheduled trips | from 30 000 ₽ |

| Service contract for wall-mounted gas boiler | with 1st scheduled departure | from 10 000 ₽ |

| Service contract for wall-mounted gas boiler | with 2 scheduled trips | from 15 000 ₽ |

| The exact cost is calculated after check-out | engineer |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

Boiler room repair, diagnostics and prevention

| Name of works | Volume | Price |

| On-site inspection and diagnostics (without repair) | up to 50 km from MKAD | from 3,500 ₽ |

| On-site inspection and diagnostics (without repair) | from 50 to 100 km from MKAD | from 5,500 ₽ |

| Cleaning the burner (atmospheric) | power up to 60 kW | from 2,000 ₽ |

| Cleaning the burner (supercharged) | power up to 60 kW | from 3,500 ₽ |

| Cleaning the burner (atmospheric) | power from 60 to 170 kW | from 8,500 ₽ |

| Cleaning the boiler combustion chamber | power up to 60 kW | from 4,000 ₽ |

| Cleaning the boiler combustion chamber | power from 60 to 170 kW | from 6,000 ₽ |

| Checking and pumping up pressure in the expansion tank | without dismantling work | from 2,500 ₽ |

| Checking and pumping up pressure on the expansion tank | with dismantling and installation | from 4 500 ₽ |

| Refilling the heating system with a pump | system volume up to 200 liters | from 3 000 ₽ |

| Replacement of heating element, pump, heat exchanger, with coolant drain | for a unit | from 3 000 ₽ |

| Conversion of a gas boiler to liquefied gas | for a unit | from 3 000 ₽ |

| Burner settings | gas / diesel | from 2 500 ₽ |

| The exact cost is calculated after check-out | engineer |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices. The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity.

How to solder

In domestic systems with operating temperature, low-temperature soldering is used using solder and special fittings. Soldering is recommended for use when installing “warm floors”, laying the system in walls, behind sheathing - in all cases where the system cannot be observed visually.

Preparation for capillary soldering

To install copper structures, it is important to carefully measure the place where communications will be laid, cut blanks of the required size, clean, calibrate, and bend.

To cut pipes, use a pipe cutter or hacksaw with a new blade. Then the end of the workpiece is cleaned with a file and calibrated using a manual calibrator - first the inner diameter, then the outer diameter.

The soldering area is cleaned with metal brushes and sandpaper until it shines. It is imperative to clean the workpiece from chips.

Pipe stripper

Low temperature soldering

For soldering, the cleaned areas are degreased and coated with flux (both surfaces - both on the workpiece and inside on the fitting). A special fitting is put on one workpiece, and another workpiece is inserted into the fitting. Sometimes the end of one workpiece is flared and one workpiece is inserted into another.

Then the fitting (joint) is heated with a burner to a temperature of 250-500°C (solder combustion temperature). The solder rod is touched to the edge of the fitting or the joint of the workpieces - the solder melts and, under the influence of the capillary effect, seeps between the fitting and the workpiece (two workpieces). The joint is then cooled to create a tight and durable solder joint.

It should be borne in mind that it is not advisable to install a heating system in a room with a fine finish in this way - an open fire from a gas burner will damage the finish. The nuances of performing low-temperature soldering can be seen in our video:

Copper piping systems

In terms of performance properties, copper is often compared to steel. In Russia, pipes made from these raw materials are installed less frequently than in other countries. This is preceded by a high price and a small resource base.

Almost all the copper belonging to Russia in the 20th century was given to the defense of the country and the restoration of its territory after hostilities. America, on the contrary, during this period was distinguished by the rise of the economic sphere. Therefore, the government ordered an increase in sales of copper pipelines.

If you need a copper pipe, you can buy it in online stores.

The insignificant amount of copper in the earth’s crust leads to limited production, which proves the fact that it is impossible to massively switch to using only pipelines made of this material. In addition to the manufacture of copper structures, raw materials are used in the metallurgical, electrical and jewelry industries.

Copper VS polypropylene pipes

Benefits of Copper Piping Systems

Copper pipes are the only product that has not lost its position among the raw materials for the manufacture of pipeline systems, and has also secured leadership in sales in some countries. This is achieved due to the physical and chemical characteristics of the metal.

Copper retains heat perfectly. Because of this, pipes need additional structures that reduce the heat transfer process and prevent the formation of burns.

Pipes made from this material have the positive features of both steel and polypropylene pipelines. The product is very durable and has antibacterial characteristics.

The positive aspects of copper pipes include:

- complete inaccessibility to hazardous elements;

- joint use of system elements from different manufacturers;

- preservation of its qualities after contact with sunlight, which cannot be said about plastic pipes;

- optimal weight (pipes are light, which greatly simplifies the installation process);

- smooth surface, which prevents unnecessary deposits from settling on the walls;

- the material’s indifference to chlorine, which is important for tap water (albeit a little, it still contains chlorine);

- high strength of the material: a long period (more than 45 years) of unhindered use is guaranteed, but vast experience confirms a much longer period of their operation, subject to high-quality manufacturing of plumbing systems;

- low hydraulic resistance;

- non-flammability: no hazardous elements when ignited;

- long service life;

- resistance to bacteriological contamination.

Among the important features of copper piping systems are their increased mechanical strength. They are mainly used during the repair of outdated steel pipes.

The structures easily replace failed branches and risers. When giving preference to fittings and copper pipes for installing a water supply system, you must ensure that you have a sanitary certificate that allows their use in these systems.

The main disadvantage of such a product is considered to be overpriced . When installing copper systems, their final cost includes:

- insulation;

- solder for soldering;

- paste;

- gas.

Estimated cost

Copper pipeline systems are characterized by increased resistance to chemical damage upon contact with hot and cold water, ultraviolet rays and certain acids (for example, hydrochloric acid), as well as during temperature interruptions.

But soft and acidic water supplied in mountainous areas can dissolve copper ions. This has virtually no effect on the strength of the material, however, they should not be present in pipelines for reasons of cleanliness.

Installation of copper pipes

When installing copper pipes, use special welding equipment or other tools to make high-quality connections. These actions require the mandatory assistance of experienced specialists.

Types of copper pipes

Copper pipelines are laid on the wall, in the floor, under plaster, in installation shafts or in a groove in concrete, brick, or plaster layer for laying communications. Such pipes are manufactured with a minimum diameter of 6 mm.

They come in different hardnesses:

- soft;

- hard;

- semi-rigid.

The soft pipe is packed into a coil. Its length is more than 15 m. They bend easily, making installation easier and the number of connections significantly reduced.

Read with this article: Unannealed copper pipe, what is the difference between annealed and unannealed

In addition to these advantages, such pipes have a significant disadvantage. When pressure is applied to the walls, they are damaged.

Varieties and basic characteristics

During the installation of water supply systems, soft pipes with a diameter of no more than 22 mm are used.

Structures with large diameters are usually rigid. Taking into account the increased strength, they are used when making straight long fragments and open areas (such areas are found in boiler rooms).

If the system is laid in different directions, soft pipes are used that bend easily. They are also used when performing “warm floors”.

Copper pipes are usually secured by soldering or special fittings for water pipes. They can be clamped or crimped. Those connections of copper pipes that are equipped with fittings or pipes made from other raw materials are often made detachable.

Installation rules

Pipes are cut using a circular pipe cutter or metal saw. After cutting with beveling equipment, it is necessary to remove any burrs and sharp edges that have arisen.

The socket connection method, which involves subsequent soldering, is most often used. To do this, you need to use special solder (high-melting or low-melting solder), flux or solder paste, consisting of a mixture of flux and low-melting solder.

Hot and cold water systems typically use fusible solder joints. The same method is applicable to heating systems where the highest temperature does not exceed 110°C. However, it should be taken into account that it is better not to use this solder when connecting pipes in the gas supply system and “warm floors”.

Connections using refractory solder are used without any restrictions. Low-melting solder is a joining procedure using solder with a minimum melting point of 450°C.

The connections are heated using acetylene or propane-butane compounds. For the same purposes, powerful electric soldering irons are often used.

To properly heat the connections, control their temperature and fill the cracks with solder, special skills and knowledge are required. This includes the sequence of performing connecting actions when soldering tees. This takes into account how they are located in the system.

Soldering with solder

Soldering with refractory solder is performed using an acetylene heating pad. The temperature must be at least 450°C. If the diameter of the pipes is less than 20 mm, a propane-butane torch is used in the connection.

The final result of the connection depends on the skill level of the master. Poor quality is indicated by excessive overheating of the links that connect. This fact contributes to rapid chemical destruction during use.

Hard soldering is used where the water temperature level is at least 110°C. Such cases include the connection of a pipeline and a device for collecting thermal energy from the Sun.

This procedure is greatly simplified if you use special connections. They do not imply the presence of skill and rich experience in this area.

Copper pipes do not require layers of protective coating (paints, metals and alloys) to be applied to the surface of the structure.

Pipes laid under plaster are packed in a protective casing along their entire length. It protects the surface of the system from scratches and impacts, and also allows them to move freely.

Copper has an enhanced process of transferring internal energy from one body to another upon their direct contact (20 or even 30 times more than plastic). Therefore, hot water pipes must have elements that reduce the heat transfer process and act as the main thermal resistance in the structure. Otherwise, the water will transfer heat to the environment and quickly cool down.

Basic mistakes when installing plumbing systems

Copper makes it possible to produce a system that will have a long service life. This can be done if the work is done in compliance with all the rules.

Plumbing system

But not every installer has a high level of professionalism. To avoid gross mistakes when installing pipes, it is better to monitor the work process yourself. And to do this, you need to carefully familiarize yourself with the main errors that arise when installing systems.

| Error name | Short description |

| Burrs remain. Refusal to perform chamfers after cutting pipes | If copper pipes are made correctly, they work for a long time without any breakdowns. But gross errors during system installation lead to serious problems. These mistakes happen even among experienced professionals. Errors reduce pipe cross-sections, increase irretrievable energy losses in sections of hydraulic systems and contribute to the formation of nonlinear fractal waves (flow turbulence). Due to mistakes made, copper oxide is washed off from the walls of pipes and connecting elements, resulting in accelerated corrosion. First of all, this applies to such a shaped element as a knee. The inner walls of the pipes are filled with a layer of copper oxide, which has a protective function. It prevents contact of raw materials with oxygen. The occurrence of flow turbulence is directly affected by the presence of “dead zones”, where there is almost no water movement. In such areas, which include the hot water supply system, substances harmful to health are generated. |

| Refusal of filters to reduce the cost of the system | In the piping system, mechanical filters are made from copper. They hold solids with a size of at least 25 microns. These elements damage the copper oxide layer, making the pipes unsuitable for further use. Often, installers do not use filters in their work to reduce prices. |

| Targeted reduction of pipe diameter | Strength characteristics are lost due to the fact that water flows faster. The copper oxide layer on the pipe walls is destroyed, and the noise of the water flow increases. |

| The use of hard solder for soldering copper pipes having a small diameter and thin walls up to 1 mm | Due to the increased soldering temperature, the thin walls of the pipe overheat and the metal surface is damaged. Because of this, centers of chemical destruction appear. |

When copper comes into contact with other metals, it increases their corrosion. But stainless steel in close contact with copper does not cause chemical damage.

Copper, when combined with plain steel, contributes to the emergence of a chemical source of electric current. As a result, the iron or zinc dissolves, damaging the pipe walls.

For this reason, the connection of these metals must be electrically insulated, which is done with Teflon tape or special dielectric gaskets. If copper ions are dissolved in water, they disrupt the integrity of elements made of other metals.

It is possible to use steel and copper in one system under one condition. The total amount of chlorine and sulfate ions present in the water should be less than 50 mg/l.

Connection of copper and aluminum pipes

In case of higher concentration, special corrosion inhibitors are used. Care should be taken to ensure that steel particles are not located behind the copper pipes (in the direction of the water flow).

If water affects the chemical destruction of galvanized steel pipes, they are not installed in front of copper ones.

Corrosion can be avoided by installing special filters in front of copper pipes. But it is recommended that the entire plumbing system be made from one raw material: copper and its alloys.

It is better not to use copper systems if the work uses aluminum elements (for example, radiators). However, there are ways to get rid of electrochemical corrosion in copper pipes with aluminum radiators. To do this, you just need to add certain corrosion inhibitors to the water.

Detachable and press connections

To make a press connection, you need a specialized tool - crimping pliers. They are available both manual and electric. After stripping the pipe and fitting, they are combined, pliers are applied to the joint from the outside and crimping is performed. The connection is considered permanent and quite reliable.

Detachable coupling is done following the example of metal-plastic pipes, since the principle of combining a brass fitting with a pipe is exactly the same. Accordingly, the cost of the connector is several times higher than that of a soldering fitting. But for installation you only need 2 wrenches. Details of the work are presented in the video:

How to decipher the markings

Symbol diagram for copper pipes:

Explanation of abbreviations:

| Name | Short designation | Decoding |

| Preparation method | D | cold-deformed (drawn or cold-rolled) |

| KR | pressed | |

| Section shape | KR | round |

| Precision manufacturing | N | normal in wall thickness and diameter |

| P | increased in wall thickness and diameter | |

| AND | normal in wall thickness and increased in diameter | |

| TO | increased in wall thickness and normal in diameter | |

| WITH | normal in average diameter | |

| U | as a percentage of wall thickness | |

| State | M | soft |

| P | semi-solid | |

| T | hard | |

| L | soft, increased plasticity | |

| F | semi-solid high strength | |

| H | high strength hard | |

| Dimensions | outer diameter and wall thickness | |

| Length | ND | unmeasured |

| KD | multiple of measured | |

| Special conditions | B | increased length accuracy |

| ABOUT | increased accuracy in curvature | |

| R | regulated tensile test requirements | |

| N | regulated requirements for Vickers hardness testing | |

| BT | pipe in loose coils | |

| BOO | pipe in coils of layer-by-layer ordered winding | |

| BS | pipe in coils of flat spiral winding | |

| X | Placed in place of missing data (except for length and designation of special conditions) |

Example of a symbol:

Drawn pipe, round, of normal accuracy in wall thickness and diameter, semi-solid, outer diameter 28 mm and wall thickness 3 mm, length 3000 mm, made of M3 grade copper, increased accuracy in length, with regulated tensile test requirements:

Pipe DKRNP 28×3x3000 M3 B R GOST 617-2006

Heating system calculation

Calculating a heating system is a difficult task for a non-specialist. When installing copper in an apartment, there is no choice - you cannot underestimate the internal cross-section of communications, and the internal diameter of the pipes must match that which was in the steel system.

If you are replacing a pre-existing steel system and it worked fine, install pipes with the same internal diameter (in principle, 1-2 mm smaller).

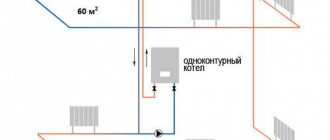

If you are installing a system for the first time, then for a house with an area of up to 100 m², a pipe with an outer diameter of 22 mm for mains and risers and 15-18 mm for connecting radiators is sufficient. For a house with an area of up to 150 m², it is worth using products with a diameter of 28 mm for risers and highways. If the house is more than 150 m² or has three floors, it is better to contact specialists and make a project.

Connection technique

When connecting copper pipes with your own hands, follow the following algorithm:

- cut the workpieces to the required size;

- the edges are cleaned for a quality connection;

- the holes are widened, but if copper pipes will be used in heating systems when the energy carrier is heated above 110°C, fittings are installed;

- parts of the parts are inserted into each other, while maintaining a gap;

- the seam is heated with a gas burner;

- fill the seam with liquid solder, preventing the formation of voids and lumps of solder;

- The connected parts are left for some time to completely cool the welding site; it is forbidden to move sections of copper pipes.

If all points of the copper pipe welding algorithm are followed, a reliable connection is achieved.

Flux for welding copper pipes