Gas boilers for heating houses - the equipment transmits the energy generated as a result of gas combustion. The devices are used to heat houses in areas where there is a centralized gas supply and allow creating comfortable indoor conditions for long-term stays.

In the absence of a central gas supply, heating can be carried out using cylinders of various sizes. In this case, it is necessary to monitor the quality of the cylinders and their serviceability.

Cylinders of different capacities

Gas boilers are popular and are used for heating a country house. This is due to the reliability and efficiency of the equipment.

How to choose gas boilers for heating a private home? In order to answer this question, it is necessary to consider equipment options and its specifics.

Based on their functional features, they are divided into single-circuit and double-circuit boilers.

Single-circuit

Heating scheme for a country house based on a single-circuit boiler

Used for heating only. In order for the device to perform the function of providing the room with hot water supply, you will have to additionally purchase a boiler. Its size is chosen depending on the number of people permanently living in the house. The more residents, the larger the boiler volume should be. The recommended boiler size is 100 liters per person.

It must be taken into account that while the boiler is operating, the single-circuit boiler does not heat water for the heating system. Heating is resumed only when the water in the boiler reaches a certain temperature. With a large flow of hot water, the boiler may not cope well with the heating function. A break in the operation of a gas boiler for heating can be very long. As a result, the room will be cool.

Wall or floor option

The first lighter and more compact models. They can be placed in the bathroom or kitchen. They have low power and do not allow heating large areas. Weight does not exceed 70-80 kg.

- The floor-standing version is larger, weighs more and costs more.

- Most devices have an open combustion chamber and require forced ventilation assembly.

- The product uses expensive materials.

- Preferred for use in large houses. The service life of such a device is from 50 years.

Dual-circuit

Heating scheme for a country house based on a double-circuit boiler

For heating a private home, this is equipment that simultaneously performs several functions: heating the room and providing hot water supply.

The device has a built-in burner. Hot water flows into the tap immediately after it is opened. If there is no recirculation pump and low water pressure in the system, in order for hot water to come out of the tap, you will have to wait a few minutes until the remaining cold water in the system drains. The waiting time depends on the distance of the water intake from the heating equipment, the diameter of the pipe and other factors.

Purchasing a double-circuit gas boiler is economically beneficial, but more expensive than purchasing a single-circuit plus boiler. The device takes up much less space.

When hot water supply is provided, the supply of heated water to the heating system is not suspended.

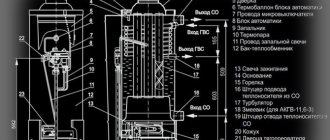

The equipment ensures uninterrupted operation of both heating and hot water supply systems. Two independent circuits are provided specifically for this purpose. Viessmann Vitodens boiler and its diagram

Two circuits or a separate boiler?

The most intriguing question is: in what cases is it worth using a double-circuit boiler for hot water, and in what cases is it better to install a separate tank.

If, for example, you have an apartment with its own heating, but only one bathroom, then you can quite easily use a boiler with two circuits. The same applies to private houses. In this case, there will be plenty of hot water.

If you have a substantial house for a large family, 2-3 bathrooms, then in this case it is better to use an indirect heating boiler in conjunction with a single-circuit boiler. The same applies to public facilities.

So, we looked at the features and main characteristics of double-circuit boilers. We hope that the information presented will help you decide on the choice of device for your home. Remember that a properly selected unit will be able to keep you warm and provide hot water. May your home always have good weather, warmth, food and hot water!

Methods for removing combustion products

Double-circuit boilers are divided according to the method of removing combustion products:

- chimneys,

- condensation,

- turbocharged.

In chimney systems, combustion products are removed through a pipe. In condensing boilers, the installation of the chimney requires complete sealing. Turbocharged systems require the additional installation of a fan in the chimney.

Turbo boiler nova

- Power indicator

- Heating indicator

- Manual adjustment of hot water supply

- Manual heating adjustment

Be careful when plugging the boiler into a 220V socket - the polarity of the connection matters; if the boiler turns on for just a few seconds, the red indicator lights up and the water stops heating. Reverse the plug and plug it back into the outlet.

Where can gas boilers be installed?

The equipment is wall mounted or installed on the floor. Both types have their own characteristics.

Wall-mounted ones are usually called mini-boiler rooms. One product body contains a heat exchanger, a burner, a control device for it, circulation pumps, an expansion tank, a pressure gauge, a thermometer, a security system and other elements. This technique incorporates all the most advanced modern technologies.

Wall-mounted boilers have a number of advantages, these include:

- Lower cost. On average, the price difference between wall-mounted and floor-standing boilers of the same power is 20% or more.

- The equipment is much easier to install. This allows you to significantly save on the installation of individual elements.

- In addition, the advantage of the device is its small dimensions. This is a compact device that, if necessary, can be covered with furniture panels, making it completely invisible.

- The wall-mounted boiler fits organically into the interior of the room.

The device can have a power of 12-42 kW. The heating area is respectively 50-400 m2.

The equipment is divided into products with forced ventilation and natural draft. The world's leading manufacturers produce products of both types, which allows you to choose the most suitable one depending on the initial data of the room.

Features of wall-mounted boilers with natural and forced draft

Scheme in heating boilers with natural draft

A product with forced ventilation provides for the removal of decomposition products using a built-in fan. In addition, they do not require an influx of fresh air necessary to maintain combustion. Equipment with forced ventilation does not burn oxygen in the room. The devices are suitable for rooms where there is no chimney.

In wall-mounted boilers with natural draft, decomposition products are removed through a traditional chimney, which removes harmful substances to the street.

Wall mounted with piezoelectric ignition

Wall products are also distinguished by the type of ignition. It can be electric or piezo ignition. Boilers with an electric ignition system are much more economical. The system does not have a pilot light that burns continuously. This allows you to significantly reduce gas consumption. In the event of a power outage, the equipment automatically resumes operation.

The model with piezo ignition must be turned on manually when there is a power outage. This is especially inconvenient if the outage occurs during the day when no one is home. When residents return, the room will be cold. To resume heating, the system will have to be turned on and wait until the water in it heats up to the desired temperature.

Burner type

Burner type of wall-mounted boiler

They are divided by burner type. It can be regular or modulated. The second type allows for economical operation of the boiler. The device independently regulates power depending on heat demand.

The modulating burner guarantees comfortable conditions for providing hot water and constantly maintains the temperature at the set level. The device turns on automatically when the temperature in the system drops, and turns off after heating.

Most models of wall-mounted gas boiler equipment are equipped with additional products that ensure safe operation of the equipment.

- the fire sensor, in case of loss of flame for any reason, automatically turns off the gas supply to the device;

- The thermostat completely turns off the wall-mounted boiler in case of an emergency increase in temperature;

- If the power supply disappears, a special device also completely blocks the operation of the equipment.

Models and cost

Single-circuit wall-mounted boilers are offered by the following manufacturers: Vaillant; Baxi; Ariston; Bosch; BERETTA, NOVA

Vaillant

Popular models:

- BERETTA CITY 28 RSI (turbo). Average cost: $510;

- Bosch WBN 6000-24H RN. Average cost: $580;

- Ariston CLAS EVO SYSTEM 24 FF. Average cost: $490;

- NOVA FLORIDA PICTOR DUAL LINE RTFS 28. Average cost – $630.

The choice of a specific product depends on the area of the room, functionality and performance characteristics.

Double-circuit wall-mounted boilers are offered by the following companies: Ferroli, Ariston, BERETTA, Chaffoteaux and others.

Popular models:

- Chaffoteaux ALIXIA S 18 FF. Average cost: $400;

- Ariston MATIS 24 FF. Average cost: $410;

- Ferroli Domina F24. Average cost: $380;

- BERETTA CIAO 24 CSI (turbo). The average cost is $420.

These devices mostly have the same power. The equipment differs in performance characteristics, efficiency, and functionality.

Floor equipment

Double-circuit floor-standing gas boiler

It is installed mainly in a separate room. The heat exchanger of the device can be made of high-quality steel or cast iron. Both materials have their pros and cons.

The cast iron heat exchanger is not susceptible to moisture. It is less susceptible to corrosion. Cast iron is a brittle material. This increases the risk of damage to the heat exchanger when transporting equipment, as well as loading and unloading it. In addition, the destruction of cast iron products occurs due to the use of too hard water in the system.

A heat exchanger made of steel has less weight than a cast iron one; the metal is not susceptible to damage during transportation. Failure to comply with the operating rules of the equipment leads to metal corrosion and subsequent failure of the heat exchanger.

Models made of copper and stainless steel are less common. Both varieties are not subject to corrosion and are not afraid of mechanical damage. The cost of metal is significantly higher, which affects the price of the heat exchanger and boiler itself.

You can minimize the risk of breakdown of a steel floor-standing boiler and extend its service life by carefully ensuring that the temperature in the system does not fall below the so-called dew point. In this case, condensation does not form on the surface, which has a destructive effect on the metal.

Types of burners of floor-standing boilers

Types of burners of floor-standing boilers

Floor-standing equipment may have an atmospheric or inflatable burner. Each of them has its own characteristics. An inflatable burner has a high cost and at the same time high efficiency. Atmospheric burners are much quieter and less expensive. In addition, the atmospheric burner is included in the cost of the main equipment, being its integral part.

An inflatable burner is purchased additionally. It is not included with the boiler. Equipment with an atmospheric burner has a power of 10-80 kW. Boilers with inflatable burners can have a power of several thousand kilowatts. This allows the device to be used for heating very large areas.

The heat exchanger of a floor-standing boiler is afraid of the formation of scale resulting from the deposition of mineral compounds.

Floor-standing boiler heat exchanger

Scale interferes with normal heat exchange, which, in turn, reduces equipment productivity and also leads to excessive gas consumption.

What is the price

The first principle of dividing gas boilers in terms of cost is the difference in the control system. Mechanical non-volatile control will cost less and even last longer. However, with electronic control, the calculation is for maximum comfort, and the durability of a high-quality boiler is still calculated in decades.

The second principle is the localization of boiler production. Foreign boilers are sometimes an order of magnitude more expensive than their domestic counterparts; in addition, among imported models there is rarely the simplest version of a gas boiler; almost all offers have wide functionality with a correspondingly high cost.

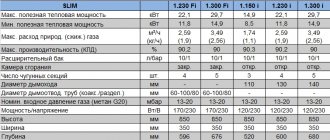

| Manufacturer | Model | power, kWt | Installation | DHW | The combustion chamber | Price, rub |

| Ariston | Egis Plus 24 CF | 25,8 | Wall | Yes | open | 38 500 |

| Unobloc GPV 24 RI MET | 24,0 | Floor | No | open | 85 000 | |

| Clas EVO 24 FF | 24,0 | Wall | Yes | closed | 48 600 | |

| Buderus | Logamax U072 - 24 | 24,0 | Wall | No | closed | 44 500 |

| Logamax U052-24 K | 24,0 | Wall | Yes | closed | 51 000 | |

| Logamax plus GB072 24 K | 24,0 | Wall | Yes | closed | 88 500 | |

| Viessmann | Vitopend 100-W WH1D268 | 24,0 | Wall | Yes | open | 47 600 |

| Vitopend 100-W WH1D274 | 24,8 | Wall | No | closed | 47 900 | |

| Vitogas 100-F GS1D870 | 29,0 | Floor | No | open | 140 000 | |

| Borinskoe | AOGV-23.2-1 Eurosit | 23,2 | Floor | No | open | 15 700 |

| AKGV-23.2-1 Eurosit | 23,2 | Floor | Yes | open | 17 800 | |

| Zhukovsky | AOGV-23.2-3 ZHUK (01), square | 23,2 | Floor | No | open | 21 600 |

| AKGV-23.2-3 Comfort | 23,2 | Floor | Yes | open | 22 200 | |

| AKGV-23.2-3 ZHUK (01), square | 23,2 | Floor | Yes | open | 25 600 |

Advantages

Gas boilers are one of the most common; the equipment has a number of advantages in comparison with electric and solid fuel boilers:

- Depending on the power, the equipment allows you to heat both a very small room and a country house of impressive size;

- Gas boilers have a high efficiency. A number of models have an efficiency of up to 98%;

- The cost of gas for equipment is much lower than the price of electricity and solid fuel;

- The device delivers much more energy than it consumes;

- There is no need to watch the flame during installation. Gas is supplied to the device continuously. The owner will not have to get up at night to add fuel to the boiler;

- If for some reason the flame in the equipment goes out, the built-in sensor independently notifies the electric ignition system, resulting in a spark being supplied to the burner;

- The equipment is easy to use. Start-up and shutdown are carried out using one button.

- Gas boiler equipment has a long service life. If the rules of use are followed, it can serve for decades without losing its performance and characteristics.

The required temperature is set and adjusted manually or using weather-dependent automation;

Flaws

Like any other equipment, gas boilers have their drawbacks. These include:

- To install the equipment, you will have to meet certain conditions that relate to the technical side. Relevant documents must be completed. The installation is approved by Gaztekhnadzor. To sign the documents, a project must be provided, a copy of the agreement with the organization carrying out the installation, a copy of the license of this company to carry out activities for the installation of gas equipment;

- Before installation, you should install a chimney, the main function of which is to remove waste substances. If there is a fireplace or a second boiler in the house that runs on a different fuel, a separate chimney is provided for gas equipment. Connecting it to a common one is strictly prohibited. A spark from a boiler in a common chimney can lead to a fire or explosion;

- Installation of a floor-standing boiler is carried out only in a well-ventilated room with a separate exit to the street and an opening window or vent. This is important for equipment with an atmospheric burner;

- At low pressure in the gas pipeline system, the boiler may begin to smoke, and its efficiency decreases. The same applies to burner wear. Over time, it also begins to smoke;

- When installing a device for heating a room with an area of less than 100 m2, it is necessary to install an automatic system that monitors gas leaks. Therefore, for small buildings, installation of gas boiler equipment may not be economically viable.

Flow devices and heating equipment

There are also flow-through heaters. These are geysers that are installed on running water, that is, they are built directly into the main line.

Passing through the built-in heat exchanger, the water heats up and reaches the consumer already hot. The equipment is used to provide the premises with hot water supply. Such devices are not used for heating systems. Constant supply of hot water to the device is dangerous due to overheating of the device and its subsequent failure.

Gas boiler and solar collector, how water is heated

For heating systems with limited space, wall-mounted gas boilers are mainly used. When choosing between two types of equipment, a wall-mounted boiler or a column, you need to focus on the functions that the equipment should perform.

For heating water and heating, preference is given to double-circuit boilers. Or simultaneously two independent products - a boiler and a column. The column will provide a constant hot water supply, and the boiler will work to heat water in the heating system. The disadvantage of using two devices at the same time is the supply of gas to both points. Also, 2 devices take up much more space than one.

Storage boilers - design and operating principle

Instantaneous and storage water heaters

Storage boilers, or boilers as they are also called, are equipment designed to heat large amounts of water used for hot water supply to a room.

The device operates primarily from the mains and is an oval or round tank, which is enclosed in a layer of heat-insulating material, on top of which there is a decorative casing. Polyurethane foam is usually used as insulation.

The container is made from:

- of stainless steel;

- plastic;

- steel with enamel coating.

At the bottom of the tank there is a heating element, which heats the water, the temperature of which is limited by a thermostat. In most models, the maximum water heating temperature is 75 ºС.

In the absence of water extraction, the equipment works to maintain the temperature at the set level. The system automatically turns on the heating element for heating, and after reaching the required temperature, turns it off.

The heating element is equipped with additional overheating protection, which automatically turns off the heating element when the water temperature reaches 85 degrees.

The most optimal water heating temperature for a boiler is 55 ºС. With this operating mode, the device not only provides the required amount of hot water, but also saves energy. Water is collected using a tube that goes into the top of the tank. In this place the water has the highest temperature.

Cold water replenishment occurs in the lower zone where the heating element is installed. To protect equipment from electrochemical corrosion, the device is equipped with a magnesium anode, which tends to deteriorate over time and therefore requires regular replacement. On average, the anode lasts 2-3 years. After this period, a new one is purchased and installed.

The cost of heating a country house

The cost of heating a country house with gas depends on the availability of a central gas supply. In its absence, the system can operate from a cylinder. In this option, the connection is carried out as quickly as possible. In addition, refusing to tie into the central system and laying gas pipelines in sections allows for significant savings.

Launching such a system will cost 50,000-150,000 rubles, depending on the selected equipment. You can purchase large volume cylinders for liquefied gas from specialized companies. A number of them provide on-site services for refueling cylinder equipment at the installation site.

Heating from a central gas supply system, taking into account the design and connection, on average will cost at least 100,000 rubles more.

To heat 100 m2 of area, an average of 10 kW of power per hour is required. To calculate monthly consumption, multiply by 30 days and 24 hours. The result is 7200 kW per month. 10 kW of power is approximately equal to 1 m3 of methane gas.

Boiler power calculation

Like any boiler, a double-circuit boiler must be selected taking into account the required power. You need to select it wisely based on the heat loss of your home, which you can’t always calculate on your own. The roughest approach is to provide 1 kW of power per 10 square meters of your home.

But it's another matter if you are going to use the second circuit on an ongoing basis. Based on the boiler power, the amount of hot water released per minute depends. Everything is simpler here. You need a minimum of 24 kW of power to be sure that you will have enough hot water production. Typically, a boiler of this power is capable of releasing 12-14 liters of water per minute. This volume is just enough to take a shower or completely wash the dishes.

Possibility of installing a gas boiler for heating a frame house

They can be installed in country houses of any type. When installing a heating system for a frame country house, any gas equipment can be used. The design has no restrictions in the choice of technology. They are the most effective and cost-effective.

When choosing a gas boiler, it is important to consider the dependence of the device on the electrical network. For country houses where there are frequent power outages, you can install a simplified system without automation. The equipment will maintain the water temperature in the system regardless of the room temperature. You can also additionally use a heat generator, which independently generates electricity from heat, which is necessary for the uninterrupted operation of the automation.