The main technical characteristics of aluminum heating radiator models are information that it is advisable to know before choosing and purchasing them. Along with the appearance (design) of the heating device and its cost, technical data allows you to compare different models and choose the option that is optimal in terms of the main parameters.

There are quantitative and qualitative characteristics of aluminum radiators. Quantitative ones allow you to compare heating devices according to their weight and size parameters and heat flow power. In turn, quality characteristics take into account design features and manufacturing technology.

Section power

If you are interested in the power of an aluminum heating radiator section, you should read the documents for the device. If the volume is 0.5 liters, then manufacturers usually declare this parameter at 180 W or less. If the temperature of the coolant water varies from 65 to 70˚C, then in reality the thermal power of one section of the aluminum radiator will be less and will be approximately 140 W.

When getting acquainted with the characteristics of the battery, buyers quite often pay attention to the heat transfer conversion formula: ∆t 70°C = 160/200 W. The difference between the average air temperature and the average temperature in the heating system is denoted by ∆t. This suggests that for a ∆t indicator of 70˚C, the air temperature in the room can be 20˚C, and the average temperature in the heating system should be equal to 100˚C, while the return will be equal to 80˚C.

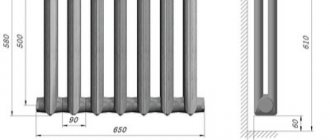

But such figures are quite difficult to achieve in reality. Therefore, taking the power of 1 section of an aluminum radiator, you will have to determine the heat transfer, taking into account the ∆t indicator equal to 50°C. As an example, consider the middle section of the battery with the following dimensions: 100 x 600 x 80 mm. It is capable of heating approximately 1.5 m2 of area, which corresponds to a heat output of 140 to 160 W. When choosing the right number of sections for a room, you should take into account the condition and location of the walls. If the room is corner and one of the walls freezes, this fact should be taken into account.

Selection, installation and operation of cast iron heating batteries

Stages of installing a radiator to a heating system.

If the choice (lightweight radiators or cast iron) is made in favor of the latter, then you need to calculate the number of batteries in the room and the number of radiators in each of them. To do this, you need to know the technical characteristics of a particular model, first of all, the amount of heat generated. Another important task is to determine the location for installing the batteries and the method of mounting: wall or floor. Based on this, a specific sample is selected. Photos of almost most cast iron heating radiators can be found on the Internet. Cast iron radiators have different external volumes, including being quite voluminous or completely flat, and having different heights and widths.

A common place in a living room where you can install a battery is a niche located under the window sill. Its parameters dictate the size of the battery. The technical characteristics of this battery should provide 1 kW of heat per 10 m² of room area. Moreover, if the volume of the room is larger than usual due to the high ceiling, or there is a second window, then 1.2 kW of heat is needed for the same area. If the room occupies a corner position, it makes sense to add a few more extra sections, since there is more heat loss there.

The mounting method dictates both the weight of the battery and the strength of the wall near which it is placed. If it is hung on the wall, then it is worth remembering that at least three brackets are needed for each battery. Today, cast iron batteries often use floor mounts, and many models have ready-made legs. If the wall is made of wood, then you should use corner fasteners. Next, you need to carefully install the pipes supplying the coolant and screw them on, ensuring the tightness of the threads as much as possible. At the same time, do not overdo it in applying force so as not to tear it off, otherwise water will leak.

https://youtube.com/watch?v=8l2cyQIMvMQ

Repairing a cast iron battery most often consists of eliminating leaks at the connection points with the pipes. The question arises: how to wash the radiator from the inside? It also has a simple, albeit time-consuming solution. It is disconnected from the battery, and then with the help of a flexible brush and a hose with high water pressure, all accumulated dirt is easily washed out. Like repairs, this procedure is best left to a specialist. Independent steps can be quite successful, but they can also lead to damage.

Cast iron batteries will become an uninterrupted and reliable source of heat for you, your children and grandchildren.

More information about power. Calculation of the number of sections

Knowing the power of one section of an aluminum radiator, you can determine the number of elements. You need to use the following formula: K = S * 100 / P. In it, the letter K denotes the number of sections. S is the area of the room, and the power of one section is denoted by the letter P. If we take into account the average power, which is 150 W, and the area of the room is 25 m2, then the calculation will look like this: 25 x 100 / 150. This will allow you to understand that for efficient heating of a room with the mentioned parameters, 16 sections are needed. Using this formula, you can calculate the volume of the required number of sections to accommodate a particular area.

Connection options

The most effective is a diagonal connection, in which heat loss is only 2%.

However, the appearance of this connection somewhat spoils the surrounding design, so they often give preference to products with side and bottom connections, which look more aesthetically pleasing.

with side connection

With a side connection, the inlet and outlet pipes are connected from above and below to the section on one side of the radiator, which ensures uniform heating of all sections.

This connection can be used with a large number of sections - up to 15.

About the power of radiator sections of 500 and 350 mm

One section per 500 mm is a standard part of a conventional battery, which is most often found in apartments and houses, as well as offices. Some manufacturers mention in documents that the power of one section of an aluminum radiator can range from 180 to 230 W. The more expensive the products of a particular manufacturer, the higher the heat dissipation of the battery will be. This is why you shouldn’t chase cheap Chinese batteries. In addition, their service life is short.

You can also find a smaller battery on sale, which will come in handy in limited space. This applies to walls with large windows or areas with narrow pockets. The power of one section of an aluminum radiator in this case will be lower, since the coolant used is supplied in a smaller volume and the battery area is smaller. The value described here ranges from 120 to 160 W. The final value will depend on the manufacturer. It is necessary to choose the radiator correctly. After all, if its power is insufficient, then the apartment will be cold, and if you hang a battery with a large number of sections, then you will waste electricity and gas. However, the last factor is relevant only for private houses with appropriate heating systems.

Recommendations for calculations before starting work

To independently calculate the required number of heating battery sections, you must know the following parameters:

- dimensions of the room for which the calculation is being performed;

How to measure a room - the power of the entire battery or each of its sections. This information is provided in the technical documentation supplied by the heating unit manufacturer.

Calculation of sections for CONDOR radiators

Heat transfer indicators, the shape of the battery and the material of its manufacture - these indicators are not taken into account in the calculations.

Important! Do not perform calculations for the entire house or apartment at once. Take a little more time and do the calculations for each room separately. This is the only way to obtain the most reliable information. At the same time, in the process of calculating the number of battery sections for heating a corner room, you need to add 20% to the final result. The same reserve must be added on top if there are interruptions in the heating operation or if its efficiency is not enough for high-quality heating.

Key Features

When choosing aluminum radiators, you can count on their efficiency and light weight. The latter will not cause any inconvenience during installation and dismantling. To control the temperature, such batteries have a regulator.

To install the device, the technician does not need to have special knowledge and skills. The specific thermal power of one section of an aluminum radiator, according to experience, is the largest among similar devices. Such batteries are very original and presentable, so they can be used not only in ordinary apartments, but also in luxury houses.

Advantages and disadvantages of aluminum models

The main advantage of these products is their compactness, light weight, and affordable price. In addition they:

- warm up quickly and quickly release heat; have an optimal “thermal power/cost” ratio;

- have a fairly long service life;

- thanks to the sectional design, they allow you to select the optimal length for each specific room and calculate its cost (when selling, the cost per section is indicated);

- have an attractive appearance and durable paint coating;

- they use a convection heating method, due to which dust does not accumulate;

- easy to install even on drywall;

- varied and interesting in design.

The disadvantage of these radiators is their susceptibility to corrosion, leading to deformation.

Corrosion resistance is enhanced by the internal polymer coating. In its absence, to prevent battery rupture, the taps on the coolant supply pipes must not be turned off.

In addition, the disadvantages are also:

- low resistance to acid solutions that can be added to coolants;

- poor tolerance to sudden changes in fluid pressure;

- relatively rapid formation of gases inside the product, creating the need for its regular removal.

Negative reviews

Before choosing an aluminum radiator, you should read consumer opinions, which are not always positive. For example, some buyers note that water leaks are sometimes noted at intersectional joints. The heat distribution in such batteries is uneven. It focuses on the ribbed surface.

Buyers also do not like the fact that the convection return is very small. Such a battery may not last long - up to 15 years. But some manufacturers have corrected this shortcoming by increasing the warranty to 25 years. Buyers quite often refuse aluminum radiators for another reason that they are chemically reactive, so corrosion is a serious enemy for these devices. But manufacturers introduce anti-corrosion treatment into the production process, covering the surface with a layer of oxide film.

Approximate calculation for standard premises

A very simple calculation option. It is based on the fact that the size of mass-produced heating batteries is practically the same. If the room height is 250 cm (standard for most living spaces), then one radiator section can heat 1.8 m2 of space.

The area of the room is 14 m2. To calculate, it is enough to divide the area value by the previously mentioned 1.8 m2. The result is 7.8. Round up to 8.

Thus, to warm up a 14-meter room with a 2.5-meter ceiling, you need to buy a battery with 8 sections.

Important! Do not use this method when calculating a low-power unit (up to 60 W). The error will be too large.

Selection of heating radiators by thermal power

Manufacturing Features

Once you know the power of a 500 mm aluminum radiator section, it is important to inquire about other characteristics, for example, the method of manufacturing the battery. Such devices are made by casting or extrusion technology. The first method provides that all sections are manufactured separately. The device ends up being quite durable, since the components include silicon additives (about 12% of the total volume).

The casting process is carried out under high pressure. This method allows radiators to be made in a variety of shapes. Such batteries can withstand operating pressure from 6 to 16 atmospheres. The water channels are slightly widened to allow water to flow as freely as possible. The walls are durable, as they have a fairly impressive thickness.

The power of 1 section of a 500 mm aluminum radiator is not all that you should know about such a device if you are planning to purchase it. For example, the final performance is influenced by the manufacturing method. Battery production can be carried out using the extrusion method. This method involves the use of extrusion. All radiator components are manufactured separately and then fastened together.

The collector is cast from silumin, all parts are well pressed and firmly connected. The extrusion method is cheaper than casting, but the radiator cannot be improved during operation.

Overview of different types

Before purchasing equipment that is so valuable for a comfortable life, you should analyze all the properties of radiators made of different materials and understand which ones are best to choose for heating your private home.

Real “veterans” of the market. They are characterized by high performance, impressive durability and resistance to various types of loads. They have proven themselves when used in systems with high operating pressures - on average up to 10 bar.

The sections of such batteries have a fairly large volume and thick walls, which guarantees fairly highly efficient heating. The service life of cast iron appliances in most cases significantly exceeds 50 years.

The heat transfer rates of 1 section of the device can fluctuate on average from 100 to 200 W. The specific value is determined by the standard size of the compartment. You can see the comparative characteristics of cast iron and bimetallic radiators in this article.

In general, cast iron batteries, known for their almost absolute resistance to contact with low-quality coolants, are very popular among domestic consumers - this is due to the characteristics of their operation.

Radiators made from this material have proven themselves in private housing construction. The design features and raw materials are such that the finished product weighs much less compared to the previously discussed cast iron analogue and has less thick walls, which ensures faster heating of the unit.

Modern steel batteries can be used in systems with operating pressures of up to 10 atm and temperatures of no more than +150 degrees. Models with horizontal and vertical channels are available for sale.

Additional advantages of such devices include a wide range of design solutions - batteries from the factory can have a variety of colors, which allows them to fit seamlessly into any interior.

Aluminum

Aluminum products compare favorably with their “brothers” in their light weight, elegance and high heat transfer rates. Such products combine 2 mechanisms of heat transfer: through convection and radiation, which makes them the most effective devices for heating residential premises. At the same time, the permissible operating pressure in the system is also impressive - up to 18 atm.

Aluminum is characterized by high heat transfer, which allows for the most efficient heating. In general, when using aluminum batteries, there is approximately 20-30% savings in thermal resource consumption compared to devices made from other materials.

Bimetallic

The products are manufactured using simultaneous use of high-strength steel (internal manifold) and aluminum (external part of the product). In terms of operating pressure, bimetallic batteries are significantly superior to previously considered options - up to 35 atm.

The combined use of aluminum and steel in the design of devices has significantly increased their resistance to contact with coolant, as well as strength, resistance to corrosion damage, and heat transfer performance. At the same time, the units have relatively compact dimensions and a generally neat appearance.

Bimetallic heating radiators are characterized by relative ease of installation and are equally well combined with centralized and autonomous heating systems. How to calculate how many radiator sections you need, see here.

The design of the device is represented by a seamless copper pipe. Other metals are not used in the manufacture of such units. The diameter of the pipe is about 2.8 cm. Additionally, there are copper ribs and a decorative casing, usually made of solid wood.

In terms of thermal conductivity, copper exceeds aluminum by about 2 times, and cast iron and steel by an average of 5-6 times. Combined with low inertia, the radiator provides quick and effective heating of the room being served.

The battery capacity holds a little water, thanks to which the unit warms up within 3-5 minutes. This property is especially relevant for autonomous heating systems - this eliminates the need for constant heating and “running” large volumes of coolant through the pipeline, as, for example, in the case of cast iron batteries.

Copper is resistant to corrosion. performs well when working in combination with a low-temperature coolant, is characterized by high ductility and resistance to aggressive environments.

Features of anodized aluminum radiators

What is the power of the aluminum radiator section, you now know. But before purchasing a heating device, it is important to inquire about the technology used to make the battery. If you have an anodized aluminum radiator in front of you, then you should know that the material undergoes better cleaning during the production process. This allows you to slightly change the structure of the metal. Anodized radiators, unlike pure aluminum ones, are almost resistant to corrosion. The individual parts are connected to each other by couplings, and not by nipples. These couplings are located outside the heating device.

Anodized aluminum batteries are smooth inside, which contributes to higher heat transfer rates. In addition, such devices are able to withstand higher operating pressures. It can reach 70 atmospheres. However, annotated aluminum radiators belong to a more expensive price category than simple ones. However, the latter have worse performance characteristics.

Design and operating principle

Aluminum batteries can be solid or sectional. For strength and corrosion resistance, silicon, zinc, and titanium are added to aluminum during the manufacturing process.

The sections are connected by threaded connecting elements. The connections are sealed with silicone gaskets. To prevent ruptures, the inside of the radiators is coated with polymer materials.

Feedback on features of use

When you know the power of one section of an aluminum radiator, but you still don’t know whether it’s worth purchasing such a heating device, you should familiarize yourself with consumer opinions regarding the operating features. For example, it is recommended to wash such batteries with running water once a year. Before starting operation, it is important to make sure that the radiator is installed correctly and is connected to the system with quick-release connections.

It is impossible to install such devices in the same base as a boiler that has a built-in copper heat exchanger. Consumers emphasize that when copper and aluminum come into contact, a galvanic couple is formed. In this case, copper acts as a strong metal that attracts aluminum ions, turning it into foil over time. Craftsmen emphasize that this law is not applicable to systems made of polypropylene or metal-plastic pipes. In this case, there is no direct contact between copper and aluminum.

How to increase efficiency?

If the batteries have already been installed and have not met their owner’s expectations for high-quality heat, steps can be taken to increase their power.

- You can start by cleaning. Few people know that ordinary dust reduces the heat transfer of a structure by up to 20-25%.

- If this was not enough, you need to invite plumbers to clean the inside of the aluminum radiators.

- You can increase the heat transfer of an aluminum radiator by as much as 15% by painting it dark.

- Installing a heat reflective screen behind a radiator will direct heat into the room rather than heating up the wall. It is better to buy a ready-made model, but you can also use regular foil or a metal sheet. The latter is most preferable, since it will not only reflect the heat, but also, having heated itself, will share it with others.

- You can increase the area of aluminum radiators by making casings from the same metal. When they heat up, they will give off heat for a long time, even if the heating is temporarily turned off.

- Increasing the sections in the battery also helps to increase its power.

If you use at least one of these options, the efficiency of the heaters will increase by at least 10%, while reducing energy costs.

Heat transfer is the most important indicator that needs to be taken into account when installing aluminum radiators. By correctly calculating and taking into account all the factors that influence it, you can create a microclimate in the room that will not only be pleasant to people, but will also have a positive effect on their health.