NAKS-TPA » Articles about pipeline fittings » Articles about pipes

Articles about pipes

Nax-TPA Supply of pipeline fittings, plumbing fixtures, pumps, heating equipment. 10/13/2021

91 Views

Guidelines for technical equipment and modernization of thermal units

- Principles of constructing ITP

- The principle of operation of the node.

- ITP modernization options

- Legend:

- Conclusions and recommendations

- Appendix A

- Appendix B

Types and features of a heating point

The heating station regulates the supply of coolant, its temperature, and is connected to the heating system.

The heating station includes equipment that allows connecting power plants to heating networks, liquid supply systems, measurement and control devices. Usually the heating unit is located in a separate room or building.

The purpose of any type of TP is to regulate the coolant supply. All elements of the system - mains, pipelines serving apartments, radiators - are designed to work with a coolant of a certain temperature, purity, and gas content. Violation of these indicators leads to clogging and system failure.

TP controls the indicators of incoming and outgoing water. The consumer receives liquid at the optimal temperature under the pressure for which the heating, ventilation, and plumbing systems are designed. If any indicators change to an unacceptable value, the control system turns off the water supply.

Here, the coolant is transformed, for example, steam condensation and transformation into superheated water.

TP can serve a different number of consumers and include different heat consumption systems. The methods of installation and installation of equipment also differ.

Central heating point

In order for houses to warm up well, the installation must be in every building.

The peculiarity of the heating unit is a large number of connected consumers. The central heating station serves several houses, an enterprise or even an entire neighborhood. Usually it is placed in a separate building, but installation in the basement is allowed if its size allows it.

This option is not very convenient for the average consumer - an apartment dweller. The central heating station sets the same coolant temperature, not taking into account that the length of the pipelines is not the same. Nearby buildings, as a rule, overheat, distant ones receive very cool water. During preventative and repair work, an entire neighborhood is left without heat.

Individual heating point

ITP has smaller dimensions and can be located in a basement or a separate building.

ITP is an individual heating point. It performs the same functions as the central heating station, but to a lesser extent. It supplies coolant to 1 building or even one part of it. Since its dimensions are much smaller, the heating unit is placed in the basement or in another technical room.

The advantage of an individual heating point is the supply of water to consumers at the same temperature. The length of the pipeline, even in a high-rise building, is not so long as to affect the temperature. This option is more economical, since less heating is required to maintain optimal conditions in apartments.

Modular heating substation

A block or modular heating unit is a finished factory product. The blocks are compact, assembled and work according to the same scheme. They can be placed in the smallest area. The units are installed very quickly: you only need to connect the external wires. Depending on the number of consumers, a modular point can be either individual or central.

Advantages and disadvantages

Each type of TP has its own advantages and disadvantages. Advantages of TsTP:

- coolant parameters - temperature, pressure, are maintained and controlled automatically;

- The point serves a large number of consumers.

This solution has many more disadvantages:

- Each consumer receives a strictly dosed amount of heat. However, these shares are equal only at the central heating point level. Due to different pipeline lengths, building occupants receive water at different temperatures.

- The longer the pipeline, the greater the heat loss. Because of this, it is necessary to increase the temperature at the central heating station, which leads to an increase in heating and hot water costs.

- During renovations, a large number of residents are left without heat.

- Hot water circulation is uneven. In houses located far from the central heating point, cold water has to be drained for a long time before receiving heated water. The meter takes this entire volume into account as hot water consumption.

ITP in the basement of a house saves up to 30% of hot water costs

ITP is much more profitable:

- Less heat loss during coolant transfer. Installing ITP in a building saves from 15 to 30% of costs.

- All apartments receive the same amount of heat based on area.

- The water comes out of the tap really hot and immediately.

- Since the heating unit operates without high load, the likelihood of breakdowns is lower. Installation and repair of equipment takes less time.

- When a transformer substation fails, fewer residents suffer.

The disadvantages of the individual complex are associated only with its limited capabilities. TP serves 1 house, sometimes even part of it. To modify an entire neighborhood will require a lot of money.

The advantages and disadvantages of MTP are determined by its purpose. However, such a system has its advantages:

- The finished module takes up minimal space. Even if it is a central heating station, it can be installed in the basement.

- Installation is extremely simple - you just need to connect it to the heating main and electrical network.

The higher the degree of automation of a heating unit, the lower the costs for its maintenance and service.

Maintenance

Once a week, the management of the operating organization inspects the central heating point. And once every three months - the technical director of the heat supply company. Check:

- heating fluid parameters;

- condition of heat exchangers, instrumentation, and other equipment;

- condition of pipe connections, thermal insulation;

- correct settings of electronic units;

- condition of electrical panels;

- energy efficiency of the system;

- coolant leaks.

During the inspection, the condition of the equipment is determined, damaged and worn elements are identified. If necessary, equipment is dismantled and replaced. Maintenance work is carried out in protective clothing to avoid burns. Operation of faulty equipment is prohibited.

In conclusion, we will give an exact answer to the question of what a central heating station is - this is a set of equipment for the preparation and distribution of hot water. The need is caused by the fact that at the exit from the central boiler room the coolant is too hot to be supplied to consumers. Therefore, it passes through the central heating station, which creates the required water parameters. You may also be interested in flushing accessories and seals for heat exchangers.

Principle of operation

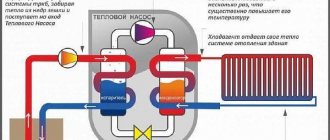

Scheme of operation of IHP in a private or apartment building

The principle of operation of a modern heating unit is simple. The liquid from the main gives off its heat through a heat exchanger to the hot water supply and heating system. The coolant is then transferred through a return pipeline to the boiler room or power plant, where it is heated again. The heated liquid from the TP is distributed among users.

The heating point supplies users with heating media and hot water. The operating schemes of the systems are different.

Tap water enters the TP. Part of the cold water is supplied to consumers, the other part is heated in the 1st stage heater. The heated liquid enters the circulation circuit. The pump ensures constant movement of hot water along the circuit from the heating unit to the users and back. The inhabitants of the house draw hot water as needed.

Since the liquid gradually cools, it is periodically reheated in the 2nd stage heater. Since the volume of water in the circuit decreases, it is necessary to constantly take in cold water, heat it up and replenish its deficiency.

The operating diagram of a thermal heating unit in an apartment building is somewhat different. It is simpler: water, having given off heat to pipes and radiators, returns in almost the same volume as it was supplied. Leaks are possible, but small. The losses are compensated by a make-up system operating on the basis of the primary heating network.

Permission to operate

The operation of AITP complexes (automated ITP) requires obtaining permission, for which documentation is provided to Energonadzor. These are technical connection conditions and a certificate of their implementation. Needed:

- agreed upon design documentation;

- act of responsibility for operation, balance of ownership from the parties;

- act of readiness;

- heating points must have a passport with heat supply parameters;

- readiness of the thermal energy metering device - document;

- certificate of existence of an agreement with the energy company for the provision of heat supply;

- work acceptance certificate from the installation company;

- An order appointing someone responsible for the maintenance, serviceability, repair and safety of the ATP (automated heating point);

- list of persons responsible for maintenance of AITP installations and their repair;

- a copy of the welder’s qualification document, certificates for electrodes and pipes;

- acts on other actions, as-built diagram of an automated heating point facility, including pipelines, fittings;

- certificate for pressure testing, flushing of heating, hot water supply, which includes an automated point;

- briefing

An admission certificate is drawn up, logs are kept: operational, on instructions, issuance of work orders, detection of defects.

Key components of a heating substation

Components of an ITP device

The thermal complex includes several main elements:

- A heat exchanger is an analogue of a boiler room’s thermal boiler. Here, the heat from the liquid in the main heating network is transferred to the coolant TP. This is an element of a modern complex.

- Pumps – circulation, make-up, mixing, booster.

- Dirt filters – mounted at the inlet and outlet of the pipeline.

- Pressure and temperature regulators.

- Shut-off valves - act in case of leaks, emergency changes in parameters.

- Heat metering unit.

- Distribution comb – distributes coolant to consumers.

Larger TPs include other equipment.

Selection of systems

ITP with an elevator is cheaper, but more expensive to operate.

Water is prepared for transfer to users using a control unit. Based on the type of this element, there are several operating schemes for the heating unit.

Elevator – installed on an old-style transformer substation. The unit mixes liquid from the main network and cooled water from the return pipeline to obtain a coolant with a temperature suitable for secondary networks. The temperature is maintained at a certain level regardless of the air temperature outside or indoors. When overheating, the only way to remove excess heat is to open a window. If there is underheating, you have to connect electric heaters.

The thermal unit circuit with a controller is much more efficient. The heat exchanger and control equipment allows you to regulate the water temperature in the heating circuit based on real air readings. There are 2 systems of this kind:

- Dependent circuit - increases or decreases the temperature of the supplied liquid by mixing the cooled coolant from the return pipeline. The controller monitors temperature changes and automatically turns on pumps and valves. The installation of pressure regulators is mandatory, since this indicator is different in primary and secondary networks.

- Independent - the water used to heat the house circulates in a closed circuit, the heat from the coolant from the main is transferred only through a heat exchanger. Pressure regulators are not needed here; temperature adjustment is performed more accurately and quickly. The cost of a TP with an independent circuit is higher, but it is more economical to use: the water is not polluted, does not overheat, and does not lead to corrosion of pipes and radiators.

Hot water supply is also implemented according to 2 schemes:

- Single-stage - water from the water supply is supplied to the heater. It is heated by the network coolant that came from the source. The cooled network supply is transferred to the source, and the heated water supply is supplied to the consumer.

- Two-stage - water is heated in 2 stages. First, due to the coolant from the return pipeline - up to +5–+30 C, then it is heated up through the use of a supply heat pipe - up to +60 C. In this case, waste energy from the return pipeline is used - it is cheaper.

The more effectively a heating system reduces the cost of heat supply services, the more expensive its installation.

ITP schemes

Any node has an individual connection diagram, which is selected based on the characteristics of the energy source and the design of the building. There are two types: dependent and independent.

In the first connection option, water is supplied directly from the heat source, and the temperature is controlled by mixing with return water.

In the second case, the key element is a heat exchanger with two circuits. From the boiler room, the heat carrier enters the soldered heat exchanger and delivers energy to the additional circuit. This is how the heating system in residential buildings works.

The standard ITP scheme includes:

- 3 systems (DHW, heating and ventilation);

- Feeding of connected heating and water supply systems according to an independent scheme;

Balancing the system

Balancing valves are adjusted after installation of the equipment and startup of the coolant.

Calculations of any hydraulic circuit are very complex. During installation, features and deviations appear that cannot be taken into account during calculations: blockages, scale, narrowing. In practice, hydraulics are linked at the design stage, and then adjusted using balancing valves. This device is an adjustable washer. With its help, the valve capacity, that is, the hydraulic resistance, is changed. In this way, the work of all circuits is connected.

Balancing valves are installed on all components and systems of TP: heat exchanger, pumps, water supply, ventilation, heating circuits. Additional devices are required to coordinate the operation of the circuits and compensate for the operation of the pumps.

Compliance with all regulations

The design and installation of IHP by Acrux specialists is carried out in full compliance with the requirements of SNiP 41-01-2003 “Heating, ventilation and air conditioning”, 2.04.07-86 “Heat networks”, as well as SP 41-101-95 “Design of heating points " Thanks to the use of certified materials, compliance with all standards and highly qualified heating engineers, we guarantee reliable operation of the installed heating units throughout the entire period of operation.

Installation efficiency

An individual heating unit in an apartment building reduces heating and hot water supply costs:

- The heat meter itself does not affect its consumption, but it takes it into account correctly. Heating companies often increase the cost of services without supplying sufficient heat energy. With accurate accounting, it turns out that before the installation of the TP, residents overpaid.

- Automation reduces maintenance costs. More precise temperature control also reduces costs.

- A closed heating system is more profitable: there is no need to constantly purify water, repair pipes and radiators. There is less heat loss in a closed system.

- The ITP works according to a schedule: it lowers the temperature at night, stops pumps, and increases it in the morning.

A heating station saves from 1.5 to 8 million rubles over 5 years.

Appendix B

List of sources used

- Federal Law of November 23, 2009 N 261-FZ (as amended on December 29, 2014) “On energy saving and increasing energy efficiency and on introducing amendments to certain legislative acts of the Russian Federation”

- Rules for the technical operation of thermal power plants (approved by order of the Ministry of Energy of the Russian Federation dated March 24, 2003 N 115)

- Federal Law of July 27, 2010 N 190-FZ (as amended on December 29, 2014) “On Heat Supply” (as amended and supplemented, entered into force on March 3, 2015).

- Presentation of the report at the meeting of the City Non-Departmental Commission on March 27, 2015. “Results of monitoring the equipping of apartment buildings in St. Petersburg with metering units as of March 27, 2015”

- JSC "SHAD-International" Description of a water jet with an adjustable nozzle (VARS). Patent No. 2151918. https://www.shad-in.ru.

- Methodology for determining the need for fuel, electrical energy and water in the production and transmission of thermal energy and coolants in municipal heating systems. (approved by the State Construction Committee of the Russian Federation on August 12, 2003)

Areas of application

IHP for heating air in the ventilation system

TP are necessary for proper distribution of heat between consumers. These include:

- Hot water supply. Part of the heat, as hot water is supplied through pipes, is used to heat the bathroom and kitchen.

- Heating systems – maintain a comfortable temperature in residential and public spaces.

- Ventilation system – the air is heated before entering the building.

- Cold water supply does not apply to consumers, but to supply elements. Cold water serves as a regulator.

They install TP for heating, water supply, air conditioning in both old and new buildings.

Where does the noise come from?

Vibration of pump casings, boilers and pipes creates airborne noise. It enters the apartment via a frame. When equipment comes into contact with a building, vibrations are created, which are transmitted from the metal to the concrete, and then to the living space. The noise transmission channels are: metal studs on which the pipes are held; brackets near the walls along the pipe laying; non-vibration-insulating mounting of equipment to the floor.

However, when using modern heating units, complete noise insulation is ensured. The noise does not disturb the peace of residents and complies with all SNiP (building codes and regulations). Thus, noise pollution in the area is reduced. This result is achieved due to the fact that:

- Pumps are connected to pipelines with flexible anti-vibration rubber inserts;

- The pumps have a low noise level;

- Rubber-metal supports are used between the pump frame and the floor;

- There is a gap between the surface of the insulation pipe structure and the building structure. Tight sealing of pipes into the walls of a building is unacceptable.