Organizing a heating system for a large commercial or industrial premises is not an easy task. If the area of the room is really large, a classic heating system simply will not be able to heat it efficiently. The use of additional heating devices is accompanied by additional financial costs, which is not always acceptable or justified.

Is there equipment that can efficiently heat large rooms while consuming a minimum of energy resources? Yes, it exists. One of the options that is definitely worth paying attention to is a heating system using water fan heaters.

Water fan heaters are modern heating equipment that is ideally suited for servicing large premises. Water fan heaters allow you to use the best capabilities of two heating systems - water and air.

Where can water heaters be used?

Water fan heaters are rarely used to service private houses and apartments. For this task, there are a lot of devices that are more practical in terms of installation and operation. Water fan heaters are considered industrial heating equipment. They are installed in commercial, industrial and public premises of medium and large areas.

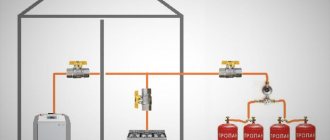

To organize such a heating system at a facility, two conditions are necessary: the presence of a water heating system and electricity at the facility.

A heating system based on water fan heaters allows high-quality, uniform and economical heating of the halls of supermarkets, shops and shopping centers, car showrooms, industrial premises (workshops, workshops), warehouses, hangars, gyms, large office premises, etc. With an air-water heating system There is a big plus - water fan heaters do not “burn” oxygen and do not dry out the air. For this reason, they are actively used to create an optimal microclimate in greenhouses, greenhouses and botanical gardens.

Thermaltake NiC C5 CLP0608

As we already mentioned in the introduction of today’s article, Thermaltake has released four coolers of the new NiC line. Model C5 (CLP0608) is the oldest and most expensive of them. The NiC (Non-interference Cooler) series of coolers is designed specifically for systems with memory modules equipped with high radiators, which have recently become very popular.

The box, made of thick cardboard, is no less informative than that of Phanteks. Here are technical specifications, a description of key features with photographs, and a list of supported platforms.

Inside the cardboard box there are soft polyurethane inserts in the shape of the cooler, in which it is fixed. Accessories are sealed in a separate box. These include steel guides and a set of fasteners, a plastic reinforcing plate, as well as instructions and thermal paste.

The Thermaltake NiC C5 costs $5 more than the Phanteks, which is $55. The cooling system comes with a three-year warranty. Country of origin: China.

Thermaltake NiC C5 is a bright and catchy mid-sized cooler. The red fan frames contrast with the black impellers and black plastic “shells” that cover the radiator.

You simply can’t help but pay attention to such a cooler. Its height is 160 mm, width is 148 mm, and thickness is only 93 mm, which is really not much for a cooler with two fans.

The fans are set to blow-in and blow-out and are secured in plastic shells that leave the sides of the radiator open...

...as well as its top and bottom in the heat pipe areas.

The radiator itself is made of 52 aluminum plates 0.4 mm thick, pressed onto heat pipes with an interfin distance of 1.7 mm.

The area of this radiator is slightly larger than that of the Phanteks PH-TC12DX - it is 5780 cm2.

Five six-millimeter nickel-plated heat pipes are soldered to the base in grooves in which they are laid without gaps.

The nickel-plated copper plate measures 40x40 mm and has a minimum thickness of 1.5 mm (under the tubes) and is perfectly polished.

However, unlike the Phanteks base, its evenness leaves much to be desired. The bulge in the center of the base did not fail to affect the usefulness of the contact between the cooler radiator and the processor heat spreader.

Two fans of standard size 120x120x25 mm rotate synchronously and are equipped with a speed controller.

It is installed on a short cable extending from the three-pin connector for connecting fans to the motherboard.

In our opinion, this method of adjustment is inconvenient, since to change the fan speed you will have to open the system unit case each time. As for the fans themselves, they are interesting in the shape of the blades, consisting of two sail-shaped halves.

The description of Thermaltake NiC C5 does not explain this solution in any way, which is strange, because marketers are so fond of such “features”. In our opinion, these blades are made to increase the pressure of the air flow pumped between the fins of the radiator, because the NiC C5 has a relatively dense air flow.

The fan speed can be adjusted from 1000 to 2000 rpm. Maximum airflow is stated at 99.1 CFM, static pressure is 2.99 mm H2O, and noise levels should range from 20 to 39.9 dBA.

The 40mm stator sticker shows the name of the fan model and its electrical characteristics.

With 3.8 W stated in the specifications for each “turntable,” one fan consumed a little more than 4 W, which is twice as much as Phanteks. But the starting voltage turned out to be slightly lower - 3.8 V. Cable length - 300 mm. The bearing is ordinary - sliding, with a standard service life of 40,000 hours, or more than 4.6 years of continuous operation.

The installation procedure for NiC C5 is described in detail in the instructions, but in our case - for a platform with an LGA2011 connector - it is no different from installing the Phanteks PH-TC12DX.

Once installed on the board, the distance to the bottom edge of Thermaltake NiC C5 is only 36 mm.

However, as we mentioned above, it is narrower than most other dual-fan coolers, so it is unlikely to interfere with the installation of RAM modules with tall heatsinks.

Thermaltake is only 3 mm taller than Phanteks, so it will most likely fit into narrow system unit cases without any problems.

Well, in our opinion, it looks more attractive. However, it depends on the taste and color, as they say...

How does a water fan heater work and how does it work?

The water fan heater consists of a housing (box), a copper-aluminum radiator-heat exchanger and a powerful fan. The heat exchanger and fan are installed inside the box. There are blinds on the outside of the box through which warm air comes out. The opening angle of the blinds can be adjusted, thus directing the flow of warm air to the desired sector of the room.

The operating principle of a water fan heater is similar to the operating principle of a conventional electric fan heater or heat gun. Warm air currents are distributed throughout the room thanks to the operation of the built-in fan. Only the heat is generated not by an electric heating element, but by hot water, which enters the heat exchanger directly from the heating system.

Thus, the entire heating function relies on water from the central heating system. Additional costs are incurred only by the operation of the fan, but they are not so significant. In essence, a water fan heater is a heating battery equipped with a fan. Everything is extremely simple, and the effect exceeds all expectations. The room is heated quickly, efficiently and evenly with the lowest possible financial costs.

Introduction

For quite some time now, in the field of air cooling systems for central processors, we have not seen any innovations or truly interesting solutions to increase efficiency while reducing noise levels. So manufacturers have to update their cooler lines and attract potential buyers in other ways, in particular by equipping devices with two fans at once. This trend has indeed been observed recently, since this is the simplest and, as you probably understand, inexpensive way to increase efficiency without significantly affecting the final price of the product. In particular, Thermaltake, having previously shown at CES 2013, in March of this year announced four new coolers of the NiC (Non-interference Cooler) series, three of which are equipped with two fans. Phanteks, a less prolific company in this regard, has also released a new product, which also has a pair of fans in its arsenal. There are other companies that have recently added coolers with two “turntables” to their product range. That is, it is quite possible to talk about a peculiar fashion for two fans in processor coolers. We will find out how all this turned out using the example of the Phanteks PH-TC12DX and Thermaltake NiC C5 coolers.

Advantages

- Economical. If you are looking for efficient and most economical equipment for heating large areas, we recommend buying a water fan heater and organizing an air-water heating system at the site. Heating with a water fan heater is really beneficial. Heat is provided by a central heating system. Only the fan runs from the mains.

- Fast heating . It will take several hours to warm up a large room with conventional radiators. A heating system with water fan heaters will do this much faster. A powerful fan quickly accelerates the heated air, and comfortable temperature conditions are quickly created in the room.

- Ability to create temperature zones. The direction of movement of warm air flows can be adjusted by changing the position of the blinds. This way you can create local heating zones with a higher temperature in the room.

- Power adjustment . The ability to adjust power allows you to save even more. Almost all water fan heaters can work in conjunction with remote temperature sensors. When the set room temperature is reached, the device reduces power and switches to economical operating mode.

- Easy installation. For a specialist, installing and connecting water fans does not present any difficulty. The water fan heater can be installed anywhere in the room and connected to any water heating systems.

- Safety. Another important advantage of water fan heaters is a high level of safety. The protective box eliminates the possibility of getting burned on the heat exchanger when touched. The box itself never heats up to high temperatures. The device does not have a heating element that could cause a fire. Water fan heaters operate with relatively low coolant temperatures (maximum - 130°C, standard - 90°C), so fire is impossible even if fabric, paper or other flammable object accidentally gets into the box.

- Neat appearance. Despite the fact that water fan heaters are part of industrial heating systems, they look quite aesthetically pleasing. All technical elements and connection pipes are hidden from view. Only a neat box with blinds remains in sight.

Acceleration of the heating battery

Off-season. It's cold outside. Utility workers, fagots, waste heating. The batteries heat up at half power. Dubak at home. The bald cat is freezing and suffering. How long?! Do you think I ran for an electric heater? Hell yeah! Our method is to accelerate the heating battery.

So, according to the standards, each room must have a certain number of heating radiator sections. The quantity depends on the footage. The average power of one section of a cast iron or aluminum radiator is about 200W. But this is passive heat transfer, and heat can be forcibly removed! This is what we'll do

▌Loot the loot!

If the battery is warm at the output, it means there is somewhere to grab more energy. There is potential for overclocking! And good overclocking is unthinkable without good cooling! Therefore, we move behind the coolers.

I decided not to worry and bought the cheapest coolers. 40 rubles each. Regularx 80x80x25. They are exactly the width of the radiator section. I took a dozen at once:

Then I connected them with zip ties into a powerful battery:

To connect I used plastic ties:

It's fast, simple and reliable. If you tighten it well, it will be like cast.

Then we connect all the propellers in parallel. If there is a yellow wire, bite it off and throw it away. This is a speed sensor, we don't need it. And we connect all the red ones together with the red ones. Black with black.

All that remains is to hook up the connector:

If there is no connector, then it doesn’t matter. You can stupidly twist the wires with the power supply.

And take the power supply from the router. You can take absolutely any block. If only it gave a current of 1A and the output voltage was constant, i.e. DC. The voltage itself can be from 5 to 15 volts. The higher the voltage, the more efficient, but the noisier. At 15 volts, the battery turns into a powerful fan heater, pumping the room in a matter of minutes.

I took it to 5 volts. It was simply at hand. With it, the coolers rotate barely, they are almost inaudible, but the battery is enough for this.

I used plastic ties to put everything on the battery

Connected the power... Let's go!

Yes, they need to be hung in such a way as to ventilate the radiator as efficiently as possible. My radiator has parallel fins inside. Air moves along them from bottom to top by convection. That’s why I installed the fans so that they accelerate this convection, blowing from bottom to top.

A cast iron battery may have a different optimal location. For example, blow from the side or front. In general, look and decide for yourself. The ideal option would be to completely cool the battery to room temperature.

And, of course, you can not fence the battery with coolers, but take a regular household fan and direct it to the radiator. The effect will be no worse.

This battery also has a nice bonus. If you are not the last participant in the heat chain, then your vile neighbors who listen to music loudly or stomp over your head will freeze the hell out along with the cockroaches!

The same method can be used to increase the power of electric radiators. Of course, they will not consume less electricity - the law of conservation of energy is unshakable. With forced pumping they will simply stop turning off. But there is also a plus in this, firstly, the radiator will not be so hot, it will be more difficult to get burned. And secondly, the load on the power grid will be much lower, the machines will not be knocked out in vain. After all, a constantly working 800W radiator is much less hardcore for wiring than a 3KW monster clicking back and forth like an iron. And in terms of output power they will be approximately equal.

Z.Y.

This creative was born when the CS complained to me on ICQ that his ass was freezing. So he was sent for coolers and after a small upgrade of the radiator, Africa finally arrived in his apartment. Here are his photos.

This is such bullshit, kids. Cold batteries and a warm apartment for you

Flaws

- Difficulty moving. Due to the peculiarities of operation and installation in mobility, water fan heaters are clearly inferior to portable heating devices (portable heaters, electric fan heaters, heat guns). The device is connected to the pipes of the central heating system. You can move it to another place. But this will be accompanied by appropriate dismantling and installation work.

- Dependence on central heating. The operation of the water fan heater is directly related to the operation of the central heating system. It will not be possible to use a water fan heater as an alternative heating source during the non-heating season. In the event of an accident, the operation of water heaters will be blocked.

- Noise. Unfortunately, an absolutely silent fan has not yet been invented. All fan heaters create some noise when operating.

- Not suitable for heating freezing rooms. All heating systems that use water as a coolant operate only at above-zero temperatures. The room temperature should not be allowed to drop below zero.

Basic elements of the heating system

Before you set up air heating with your own hands, you need to get acquainted with the elements of which it consists.

Air heating devices

The main task of the equipment is to heat the air entering inside to the desired temperature. Almost all known heat sources can be used for this.

Depending on the type of heating device, air masses are either passed through a heat exchanger with hot steam, water, etc., or heated directly inside the heater.

Heat generators used to heat air in an air heating system should not heat the air to a temperature above 70º so that after mixing with the air in the room it does not lose its properties as an inhalable medium (+)

In practice, four types of structures are used as heat generators for air heating systems:

- Direct heating fuel systems. In them, the air is heated from the heat obtained from the combustion of any fuel. This type includes coal, gas, diesel, pellet and other heaters.

- Direct heating electrical equipment. It is a powerful fan heater that is connected to the air ducts.

- Indirect heating devices. It is assumed that there is a heat exchanger in which hot liquid circulates. The latter can be heated in any way: using a wood stove or any other heating device. As an option, you can consider connecting coolant from a centralized heating system.

- Combined design. It consists of two, sometimes three systems of different types, combined into a common design. The most effective and practical option is obtained by combining an electric and liquid system.

The last option is considered the most successful, since such equipment will be able to provide the house with heat even in the event of a power outage or problems with fuel. However, for obvious reasons, such devices are more expensive. Spending money on them is not always justified, especially if power outages are extremely rare.

Main pipelines are made of galvanized metal. These are rigid structures to which flexible bends are connected

Channels for the movement of air masses

A duct-type heating system will not be able to operate without a network of air ducts. Along them, air masses move into the premises and return to the heat generator. Circular transportation is most often used, since single-pipe structures, which can also be used, have limited functionality and a large number of disadvantages. In the drawing, this design resembles two trees.

The role of the trunks is played by two rigid main pipelines made of galvanized metal. One of them is the feeder, the second is the return. “Branches” are connected to them through adapters.

These are flexible air ducts of a smaller cross-section that extend to the rooms. They must be sealed with aluminum tape and insulated. Insulation in this case not only retains heat, but also absorbs sounds.

For insulation, as a rule, foil insulation of different brands is used. For highways, a coating with a thickness of 3 to 10 mm is selected. For distribution channels, material with a thickness of 25-30 mm is suitable.

Inside single-story buildings, heated air is directed from bottom to top, so air ducts can be built into the floor. In two-story buildings, a network of air ducts can be laid along the ceiling of the first floor or in the thickness of the interfloor ceiling.

Air ducts must be insulated. The insulating material not only protects heat, but also absorbs sound

In this case, hot air is supplied to the first floor from the ceiling. Air duct outlets on the second floor are located at the bottom of the interior walls and on the floor. The return line is also placed differently.

On the ground floor, openings for collecting cooled air are located at floor level. On the second, on the contrary, near the ceiling. Superheated air masses collect here and enter the return line.

Fans for air circulation

Air masses inside pipelines are transported forcibly. This operation is carried out by special duct-type fans. The equipment is installed on both return and supply air ducts. In addition, most often they are also structural elements of the air heater.

When choosing a fan, in addition to technical characteristics, it is advisable to take into account the following parameters:

- ability to work at different speeds;

- minimum noise level;

- lack of sensitivity to voltage changes;

- equipped with a soft start system;

- possibility of smooth adjustment of equipment speed.

You need to understand that fans are responsible for the pressure performance of the equipment, in fact, they determine it. Therefore, the technical parameters of the equipment must precisely correspond to the specifics of a particular system.

Installation diagram of an in-duct fan inside the air duct: 1 - axial type fan; 2 - air heater, constructed of copper pipes with aluminum plates; 3 - air distributor with flaps that change direction

Flow distribution: grilles and diffusers

All air ducts suitable for the room are connected to ventilation grilles or diffusers. These elements are intended to separate air flows intended for heating, ventilation and air conditioning, as well as to uniformly distribute air flows indoors.

Floor, wall and ceiling devices are produced, among which you can find models with movable adjustable blinds.

In-channel dampers and valves

The elements are designed to adjust the throughput of the heating system. Throttle valves must be installed in the supply air ducts. The devices regulate the pressure of air masses entering different rooms and make it possible to fix it if necessary.

Various sections of air ducts are equipped with valves. It is mandatory to install supply valves that regulate the flow of air from the street.

In addition to valves that control the inflow and outflow of air flow, ventilation systems are equipped with smoke exhaust valves and fire-fighting analogues. In case of fires, they prevent the spread of fire and combustion-stimulating gases, remove fumes and fumes from the premises

Air preparation equipment

Considering that air heating is often combined with air conditioning systems, air preparation is becoming a popular option. In this case, the design is equipped with various filters: carbon, mechanical, electrostatic.

They purify the air of all kinds of impurities. Additionally, humidifiers, ionizers, ventilation anemostats, sterilizers, dehumidifiers and similar equipment can be installed.

This is what a diffuser looks like, evenly distributing flows at the outlet of the air duct

Automatic control systems

Air heating in itself, and especially combined with ventilation and air conditioning, is considered a rather complex system. To coordinate its functioning, automatic control units are used, which make it possible to quickly and accurately change the system’s operating parameters.

If necessary, the owner can set the characteristics he needs, obtaining the most comfortable microclimate for him in the house.

Control units differ in functionality and are selected individually for each specific heating system. Properly selected automation allows you not only to fully control the air heating, but also to change the settings included in the program at a distance, distribute air flows in a zoned manner and turn on the heating in the smart home system.

Let's sum it up

By purchasing a heater, you get:

- uniform heat distribution in the room

- no noise from the device

- possibility of heating a certain area of the room

But be prepared for the fact that it is unprofitable to use heaters in empty and large rooms, since these devices require considerable time to uniformly heat even a small area.

By choosing a fan heater, you gain the following features:

- high room heating rate

- long operating time

- fast heating function for large industrial premises

- affordable cost of the heating device

Please note that due to the powerful air flow. created by the fan heater. The device is not recommended for use indoors where there may be people who are allergic to dust and other small particles

Choosing between these devices and the features that set them apart is not easy. It all depends on your preferences and goals. But we hope that we have successfully helped you understand this topic. If you still have questions, you can call our consultants and get all the missing information.