Energy prices are constantly rising. And every family does not want to pay a lot of money for heating their home. And here a logical question arises - “What to do?” Get warm! In this case, heating costs will be significantly lower. And often, among the variety of insulation materials, people choose polystyrene foam.

Characteristics

The production of polystyrene foam began more than eighty years ago. The first block was released in Germany, after which it began to be used everywhere in various territories. The basis for the insulation boards are polystyrene beads. Initially, they are elements with a dense structure that do not even remotely resemble foam plastic. At the first stage of production, they are foamed. Next, the base is dried and cured, which is subsequently immersed in a special chamber, where it is sintered with steam at a certain pressure. At the pre-sale stage, the foam comes in large blocks that are cut to specification.

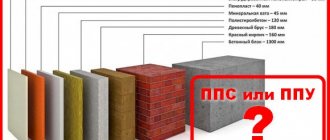

The size of the standard sheet that is used for insulation is one meter long and wide; there are also options for a foam sheet with half the width. The most popular sheet size is 120 by 60 cm. The difference between types lies not only in size, but also in the density of the material. The normal density for insulating facades is 25 kg per cubic meter. Slabs with a density of 15 and 40 kilograms are also produced. This indicator directly affects thermal conductivity. The higher the number, the lower the thermal conductivity and the higher the price for the foam. Denser insulation can withstand greater loads, so it is often used for floor insulation.

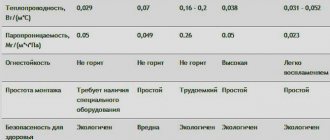

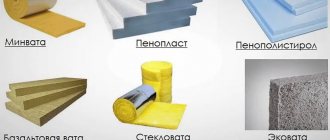

Due to the fact that the balls undergo preliminary foaming, this saturates them with gas, which causes the low thermal conductivity of the foam. Its indicator is within 0.038 W/(m×K). Typically, polystyrene foam comes in white color, but during the manufacturing process of polystyrene beads, the manufacturer can add any desired pigment to distinguish their product from other options. In some cases, foam plastic can also be called extruded polystyrene foam and polyethylene foam. These materials differ from polystyrene foam in the production method, as well as in the underlying material.

Properties

Based on the characteristics and experience of using polystyrene foam, it is quite easy to highlight its strengths and weaknesses. The advantages of such an insulator include:

- minimum weight;

- environmental cleanliness;

- low cost;

- possibility of self-installation;

- the possibility of insulating various surfaces;

- ease of processing and adjustment;

- resistance to biological processes;

- soundproofing properties.

The solids in polystyrene foam make up only a few percent of the total volume of gas that is contained in the material. This determines its light weight. Thanks to this, the insulation is perfect for use with frame buildings, since it does not exert significant pressure on the foundation and walls. This feature also simplifies the process of lifting the material to a height and self-installation. Polystyrene is a polymer, which in its structure and composition does not pose any harm to human health and the environment if it is not consumed as food, so you can insulate a building with polystyrene foam without fear that harmful substances will begin to be released from heating over time. The comparative cost of such material is low, so it is suitable for low-cost insulation of temporary buildings.

Installation of the material does not cause any particular difficulties, so it can be done without outside help. Due to its versatility, insulation can be applied to any accessible surface. At the same time, polystyrene foam does not react with most building materials, unless you take organic solvents into account. Therefore, when laying polystyrene foam on wooden, brick or concrete surfaces, there are no problems. The insulation can be processed with a regular knife or hacksaw, which simplifies the process of adjusting it to different shapes. Material of small thickness can take curved shapes, so insulation of semicircular bay windows is available. Polystyrene foam is an excellent insulation material for basements and foundations. This is due to the fact that it can remain in the ground for many years without changing its properties, since it is not subject to rotting processes and mold and mildew do not develop on the surface of the foam. A wall insulated with foam plastic acquires additional soundproofing properties, which is also a positive effect.

It is important to know about the disadvantages, which, however, are offset by the existing advantages:

- instability to organic solvents;

- low mechanical strength;

- fire hazard;

- lack of vapor permeability.

It is not recommended to use insulation during painting work. Certain types of paints that are diluted with solvents can damage the material by decomposing it. A surface insulated with foam plastic requires additional reinforcement by installing a fiberglass mesh to increase its strength, since even a slight mechanical impact can leave a dent in the material. Although fire retardants are added to the insulation during production, this does not make it absolutely fireproof. When exposed to high temperatures, the material melts, releasing carbon dioxide, but is capable of self-extinguishing. Due to the density of the material, air does not pass through it, which provides insulation from moisture, but creates a barrier to its outflow, which can result in the formation of mold under the insulation.

Note! Rodents can live inside the insulation boards. Mice and rats do not eat it, but simply make passages inside, creating a home. Poultry also like to peck at the foam, damaging its integrity.

Pros:

- Excellent interaction with other types of materials, which provides multifaceted design possibilities.

- Minimum weight, which is considered convenient during installation.

- Ease of processing, which helps significantly speed up project completion.

- High air permeability, which is a necessary property for long-term service.

- The required high thermal resistance, which ensures the maintenance of high temperatures inside the home.

- Affordable price compared to other alternative options.

Is it worth insulating from the inside?

The question of insulating a house or other building with foam plastic from the inside raises a lot of controversy, since it is difficult to answer this question unambiguously. It is worth saying that this method of foam insulation exists, but it also has opponents. The main argument is that heat-intensive materials should be placed indoors, since they absorb ambient temperature, and thermal insulation materials should be left outside so that they prevent the penetration of cold into building materials. Insulation from the inside with foam plastic is possible if you provide high-quality ventilation of the room, which will promptly remove moisture, which will prevent the formation of mold. It is also important to calculate everything correctly so that the dew point does not shift towards the living space. In this case, due to the difference in air temperatures inside and outside, condensation will occur between the insulation and the wall, which will lead to the destruction of the blocks. A video of the process of internal insulation with foam plastic is below.

High-quality insulation of walls with foam plastic from the outside with step-by-step instructions

There is not always a need for specialized equipment, but established standards and optimal technology for solving the problem must always be observed. Based on reviews of foam insulation of the exterior of the house, we can draw a simple conclusion that you need to follow a specific step-by-step action plan. Professionals consider this to be quite a labor-intensive task, so it must be approached very responsibly. The sequence of insulating walls from the outside with polystyrene foam, step by step:

- Sheets of material should be glued together in a brick pattern so that they overlap one another in the middle. Each element must be completely coated with the adhesive mixture. A special antifungal impregnation is added to this glue beforehand.

- Using a construction float, all irregularities at the joints are removed to achieve an ideal surface. Minimum size cracks must be filled with putty.

- Next, a reinforced layer is applied using facade mesh and an adhesive mixture. This allows you to achieve the desired structural strength.

- The strengthening layer is considered to be the creation of a leveling surface using the same glue.

- Then a primer is applied, which will be an excellent binding element with the next layer.

- The final design stage is the installation of a decorative layer, for example, brick-like paint, modern plaster or tile jointing.

The opinion of professionals has always been considered relevant in many areas of human activity, so it is always better to take it into account. Of course, there are cases when attitudes towards a certain topic are divided, so it is necessary to carefully and adequately analyze all statements. The complete organization of heat in a house requires the right approach, so the choice of building materials is considered an important point. Preliminary consultations and reliable information can be the key to high-quality implementation of a complex project.

Reviews

“We used polystyrene foam to insulate the roof of the garage, which is adjacent to the house. There are no complaints regarding the thermal insulation qualities of the material, since the temperature in the garage has increased significantly. The seams between the foam sheets were treated with adhesive foam to prevent the formation of cold bridges. The main problem is that there are mice in the foam. Especially at night you can hear them moving around inside the insulation. Most likely, over time, the holes will become through, which will negate all insulation. We don’t plan to use foam plastic for other rooms, so as not to observe the same effect.”

Julia, Moscow region

“Foam itself is a pretty good insulator. But before using it, you should think about what specific needs the room that will be insulated has. If there is a problem with rodents in the area or in the house, then it is better not to use this type of material. It is worth using a different type of insulation even if there is high humidity and poor ventilation inside the room. The insulation material can be considered one of the cheapest and ideal for insulating city apartments, but it is not suitable for country houses and dachas.”

Elena, Yaroslavl

“I used polystyrene foam as insulation during construction. The first floor was completed before the frost, but the second floor remained unfinished, so we had to think about how to quickly insulate it. A wooden beam was placed around the outside perimeter as a sheathing for siding. I laid foam plastic between it, gluing the joints with special foam. Siding was laid on top. In February it was noticeable that the thermal insulation was working perfectly. I have experience in using such insulation, because two years before insulating the house I used it for a change room and was pleased with the result. I consider the main disadvantage of the material to be destruction under the influence of ultraviolet radiation, as well as the fragility of the sheets.”

Evgeniy, Ufa

“The need for insulation became acute after we bought a corner apartment in an old brick building. In summer the temperature was tolerable, but the first winter showed disappointing results. I decided on polystyrene foam on the advice of friends, who persuaded me for a long time, praising the material. Four years after insulation, no deficiencies were noticed. In winter, the wall surface remains dry, and in summer the apartment is not too hot. Thanks to the use of polystyrene foam, it was possible to reduce heating and air conditioning costs. During the entire period of use, no cracks or other damage appeared on the finishing surface.”

Nikolay, Verkhnaya Salda

“We are the owners of an end apartment in which two walls face the street. We decided to replace the old wooden windows with plastic ones, which worsened ventilation and led to the appearance of moisture on the walls in winter. Frequent ventilation did not give a positive result. Over time, cracks were noticed under the window sill. It was decided to insulate the apartment. We looked for a suitable material based on reviews on the Internet and chose polystyrene foam. The insulation with polystyrene foam was carried out in early autumn, so I was looking forward to the colder weather to test the effectiveness of the foam plastic. In winter, the effect of wet walls disappeared thanks to polystyrene foam, and the apartment became noticeably warmer, which allows you to save on heating. Insulation was relatively expensive, since polystyrene foam was laid on two walls, but the result is worth it. The neighbors realized the benefits and decided to also use the insulation of the walls using polystyrene foam.”

Elena, Saratov

Disadvantages of expanded polystyrene

In addition to its undoubted advantages, the material also has its disadvantages. These primarily include:

- flammability of the material. To minimize risks, special ingredients are currently added to types of polystyrene foam to promote self-extinguishing;

- the material must be protected from mechanical damage, exposure to ultraviolet radiation and solvents. If the slabs are used outdoors, care must be taken to protect them.