Water heating of a garage is considered one of the most effective and economical ways to increase the comfort of a room. We'll tell you how to make heating yourself. Installation procedure.

In winter, many car owners have difficulty caring for their equipment. Due to insufficient heating of the garage, the lubricant hardens and loses its mobility, the car has difficulty starting, and repairs become a chore. High-quality thermal insulation and installation of a heating system will help solve low temperature problems. Water heating of a garage is considered one of the most effective and economical ways to increase the comfort of a room.

Not everything is so clear

However, a heated garage for a car in some conditions can cause the same troubles as excessive humidity in unheated rooms. In frosty weather, melted snow, accumulating as moisture in hard-to-reach places, can cause corrosive changes in the metal. A solution to the problem may be to turn off the heating for a time when the air is dry and you do not need a garage for work. If it is necessary to repair or inspect the car, it will be enough to turn on the system shortly before the planned work.

Complete benefits

Many men devote no less time to cars than women and than, in turn, the beautiful half of humanity in their own appearance. Evidence of the car owner’s care for his car is not only the cleanliness of the body and interior, the absence of damage and the surface polished to a shine, as well as the external and internal design of the car, but also the conditions in which the vehicle is located outside of “working” hours.

Installing a heating system in the garage will help protect your car friend from problems typical for vehicles in unsuitable conditions (corrosion, freezing of lubricants) and guarantee comfortable conditions in case of repairs. Water heating in a garage is one of the best options for creating optimal conditions for storing vehicles.

Garage water heating scheme and variations

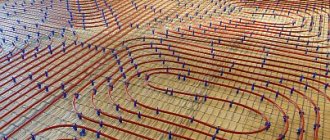

The garage water heating circuit consists of a boiler, metal radiators with a high degree of thermal conductivity and connecting riser pipes (more details: “Riser heating system - device with examples”). The water heated in the boiler is supplied through the riser to the batteries, gradually warming them up. Heated batteries warm up the air in the garage. Next, the cooled water returns to the boiler for subsequent heating and further movement to the radiators through a closed system. A visual representation of the diagram of a garage water heating system is shown in the drawings and photos (about

Principles of the natural circulation process

The process of water movement in the heating circuit without the use of a circulation pump occurs due to natural physical laws.

Understanding the nature of these processes will allow you to competently develop a heating system design for standard and non-standard cases.

Maximum hydrostatic pressure difference

The main physical property of any coolant (water or antifreeze), which facilitates its movement along the circuit during natural circulation, is a decrease in density with increasing temperature.

The density of hot water is less than that of cold water and therefore there is a difference in the hydrostatic pressure of the warm and cold columns of liquid. Cold water, flowing to the heat exchanger, displaces hot water up the pipe.

Preparing the boiler for installation

To begin with, you should seal a pipe with a length of 60 to 80 cm at one end of a sufficiently large diameter with a metal sheet. Next, you should assemble a flange for further connection of heating elements to it. The finished structure is fixed to the boiler using bolts. A couple of pipe sections are also welded to the boiler. The diameter of each of them must correspond to the diameter of the pipes used in the heating system installed in the garage. By connecting all the radiators to the riser, and the riser itself using a rubberized hose to the electric boiler, you will get a unified heating system. A visual sequence of connecting structural elements is demonstrated in drawings and photos (about

Foundation

Most often, a potbelly stove in a garage is installed on a metal sheet. But in some cases a foundation can be made for it. This operation is performed in the following order:

- We disassemble the base of the floor and make a rectangular pit 40-50 centimeters deep.

- Fill the bottom of the hole with a layer of sand, fine brick chips or crushed stone.

- Fill the rocky bottom with cement. When performing this procedure, you should check the horizontalness using a level.

- We wait until the cement is completely dry, after which we lay several layers of roofing material. It acts as a waterproofer and protects the potbelly stove from moisture that can seep out from the soil.

After the foundation is ready, you can proceed to the next stage - making a potbelly stove.

General requirements

In the case of installing a heating system with your own hands, the property owner can personally choose the timing and need to turn it on.

Most often, the heating is turned on during repair work, and turned off while the car is being stored.

Safety

One of the main requirements for garage heating is its safety. The room contains a large amount of fuels and lubricants, as well as highly flammable items.

In cooperatives where structures are located end to end, a fire in a separate area can lead to the burning out of a significant area. For this reason, all heating systems must be capable of emergency shutdown in the event of an emergency.

Feasibility

For property owners, the economic feasibility of the methods used is important. If the installed heating system requires significant operating costs, you should think about choosing a different method.

Proper garage heating should be reliable and resistant to temperature changes outside the room. This also applies to energy supply interruptions.

The garage heating scheme involves preliminary thermal insulation of the room. Heating unprotected buildings is pointless - the heated air will escape through the cracks of the enclosing structures.

If no insulation measures are taken, no matter how high-quality the system is, it will not heat the garage, but the space around it.

Construction of a potbelly stove

Storing your car in a warm garage during the winter allows you to avoid many problems. Proper engine starting, clean windows, ease of repair, maintenance - all this significantly increases the operating time of the car, preserving health, including the owner. In a warm room, the body is reliably protected from corrosion. Those who like to repair and improve their car themselves know that frosty days make rubber and metal brittle, and repairs are complicated by constant breakage of bolts and bursting of plastic parts. A comfortable temperature helps to avoid these problems.

If there is a need for repairs in winter, then you won’t be able to stay in a cold room for a long time. Most often, heating is organized using a potbelly stove, which is easy to operate.

It is made like this:

- holes are cut in the steel barrel;

- Pipes and fittings are attached to the holes by welding.

Construction of a modern potbelly stove

For these structures, it is easy to equip the body; the main thing is the organization of modifications.

Heating using a potbelly stove is allowed - it heats up quickly and gives off heat. It is quite possible to design a stove for heating a garage yourself, provided you have a small welding machine.

Sometimes brick stoves are built in garages, but they will take up a lot of space and will not be able to heat the room faster than a potbelly stove. The name of the device is conditional, because in fact any fuel material can be placed in the structure.

Design features

The heating system of residential and technical premises includes heating boilers, metal radiators with high thermal conductivity, as well as connecting pipes for liquid supply.

The water heated in the boiler is supplied to the radiators through pipes and gradually increases their temperature. Until the liquid cools, the radiators heat the building, and then the water from them is discharged back into the boiler. The general heating cycle consists of repeating this process many times.

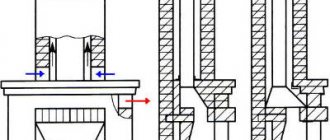

Single pipe system

A single-pipe system involves the sequential passage of coolant liquid through all batteries and its return to the boiler. This type of heating is beneficial for garage owners due to the low cost of purchasing pipes, ease of DIY installation and good thermal efficiency.

Single-pipe heating involves different heating rates of radiators, which will decrease from the first to the last. Unevenness will be noticeable in multi-story garages, but for single-story buildings this will not be a problem.

Two-pipe system

For heating large garage-type buildings, it is recommended to use a dual-circuit heating system. The pipe pumping the working fluid is supplied to each battery separately. The waste coolant from the radiators goes through the return circuits and exits into a common pipe, delivering it back to the boiler.

The final room temperature will be the same regardless of the location of the radiators, which will be a serious plus for the property owner. Among the disadvantages, it is worth noting the large number of pipes and shut-off elements, the complexity of installation and high installation costs.

A certain difficulty with garage heating lies in its inconsistency. A long absence of the owner will lead to inactivity of the system, which can cause water to freeze and pipes to burst.

A good solution would be to drain the liquid while the garage is not in use, or replace the standard coolant with antifreeze.

What does pressure depend on?

To create the necessary circulation pressure, it is necessary to calculate the entire heating system when designing a private house. It depends on the level of the middle of the boiler and the lowest battery. The greater the height difference, the better the fluid moves through the system. It is also influenced by the difference in densities of hot and cooled liquids.

A heating system with natural circulation is characterized by a change in temperature in the radiators and in the boiler, which occurs along the central axis of the devices. Hot water is at the top, cold water is at the bottom. Under the influence of gravity, the cooled liquid moves down the pipes.

Movement directly depends on the installation height of the radiators. Its increase is facilitated by the angle of inclination of the supply line, which is directed towards the batteries, and the slope of the return line, directed towards the boiler. This makes it easier for the liquid to overcome the local resistance of the pipes.

When installing a heating system in a private house with natural circulation, the boiler is placed at the lowest point so that all the batteries are located above.

Installation work

For water heating in the garage you will need a set of instruments and parts, including:

- heating boiler;

- metal radiators with good thermal conductivity;

- connecting pipes made of metal or plastic;

- accessories for fastening;

- locksmith tools.

Project development

Before installing the heating system, you need to determine the diameter of the pipes that will connect the radiators. Risers with a large cross-section will increase the flow of hot water to the batteries, increasing the efficiency of the design.

It is worth considering that heating large volumes of liquid will lead to increased electricity costs. The optimal scheme is a balance between the room temperature and the cost of heating. These parameters are also affected by the number of radiators in the insulated garage.

Expansion tank

The design of the garage heating system involves the use of expansion tanks. These items are made from simple plastic containers or large canisters with fill holes cut in the top.

The water circulating in the system constantly evaporates and requires regular addition of liquid, and the steam formed during boiling needs to be removed. The tank is installed at the lowest point of the heating system and at a half-meter distance from the floor.

Before installing the boiler with your own hands, you will need to prepare a metal pipe of a certain diameter with a half-meter or meter length. Its extreme end is tightly welded with a metal sheet.

The next step will be assembling flanges for attaching tubular electric heaters and fixing them to the boiler using bolts. To supply the working fluid to the installation, two sections of pipe with the diameter that will be used in the heating system are welded.

Heating batteries are attached to the walls of garages using special reinforced dowels. The distance from the floor to the radiator should be at least fifteen centimeters. For effective heating, you need to leave a few centimeters of free space between the walls and the heating elements for air circulation.

The individual structural elements are connected into a system using metal or plastic pipes with special fittings. The seams of their joints and forks require special attention during installation so that leaks do not occur in the future during operation.

The connection of metal pipes is carried out using a welding machine. Working with polypropylene will require the use of a special soldering iron. Regardless of the material of the pipes, they should be placed on the walls at a slope - this will improve the circulation of liquid.

The water heating system is considered ready after connecting the radiators to the risers and connecting them to the boiler using a rubber hose. Before starting operation, it is recommended to re-inspect the line, search for defects and seal problem areas.

A note about insulation

So, the first thing to consider is the walls and location of the garage. If the box is assembled from thin sheets of metal or brick in one row, there is no insulation in it and it is located away from the housing stock, then by heating it, you can simply “go down the drain” financially, both literally and figuratively. Moving directly to the practical plane, it is necessary to protect the walls and ceiling from temperature loss. For technical premises, which includes the garage, foam boards, mineral wool, modern liquid insulation, polyethylene foam, and extruded polystyrene are well suited.

Of course, describing the installation of each individual type on the surface of the walls or ceiling is beyond the scope of the article. But here’s some life advice on this topic: in order to reduce the cost of insulation for a garage owner, he should pay attention to the packaging of products thrown away by many department store stores. Often it contains foam inserts. By reaching an agreement with the owners of the retail outlet, or simply periodically driving around nearby garbage containers and picking up polystyrene foam, you can quickly collect the required amount to insulate the walls and ceiling of the garage. And you will get it for free.

The basis of any type of insulation will be the creation of a narrow wooden or metal frame inside the box, and, if possible, outside it (many heat-retaining materials are insensitive to humidity). First, a thin layer of polyethylene is placed into the cells of the structure to isolate the insulation from the wall, then the thermal material itself. Another layer of film is stretched on top, onto which the upper final stitching is made. The latter is done depending on the location of the insulation - street or room. Thin sheets of tin, wood or siding are used outside, fiberboard, chipboard, plaster or any other material is used inside.

Insulating a roof is practically no different from a similar process for walls - the same sheathing, insulation, moisture protection and outer covering.

Now, regarding the gates. Of course, you need to think about isolating them. It is made classically or with foam plastic fixed directly on top or with mineral wool in an iron mini-frame welded onto the gate. Of course, all this is done in cases where the surfaces are made of metal. In the rest, they act according to their own understanding.

If there are separate doors, similar actions are carried out with them - either completely replaced with insulated ones or made double. You also need to pay attention to the windows - if they are present, then the issue of exchanging them for insulated ones should be resolved.

Thick curtains indoors in front of doors and gates can also be a good method of insulation. When lowered to the bottom, they will create another thermal layer between the street and the garage space.

A small note: when carrying out the procedures for insulating and sealing the room, do not forget that this is a garage where there is a car that emits deadly carbon monoxide and CO2 when the engine is running. Ventilation and the possibility of airing are required!

Yes, after the procedures performed, the free space will decrease slightly. But! The savings in heat and fuel reach such a size that for the same amount one could buy a second garage, if we take the initial expenses for heating a room that is not protected from losses.

Economical garage heating with your own hands: how to reduce heat loss and the best way to heat it

Many motorists are sensitive to their cars, so they are ready to invest time and effort into improving their garages. Often, the room performs not only its direct functions: it is used as a workshop, storage room, and even a place for relaxation in a male company.

If you arrange economical garage heating with your own hands, you will be comfortable in it for many hours. Let's try to figure out how to properly heat a garage and what you need to pay attention to so as not to go broke paying bills.

Top 10 popular heating appliances on sale

If the garage is used for its intended purpose, that is, your iron horse is parked in it, it is convenient to choose an inexpensive and practical infrared ceiling-type heater. Here are the most popular models according to Yandex Market:

Timberk TCH A1B 1000, price 4170 rubles

Almac IK16, price 3771 rubles

Peony ThermoGlass P-10, price 6950 rubles

Makar TOR-1, price 5500 rubles

The next category is mobile gas heaters. Network buyers made their choice in favor of the following devices:

Gas oven Ballu BIGH-55, price 5490 rubles

Gas oven KOVEALittleSun (KH-0203), price 6110 rubles

Gas stove Umnitsa OEG-2, price 7684 rubles

Solid fuel boilers from domestic manufacturers are distinguished by their pleasant design and impeccable performance. Among the best are the following models:

Potbelly stove Vesuvius V5, price 7980 rubles

Heating stove Tsar stove, price 6500 rubles

META Baikal 8, price 30,650 rubles

TERMOFOR Cinderella 2016, price 6330 rubles

Advantages and disadvantages of various systems

A garage heating system must be cheap, and this is the main requirement. The owner of a garage has to invest a lot of money in maintaining and repairing the car, and arranging the premises for it. This is costly, and it is worth taking every opportunity to reduce the cost of heating.

On the other hand, savings must be reasonable: without compromising the efficiency or safety of the system.

There are many different types of systems and devices that can be used to heat a garage. They are not perfect and have their own shortcomings. Each owner has to decide which selection criteria are most important to him.

Option No. 1 – classic water heating

To connect heating to the garage, it is not necessary to install a separate boiler, but an additional load is placed on the overall system. This must be taken into account when purchasing heating devices and take them with a power reserve.

Fuel consumption also increases, but the costs are still lower compared to installing a separate heating system for the garage.

The second option is to install a garage heating system with a separate boiler. This is a good solution if the building is located far from the house and the heat loss when moving heated water through pipelines is too great.

When installing a water system with a separate boiler, it is worth using antifreeze as a coolant to prevent possible defrosting.

The coolant is heated in the boiler and flows through the pipeline to the radiators. Cooling down, it returns to the heater again. The system can be one- or two-pipe. This determines whether the radiators will be connected to the boiler in parallel or in series.

The first type of connection guarantees equal heating of all radiators, but it requires two pipelines.

For a garage, a single-pipe system is best. This scheme allows you to arrange heating with minimal costs for materials, and installation is also simplified. If there are several radiators, they are connected in series.

It is worth considering: in each subsequent device the coolant temperature decreases.

Spacious garages, commercial auto repair shops, and service stations are equipped with a full-fledged dual-circuit heating system. You have to spend money on more materials and complex installation, but the heating of the room will be uniform and efficient.

Option No. 2 - heating with gas

Gas heating is the cheapest, but to connect to the main line you will have to obtain permission from the relevant services. In many cases, garage owners try to avoid a long approval procedure.

Another nuance: for unauthorized connection to the main pipeline or carrying out commissioning work, you can pay a serious fine.

Therefore, it is advisable to do everything according to the rules or use bottled gas mixtures.

If you connect to the mains, you can provide cheap and highly efficient heating. If you have to use liquefied gas, then you should choose a device that uses fuel economically. This could be a gas heat gun, an infrared heater or a convector.

Option No. 3 - electric heating

Electrical appliances are considered the safest. They are easy to use, compact, efficient and can instantly warm up rooms. Any buyer will find a model of the required power and with the necessary technical parameters.

The only drawback of electricity is the high cost, and this immediately negates all the advantages. Such electrical appliances should be chosen only for rooms where the owner spends little time. For constant heating of a garage, electric heaters are unprofitable.

A rational solution is to purchase a mobile infrared heater, convector, fan heater or heat gun. They are easy to carry and move from place to place. The most powerful and practical devices are heat guns.

An unsuccessful option is an oil heater. The device has its advantages, but is more suitable for long-term heating. In addition, it consumes a lot of energy resources and slowly warms the air.

However, there are exceptions. So, a homemade heater assembled from an old cast-iron radiator and heating element will cost literally pennies. The power of the heating element is chosen by the owner himself, and used oil can be used as a coolant.

Option No. 4 - solid fuel devices

Solid fuel boilers and stoves are very profitable due to the low cost of coal and firewood. The disadvantages include the need to build a chimney, which leads to a slight increase in the cost of the system.

These costs are paid off due to the long service life, efficiency of the stoves, and low cost of fuel (you can use waste: sawdust, wood scraps, any combustible materials).

A solid fuel stove is cheap and does not require connection to centralized communication networks or obtaining permission for installation. However, it is worth mentioning the disadvantages: increased fire hazard, the need for constant combustion control, the smell of smoke in the room, the release of harmful substances into the air.

Option No. 5 – liquid fuel stoves and boilers

Heating appliances running on diesel fuel, diesel fuel, and waste fuel are popular. You don't have to buy them in the store. It is quite possible to assemble an oil-fuel boiler, a stove for a garage, and even a heat gun with your own hands. The housings of such devices are made from gas cylinders, old barrels, and heat-resistant steel sheets.

Homemade stoves are not as economical as industrially produced models, but they also allow you to save a lot on heating costs. The fuel consumption of a homemade miracle stove or a homemade heat gun is approximately 0.5-0.7 l/hour, depending on the power.

Review of popular models of garage stoves

There are a variety of options for garage stoves on the markets. They differ in the heating principle and design solutions. Some models deserve special attention:

- The Bullerian stove is made to run on solid fuel. The design has a convection mechanism for high-quality heating of air masses that move through the pipes;

- a durable option is the Stavr stove. It is made of cast iron, a similar material can withstand high temperatures;

- Termafor stoves have convection pipes in their design, which are placed in the combustion chamber. Such models are designed for both standard and pyrolysis combustion;

- The Alaska stove has a stylish design and good heat output. The design is equipped with a hob;

- A cheap alternative to Buleryan is the model of the domestic manufacturer Breneran. It can operate on wood and waste from the manufacturer.

| Image | Model | Construction type | Price, rub |

| "Delta" D-81G | Heat gun | 3930 | |

| Ballu BHDN-80 | Diesel indirect heating device | 55900 | |

| ELITECH TP 3G | Ceramic gas panel | 2960 | |

| Resanta | Gas heat gun | 6700 | |

| Breneran AOT – 06/00 | Wood stove | 10500 |

Some stove models are assembled independently

What type of heating is most profitable?

It all depends on the specific operating conditions and preferences of the garage owner. The cheapest system is a single-pipe water system powered by a gas boiler.

You will have to invest a lot of money in its arrangement, but it is so economical that the costs will be recouped in 1-2 heating seasons. However, this solution is not suitable for everyone.

You can economically heat your garage using gas cylinders or solid fuel. These options are not suitable if it is not possible to control the operation of the devices, but they are good for heating while the owner is in the garage.