A warm water floor is a special heating system, which is characterized by a simple installation technique, an affordable price and low costs during use. It is also worth noting that the water system, unlike the electric one, is completely safe for people and animals.

We provide installation services for heated water floors in an apartment, house or commercial premises.

There is nothing complicated in the installation technology, so with the desire and certain knowledge, anyone can install heated floors. As a result, this will reduce costs, which directly affects the cost and operation of the heating system.

Warm floor and finishing coating

The warm water floor system is best combined with installation under porcelain stoneware and tiles.

- Firstly, both materials are strong and durable.

- Secondly, they do not emit harmful substances when heated.

- And thirdly, heating perfectly complements the tiles (the material itself is cold), and you can even walk on it barefoot thanks to its high heat capacity.

Of course, heated floors can also be installed under laminate, linoleum, PVC tiles and even carpet, if there is a special mark.

But, for example, there is no point in heating the carpet, and the surface temperature cannot be exceeded above 31°C, according to SNiP 41-01-2003. Otherwise, it will provoke the release of harmful substances.

| Zones | Floor temperature, °C |

| Living spaces | 26°C (average) |

| Rooms with high humidity | 31°C (average) |

| Non-residential premises | 31°C (average) |

| Above the pipe | 35°C (maximum) |

| Parquet and laminate floors | 27°C (maximum) |

| Permanent stay of children (according to sanitary standards VSN-49-86) | 24°C (maximum) |

Control system and circuit testing

The control system for water heated floors includes:

- Pump;

- Boiler;

- Collector;

- Thermostat.

The arrangement of all elements in compliance with technical parameters is a very complex thermal engineering task. A lot of parameters are taken into account, starting from the number of fittings and the length of pipes, and ending with the thickness of the walls and the region of the country. In general terms, you can focus on the following data:

- The pump can only be used as a circulation pump. The “wet” type of pump is more reliable than the “Dry” type and less demanding to maintain.

To calculate performance, use the following formula:

P = 0.172 x W.

Where W is the power of the heating system.

For example, with a system power of 20 kW, the pump capacity should be 20 x 0.172 = 3.44 m3/h. Round the result up.

The pressure is calculated using a more complex technique. After all, the pipes are located horizontally, and the pump characteristics show vertical pressure. Use the following formula: H = (L * K) + Z/10. Where L is the total length of the circuits, K is the pressure loss coefficient due to friction (indicated in the pipe passport, converted to MPa), Z is the pressure reduction coefficient in additional elements

Z1 – 1.7 thermostat valve;

Z2 – 1.2 mixer;

Z3 – 1.3 valves and fittings.

Using an example, it looks like this, let’s say there are 3 circuits, 120 m each. In total there are 18 fittings, 3 thermostat valves, 1 mixer. Pipe – corrugated stainless steel ø16 mm, loss coefficient 0.025 MPa.

H = (120*3*0.025) + ((1.7 * 3) + (1.3 * 1) + (1.2 * 18))/10 = 9 + (5.1 + 1.3 + 21 .6)/10 = 11.8 m. The result is rounded up - the pump head is 12 m.

- The boiler power is calculated using the formula W = S * 0.1. Where S is the area of the house. There are also a lot of correction factors, depending on the thickness and material of the walls of the house, the climate of the region, the number of floors, and the presence of adjacent rooms.

Please note that the outlet water temperature should be more than 30 – 35˚C. To withstand this temperature, a mixer is installed in front of the collector. In it, water is mixed to the desired temperature before entering the circuit.

- The collector regulates the water supply in each circuit. Without it, the water will follow the path of least resistance to flow, that is, along the shortest circuit. The adjustment is carried out by servo drives, according to data from the thermostat.

- Thermostats monitor the temperature in controlled rooms by taking readings from temperature sensors.

Before crimping the circuit, it is washed and only then connected to the manifold. Water is supplied at normal pressure, but the temperature is increased by 4˚C per hour, up to 50˚C. In this mode, the system should function for 60-72 hours. IMPORTANT: constant monitoring is required during crimping!

At home, without the use of special equipment, it is impossible to pressurize with high pressure.

If the inspection does not reveal any installation flaws, then you can proceed to further operations.

Installation in an apartment

Probably, many residents have had the idea to independently connect water heated floors “for free” to a central heating or hot water system. And some even do this, but in most cases it is prohibited by local law.

For example, in Moscow there is government decree No. 73-PP dated February 8, 2005; Appendix No. 2 clearly states that it is prohibited to re-equip public water supply systems for floor heating.

If you break the rules, at best, you can get a fine on your first visit to the plumbers. And at worst, there is a risk of leaving your neighbors without heating.

In some regions the ban does not apply, but connection requires an examination so as not to disrupt the operation of the system.

In general, from a technical point of view, such options are possible, but only if a separate pumping and mixing unit is connected and the pressure in the system is maintained at the outlet.

Note! If there is a jet pump (elevator) in an apartment building, then metal-plastic and polypropylene pipes cannot be used.

Advantages and disadvantages

The main advantage of a hydraulic heating system is uniform horizontal heating of the room. The heat in the room spreads vertically, thereby providing a healthy microclimate, which radiator devices cannot provide. Warm floors are an ideal option for rooms with high ceilings.

Also, water-heated floors benefit from an aesthetic point of view. They are completely invisible and do not take up free space. In addition, they are more economical when used.

The efficiency of the system will depend on the quality of the thermal insulation. This is due to the fact that the level of heat loss directly affects the reduction in heat transfer. But it is worth considering that installing such a system in a bathroom or toilet has certain disadvantages. The heating element is usually connected to a heated towel rail, which can cause the floors to overheat.

Also, water-heated floors “take away” the height of the room due to the thick concrete screed. In addition, concrete pouring makes the entire structure heavier, so sometimes there is a need to strengthen the coatings.

Floor installation methods

There are several ways to create a warm water floor.

- The most popular and reliable of them is concrete screed. Unlike electric types, 16 mm pipes cannot be hidden in tile adhesive, and it will not work. Therefore, the screed is poured at least 3 cm above the pipes.

- The second method is to lay pipes in cut-out polystyrene foam grooves. The grooves are made by hand, pipes are laid inside, then the screed is poured.

- The next option is often used in houses with wooden floors, although it requires a lot of labor - laying it in wooden grooves. To do this, boards are placed on the floor, which create a gutter of the desired shape for installation.

Premises requirement

Since the structure has significant weight, a large length of pipes and many connecting nodes, the installation of the system has its own characteristics.

As a result, each layer must be laid strictly according to the instructions. But before that, you need to carefully study all the features of preparing the premises.

Warm water floors are most often used in private homes. In multi-storey buildings, they create a large load on the floors, and the risk of flooding the neighbors below cannot be ruled out.

It is also worth considering that the coolant circuit is connected to a general heating system, which most often is not intended for such purposes. As a result, cold risers may appear in your or a neighboring apartment. As a result, the relevant authorities rarely issue permission to install the system in high-rise buildings.

At the moment, two systems are often installed in new buildings at once. The first is intended for standard heating, and the second is specifically for heated floors.

The optimal solution is to install heated floors yourself at the construction stage.

When installing the structure in a finished structure, it is necessary to take into account:

- foundation strength;

- door frame size. The minimum height must be at least 2 meters 10 centimeters;

- distance from floor to ceiling, since the concrete screed is quite voluminous.

In addition, the heat index should not exceed 100 W/m2.

Types of pipes used

Three types of pipes are suitable for a warm water floor.

- Pipes made of cross-linked polyethylene (PEX-EVOH-PEX) are inconvenient to work with because it is difficult to give them the desired shape (they straighten when heated). But they are not afraid of liquid freezing and are repairable.

- Metal-plastic pipes are the best option: low price, easy to install, and keep their shape stably.

- Copper pipes are expensive; when used in a screed, they must be covered with a protective layer to prevent alkaline attack.

Advantages

A water-based heating system has many advantages. These include:

- achieving the desired level of comfort , since the floors will always be warm and the air in the room will be heated evenly;

Decision table for choosing a water heated floor system

- safety , but only in a private home. Such floors will not cause electric shock, and the worst thing that can happen is a leak. But in a private house it is not as critical as in an apartment building. Moreover, even if a leak occurs, then at most the owner’s property will suffer, but not the owner himself, since there is simply no risk of getting burned with hot water;

- saving is also one of the advantages. Water floors will save a lot of natural and financial resources, since the same water will be used as a coolant. You can also warm up the room faster using water floors if the ceiling height is very high;

- compatibility with all floor coverings is also a plus. Indeed, it is only in rare cases that certain coatings cannot be laid over the heating system. And then, if everything is done correctly, then any coating can be laid on top of the water system;

You can combine water heated floors with all floor coverings

- The cost of the water system is low , which will save some money during installation.

But such a system also has disadvantages. For example, during installation you cannot do without pouring the screed, and this is quite hard work that requires certain skills. Plus, the screed will have to be dried before use, and this will add 28 days to the duration of the repair. And during this period nothing can be done in the room being repaired. Another disadvantage is the difficulty of repairing the system itself if necessary. So it’s important to do everything efficiently from the beginning in order to avoid troubles over a long period of time.

Total costs for underfloor heating systems over 5 years

Calculation of a warm water floor

Before installation and purchasing materials, it is necessary to calculate the heated floor. To do this, draw a diagram with contours, which will later be useful when carrying out repair work in order to know the position of the pipes.

- If you are sure that furniture or plumbing will always be in a certain place, pipes are not laid in this place.

- The length of a circuit with a diameter of 16 mm should not exceed 100 m (the maximum for 20 mm will be 120 m), otherwise the pressure in the system will be poor. Thus, each circuit approximately occupies no more than 15 square meters. m.

- The difference between the lengths of several circuits should be small (less than 15 m), that is, they should all be of uniform length. Large rooms, accordingly, are divided into several circuits.

- The optimal pipe laying pitch is 15 cm when using good thermal insulation. If in winter there are often frosts below -20, then the step is reduced to 10 cm (only possible near external walls). And in the north you cannot do without additional radiators.

- With a laying step of 15 cm, the pipe consumption is approximately 6.7 m for each square of the room, when laid every 10 cm - 10 m.

In general, the question of how to calculate a warm water floor requires separate consideration, since many nuances are taken into account when designing: heat loss, power, etc.

The graph shows the dependence of the flux density on the average coolant temperature. The dotted lines indicate pipes with a diameter of 20 mm, and the solid lines indicate 16 mm.

The graph shows data that is valid only when using a 7 cm thick cement-sand screed covered with tiles. If the thickness of the screed is increased, for example, by 1 cm, then the heat flow density decreases by 5-8%.

- To find the flux density, the amount of heat loss in the room in Watts is divided by the area where the pipes are laid (the distances from the walls are subtracted).

- The average temperature is calculated as the average value at the entrance to the circuit and the return exit.

The optimal temperature at the inlet and outlet should not differ by more than 5-10 degrees. The maximum coolant temperature should not exceed 55°C.

To calculate the length of the circuit, the active heating area in square meters is divided by the laying step in meters. To this value add the size of the bends and the distance to the collector.

Using the above diagram, you can only perform a rough calculation and make final adjustments using the mixing unit and thermostats. For accurate design, be sure to contact professional heating engineers.

Design and principle of operation

For water heating of a heated floor, a system of pipes is used through which the coolant circulates. Most often, pipes are poured into a screed, but there are dry installation systems - wooden or polystyrene. In any case, there is a large number of small cross-section pipes laid under the floor covering.

Where can it be mounted?

Due to the large number of pipes, water heating is done mainly in private homes. The fact is that the heating system of early high-rise buildings is not designed for this heating method. It is possible to make a warm floor using heating, but there is a high probability that either your place will be too cold, or your neighbors above or below will, depending on the type of power supply to the system. Sometimes the entire riser becomes cold: the hydraulic resistance of the water floor is several times higher than that of a radiator heating system and it can block the movement of the coolant. For this reason, it is very difficult to obtain permission from the management company to install a heated floor (installation without permission is an administrative offense).

Water-heated floors require a large number of small-diameter pipes

The good news is that in new buildings they began to make two systems: one for radiator heating, the second for water heated floors. In such houses, permission is not required: the corresponding system was developed taking into account higher hydraulic resistance.

Principles of organization

To understand what you need to make a water heated floor with your own hands, you need to understand what the system consists of and how it works.

Adjusting the coolant temperature

In order for your feet to feel comfortable on the floor, the temperature of the coolant should not exceed 40-45°C. Then the floor warms up to comfortable values - about 28°C. Most heating equipment cannot produce such a temperature: at least 60-65°C. The exception is condensing gas boilers. They show maximum efficiency at low temperatures. From their output, the heated coolant can be supplied directly to the underfloor heating pipes.

When using any other type of boiler, a mixing unit is required. In it, cooled coolant from the return pipeline is added to the hot water from the boiler. You can see the composition of this connection in the diagram for connecting the heated floor to the boiler.

Diagram of a water heated floor

The operating principle is as follows. The heated coolant comes from the boiler. It goes to a thermostatic valve, which, when the temperature threshold is exceeded, opens the admixture of water from the return pipeline. In the photo there is a jumper in front of the circulation pump. A two-way or three-way valve is installed in it. Open it and mix in the cooled coolant.

The mixed flow through the circulation pump enters the thermostat, which controls the operation of the thermostatic valve. When the set temperature is reached, the supply from the return stops; if it is exceeded, it opens again. This is how the temperature of the water heated floor coolant is adjusted.

Contour distribution

Next, the coolant enters the distribution comb. If a water heated floor is made in one small room (a bathroom, for example), in which only one loop of pipes is laid, this unit may not exist. If there are several loops, then it is necessary to somehow distribute the coolant between them, and then somehow collect it and send it to the return pipeline. This task is performed by the distribution comb or, as it is also called, the underfloor heating manifold. Essentially these are two pipes - supply and return, to which the inputs and outputs of all underfloor heating circuits are connected. This is the simplest option.

Heated floor mixing unit with the ability to automatically maintain temperature

If the heated floor is installed in several rooms, then it is better to install a collector with the ability to regulate the temperature. Firstly, different rooms require different temperatures: some prefer +18°C in the bedroom, others need +25°C. Secondly, most often, the circuits have different lengths and can transfer different amounts of heat. Thirdly, there are “internal” rooms - in which one wall faces the street, and there are corner ones - with two or even three external walls. Naturally, the amount of heat in them should be different. This is ensured by combs with thermostats. The equipment is not cheap, the circuit is more complicated, but this installation allows you to maintain the desired temperature in the room.

There are different thermostats. Some control the air temperature in the room, while others control the floor temperature. You choose the type yourself. Regardless of this, they control servomotors mounted on the feed comb. Servomotors, depending on the command, increase or decrease the flow area, regulating the intensity of the coolant flow.

Theoretically (and practically it happens), situations may arise when the supply to all circuits is cut off. In this case, the circulation will stop, the boiler may boil and fail. To prevent this from happening, be sure to create a bypass through which part of the coolant passes. With this system design, the boiler is safe.

You can watch one of the system options in the video.

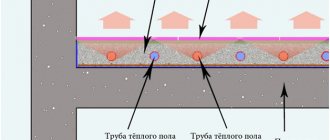

Warm floor pie

The technology for laying a warm water floor consists of several layers, which are laid in a certain sequence. The total thickness of the cake is 8-14 cm, the load on the floors is up to 300 kg/sq. m.

If the base is a concrete slab:

- waterproofing;

- damper tape around the perimeter;

- insulation;

- reinforcing mesh;

- water heated floor pipe;

- screed

For waterproofing, it is permissible to use ordinary polyethylene film or special materials. Damper tape is made from cut strips of thermal insulation 1-2 cm thick, or you can buy a ready-made version with a self-adhesive base. The choice of insulation depends on several factors: region, base material. For example, for floors on the ground, extruded polystyrene foam with a thickness of at least 5 cm (optimally 10) is used, and if there is a warm base under the floor of the first floor, then thinner options from 3 cm can be used.

The main purpose of insulation is to direct the heat from the heating upward and prevent large heat losses.

If the base is ground floors:

- bulk soil 15 cm;

- crushed stone 10 cm;

- sand 5 cm;

- rough screed;

- waterproofing;

- damper tape around the perimeter;

- extruded polystyrene foam at least 5 cm;

- reinforced screed with coolants.

It is important to carefully compact the preparatory layers for the rough screed layer by layer. If the base is compacted tightly and extruded polystyrene foam is used, it will not be necessary to make a rough screed.

Design

Installing a water circuit in cottages with gas boilers is considered a particularly profitable and optimal solution. This design is less expensive in terms of energy consumption and is easy to operate, making it the most efficient.

The system can work flawlessly only if there is a professionally designed project and proper installation.

Therefore, before you start installing water heating in a frame house or in a country house, the first thing you need to do is prepare a project. When drawing up a project, you should consider the type of material that will fit into the “pie” and the thickness of each layer.

In addition, it is necessary to prepare a pipe placement plan. You can draw the diagram on a regular sheet of paper with a box, where each box will be a step in laying out the contour.

The step depends on the climatic characteristics of the region. In temperate climates:

- with good thermal insulation in the house - step 20 cm;

- in the absence of high-quality insulation of walls made of brick, concrete or wood - 10 cm;

- in large rooms, in the presence of warm and cold walls, the step taken is different, for warm walls it is larger, for cold walls it is smaller.

Installation of heated floors

Let's say a good foundation has already been prepared: a flat concrete slab or backfill layer without strong drops. Differences should not exceed 7 mm when checking with a two-meter rod. If there are uneven spots, they can be filled with sand.

Waterproofing

Some people put waterproofing under the bottom of the insulation, some, on the contrary, at the top, and some use both. If extruded polystyrene foam is used, it practically does not need waterproofing, so its position is not so critical. But it will not allow cement laitance to penetrate between the seams of the insulation and go into the slab and will additionally hold back moisture from below. If you attach it to the bottom of the insulation, then you can attach the pipes to the heated floor directly to the insulation. If the waterproofing is laid on top, then laying a mounting mesh will be required to secure the pipes.

We lay the waterproofing with an overlap of 20 cm on the walls and on each other. We glue the joints with tape to seal.

Damper tape

If you bought ready-made tape, simply glue it around the perimeter. It usually has a thickness of 5-8 mm and a height of 10-15 cm. The height should be above the pouring level, the excess is cut off with a knife. If the tape is made by yourself, then be sure to glue or screw it to the wall with self-tapping screws.

The linear expansion of concrete is 0.5 mm per meter when heated to 40°C.

Insulation

Sheet insulation for a warm water floor is laid with offset joints so that it is tightly connected.

Reinforcement

The first layer of reinforcing mesh is usually laid on the insulation and used as a base for attaching the contours and uniformly distributing heat over the surface. The meshes are tied together with wire. The pipes are attached to the mesh using nylon clamps.

The diameter of the mesh rods is 4-5 mm, and the cell size depends on the pipe laying pitch, for convenient fastening.

In addition, it is imperative to lay the reinforcement on top of the pipes, since even when using a mesh from below, it will have almost no effect if it lies at the very bottom. Or, during pouring, place the mesh on stands, creating a gap.

Pipe fixation methods

A water heated floor can be laid in several ways, we list them.

- Polyamide tension clamp. Used for quick fastening of pipes to the mounting grid. Consumption – approximately 2 pieces per 1 m.

- Steel fastening wire. Also used for mounting to a grid, the consumption is exactly the same.

- Stapler and clamps. Suitable for quickly fixing pipes to thermal insulation. The consumption of clamps is 2 pieces per 1 m.

- Fixing track. It is a U-shaped PVC strip that serves as a base for laying 16 or 20 mm pipes into it. Rigidly attached to the floor.

- Mats for warm water floors made of polystyrene. A pipe is laid in the middle of the grooves between the posts.

- Aluminum distribution plate. Used when installing on wooden floors, it reflects and evenly distributes heat over the surface.

Application of various types of pipe fasteners

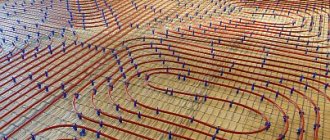

Pipe laying

The pipes are laid with a distance of 15-20 cm from the walls. It is highly advisable to make each circuit from a single pipe without welding, and their length should not be more than 100 m. The pitch between the pipes near the walls is 10 cm, closer to the center - 15 cm.

The layout of a heated floor can be different, for example, a spiral or a snake. On external walls, they try to make the laying step more frequent or draw a contour from the feed next to cold walls. An example of a circuit for enhanced heating of external walls is shown in the photo; this option is best used in cold regions:

In other cases, the contours are usually laid in a spiral (snail), this is a universal option.

In places with a large accumulation of pipes, in order to avoid overheating of the surface, some of them are covered with a heat-insulating tube.

Metal-plastic 16 mm and 20 mm are easy to bend manually, without the use of special tools. In order to bend the pipes evenly with an angle of a small radius and at the same time prevent it from cracking, the corners are bent in several passes (hand interceptions). At an angle of 90° you will need approximately 5-6 interceptions. This means, first, resting your thumbs, make a slight bend, then move your hands slightly towards the bend and repeat the actions.

It is unacceptable to have kinks on the pipes in places of sharp turns.

Polypropylene pipes are much more difficult to bend because they are springy. Therefore, to bend them, they are heated or welded using special fittings, but in the case of heated floors, they are simply attached to the mesh, making the bends less sharp.

Installation of a water heated floor begins by connecting the first end of the pipe to the distribution manifold, and after laying the room, immediately connect the return (second end).

Connecting circuits

In most cases, the circuits are connected through a distribution node. It has several functions: increasing the pressure in the system, adjusting the temperature, uniform supply to several circuits, and combining with radiators.

There are many connection schemes to the boiler, which we wrote about in the article about pumping and mixing units: with manual adjustment, with weather automatics and automatic adjustment using servo drives and sensors.

Eurocone fitting

The pipes are connected to the manifold using Eurocone clamp fittings.

Crimping

When you have completed the installation of all circuits, be sure to conduct pneumatic tests of the system for leaks. To do this, crimping is done using a compressor. A small household compressor with a pressure of more than 6 bar is suitable for testing. The pressure in the system is brought to 4 bar and left for the entire time until the system is started.

Since air molecules are much smaller than water molecules, even small depressurization can be detected. In addition, the water may freeze if you do not have time to turn on the heating, and nothing will happen to the air.

Installation errors and their consequences

Strict adherence to the recommendations of specialists when installing heated floors yourself is an important condition for the successful functioning of the system.

Most often, beginners make the following mistakes:

The height difference between the beginning and end of the pipe. If it exceeds half the diameter of the pipes, air pockets will form inside. As a result, the circulation of the coolant will be difficult and the quality of heating will decrease. To prevent this from happening, it is important to place the pipes strictly parallel to the floor.- Connection of pipes within one circuit. There is no point in installing a circuit of 2 pipe sections and filling it with concrete. This may cause leakage. Each circuit must consist of a whole piece of pipe. Connections should only be made to the collector group.

- Neglect of hydraulic testing. A test run of the system at maximum pressure must be carried out before pouring concrete into the pipes. Otherwise, it will be almost impossible to find a leak, if one occurs.

- Pouring screed onto empty pipes. The concrete pushes through the pipe material and the circulation of the coolant will subsequently be difficult.

- Premature heating start. Heating the pipes until the concrete gains strength will lead to cracking of the screed.

Heated floor screed

Filling the screed is done only after installation of all circuits and hydraulic tests. It is recommended to use concrete of at least M-300 (B-22.5) with crushed stone with a fraction of 5-20 mm. The minimum thickness of 3 cm above the pipe is done not only to obtain the required strength, but also to distribute heat evenly over the surface. Weight 1 sq. m of screed with a thickness of 5 cm is up to 125 kg.

If the screed thickness is more than 15 cm or under high loads, additional calculation of the thermal regime is required.

As the thickness of the screed increases, it takes more time to heat it up to a certain temperature after switching on, and the inertia of the system also increases. The lower the thermal conductivity of the screed, the higher the coolant temperature will need to be set.

Expansion joints

Examples of dividing a large room into zones

The absence or incorrect position of temperature gaps is the most common cause of screed failure.

Shrinkage seams are made in the following cases:

- the room has an area of more than 30 sq. m.;

- the walls are more than 8 m long;

- the length and width of the room differ by more than 2 times;

- above expansion joints of structures;

- The room is too curved.

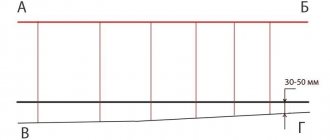

To do this, a damper tape is laid around the perimeter of the seams. At the seam site, the reinforcing mesh must be separated. The deformation gap should be 10 mm thick at the base. The upper part is treated with sealant. If the room has a non-standard shape, it needs to be divided into simpler elements of a rectangular or square shape.

If pipes pass through expansion joints in the screed, in these places they are laid in a corrugated pipe, 30 cm of corrugation in each direction (according to SP 41-102-98 - 50 cm on each side). It is recommended not to separate one circuit with expansion joints; supply and return pipes should pass through it.

Correct passage of contours through technological seams

When laying tiles on expansion joints, the likelihood of them peeling off increases due to different expansion of adjacent slabs. To avoid this, the first part is laid with tile adhesive, and the second part is attached with elastic sealant.

For additional separation, partial profile expansion joints can be used. They are made using a trowel, 1/3 of the thickness. After the concrete has hardened, they are also sealed with sealant. If pipes pass through them, they are also protected with corrugation.

Cracks in the screed

A fairly common occurrence is the appearance of cracks on the screed after drying. This can be caused by a number of reasons:

- low density of insulation;

- poor compaction of the solution;

- absence of plasticizers;

- the thickness of the screed is too thick;

- absence of shrinkage seams;

- concrete drying too quickly;

- incorrect proportions of solution.

It's very easy to avoid them:

- insulation should be used with a density higher than 35-40 kg/m3;

- the screed solution must be plastic when laying and with the addition of fiber and plasticizer;

- in large rooms you need to make shrink seams (see below);

- You should also not let the concrete set quickly; to do this, cover it with plastic wrap the next day (for a week).

Screed mortar

For heated floors, it is necessary to use a plasticizer to increase the elasticity and strength of concrete. But you need to use special types of non-air-entraining plasticizers for heated floors.

Without experience, it will not be possible to make a cement-sand screed for a warm floor without crushed stone/gravel, and the correct branded DSP will cost more than factory-made concrete. Therefore, in order to avoid cracks due to a violation of the composition of the solution, concrete with crushed stone is poured.

Mortar M-300 from cement grade M-400, washed sand and crushed stone is made according to the following proportions.

- Mass composition C: P: Shch (kg) = 1: 1.9: 3.7.

- Volumetric composition per 10 liters of cement P: Shch (l) = 17:32.

- From 10 liters of cement you will get 41 liters of solution.

- The volumetric weight of such M300 concrete will be 2300-2500 kg/m3 (heavy concrete)

There is also another option using granite screenings instead of sand; the following elements were used for its preparation:

- 2 buckets of crushed stone with a fraction of 5-20 mm;

- water 7-8 liters;

- superplasticizer SP1 400 ml of solution (1.8 liters of powder is diluted in 5 liters of hot water);

- 1 bucket of cement;

- 3-4 buckets of granite screenings with a fraction of 0-5 mm;

- bucket volume – 12 liters.

High-quality concrete should not release water during installation (delaminate). If everything is done correctly and the air temperature is 20°C, it should begin to set after 4 hours, and after 12 hours it will not leave marks from heels.

3 days after pouring, the screed will gain half its strength, and will harden completely only after 28 days. It is not recommended to turn on the heating system before this point.

TVP Installation Guide

Before laying the heated floor structure, you should carry out preparatory work: purchase components, mark the installation location of the cabinet, drill holes in the walls for communications. Then you can proceed to the first stage.

Step #1 - subfloor installation

If you plan to install a heated floor directly on the ground, it is recommended to choose one of two options:

- make a “rough” screed from cement pouring;

- instead of screed, pour, compact and level a layer of sand.

A layer of sand will be required in any case, since it also serves as the basis for the screed. A layer of waterproofing is placed on it, the most basic option is a thick polyethylene film.

Compaction and leveling of the sand layer is very important. Small depressions up to 5 cm deep are allowed, but for pipe installation it is better if it is perfectly smooth

When making calculations, it should be remembered that heat loss when installing the system on the ground is higher, therefore, the temperature of the coolant in the pipes should be higher than usual.

Step #2 - laying a heat-insulating layer

The insulation is laid on a clean, level floor. Before starting work, a strip is cut on the walls - the level of the clean floor; small depressions, if they were formed during the construction work, are filled with clean, dry sand.

Installation instructions:

- Spread the waterproofing - lay sheets of film with a density of 150-200 microns with an overlap of at least 10 cm and wrap them on the walls.

- Lay the slabs of extruded polystyrene foam with the markings facing up, joining the grooves together. It's better to start from the far corner.

- If necessary, cut out fragments with a construction knife.

- Secure the slabs with disc dowels at the corners, along the middle of the joints and in the center of the slabs.

- Seal the seams with construction tape.

If laying a second layer is required, then it is better to change the direction of the upper slabs, that is, lay them perpendicular to the lower ones.

When laying, avoid large gaps and cracks. If they do form, the voids can be blown out with foam or covered with scraps of polystyrene foam

To move on the slabs during installation, it is recommended to use thin boards or pieces of plywood - the structure of the slabs, despite their density, can be deformed.

Step #3 - marking and placing pipes

Markings are applied to the surface of the slabs using a marker or paint cord. If profile mats are used instead of EPS, markings will not be required.

There is a risk of bending and twisting of the pipe when unwinding, so it is better to use a special device for unwinding the coil. It will take longer to unwind manually

Before starting pipe installation, it is also recommended to install collectors and prepare places for connections.

Installation instructions:

- Unwind 15-20 m from the pipe, put a heat-insulating sleeve and a fitting on the end for connection.

- Connect to the collector.

- Carefully lay the pipe according to the markings.

- Secure the outline with harpoon staples.

- Bring the pipe to the manifold and connect the other end.

The length of each loop must be recorded, and not just remembered, but written down near the fitting on the wall.

A damper tape or some substitute is placed along the edges - for example, pieces of foam plastic 1.5-2 cm thick. They hold up well on liquid nails

Transit pipes passing through walls or transition zones are insulated as much as possible with sleeves. Instead of expensive imported products, you can use ordinary insulation - foamed polyethylene.

Step #4 - installation of reinforcing mesh

Properly laid fittings should be located above the pipes, not under them or between them. An acceptable option is a metal mesh with a 10*10 cm cell made of 3 mm wire.

It is also incorrect to fix the contours to a metal mesh; in this case, it will serve as a stand, not reinforcement. Proper installation - when the mesh is above the pipes

Nowadays, many people use plastic mesh instead of wire mesh. This option is also suitable, since the polymer creates the necessary rigidity.

Step #5 - system testing

Until hydraulic tests have been carried out to check the tightness of the system, the screed cannot be poured. Usually the circuits are checked one by one.

First, a main line and a pump are connected to the pipe, and water is supplied. For drainage, use a hose connected to the drain pipe of the manifold.

A pressure test pump is the best tool for testing the system. It can be rented. You can also hire a specialist for testing, who usually has the necessary tools

During inspection, staples may fly off as the pipe tends to straighten under pressure. The harpoons that fly off are attached 5 cm from their original place; after pouring the screed, they will no longer fly off.

Step #6 - laying cement screed

The pipes are left under a pressure of 5 bar and the screed is laid. Usually the traditional beacon method is used. You can use a metal profile for drywall as beacons.

A regular screed solution is not suitable; plasticizers and fiber must be added to the cement, since the load will be not only mechanical, but also temperature

Laying is done in parts, starting from the far corner. Immediately after pouring, each fragment must be leveled, dips and sagging must be eliminated.

After 2 days, the surface is cleaned, the damper tape is cut, the screed is sprayed with water and covered with film (the last two steps are repeated for 10 days).

Installation on a wooden floor

Wood does not conduct heat as efficiently as concrete, but installation on it is also feasible. For this purpose, distribution plates made of aluminum are used. The pipes are laid in wooden grooves made by attaching pre-prepared boards.

For installation of linoleum, carpet and other materials that require a flat surface, a leveling layer of chipboard, plywood or gypsum fiber board is laid over the pipes. If parquet or laminate is used as the finishing coating, the design of the heated floor can be slightly simplified, without the use of a leveling layer.

When choosing plywood and chipboard, make sure that they have sanitary, hygienic and thermomechanical characteristics that allow them to be used together with heated floors.

Methods for laying the contour

There are three main ways to lay a circuit in a private house with your own hands, but they all have one thing in common - the pipes are mounted from the walls towards the center:

- “Snail” - the contour is laid in a spiral from the walls to the center, and back. At the same time, the structure tapers towards the center of the room. When drawing up a diagram, you should remember that you need to leave space between the pipes for them to return to the supply source. Using this scheme, the heating of the floor covering is uniform, while the level of hydraulic resistance is reduced. The amount of pipe material with this installation is less than with other methods. The main disadvantage is complicated installation.

- “Snake” - pipes are placed along the walls in the form of loops. The option is easy, but with it it is not possible to achieve uniform heating of the floors, since the temperature at the entrance and exit differs significantly.

- Combined method - it combines both schemes. Suitable for rooms with cold walls. The contour is laid along the walls in a “snake” pattern, and along the . This method allows you to save on pipes and increase the energy efficiency of the device.

Accessories

Upon completion of the calculation part, they begin to select individual elements of the system. Materials for water heated floors include the following components:

- Pipes. Necessary for transporting coolant and transferring thermal energy into the room. The best choice is products made of cross-linked polyethylene with a protective airtight shell. They are equipped with connecting fittings.

- Control and distribution devices. Manifolds serve to uniformly distribute liquid over individual circuits. The package must include a thermostat and liquid flow limiting devices. For external control, a controller for a heated floor is required - a thermostat.

- Heating boiler. Coolant heating source. Power is calculated according to the parameters of the heated floor. It should not be less than the total nominal value of the entire system.

- Security group. This includes bypasses, pressure valves and measuring instruments - pressure and temperature sensors.

The selection of materials and components should also be carried out by specialists. You should not skimp on the services of professionals - heated floors instead of radiators will be the only source of heat in the house. Therefore, the system must work reliably and quickly respond to changes in outside temperature.

When drawing up a project, it is recommended to provide for the installation of air temperature sensors not only in individual rooms, but also on the street. They are connected to a common control unit. Its settings will allow you to set different thermal modes depending on changes in external factors. These are not required components, but their presence will help optimize the operation of the entire system. The main advantage will be a reduction in energy costs.

Steam and waterproofing

When using the “wet” method of installing heated floors on floors, if the architectural and construction part of the project does not provide for vapor or waterproofing, it is recommended to lay a layer of glassine over the leveled floor to prevent the flow of cement milk through the floor during pouring the screed, as well as to avoid the formation of condensation between the insulation and the concrete base.

If the project provides for an interfloor vapor barrier, then additional waterproofing is not necessary.

In wet rooms (bathrooms, lavatories, showers, etc.), in addition to the vapor barrier under the insulation, waterproofing is installed in the usual manner on top of the heated floor screed.

Many suppliers of underfloor heating system elements recommend laying a layer of aluminum foil on top of the insulation layer. Ready-made foil-coated thermal insulation mats and slabs are also produced.

In cases where heated floor pipes are installed in an air gap (for example, in floors along joists), foiling the thermal insulation makes it possible to reflect most of the radiant heat flow directed downwards, thereby increasing the efficiency of the system. The same role is played by foil when constructing porous (gas or foam concrete) screeds.

If the screed is made from a dense cement-sand mixture, foiling the thermal insulation can only be justified as additional waterproofing, since the reflective properties of the foil cannot manifest themselves in this case due to the absence of an air/solid boundary.

It must be borne in mind that the layer of aluminum foil poured with cement mortar must have a protective coating of polyethylene film, otherwise, under the influence of the highly alkaline environment of the cement mortar (pH = 12.4), the aluminum will quickly collapse.

Design for a private house

Neglecting this rule may cause negative consequences. This is explained by the constant movement of the soil and, accordingly, all the layers located above. Movements can be observed even on compacted and compacted soil that has been lying unloaded for a long time.

After laying a heated floor cake, which has a fairly impressive mass, cracks may form due to subsidence. The most negative consequence may be the tearing of the elements of the heated floor, that is, all the costs for its arrangement will be in vain.

Selection of pipes for floor heating

Contrary to popular belief, the choice of pipes for installing a heat exchanger in the floor is not so wide. There are two options: cross-linked polyethylene and copper. The most obvious advantages of special materials are durability, resistance to deformation, and a low coefficient of linear expansion. But the main advantage is the oxygen barrier, which ultimately prevents the formation of sediment on the inner surface of the pipes.

The purpose of using copper is the high thermal conductivity of the tubes and resistance to corrosion. An obvious disadvantage is the complexity of installation and the high risk of failure if there are solid particles (sand) in the coolant. Despite the fact that all you need for soldering is an inexpensive gas lamp and flux, bending the coil correctly is a difficult task. This is despite the fact that there can be several dozen turns of the copper tube and one mistake, resulting in a break, leads to the failure of the entire segment or the need for additional soldering.

Polymer (polyethylene) tubes have a higher coefficient of thermal expansion; in addition, they lose their strength properties when heated above operating temperatures, however, in heated floors, in principle, the coolant does not heat up above 40 °C. Ease of installation is an obvious plus. It bends easily and is laid in a spiral or coil. The pipe is supplied in coils of 200 m, allowing you to lay warm floors without a single connection throughout the entire volume of the future screed. Most branded polyethylene tubes require the use of special tools for crimping and welding.