In winter, a country house must be heated even in the absence of the owners. The problem of heating a cottage far from the gas distribution network often becomes an insurmountable obstacle to life on earth. Heating with electricity is too expensive even for a wealthy person, and hiring an outsider to stoke a wood or coal stove is risky. The most progressive solution to this problem is heating using a geothermal heat pump (GHP).

What is a geothermal heat pump

Planetary energy can be used on any part of the earth. Geothermal springs with boiling water bubble up only where hot magma comes close to the surface. In the rest of the space, heat from the center of the Earth is distributed evenly. Therefore, at a depth below the soil freezing level, the same temperature is maintained year-round.

The purpose of the HHP is to pump heat from the soil or reservoir into the house. Energy is collected from the surrounding area by pipes, and then a compressor heats the water for the heating system of the cottage. Therefore, from 1 kW of electricity spent, 3-5 kW of heat is obtained.

Device

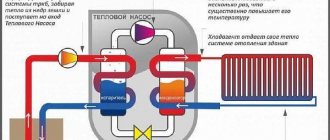

For the gas turbine to operate, three independent systems are required: intra-house, compressor, and external circuits. They are combined into one circuit by heat exchangers in which various coolants circulate.

The gas turbine unit consists of the following components:

- Home heating system, for which it is better to use heated floors.

- Hot water supply.

- The condenser transfers the energy collected from outside to the indoor heating fluid.

- The evaporator takes thermal energy from the coolant circulating in the external collector.

- The compressor pumps refrigerant from the evaporator, converting it from a gaseous to a liquid state, increasing the pressure and cooling it in the condenser.

- An expansion valve is installed before the evaporator to regulate the flow of refrigerant.

- The external collector pipes are laid on the bottom of the reservoir or lowered into wells.

- Pumps.

- Automation for controlling the turbocharger according to a given room heating program, which depends on changes in the outside air temperature.

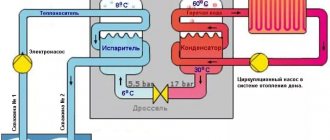

The external circuit coolant is pumped by a pump and heated underground or in a reservoir. Inside the evaporator, energy is transferred to the refrigerant, which enters the compressor where the pressure and temperature increase.

The condenser transfers heat to the cottage heating system. The refrigerant then passes through the choke, where the pressure drops sharply due to the increase in volume. When it transforms into a gaseous state, the temperature of the refrigerant decreases greatly. A significant temperature difference accelerates the absorption of heat by the refrigerant from the external collector.

Operating principle

The excess heat transfer scheme has been used in everyday life for 70 years. For example, ice forms inside a freezer due to heat extraction from the refrigerant. From the outside, this energy is discharged into the indoor air by the radiator grille. Touch it with your hand - it is always hot when the refrigerator is running.

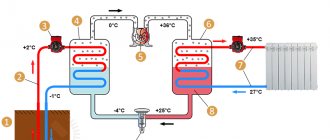

The same operating principle is used for the operation of the gas turbine engine, but the processes are a little more complicated:

- When the refrigerant enters the evaporator, this phase is called isothermal expansion. Freon receives heat from the external collector, the pressure drops.

- Then adiabatic compression occurs - the compressor increases the pressure of the refrigerant. At the same time, its temperature rises to +70 °C.

- Passing the condenser, freon becomes a liquid, as it transfers heat to the heating circuit at increased pressure. This phase is called isothermal compression.

- When the freon passes through the choke, the pressure and temperature drop sharply. Adiabatic expansion occurs.

Operating such a complex mechanism is almost as easy as operating a refrigerator. When the installation work is completed, and all systems are connected, tested, adjusted, the user will only switch a few toggle switches and buttons. For example, to set different heating temperatures for a children's room, living room, kitchen.

Advantages

The main advantage of the gas turbine engine is that you do not need to burn coal, gas, or wood to heat your home. A heat pump collects energy from the surface of the earth or from deep wells, concentrates it, and then sends it to the heating system of the cottage.

Over time, the geothermal heat pump is becoming more and more in demand, as it has a number of advantages:

- Environmentally friendly.

- Uses a renewable energy source.

- After commissioning is completed, there are no regular costs of consumables.

- Automatically adjusts the heating inside the house based on the outside temperature.

- The payback period for initial costs is 5-8 years.

- You can connect a boiler for hot water supply to the cottage.

- In summer it works like an air conditioner, cooling the supply air.

- Long service life - more than 30 years.

- Minimum energy consumption - generates from 4 to 6 kW of heat with 1 kW of electricity consumed.

- Complete independence of heating and air conditioning for a cottage “remote from civilization” in the presence of an electric generator of any type.

- Adaptation to the smart home system for remote control and additional energy savings is possible.

The rise in energy prices has almost no effect on the budget of gas turbine owners. If you install a wind or solar generator, you will have absolute energy independence.

Flaws

Installation and commissioning of gas turbine pump systems is a technologically complex set of works that can only be performed by experienced specialists. Not everyone can do the same with their own hands, so it’s easier to buy a geothermal heat pump with installation and subsequent maintenance. The total cost of equipment and component materials is significantly higher compared to conventional gas heating equipment. Therefore, the payback period for initial costs extends over many years.

There are other disadvantages:

- Due to the constant extraction of geothermal energy near the location of the external collector pipes, the soil cools. In the north, the short summer does not provide the opportunity to fully restore the energy potential of the environment. Because of this, the efficiency of the turbocharger gradually decreases over about 5 years. Then thermal equilibrium stabilizes.

- Drilling wells is an expensive undertaking, especially in dense soil or rock.

- There is an option with an open external collector, when you can get by with two wells: one for collecting groundwater, and the second for draining back into the aquifer. This option is only possible if the water quality is good, because filters quickly become clogged if there are too many hardness salts or suspended microparticles. Before installation, it is necessary to do an analysis of the water from the well.

- The heating is filled with water heated to +35 °C. At this temperature, conventional radiators will not effectively heat the building, so it is necessary to use a “warm floor” system.

- The electric motor, compressor, and pump create vibration and noise during operation.

Unpleasant effects can be easily avoided if the equipment is placed in a utility room or basement. Be sure to install forced ventilation. Freon leakage is dangerous to human health.

How to create a heat pump yourself

Regardless of the choice of system type (from the three options described above), to create the installation you will need a heat pump, which consists of a compressor station, evaporator, throttle valve and condenser. You can buy a ready-made system, but its cost will be quite high. If your budget does not allow you to purchase a unit, you can install it yourself.

Before designing and installing your own autonomous heating system, you need to make sure that all electrical wiring in the house is in proper condition.

There are two main ways to create a DIY installation: based on a refrigerator or an air conditioner. Let's take a closer look at them.

Types of pumps

Over time, the benefit of a geothermal heat pump for heating a home, despite high prices, is becoming increasingly obvious due to the constant increase in fuel costs. A properly selected and high-quality installed gas turbine unit provides heat regardless of the time of year and market fluctuations in energy costs.

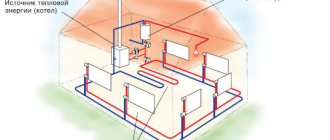

There are several options for installing an external collector, which allows you to adapt the heat pump to the specific conditions of the land adjacent to the house:

- The pipes are laid in trenches to a depth below the soil freezing level. In the south of Russia, the ground freezes to a maximum of 0.5 m, so it is easier to completely remove the layer of earth at the installation site with a grader, lay the collector, and then fill the pit with an excavator.

- If there is a body of water near the house at a distance of no more than 100 m, then the most economical and effective option is used - the pipes are laid under water to a depth of 3 meters or more.

- Dry sandy soils will not provide sufficient heat flow, so drilling wells up to 50 meters deep is used to reach the aquifer. Pipes are lowered into the wells.

- If the water from the well is of good quality, then it is enough to drill only two: one to draw groundwater, and the second to drain back into the aquifer.

Drill a drain well at a distance of 20 meters from the intake well and downstream of the aquifer.

Water-to-water type

A relatively inexpensive type of water-to-water turbocharger is recommended for use when there is a lake, pond, river or sea nearby. The efficiency of such a system is achieved due to the maximum amount of convective heat exchange between the external environment and the coolant that circulates in the collector pipes. Savings are achieved due to ease of installation. The coils are spread on the surface of the water, then weights are attached to the pipes and the system is flooded to a depth of 3 meters or more.

If there is no reservoir nearby, then you can use the option with an open collector. In this case, the energy potential of good quality groundwater is used. Then the system and the pump are not threatened by siltation, deposition of hardness salts, or accelerated corrosion. Water is taken from one well, pumped through the gas turbine heat exchanger, and then poured into another, which should be located at a distance of 15-20 meters.

If a drilled well quickly silts up or the water contains a lot of hardness salts, then stable operation of the gas turbine pump is ensured by drilling more wells. The loops of the sealed outer contour are lowered into them. Then, cement from a clay-sand mixture is poured into the wells.

Soil-water type

When there is no reservoir near the house and it is not possible to drill wells, then the pipes are laid horizontally below the freezing depth of the soil. If the groundwater lies close to the surface, then the efficiency of the ground-water system is almost the same as that of a water-water turbocharger, since the operating principle is the same. In the south of Russia, the amount of soil freezing is less than 0.75 m, so they dig a pit 1 meter deep, lay out the external circuit pipes, and then fill them up. In northern regions, the soil freezes deeper, so it is more economical to dig parallel trenches.

How to install geothermal heating

The installation of a geothermal heating system includes three stages:

- Drilling and installation work is being carried out at the site.

- Equipment and a heat pump are purchased and delivered.

Construction of a horizontal contour Source stroyfora.ru

- The external and internal circuits are mounted. They are connected through a heat pump, then commissioning work is carried out.

Horizontal, vertical and underwater circuits have their own installation features: The horizontal tubular heat exchanger is laid below the freezing depth. If the groundwater lies high, a sand cushion is created, and measures are taken to level out heaving, deformation and extrusion of the contour.

The length of the horizontal heat exchanger is determined by calculation: 40 m of pipes per 1 kW of thermal energy. Such a system may require a large area (up to 2.5 acres), and you will have to figure out how to use it later, since buildings with an underground foundation or planting trees cannot be built above the heat exchanger.

A vertical underground circuit is almost a third more efficient than its horizontal counterpart. The depth of the well is calculated from the ratio of 10-30 m of pipes per 1 kW (depending on the properties of the rocks). If the depth turns out to be too great and economically unfeasible, you can make several small wells that together provide the required power.

Installation of equipment for a vertical circuit Source 24aul.ru

Selection criteria and calculations

When choosing gas turbine equipment for preliminary calculations, a simplified formula is usually used: 700 watts of heat are required per 10 m² of heated building. Then a 17.5 kW heat pump is suitable for a house with an area of 250 m². To provide the cottage with hot water, multiply the final figure by 15%.

When calculating the payback period of a gas turbine unit, take into account the operating costs for the entire service life of the equipment - at least 30 years. Assuming that current fuel prices remain unchanged, then geothermal heat pumps are the most economical heating method for country cottages.

In just 1 year the savings will be compared to:

- gas boiler - 70%;

- electric heating - 350%;

- solid fuel boiler - 50%.

If you multiply the benefits received by 30 years, the savings will be many times greater than the initial costs.

Manufacturers and reviews

In Europe, geothermal heat pumps for heating pay for themselves in a few years. But their heating costs are much higher, as is the price of energy. For our country, 10 thousand - 15 thousand dollars spent on installation will be returned for years, if not decades. This does not mean that it will not pay off at all (although this may happen), but not very soon. And, nevertheless, it is not worth installing a geothermal heat pump from China. Although they are cheaper, and sometimes significantly, they do not have spare parts, services, or warranties. If something happens to the equipment, you will be left with your own problem.

Which units are worth purchasing? First of all, these are German. Germany has the strictest laws regulating building materials and equipment for the home, and very strict certification. If the installations are approved for operation in Germany, then they are definitely safe and of high quality. There are many examples of this in any field of construction. The same famous “German quality” is also inherent in geothermal pumps for the home.

Scheme of organizing a home heating system using heat pumps

In addition to German units, many other European manufacturers have good reviews. Some of them have been producing similar equipment for more than 50 years, so the technologies have long been verified and debugged. For example, Nibe geothermal heat pumps in Sweden were installed not only in apartments and private houses. The Nibe thermal pump has even been installed on a large pig farm, where piglets warm themselves from its heat. In this version, by the way, the probes were not placed in the ground or in boreholes. They took heat from the slurry: they laid an external circuit along the sides of the sewer channels. This is definitely a free source of heat. The farm owner is very pleased: his investment paid off in 1.5 years.

Daikin geothermal heat pumps use inverter control, which reduces energy costs by another 20% compared to similar conventional units.

Swedish Danfoss geothermal pumps combine three patented technologies. Two of them allow you to heat water for domestic hot water faster at lower costs and achieve higher temperatures in the heating circuit. Another one controls the operation of the circulation pumps, optimizing their speed. This allows for maximum performance.

You might be interested in reading about how to make a heat pump with your own hands or about heating using biogas.

Review of popular brands and their prices

To provide a private home with geothermal energy, it will be necessary to solve a large number of technological problems. This is done efficiently and on time only by experienced specialists from Russian companies who have been working in the market for a long time.

Popular heat pump manufacturers can be divided into three price categories:

- Cheap Chinese ones. For example, Meeting (China) with a maximum power of 7 kW for a heated area of 50-100 m² at a price of 95,200 rubles.

- Under the American brand Mammoth, equipment is produced in China: maximum power 7.8 kW, heated area 50 m², price 261,000 rubles.

- The most expensive products are produced by German companies. For example, Stiebel Eltron: maximum power 9.9 kW, heated area 50 m², price RUB 645,000.

To avoid unforeseen situations in the future, it is better to choose a company that provides a full range of services: performs design work, supplies equipment, performs installation, commissioning and maintenance.

Prices for the range of geothermal heat pumps

geothermal heat pump

How to make a unit with your own hands?

Regardless of which resource option (earth, water or air) is chosen for heating, a pump will be needed for the system to function correctly.

This device consists of the following elements:

- compressor unit (intermediate element of the complex);

- evaporator , transferring low-potential energy to the coolant;

- throttle valve , through which the refrigerant finds its way back to the evaporator;

- condenser , where freon releases thermal energy and is cooled to its original temperature.

You can purchase a complete system from the manufacturer, but this will cost a decent amount. When there is no free money at hand, it is worth making a heat pump with your own hands from the parts at your disposal and, if necessary, purchasing the missing spare parts.

When planning to install a geothermal heating system in a private home, you first need to take care of reducing the level of heat loss. To do this, the walls must be insulated with special material, the doors and window frames must be equipped with foam pads, and the floor and ceiling must be protected with foam panels. Then the maximum amount of heat released by the pump will remain inside the room.

When the decision to make your own heat pump is made, you must definitely check the condition of the electrical wiring and electric meter in the house.

If these elements are worn out and old, it is necessary to inspect all areas, identify possible faults and eliminate them before starting work. Then the system will work flawlessly immediately after startup and will not bother the owners with short circuits, fires in wiring, or knocked out plugs.

Method #1. Assembly from the refrigerator

To assemble the heat pump with your own hands, remove the coil located at the back from the old refrigerator. This part is used as a capacitor and is placed in a highly durable container that is resistant to aggressive temperatures. A properly working compressor is attached to it, and a simple plastic barrel is used as an evaporator.

If a very old refrigerator is used to create a pump, it is better to replace the freon in it with a new one. You won’t be able to do this on your own, so you will have to invite a specialist with special equipment. It will quickly replace the working fluid, and the system will work in the desired mode

The prepared elements are connected to each other, and then the created unit is connected to the heating system through polymer pipes and the operation of the equipment begins.

Step-by-step instructions for assembling a heat pump from a refrigerator are described in this article.

Method #2. Heat pump from air conditioner

In order to make a heat pump, the air conditioner is modified and some main components are redesigned. First, the outdoor and indoor units are swapped.

The evaporator, which is responsible for transferring low-grade heat, is not additionally installed, since it is located in the internal block of the unit, and the condenser transmitting thermal energy is located in the external block. Both air and water are suitable as coolants.

If this installation option is not convenient, the condenser is installed in a separate tank designed for correct heat exchange between the heating resource and the coolant.

The system itself is equipped with a four-way valve. For this work, a specialist with professional skills and experience in conducting events of this kind is usually invited.

Modern split systems are ineffective at low temperatures, so professionals do not recommend using them for making heat pumps yourself

In the third option, the air conditioner is completely disassembled into its component parts, and then a pump is assembled from them according to the traditional generally accepted scheme: evaporator, compressor, condenser. The finished device is connected to the equipment heating the house and started to be used.

The site has a series of articles on making heat pumps with your own hands, we recommend that you read:

- How to make a heat pump for heating a house with your own hands: operating principle and assembly diagrams

- How to make an air-to-water heat pump: device diagrams and self-assembly

Geothermal System Installation

The construction of the gas turbine complex consists of three independent sections of work: the internal heating system, the heat pump and the external circuit.

Installation of the external circuit consists of the following steps:

- Complete design work.

- Carry out test drilling to analyze the soil.

- Drill wells with vertical placement of collector loops or dig a pit for horizontal pipe laying.

- Place external circuit pipes in the pit or wells.

- Fill the pipes with coolant and bleed air from the system.

- Connect all loops of the circuit to the collector.

- Perform a pressure test of the entire system to identify and eliminate possible leaks.

- Connect the manifold to the turbocharger equipment.

- Do a test run.

- Connect the heating system of the house and regulate the operation of the entire complex.

To place the equipment, select a separate utility room with a temperature not lower than +14 °C. Prepare the home heating system for commissioning.

What costs does installation require?

The compressor, pumps, automatic gas turbine units require uninterrupted power supply. In case of a power outage, purchase an electric generator with automatic start.

Installation of a gas turbine unit includes costs for:

- a set of basic equipment with a compressor, heat exchangers, automation;

- drilling wells and digging pits;

- collector installation;

- coolant for external pipes - propylene glycol;

- boiler for hot water supply;

- installation;

- commissioning works.

Total installation costs, taking into account the cost of wells, range from 5 to 10 thousand dollars. When using an open reservoir it will be 30-50% cheaper.

Briefly about the main thing

Geothermal heating is a promising but underappreciated system for private homes. It can be organized in three ways: in a vertical well, in the form of a horizontal underground collector, or under water.

Heating with underground heat is economically beneficial; The maximum effect from the installation can be achieved by using heated floors. The system operates year-round: in winter it heats rooms, and in summer it reduces the air temperature, which eliminates the need for air conditioning. Many country house owners are in no hurry to choose environmentally friendly technology due to the high costs of purchasing and installing equipment.

Recommendations for care and maintenance

After completion of commissioning work, the owner controls only two buttons: on/off and winter/summer mode (heating or air conditioning), and also regulates the temperature in different rooms.

Annual inspection and maintenance are carried out by service specialists: monitoring the absence of leaks of freon, lubricant, coolant, and the operation of automation.

The gas turbine achieves maximum efficiency if you decide on the choice of heating system at the early stages of building design. Then it is possible to choose the optimal materials and thickness of enclosing structures with the required thermal conductivity and thermal inertia.

The greatest heat loss usually occurs through windows. Therefore, triple glazing is not a luxury at all, but an economically sound construction solution. The ideal option is to use glass that can reflect infrared rays.

Heating circuit

A heat pump, unlike gas, coal or electricity boilers, heats the medium to an average of 40⁰C. This is the optimal temperature at which both equipment wear and electricity consumption are minimal. For conventional radiators, such indicators are not enough. Therefore, with a heat pump, they usually use not pipes and radiators, but heated floors. It is more efficient when heating the coolant this way. Only the pitch between the pipes should be smaller. It is worth considering that heated floors create restrictions on the choice of furniture and dry out the air. Additional moisture will be required. In summer, floors can work for cooling.

Service

For some, geothermal pumps seem complicated and unusual. However, such equipment is undemanding and easy to use.

The maintenance process involves a thorough inspection of the system before the heating season. To prevent problems, you need to periodically monitor the operation of the pump. External inspection should be carried out monthly. This is done in order to ensure the integrity of the cables and the entire structure. Once every six months you need to analyze the coolant for density and acidity. If necessary, the chemical composition is restored.

Installation based on a refrigeration unit

To create a heat pump, an old refrigerator is suitable, from which the coils are removed (they will be used as a condenser). The snakes must be placed in a container whose material is resistant to temperature fluctuations. A compressor unit is mounted to the tank. An ordinary plastic barrel can serve as an evaporator.

All three elements of the system are hermetically connected to each other by a piping system and connected to the heating system.

conclusions

Geothermal equipment is one of the best ways to create autonomous heating if the ability to connect to centralized communications is not possible due to various reasons. When choosing the optimal system option, many factors are taken into account, including the location of the heated object and the budget of its owner. You can make a heat pump yourself. There are many options for assembly based on an old refrigerator or split system. Useful information can be gleaned from the video below.

Advantages and disadvantages of ground water pumps

A ground-water heat pump has the following advantages:

- Autonomous installation. The ground water pump does not depend on energy carriers; no permits or projects are needed to consume this thermal energy.

- Environmental friendliness. Heat pumps are installations that do not emit harmful emissions into the atmosphere, and also use the inexhaustible energy of the Earth.

- Safety. This heating is safe, since the maximum temperature here reaches 600C, which means the equipment is fireproof and explosive.

- Universal equipment. The soil pump can be used in conjunction with a gas or other boiler.

- Low costs when operating a soil pump. The ground water installation does not require any additional maintenance.

Disadvantages of ground source heat pumps:

- High price. The installation itself is quite expensive, and it also requires a lot of money to install it. Operation of special equipment, installation of a heat exchanger, etc. These are all expensive services. This equipment is much more expensive than boiler equipment.

- The service life of the soil pump is about 25 years. At this price it's not that much. After this period, as a rule, either repairs or drilling of another well are needed.