Modern houses, regardless of the material used in their construction, need to be designed and costed. It is at this stage that the characteristics are calculated for building heating systems. In those schemes where ordinary water circulates, the amount of coolant is calculated based on the thermal load of the entire building.

This indicator is necessary for accurately selecting the tank capacity intended for pressure regulation. This parameter is directly related to the design load of the heating system of a private building. Properly selected equipment used for heating a residential building will normally cope with the main task - creating a comfortable temperature regime in residential and auxiliary premises.

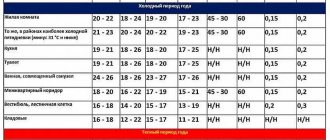

Table with standard indicators for residential premises Source stroypol14.ru

When performing a calculation, an exact expression is required that gives the correct result for choosing a boiler.

We calculate indicators of the amount of coolant: theory and practice

In individual residential buildings or apartment buildings the following is usually used:

- process water;

- propylene glycol;

- ethylene solution.

It is important that any coolant meets the requirements specified in regulatory documents. In Russian standard there are 5 conditions that must be met:

- optimal value of coolant movement;

- low viscosity while ensuring flow like ordinary water;

- slight expansion when the system cools;

- elimination of toxicity;

- inexpensive price.

Calculating the performance of a heating system cannot be considered simple; experience is required.

House heating system diagram Source odstroy.ru

To correctly determine indicators using calculation formulas for the further use of a reliable heat carrier, it is recommended to use the services of a specialist involved in the design of individual heating schemes or a competent plumber.

Coolant flow in the heating system: calculation formula

The volume of media used in home heating circuits is expressed in kilograms expended per second. The value is used to calculate the amount of heat generated to ensure a comfortable temperature in residential premises. Typically, modern devices - batteries - are used in heating systems of private houses.

To determine the calculated indicators, equipment data is required, in particular the parameters of the heating boiler, designed to heat 1 liter of technical fluid.

An example of a heating boiler table for a private house Source kupisantehniky.ru

The expression used to calculate the coolant flow rate for a residential heating system:

G = N / Q, where:

- N is the power characteristic of the equipment, indicated in Watts.

- Q is the amount of heat, expressed in J/kg.

The value obtained during the calculation is multiplied by a factor (3.6 x 1000) to convert to kg/hour.

Energy survey of the designed operating modes of the heat supply system

When designing, the heat supply system of JSC Termotron-zavod was designed for maximum loads.

The system was designed for 28 heat consumers. The peculiarity of the heat supply system is that part of the heat consumers is from the output of the boiler room to the main building of the plant. Next, the heat consumer is the main building of the plant, and then the rest of the consumers are located behind the main building of the plant. That is, the main building of the plant is an internal heat consumer and a transit of heat supply for the last group of heat load consumers.

The boiler room was designed for 3 DKVR 20-13 steam boilers, running on natural gas, and 2 PTVM-50 hot water boilers.

One of the most important stages in the design of heating networks was the determination of design heat loads.

The estimated heat consumption for heating each room can be determined in two ways:

- from the room heat balance equation;

- according to the specific heating characteristics of the building.

The design values of thermal loads were made according to aggregated indicators, based on the volume of buildings by texture.

The estimated heat consumption for heating the i-th production premises, kW, is determined by the formula:

, (1)

where: is the coefficient for taking into account the area where the enterprise is being built:

(2)

where is the specific heating characteristic of the building, W/(m3.K);

— volume of the building, m3;

— calculated air temperature in the working area, ;

— the estimated outside air temperature for calculating the heating load, for the city of Bryansk is -24.

The determination of the estimated heat consumption for heating for the premises of the enterprise was carried out according to the specific heating load (Table 1).

Table 1 Heat consumption for heating for all premises of the enterprise

| No. | Object name | Building volume, V, m3 | Specific heating characteristic q0, W/m3K | Coefficient e | Heat consumption for heating , kW |

| 1 | Dining room | 9894 | 0,33 | 1,07 | 146,58 |

| 2 | Painting Research Institute | 888 | 0,66 | 1,07 | 26,46 |

| 3 | Scientific research institute TEN | 13608 | 0,33 | 1,07 | 201,81 |

| 4 | Electrical assembly engines | 7123 | 0,4 | 1,07 | 128,043 |

| 5 | Model site | 105576 | 0,4 | 1,07 | 1897,8 |

| 6 | Painting department | 15090 | 0,64 | 1,07 | 434,01 |

| 7 | Galvanic department | 21208 | 0,64 | 1,07 | 609,98 |

| 8 | Procurement area | 28196 | 0,47 | 1,07 | 595,55 |

| 9 | Thermal section | 13075 | 0,47 | 1,07 | 276,17 |

| 10 | Compressor room | 3861 | 0,50 | 1,07 | 86,76 |

| 11 | Forced ventilation | 60000 | 0,50 | 1,07 | 1348,2 |

| 12 | HR department extension | 100 | 0,43 | 1,07 | 1,93 |

| 13 | Forced ventilation | 240000 | 0,50 | 1,07 | 5392,8 |

| 14 | Container shop | 15552 | 0,50 | 1,07 | 349,45 |

| 15 | Factory management | 3672 | 0,43 | 1,07 | 70,96 |

| 16 | Class | 180 | 0,43 | 1,07 | 3,48 |

| 17 | Technical department | 200 | 0,43 | 1,07 | 3,86 |

| 18 | Forced ventilation | 30000 | 0,50 | 1,07 | 674,1 |

| 19 | Sharpening area | 2000 | 0,50 | 1,07 | 44,94 |

| 20 | Garage - Lada and PC | 1089 | 0,70 | 1,07 | 34,26 |

| 21 | Foundry /L.M.K./ | 90201 | 0,29 | 1,07 | 1175,55 |

| 22 | Garage Research Institute | 4608 | 0,65 | 1,07 | 134,60 |

| 23 | Pumping station | 2625 | 0,50 | 1,07 | 58,98 |

| 24 | research institute | 44380 | 0,35 | 1,07 | 698,053 |

| 25 | West - Lada | 360 | 0,60 | 1,07 | 9,707 |

| 26 | Private enterprise "Kutepov" | 538,5 | 0,69 | 1,07 | 16,69 |

| 27 | Leskhozmash | 43154 | 0,34 | 1,07 | 659,37 |

| 28 | JSC K.P.D. Build | 3700 | 0,47 | 1,07 | 78,15 |

PLANT TOTAL:

The estimated heat consumption for heating of JSC Termotron-zavod is:

The total heat generation for the entire enterprise is:

Estimated heat losses for a plant are determined as the sum of the estimated heat consumption for heating the entire enterprise and the total heat releases, and are:

Calculation of heat consumption taking into account periodic addition of liquid to the system

In real practice, a situation often arises when it is necessary to refill heating pipes with a new coolant. This mainly happens after completion of repair work or modernization of piping units. For this purpose, the volume of water consumption in the heating system is calculated.

Formula for calculating coolant Source probaltur.ru

Usually, they use the indicators specified in the technical documentation and simply add up the values. You can calculate this parameter using a simple calculator using the diameter and length of the pipes. The values are multiplied with each other and added to the heating battery data. Basically, the volume of sections of a standard radiator is 0.45 l for the following types:

- aluminum;

- steel;

- made from alloy.

For a cast iron battery this figure is different - 1.45 liters.

There is another formula that allows you to calculate the approximate value of the volume of fluid (total) in the piping system:

- V = N x VkW, where:

- N is the boiler power, Watt.

- VkW is the amount required for the system to transmit 1 kilowatt of heat, expressed in dm3.

Accurate heat load calculations

Thermal conductivity value and heat transfer resistance for building materials

But still, this calculation of the optimal heat load for heating does not provide the required calculation accuracy. It does not take into account the most important parameter - the characteristics of the building. The main one is the heat transfer resistance of the material used to manufacture individual elements of the house - walls, windows, ceilings and floors. They determine the degree of conservation of thermal energy received from the coolant of the heating system.

What is heat transfer resistance (R)? This is the reciprocal of thermal conductivity (λ) - the ability of the material structure to transmit thermal energy. Those. the higher the thermal conductivity value, the higher the heat losses. This value cannot be used to calculate the annual heating load, since it does not take into account the thickness of the material (d). Therefore, experts use the heat transfer resistance parameter, which is calculated using the following formula:

Calculation of walls and windows

Heat transfer resistance of walls of residential buildings

There are standardized values for the heat transfer resistance of walls, which directly depend on the region where the house is located.

In contrast to the enlarged calculation of the heating load, you first need to calculate the heat transfer resistance for the external walls, windows, ground floor floor and attic. Let's take the following characteristics of the house as a basis:

- Wall area – 280 m². It includes windows - 40 m²;

- The material used for making the walls is solid brick (λ=0.56). The thickness of the external walls is 0.36 m. Based on this, we calculate the TV transmission resistance - R = 0.36/0.56 = 0.64 m²*C/W;

- To improve the thermal insulation properties, external insulation was installed - polystyrene foam 100 mm thick. For him λ=0.036. Accordingly, R=0.1/0.036= 2.72 m²*C/W;

- The overall R value for external walls is 0.64 + 2.72 = 3.36 which is a very good indicator of the thermal insulation of a house;

- The heat transfer resistance of windows is 0.75 m²*C/W (double glazing filled with argon).

In fact, heat losses through the walls will be:

(1/3.36)*240+(1/0.75)*40= 124 W at a temperature difference of 1°C

We will take the same temperature indicators as for the aggregate calculation of the heating load +22°C indoors and -15°C outdoors. Further calculations must be made using the following formula:

Ventilation calculation

Then it is necessary to calculate the losses through ventilation. The total air volume in the building is 480 m³. Moreover, its density is approximately 1.24 kg/m³. Those. its mass is 595 kg. On average, air is renewed five times per day (24 hours). In this case, to calculate the maximum hourly heating load, you need to calculate the heat losses for ventilation:

(480*40*5)/24= 4000 kJ or 1.11 kW/hour

By summing up all the obtained indicators, you can find the total heat loss of the house:

This way the exact maximum heating load is determined. The resulting value directly depends on the outside temperature. Therefore, to calculate the annual load on the heating system, changing weather conditions must be taken into account. If the average temperature during the heating season is -7°C, then the total heating load will be equal to:

(124*(22+7)+((480*(22+7)*5)/24))/3600)*24*150(heating season days)=15843 kW

By changing the temperature values, you can make an accurate calculation of the heat load for any heating system.

To the results obtained, you need to add the value of heat losses through the roof and floor. This can be done by a correction factor of 1.2 - 6.07 * 1.2 = 7.3 kW/h.

The resulting value indicates the actual energy costs during system operation. There are several ways to regulate the heating load. The most effective of them is reducing the temperature in rooms where there is no constant presence of residents. This can be done using thermostats and installed temperature sensors. But at the same time, a two-pipe heating system must be installed in the building.

To calculate the exact value of heat losses, you can use the specialized Valtec program. The video shows an example of working with it.

Anatoly Konevetsky, Crimea, Yalta

Anatoly Konevetsky, Crimea, Yalta

Dear Olga! Sorry to contact you again. According to your formulas, I get an unimaginable heat load: Kir=0.01*(2*9.8*21.6*(1-0.83)+12.25)=0.84 Qot=1.626* 25600*0.37*((22-(-6))*1.84*0.000001=0.793 Gcal/hour According to the aggregated formula given above, it turns out to be only 0.149 Gcal/hour. I can’t understand what’s the matter? Please explain! Sorry for disturbing you. Anatoly.

Anatoly Konevetsky, Crimea, Yalta

How is the lowest water flow rate calculated?

It is calculated in exactly the same way as the coolant consumption used to heat a residential building in one hour. The minimum consumption is calculated in the interval between seasons when the heating system was turned off, since this value depends on the hot water supply.

There are 2 expressions used in calculations. In those cases where the heating system does not provide for forced circulation of hot water supply or it is turned off for the period of preventive measures.

The parameter is calculated with previously known values of coolant consumption (average):

Gmin = $ x Qgr / [(Tp - Tob3) x C], where:

- Qгср is the amount of heat transferred by the devices per hour of operation during the season when the heating is turned off (average), J;

- $ is the coefficient of fluctuation of fluid consumption in winter and summer. Data corresponding to 1.0 and 0.8 (winter, summer) are accepted;

- Tp – temperature value of the coolant during the heating season;

- Tob3 – the same, but in the return pipe connected in parallel;

- C – heat capacity of the liquid, taken taking into account the coefficient 10-3, J/°C;

- temperature parameters that are inserted into the calculation formula with specific values: 70 and 300C.

Thermal engineering calculation of an individual residential building

The above methods of aggregated calculations are most focused on sellers or buyers of radiators for heating systems installed in typical multi-story residential buildings. But when it comes to selecting expensive boiler equipment, or planning a heating system for a country house, in which, in addition to radiators, underfloor heating, hot water supply and ventilation systems will be installed, using these methods is highly not recommended.

Each owner of an individual residential building or cottage, even at the construction stage, is quite scrupulous in developing construction documentation, which takes into account all modern trends in the use of building materials and house structures. They must not be standard or obsolete, but made using modern energy-efficient technologies. Consequently, the thermal power of the heating system should be proportionally lower, and the total costs of installing a home heating system are much cheaper. These measures make it possible to reduce energy consumption costs in the future when using heating equipment.

Heat loss calculations are performed in specialized programs or using basic formulas and thermal conductivity coefficients of structures; the influence of air infiltration and the presence or absence of ventilation systems in the building are taken into account. Calculation of recessed basement rooms, as well as outer floors, is carried out using a method different from the main calculations, which takes into account the uneven cooling of horizontal structures, that is, heat loss through the roof and floor. The above methods do not take this indicator into account.

Thermal engineering calculations are carried out, as a rule, by qualified specialists as part of a heating system project, as a result of which further calculations are made of the number and power of heating devices, the power of individual equipment, the selection of pumps and other related equipment.

Initial data:

- A room with external dimensions of 3000x3000;

- Window dimensions 1200x1000.

The purpose of the calculation is to determine the specific power of the heating system required to heat 1 m².

Result:

- Qsp at 100 mm insulation is 103 W/m?

- Qsp at 150 mm insulation is 81 W/m?

- Qsp at 200 mm insulation is 70 W/m?

As can be seen from the calculation, the greatest heat losses are for a residential building with the smallest insulation thickness, therefore, the power of boiler equipment and radiators will be 47% higher than when building a house with 200 mm thermal insulation.

Selecting a circulation pump

Today, not a single heating system is installed without a circulation pump. Two characteristics by which the device is selected:

- Q is the coolant flow parameter for one hour, calculated in m3.

- H is a pressure indicator expressed in meters.

The coolant, which is heated to the temperature required for heating the premises, circulates through the system and releases part of the heat into the walls facing the street. This indicator is the heat loss of the heating system of the house. The pump helps in this situation by moving the coolant through the pipes and radiators in the required mode.

Circulation pump VIEIR TsN25-4 180 mm Source zonacomf.ru

Determination of pipe parameters

The cross-section of the pipe and the material from which they are made also matter when calculating the heat for heating a room. They depend on the total power of the radiators:

- If the power does not exceed 4.5 kW, then metal-plastic pipes with a diameter of 16 mm can be used for the heating system.

- Similar pipes with a diameter of 20 mm can be used in systems whose power is in the range of 5-8 kW.

- Metal-plastic with a diameter of 32 mm is suitable for heating, the power of radiators of which is 13-21 kW.

- Polypropylene pipes with a diameter of 25 mm will perform their functions flawlessly if the battery power is from 6 to 11 kW.

If the minimum power value is 16 kW and the maximum is 28 kW, then you should purchase polypropylene pipes with a diameter of 40 mm.