Warm floors are an affordable alternative to traditional home heating that are easy to assemble without outside help. Any equipment can warm up the floor covering and room, but not all are suitable for use with water models. In this review, we will analyze the most successful boilers for working with such a heating system.

Equipment for heated floors Source valles.ru

Advice for owners of long-burning solid fuel boilers

In order for equipment to serve for a long time and with maximum efficiency, it must be chosen correctly.

The recommendations below are for those who are just planning to buy a system. A water heating boiler with two circuits is 1/4 more powerful than its single-circuit counterpart. Therefore, the power of the first must be at least 15 kW, while for the second 12 kW is sufficient. The larger the heated area, the more powerful the equipment should be.

For a good supply of hot water, the second chamber and heat exchanger of the boiler must be made of steel or copper. The cast iron firebox has a long service life.

- The dual-circuit heating system is capable of producing about 8 liters of water per minute. If this quantity is not enough for domestic needs, it is recommended to purchase a boiler with a boiler.

- Maintenance of the unit is quite simple - you just need to clean the ash pan and load fuel from time to time. Long-burning boilers can last 5-7 days on one stack.

Maintenance and safety recommendations

Before the first start-up, the owner needs to carefully inspect the pipes for leaks and the boiler itself - it should not let smoke into the room. The same applies to the chimney system. Once a year, the chimney, piping and radiators require cleaning.

For preventative maintenance, the system must be drained. To do this, an additional pipe is attached to the return circuit using a tee, at the end of which a plug is installed.

Security measures:

- The combustion chamber door must not be left open while the boiler is operating.

- It is prohibited to ignite fuel using gasoline.

- To avoid fire, do not place things on the boiler to dry.

- To load fuel, you should use special gloves.

- It is forbidden to entrust loading of the combustion chamber to children.

- You cannot store fuel in close proximity to the boiler; there must be at least a meter of distance between them.

- Overheating of the equipment is very dangerous, so you should not overload the firebox.

Modern variations of long-burning solid fuel systems with a water circuit ideally cope with the function of heat and water supply in a private home, as well as in large production, replacing gas.

Solid fuel boilers with a water circuit for heating a private house

The best known manufacturers and models: characteristics and prices

Teplodar Cooper Praktik 14

One of the best solid fuel boilers for home heating in the budget segment. A simple, energy-independent single-circuit boiler unit with mechanical control.

It features a 6 kW heating element unit pre-installed from the factory. According to reviews from owners, their power is enough to keep a house of up to 140-150 m2 warm until the morning after the last filling burns out in the evening. The burning time of one load of firewood is on average 2 hours, coal - 5-6 hours. Efficiency – 80%. Also among the advantages, owners often note convenient cast-iron grates, ease of cleaning, convection holes on the body, through which the room in which the boiler is located is heated.

The disadvantage is that the heat exchanger is made of steel, rather than the more durable cast iron. The disadvantage is partially offset by the thickness of the walls of the steel heat exchanger. In addition, the steel structure weighs less than cast iron models (on average 50 kg).

Firebox depth 40 cm: not the standard 50 cm, but quite a lot, this depth allows you to use long firewood and comfortably distribute coal in the combustion chamber.

The chimney elements and the heating element control panel must be purchased separately. When installing a chimney, it is better to use sandwich-type structures, since they can withstand elevated temperatures, and one of the features of the model, according to consumer reviews, is the very high temperature of the exhaust gases. For this reason, instead of a standard chimney, some users connect the boiler to a smoke removal system made of brick. This is a good alternative to prefabricated metal structures.

ZOTA Yenisei 18

Overall, an excellent budget boiler made in Russia, it is very popular in all regions due to its omnivorous nature (you can burn wood, coal, coal briquettes and even anthracite) and deep combustion chamber (accommodates logs up to 55 cm long, in more powerful versions - up to 60 cm ). Also, owners often like to note their compact size and acceptable burning time: 2 hours on wood and as much as 6-7 hours on coal. But in our opinion, the boiler is somewhat overrated, especially when there are analogues on the market in the form of Cooper Praktik and others. ZOTA Yenisei has excellent characteristics, but there are questions about quality and durability.

Firstly, the design efficiency is not the best, the efficiency is only 70% and most of the thermal energy simply flies away into the chimney. Secondly, Zota boilers often have questions regarding durability; the assembly is mediocre; the paint around the door burns off already in the first heating season. Thirdly, the basic kit does not include a mechanical thermostat; purchasing one means an additional 1,500-2,000 rubles and troubles. There is a stove on top, but according to practice, if you do not heat the boiler to the maximum, its functionality is questionable. It is also worth noting the presence of a socket for installing a block of heating elements, but, again, the block of heating elements itself is not included in the basic configuration.

As a result, we have what seems to be a good model for the money, but quite a compromise. A significant advantage, of course, is the depth of the combustion chamber. Available in 12, 14, 18, 20, 23, 25 kW versions.

Bosch "Solid" 2000 B SFU 12

A simple and highly reliable German single-circuit boiler with a steel heat exchanger. However, it can burn both wood and coal, coal briquettes, and coke. It has high efficiency - up to 84%. Equipped with a built-in pressure control device (no more than 2 bar), thermal protection and gas swirlers. The boiler also features a vertical loading chamber; the door for loading fuel is located on top. Because of this feature, even with a compact size, the design allows the use of long logs.

According to reviews from owners, the boiler is quite demanding on the quality of coal; the instructions indicate the minimum parameters of calorific value of 16 MJ/kg and humidity of up to 28%. Otherwise, efficiency will be lower and the need for cleaning will be more frequent. There are also special requirements for the return temperature - not lower than 65°C, even though the heat exchanger is made of steel. Otherwise, these are perhaps the only drawbacks; over many years of operation, almost all owners are satisfied with the high-quality German workmanship.

Protherm “Beaver” 20 DLO

A Slovak cast iron single-circuit boiler is one of the best and most common options if the budget is not limited to 30 thousand rubles. It has a very high efficiency for a TT direct combustion boiler - 90.2% (due to good alloy and two-pass heat exchanger design). Designed for burning both wood and coal. Almost all owners note the good build quality, simplicity and reliability of the design; in practice, the model is truly considered problem-free. It is worth noting that the ash drawer is large; it has to be cleaned less often.

In addition to the heavy weight, perhaps the only but significant drawback is the depth of the combustion chamber, which allows the use of logs only 30-32 cm long. The cost of such firewood, if you do not cut it yourself, is higher. Due to the shallow depth of the firebox, ash may also fly out of it when reloading. Available in 19, 24, 32, 39, 49 kW versions. Prices for it have increased significantly in 2022, but for a boiler with such parameters they are still acceptable.

How and what kind of coal is best to heat a household solid fuel boiler

Kentatsu ELEGANT-03 17

The cheapest among cast iron analogues is a Turkish-made and assembled boiler, designed in Japan. Thanks to the very efficient design and the presence of a layer of thermal insulation, which reduces heat loss through the body, the boiler efficiency is 80%. Owners also often note the practical water-cooled grate and compact size.

However, unlike the previous Slovak model, the build quality of Kentatsu raises many questions, from banal inconsistencies and separation of thermal insulation, sometimes to leaks due to leaks. It is worth noting that in most cases the boiler is still problem-free. Another significant drawback is that the combustion chamber is small in depth and volume; the duration of coal combustion in it is usually no more than 4 hours.

The service structure in Russia is poorly developed and in practice, in case of any problems, one cannot count on the help of official representatives. Otherwise, this is a pretty tempting offer for the price. Available in 17, 27, 34, 41 kW versions.

Cost: 29,000-32,000 rubles.

STROPUVA S20

The most successful and popular long-burning model of the Lithuanian mine type. Primarily designed for firewood, but can also burn coal. It is distinguished by a large combustion chamber volume (262 liters for the 20 kW version) and combustion duration: with wood – from 20 to 40 hours, with coal – up to 7 days. It is quite possible to maintain continuous operation of the boiler by approaching it once a day for only 20-30 minutes, and in practice the ash can be removed once every 4-5 days, the volume of the ash drawer allows. Efficiency – 85%.

Also, owners often note the convenient and compact vertical layout, which allows you to fit a heat accumulator even into a small boiler room; there have been no questions regarding quality and reliability over more than 10 years of operating practice. The boiler heat exchanger is cast iron, placed in a steel casing.

A negative feature is a decrease in power at low loads or when more than 80% of the fuel has burned out. Otherwise, the only drawbacks are the huge weight and slightly increased requirements for fuel quality (otherwise tar will form and efficiency will drop). It is also worth remembering that with a cast iron heat exchanger, the temperature difference between supply and return of more than 50-55°C creates unfavorable conditions for cast iron and leads to the formation of condensation. Available in 10, 12, 15, 20, 30, 40 kW versions.

Cost: 85,000-110,000 rub.

WEEK KO-60

An alternative long-burning model from a domestic manufacturer with a peak power of 60 kW. The whole essence of the boiler is reflected in the name - the burning duration of one load of fuel is up to 7 days. With a firebox volume of 160 liters (15-16 buckets), more or less high-quality coal actually burns out in 6-7 days, even in cold weather. When using the most inexpensive non-calorific grades of high-ash coal, the burning time is reduced to 4-5 days. Of course, in addition to coal, the boiler can also be heated with wood. The heat exchanger is made of thick (5 mm) furnace steel, this thickness implies increased durability, which is also felt in the weight of the boiler - as much as 420 kg.

Despite the enormous heating output, it is rational to use the boiler with a heated area of no more than 200-250 m2. With a larger area, it is impossible to achieve a burning duration of 7 days.

The only significant drawback is the price, which, in comparison with more practical and high-quality foreign analogues, seems simply overpriced. The owners also note the large, impractical dimensions. The permissible operating pressure is only 1.5 bar, which does not in any way affect the choice for use in a system with natural circulation, but is a problem for most closed-type systems with an operating pressure of 1.5-2 bar.

Cost: 121,000-130,000 rubles.

Buderus Logano S171-22W

A pyrolysis (gas generator) German boiler, which is considered one of the most technologically advanced in its category and practically a standard in quality and reliability. This is a volatile boiler equipped with a variety of electronic systems and mechanisms: modulated blower fan and smoke exhauster; a controller that also controls the circulation pump and supports remote control from a smartphone or PC; possibility of connecting external temperature sensors. The heat exchanger is made of extremely thick (5 mm) furnace steel, the lower afterburning chamber is additionally lined with fireclay bricks.

Overall, the practicality and thoughtfulness of the boiler is impressive. The combustion chamber accommodates logs up to 58 cm long; the design and complete set of cleaning tools make servicing the boiler extremely easy. As an example of thoughtfulness, we can cite special channels above the additional loading door, which, when it is opened, lead the smoke coming out of the firebox into the chimney; in addition, there is a button that activates the smoke exhauster, which completely eliminates the likelihood of smoke entering the room.

It is quite difficult to identify the disadvantages, but they exist. Firstly, the boiler is intended only for burning wood, no coal. Secondly, it is volatile; in case of a power outage, a generator will be needed. Thirdly, the cost of such technologies is extremely high.

Cost: 179,000-210,000 rubles.

Combining a boiler with a heating water system

A system of pipes and radiators connected to the water circuit allows the heat to be evenly distributed over the entire area of the building. The simplest type of heat exchanger can be a water reservoir, when a heat source is located directly below it. But such heating is ineffective, since the liquid will be heated only from below.

The so-called “water jacket” will be much more effective in terms of transferring thermal energy. A more complex type of water circuit consists of double top and walls along the entire contour of the boiler, inside which the coolant circulates. Due to constant circulation, the water does not stagnate, and the thickness of 3-5 cm between the walls allows the liquid to warm up as quickly as possible.

Another equally effective type of water circuit is welded from thick steel pipes, bent in waves along the walls and top of the combustion chamber like a “coil”. The coolant moves slowly through pipes with a diameter of 5-6 cm, providing excellent heat transfer

In addition, this type of circuit has an important advantage - improved maintainability

Control and monitoring unit

The boilers are equipped with special systems to regulate the water temperature in the water circuit. The simplest system is based on the operation of a thermostat - when the required temperature is reached, the blower damper is closed and thus the air flow is reduced. As soon as the water cools down, the system will work in reverse.

More advanced control systems work with the inclusion of precise temperature sensors and forced electrified air supply. When installing forced ventilation, air is supplied from above, due to which the fuel is burned almost completely. Boiler equipment of this type needs to be connected to the electrical network, but in the absence of electricity it is not able to work.

Equipping a circulation pump can save the system from completely defrosting. A boiler left unattended in winter, having used up all the fuel, will not be able to maintain the temperature level of the water in the system for a long time, as a result of which it will freeze over time. In this kind of critical situation, the control system will turn on the circulation pump, which will lead to the circulation of the coolant - in mild frosts, running water will not freeze.

Automation and Security

Solid fuel water-water boilers are equipped with a control and automatic safety unit. Of course, the peculiarities of the solid fuel combustion process do not allow the boiler to provide a level of automation similar to gas or electric boilers; however, installing a thermostat in the heating circuit allows you to control the temperature in the room.

The automation system works on the principle of regulating the air supply through a fan or by opening the damper, which is performed by the actuator, receiving a signal from the temperature sensor and from the electronic unit.

The second level of automation can be implemented by changing the coolant circulation speed set by a centrifugal pump, which is connected to an electronic control unit.

This starts or stops the circulation of water through the pipes, for which the system must have a circulation pump connected to the control electronics:

And the third, higher-quality level of automation of solid fuel boilers is achieved by regulating the fuel supply to the firebox and can only be implemented in pellet boilers.

Installation features

To heat a small home, it is advisable to install it directly in the house itself. Also, the boiler room can be equipped as a separate building or inside other outbuildings.

In this case, the heating pipe is always laid underground, always below the freezing level of the soil, and thermal insulation is ensured. In the boiler room, the air temperature should be at 10 degrees, and special care should be taken to ensure high-quality ventilation equipment.

The floor covering at the installation site must be non-flammable, level and hard. To increase the strength of the floor, the boiler is installed on a thin concrete screed. A sheet of metal with an area of at least 1 square meter must be placed in front of the heating unit. m.

During installation, you should strictly adhere to all recommendations given in the operating instructions for boiler equipment regarding the main parameters of chimneys: cross-section and height. The joints between the chimney and the chimney must be filled with heat-resistant sealant or coated with a clay solution.

Design Features

Boiler equipment of this type, in fact, is a slightly modified version of standard boilers - the design additionally includes a water circuit.

The design includes:

- firebox;

- grate;

- ash chamber;

- water circuit.

If single-circuit models are intended only for heating rooms, then double-circuit models are used both for heating the building and for supplying it with hot water.

Fuel loading can be done manually or automatically. The second option involves having a reservoir in the boiler into which fuel is added every 3-7 days. But models are more expensive than those with manual fuel supply, and therefore less common.

In addition, only fuel that has undergone special preparation is suitable for supply - coal up to 2.5 cm or the so-called “eco-peas”. Some models are equipped with built-in electric heaters that start up when the fuel supply is cut off, thus ensuring their continuous operation.

Integrating the stove into a water heating system

It is possible to integrate a furnace with a water circuit into an existing water-type heating system. If the house has, for example, a gas boiler, then you can connect a stove to it, which will replace the heating boiler.

Modern heating devices, as a rule, do not have tanks for heating water. However, they have a heat exchanger that is used for the same purpose.

Today, the market offers a large range of stoves with a built-in heat exchanger, which are capable of not only heating the room, but also providing the entire house with hot water.

Modern models of stoves involve the use of not only ordinary firewood as fuel, but also pellets - wood granules made in industrial conditions.

Selecting a location for heating equipment

All types of heating boilers are produced mainly in a floor-standing version, electric in a wall-mounted version, and gas in both a wall-mounted and a floor-mounted version. The latest variation is best installed in a spacious separate room. Such heating equipment is characterized by great power and massiveness.

A wall-mounted boiler will be an ideal solution for small-sized houses, where every square meter counts

And due to the fact that the weight of floor-standing boilers is not limited in any way, manufacturers install a cast-iron heat exchanger in it, which is much more reliable than a steel one.

Wall-mounted heating equipment is compact in size and fairly light in weight. But this type of boiler is limited in power. This minus is especially relevant for dual-circuit systems - the performance of the heating circuits will be quite low.

You should choose wall-mounted boilers only if the heated area does not exceed 200 m2 and the hot water consumption is no more than 14 l/min. If the needs are greater, then it is better to give preference to the floor-mounted variation of heating equipment.

It should be noted that many buyers, regardless of the size of their living space, prefer floor-mounted systems that are equipped with a cast-iron heat exchanger. After all, such devices are less demanding on the quality of power supply.

Circuit layout options

There are two such options:

- Flow-through.

- Cumulative.

Heating using the flow-through method requires that the water heating circuit coil be built into the jacket. This heat exchanger heats up thanks to the energy of the heating circuit. The coolant, moving along the coil, reaches a temperature of +45 ℃. The productivity of this equipment is 8 l/min.

With storage heating, the system is equipped with a boiler - a special tank for heating water. The boiler is built into the main heat exchanger or chimney. Water is heated by hot air. As hot water is consumed from the tap, cold water is supplied to the tank from the plumbing system. The maximum heating is +90 ℃.

To increase the productivity of the equipment, it is equipped with a circulation pump, which almost doubles the efficiency. However, this technology requires a source of electricity, which in turn affects financial costs.

If there are power outages in the house, the system should be supplemented with a switch that will switch the water pumping to natural circulation.

Characteristics of the heating boiler

A heating boiler with a water circuit is designed for heating residential buildings, as well as a wide variety of industrial premises. Such boilers are made exclusively from high-quality steel, which is coated with powder paint. The only fuel used is firewood. (See also: Stove with water heating boiler)

Such boilers are very profitable and convenient, first of all, because they are usually combined and have three power levels, which help to use the thermal energy they consume very economically and rationally. In addition, if necessary, a brick oven with a water boiler can be equipped with an automatic control panel, which will help control the air temperature in the room and the temperature of the water when it leaves the boiler.

On some boiler models, there are no cast iron burners on the top panel, which allows you to greatly increase the volume of water space and thereby make it possible to increase the power of the boiler itself.

Main types of solid fuel boilers

- the fuel that is used;

- number of circuits;

- device design and fuel loading option;

- Device efficiency;

- sizes.

The main unifying point is that a solid fuel boiler with a water circuit can only be installed on the floor. Various materials can be used as fuel - firewood, coal, coke and special fuel briquettes.

The peculiarity of double-circuit boilers is that they not only heat rooms, but also make it possible to obtain hot water in any quantity. In order to choose the right solid fuel boiler, you should first consult with a specialist who will help you choose the right model. This determines how well the room will be heated.

Reviews of double-circuit solid fuel boilers: advantages and disadvantages

| Advantages | Flaws |

| This is the most budget option for organizing hot water supply in the house | Fuel loading in inexpensive boilers is done manually and frequently; if it is necessary to heat the secondary circuit, fuel consumption increases |

| High efficiency and low cost of fuel compared to gas and electricity makes the economics of use profitable | Creation of a warehouse for fuel reserves, at least under a canopy or tarpaulin. |

| Most models do not require complex maintenance | Cleaning spools and removing ash - the main work is done manually on most boilers. |

| Switching from one solid fuel to another type does not require costs | Periodic inspection of the chimney, pipes and fittings. |

| Without using the secondary circuit, these are classic, equally efficient HT boilers | Limited selection of dual-circuit TT models on the Russian market |

The difference between single- and double-circuit boilers

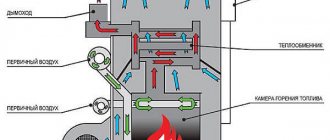

Double-circuit boilers, which are called pyrolysis boilers, differ from single-circuit boilers by the presence of an additional firebox, due to which the burnt gases do not immediately fly out into the chimney, but are saturated with air and continue to burn in the second chamber. This factor is responsible for such a high efficiency. The body of solid fuel heating equipment with a water circuit can be made of steel or cast iron.

A single-circuit boiler only provides water heating for radiators. Its design is as follows:

- firebox - a chamber in which fuel combustion occurs;

- ash pan - a box for waste generated as a result of combustion;

- chimney - a system for removing burnt gases;

- jacket - a water heat exchanger placed directly in the firebox.

The principle of operation of the equipment is as follows: firewood or coal is placed in the firebox. When burned, they release heat. Thanks to the jacket, heat is accumulated and transferred to the coolant (water), which distributes it throughout the system.

When water is heated, it expands, a quality that causes it to circulate naturally. Warm liquid goes into the radiators, and the cooled liquid returns to the boiler for heating. The advantage of a boiler with two circuits is an additional coil, which is connected to the water supply system and heats water for domestic needs.

Features of pyrolysis boilers

As mentioned above, pyrolysis boilers have two combustion chambers. In the first, the fuel burns directly, and in the other, the gases generated by this fuel burn. If you put damp firewood in the firebox, which is quite possible in winter, they begin to emit steam.

The second chamber eliminates the negative impact on the combustion process. Hot gas enters it and neutralizes moisture. On its way, the gas is saturated with air, which promotes further combustion. To separate the chambers, a grate is used, on which firewood lies. For the pyrolysis system to operate, forced air supply is required, which is provided by a smoke exhauster.

How the pyrolysis system works:

- The fuel is placed on the grate.

- They light the boiler.

- Close the firebox damper.

- They start the smoke exhauster.

- Combustion creates a high temperature in the chamber, resulting in the formation of volatile combustion products in the form of nitrogen and hydrogen.

- These formations enter the second chamber and mix with the air flow.

- Complete combustion occurs, and the released heat is returned to the first chamber.

This process provides a very high temperature, due to which the waste of burnt wood is decomposed, and the fuel is used to the maximum. The heat released by the burnt waste is used twice.

Along with numerous advantages, pyrolysis boilers also have disadvantages:

- High price.

- Dependence on electricity.

- The power declared by the manufacturer does not always correspond to reality.

- If you use the equipment half-heartedly, there is a high probability of clogging the flue with tar.

If there is gas

If there is a gas main near the house, it makes sense to consider purchasing a gas boiler. At the moment, in most regions, gas heating is the cheapest. At the same time, gas heating boilers are autonomous - you can not approach them for weeks, and practically do not require preventive maintenance. The only drawback of this solution is the considerable amount it costs to connect to the highway.

Gas is called the country's blue gold

Types of gas boilers

Depending on the type of location, gas heating boilers can be wall-mounted or floor-mounted. The maximum power of wall-mounted options is 60 kW; floor-standing units are also available with 100 kW or more. In addition, some models can work in cascade. What are the benefits of wall-mounted gas boilers? Because they can be installed in the kitchen, especially since their design matches the kitchen design.

Wall-mounted boilers can be installed in kitchens

A separate room is required for installation of a gas floor-standing boiler with a power of more than 60 kW. This can be a dedicated room in the house or an extension with a separate entrance - a boiler room. Read about the requirements for such premises for installing a gas boiler here.

Floor-standing require a separate room

You can install a gas boiler even if there is no mains, but it is possible to buy liquefied gas. In this option, a floor-standing gas boiler is installed with a burner that can work with liquefied gas (usually reconfiguration is required). It’s difficult to say right away about the efficiency of such heating: you have to calculate how much 1 kW of heat costs when using the available fuel options. Draw conclusions based on the calculation results.

Gas may be in cylinders

Types of burners

Two types of burners can be installed in wall-mounted gas boilers - atmospheric (open) and turbocharged (closed). Atmospheric burners require a chimney with good draft; turbocharged burners are connected to a coaxial chimney, which can be led directly through the wall near the boiler.

These combustion chambers also differ in the way they select air for combustion. In open burners, air is taken from the room, therefore such rooms must be equipped with supply ventilation of sufficient power. In closed combustion chambers, oxygen is supplied through one of the pipes of the coaxial chimney. Therefore, there are no special requirements for ventilation. But turbocharged boilers have their drawbacks: a chimney installed in the wall can become overgrown with frost, covered with snow, etc. In this case, the boiler does not turn on.

The main difference between wall-mounted gas boilers is the type of burner

When choosing a gas boiler, you should also pay attention to the number of positions in which the gas burner can operate. There are three modifications:

- Single stage. There are only two operating modes - full power and off. The cheapest burners, but the gas consumption is the highest, that is, such boilers are uneconomical to operate.

- Two-stage. There are two operating modes - 100% power and 50%. The third position is off. These burners are more economical and make it easier to maintain the desired temperature.

- Modulated. The most expensive, but also the most economical burners. Depending on the need, they can be turned on either at full power or at 10%, and the adjustment is smooth.

It is clear that in the long term, a boiler with a modulating burner is better for heating a private house. They are more expensive to purchase, but more economical during operation.

Condensing gas boilers

Above we discussed traditional gas boilers for heating a private home. They are also called high-temperature, since at the outlet they produce coolant with a temperature of 45-50°C and higher. Such units are ideal for working with radiator heating.

Condensing boilers are distinguished by the fact that they are effective when operating in low temperature mode - with a temperature in the return pipeline no higher than +40°C. In this case, gas is used most economically - due to the condensation of vapors contained in flue gases, more heat is transferred, which leads to a significant reduction in gas consumption.

A condensing gas boiler for heating a private house with heated floors is an ideal option

This feature of condensing boilers makes them ideal for heating a home with warm water floors. This boiler for heating a private house can produce coolant at the outlet at +35°C, then the return temperature will be about +30°C. Due to this, heating will be economical.

But, as usual, there were some drawbacks. The first is that the condensate formed is very caustic. Therefore, the chimney should be installed only from stainless steel, and of high quality. The second disadvantage is that the price of condensing boilers is higher than traditional boilers of the same capacity. This is due to a more complex design and also to the fact that condensate-resistant materials are used.