In this article we will find out when, when installing a heating system, you need to use a wall mount and when you need to use a floor mount for heating radiators. We will get acquainted with the types of fasteners, with the methods used for fixing heating devices and learn how you can install radiators with your own hands in each case.

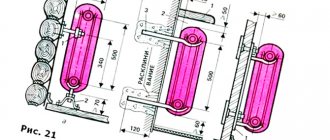

One of the ways to install a radiator.

Marking tips

The most correct way would be to place the radiator in the center of the window opening. You need to calculate the middle and mark the vertical in this place with a level. Subsequent marking will depend on the wiring. Namely:

For lower wiring, it is necessary to mark the upper limit of the installation of the heating device (a horizontal line that is parallel to the floor surface). With a lateral connection, the location where the supply pipe is located (often the top one) plays a big role. Therefore, we mark the horizontal line along the axis of the supply pipe. You need to measure the gap between the attachment points on the battery and transfer it to the marked horizontal lines.

For correct and high-quality installation of the heating device, you need to select the necessary bracket.

Types, design and application of fasteners

Wall mounting

Here, manufacturers do not spoil us with variety: wall mounting brackets come in only two varieties.

The product is suitable for lightweight aluminum batteries.

This type of fastener has a greater load-bearing capacity.

Please note: it is better to hang massive cast iron heating devices on pin brackets.

crazy hands

If for some reason you do not have the opportunity to purchase a mounting kit for wall mounting of a radiator, the situation can be saved by ordinary smooth fittings with a diameter of 10 - 12 millimeters.

Mounting for cast iron batteries

Cast bracket for cast iron radiator, cast iron

When installing brackets for radiators made of cast iron, you should be extremely careful. Before starting work, you need to make all the calculations and double-check them several times. After all, the radiator material is quite heavy, and because of this, even the most seemingly insignificant error can cause unpleasant consequences. When installing a radiator, you need to use an adjustable bracket for heating radiators made of thick cast iron. Using just such a device is very important, because it makes it possible to change the distance between the heating device and the wall.

The method of attaching cast iron radiators to the wall depends on the base material. In the case of a plasterboard or wooden base, in addition to brackets for cast iron batteries, there must be a stand, the function of which is to compensate for the large weight of the device.

You can mark the points for future holes yourself, but you will need a partner to install the heating device, especially if the battery has several sections. To be sure of the quality of the fasteners, experts advise purchasing brackets for attaching heating radiators to the wall from Germany or Austria. Their price, of course, is a little higher, but you don’t have to worry about their reliability.

Adjustable floor bracket for cast iron radiators made of steel

General information

Structurally, floor radiators are no different from their counterparts – wall-mounted units. The difference lies only in the method of their installation, as well as in the design, which includes some innovations.

However, the need to change the method of installation and fastening of radiators arose not only because of the desire of manufacturers to create something new. As you know, there is nothing more eternal than cast iron, and this statement is still relevant. Just imagine how much a battery from it will weigh, especially a working one?

In the photo - hidden floor heating radiators

The wall on which such a load will be attached must be concrete. At the same time, people are now increasingly moving outside the city to private houses, where partitions are often made of plasterboard.

Considering the height and weight of only one section of a cast iron radiator, which is at least 20 kg, it is recommended to install it only on the floor, since the walls may not withstand such a load.

Floor mount for aluminum radiators with chain

The lineup

In the manufacture of radiators, both wall-mounted and floor-mounted, the same materials are used:

- cast iron;

- steel;

- popular in city apartments - bimetal;

- more traditional for private houses - aluminum.

| Cast iron |

|

| Steel | Floor radiators made of steel are produced in several types:

|

| Bimetal | Devices made from this material are popular in city apartments. Bimetal radiators are universal, and they are heavier than aluminum ones. Installation on a wall or floor is carried out using purchased brackets. However, there are also many purely floor-standing options on the market. In the production of such batteries, two materials are used - aluminum and steel. Moreover, the latter is used in the manufacture of pipes through which the coolant passes, and the body is made of the same aluminum. Thanks to the internal structure of such a radiator, it is able to withstand very high pressure in the system. These batteries also have a longer service life.

|

| Aluminum | Typically used for autonomous heating systems. Such devices are lightweight, which makes them universal. By replacing one bracket with another, a wall-mounted radiator can easily turn into a floor-mounted heating device. |

Option for installing a floor cast iron radiator

Positive and negative qualities

The main advantage of a floor radiator is the simplest installation process, which does not require drilling into the wall. In addition, a reliable heating device of sufficiently heavy weight can be installed on the floor.

There will be no load on the wall, which will ensure its long service life. The legs designed for installing such batteries are also very reliable and can easily support the weight of the device throughout its entire service life.

Reliable floor stand for bimetallic and aluminum batteries

Tip: use a floor radiator to create thermal curtains in places where wall mounting is not possible.

To ensure greater reliability, the floor radiator can be mounted on the floor, for which special brackets are purchased; installation instructions are usually included. The wiring for such devices is hidden and laid under the floor, which significantly improves the appearance of residential premises.

Advice: remember that this process requires deliberate actions and the creation of the necessary conditions to avoid equipment failure.

Steel adjustable floor mount for cast iron radiators

What could be an alternative?

Although the design of modern floor radiators allows them to become an interior decoration, installing them yourself requires free space.

If there is none, and you don’t want to spoil the wall, you should pay attention to other types of heating devices.

- Skirting convectors, which are installed in a niche located in the floor. Such a device is considered the most efficient, since the heat from it comes from below, where the cold air descends. You can cover the niche using a special decorative grille.

Legs for installing cast iron radiators on the floor

- Air-water heating devices, complete with a fan. They can be suspended from the ceiling, directing hot air flows downward.

- Oil heaters, which are also placed on the floor, also effectively release heat. If necessary, such a heater can be moved to the room where it is coldest.

Fastenings for aluminum radiators

Brackets for aluminum radiators must have a certain length. These designs are characterized by fairly low weight and do not have additional elements. Devices made of such material will not withstand heavy and large heaters, so it can be installed on any type of surface.

There is nothing in the installation procedure that cannot be done without help. You just need to correctly mark and fasten the structure to the surface. Whatever the material used as the base of the floor or wall, aluminum radiators do not require additional fastenings.

Adjustable brackets for Rifar radiators

Is it worth it to install radiators yourself?

Many experts do not recommend installing a radiator in a city apartment yourself unless you have good skills in this matter. We are inclined to agree with this opinion for a number of reasons:

- Installing a radiator requires some time, even for experts. If you don't have experience, it will take much longer. And during the period of work it is necessary to turn off the heating throughout the riser. Although, of course, you can postpone everything to the summer, when there is no coolant in the system.

- In addition to time, as we have already said, experience is required. Connecting radiators to a heating system is a very important matter. If you undertighten or overtighten any of the connections a little, and after some time it may lose its tightness. You will flood not only yourself, but also your neighbors with hot water.

- Proper mounting of the battery to the wall is also very important. We will talk about this further.

Attaching bimetallic radiators to the wall

Externally, the brackets for bimetallic heating radiators resemble those that are used when installing a cast iron heater, but they are not made as massive.

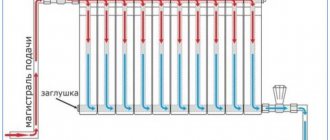

As a rule, they are made in the form of corner universal products. The recess intended for the passage of the collector is made both from below and from above. This makes it possible to install it on the left or on the right.

It is worth saying that bimetallic batteries are not produced in floor-standing versions. However, a universal bracket for floor radiators can be found on the market (if someone wants to make a floor structure out of them).

The fasteners are installed on the floor, and the battery is placed on them. As a rule, such installation is carried out when the interior partitions in the house are made of fragile materials (they can be aerated concrete, plasterboard, etc.), which do not hold various types of fasteners very well.

Glass walls, which are now in fashion, are also not entirely suitable for installing any heating equipment. In such cases, batteries should be abandoned; they can be replaced with warm floors, or tubular heating structures installed on the floor, or retro cast-iron heaters.

Universal radiator bracket for adjustment along and across the wall surface

Types of fastenings

The industry produces many variations of brackets that securely fix heating devices and ensure trouble-free operation. All of them are divided into the following types by design:

Photo 1. Three types of universal floor brackets for heating radiators with adjustable elements.

Attention! If there are differences in the height of a multi-level floor, adjustable brackets will simplify the installation and horizontal alignment of heating radiators.

Steel battery brackets

Speaking about fastenings for steel radiators, it is worth knowing that the group is divided into two more large groups. The first includes panel heating devices. In the second - tubular type batteries. They require different types of fasteners.

The batteries of the first group have welded brackets (on the side facing the wall of the room). They make it possible to hang them on installed hooks. Brackets for panel-type heating equipment are distinguished by a special shape, which is designed specifically for the brackets discussed earlier.

Installation of such batteries implies strict control of the vertical position of the room, since at least four brackets must be immediately placed on the hooks at the same time. Because of this, when deciding on the installation of panel heaters, the previously indicated scheme is not used as often as standard brackets for panel radiators (the classic representative is LK-KS 30-50).

Remember that the choice of brackets for mounting heating radiators to a wall or floor depends on the material of the heating device. After installation, the batteries should be connected to each other using pipelines, and finally to the boiler.

Selection of brackets for radiators

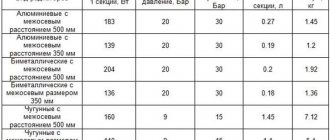

When choosing fasteners to be used when installing heating radiators, it is necessary to take into account some features of both the heating devices and the rooms in which they will be installed. By design, radiator brackets can be designed for mounting batteries on straight and corner sections of walls. Their shape (degree of curvature and structure) must correspond to the configuration of battery sections of different types. Radiator brackets also differ in the material of manufacture, which directly affects the maximum permissible loads:

- for heavy cast iron structures, fastenings must be massive, durable, made of high-quality steel;

- for less massive aluminum and bimetallic products, more elegant radiator brackets made from durable light alloys are quite suitable.

Functions and types of mounts for radiators

Fastening systems are designed for rigid fixation of radiators, thereby preventing damage to heating lines.

Reliable fastening maintains the functionality of heating circuits and fittings throughout the entire period of operation .

Batteries that are mounted in a vertical position will have maximum efficiency and will create a dense thermal curtain that separates the room from cold air flows from the window.

Cast iron appliances have a large mass and exert a load of 10-20 kilograms per fastener and point on the wall , so it is important to select products taking into account the intended method of installing radiators. Combined fastening systems will be an excellent option for private houses and apartment buildings.

Cast iron brackets

Solid cast iron fasteners are strong, durable and able to support very heavy weights . Brackets made of this material are in demand when installing cast iron equipment and heavy building heating systems.

Important! In addition to the fact that cast iron pins must be of high quality, they must be installed correctly on the wall to ensure reliable operation of the heating circuits.

Steel fasteners on strip and with pin reinforcement

Fasteners on a steel strip are quite easy to install and provide reliable support for radiators throughout the entire period of operation.

The strip can be attached to concrete and wooden walls . To install batteries consisting of less than 10 sections steel fastening strips will be sufficient

Steel fasteners with pin reinforcement are mounted into the wall using special dowels , which provide increased wear resistance and resistance to shape changes and sagging. Durable steel parts are perfect for mounting both lightweight batteries and cast iron radiators.