Purpose and scope of application

A solid fuel boiler is a device that generates thermal energy by burning solid fuels - firewood, coal, briquettes, etc.

It is used for supplying hot water and heating buildings, country houses, apartments, and summer cottages. It is popular in regions with low gasification levels or unstable power supplies.

Components of the structure

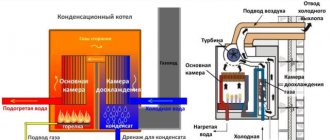

The traditional boiler construction scheme has become a design consisting of several functional modules in a single housing.

1. Heat exchanger – a device for transferring the heat energy generated during combustion to the coolant. May be made of cast iron or steel. Service life up to 20 years.

2. Firebox with a door - a chamber where the load is placed and combustion occurs.

3. Grate – a device for supplying air, uniformly distributing materials, and sifting waste into the ash pan. Made from gray cast iron.

4. Hatch – cleaning the upper channels.

5. Thermostat – maintaining the set temperature level:

- mechanical – traction control;

- automatic (microprocessor controller).

6. Additional devices - for safety and comfort:

- ignition burner;

- draft regulator;

- thermostatic valve.

The principle of operation of heating in the country

You should not confuse concepts such as a residential cottage and a summer house, since the latter building usually serves exclusively as a place of recreation and not permanent residence. If we talk specifically about heating, a country house has the following features:

- Almost all country houses do not have access to a gas main, which explains the need to install a different type of heating. This is why gas boilers for summer cottages are used much less often than other models;

- If there is electricity at the dacha, then, as a rule, it has a power limited to two phases and the possibility of installing wiring. During the warm season, the building can be heated using an air conditioner, but in cold weather the use of such equipment will not help at all;

It is important to remember that equipment whose power is more than 3.5 kW is strictly prohibited from being connected to a central outlet, since the current is too high for the connection. Devices with power ranging from 3.5 to 7 kW must be connected using a separate cable;

- It is best to heat the dacha not regularly, but with some frequency. Do not forget that a mandatory condition for country heating is that it should not defrost if the temperature drops to 0°. So, in winter the house is unheated most of the time, which explains this need. The inertia indicators of the heating system of a country house should be minimal so that it is possible to heat the entire building as quickly as possible.

Operating principle

Main stages

1. The boiler begins to work from the moment of ignition, when the temperature rises sharply to 600° in five to ten minutes. At the same time, according to the settings, the heat exchanger is heated to 40°-70°.

2. As combustion progresses, the temperature in the furnace increases to 1000°-1300°, and the heating of the coolant - water - reaches an operating value of no more than 95°, which is maintained by regulating the air supply into the combustion chamber with a valve.

Heating the coolant above 95° is dangerous for the system and can damage it!

3. After complete combustion with the formation of smoldering coals, the temperature slowly decreases.

Advantages

- Long-term autonomy with the possibility of use as a backup heat source during a power outage or gas supply.

- High efficiency factor (efficiency), reaching 85%.

- Long-term combustion mode using the resulting flue gas that supports the process.

- Cheap fuel, but with costs for transportation, loading and unloading, and storage.

- Reliability and long service life.

- Versatility.

- Simplicity of design.

- Lower price compared to other types of boilers (electric or gas) with the same power ratings.

Flaws

- The need for a dedicated room for the unit, as well as storage of supplies.

- Mandatory installation of a chimney.

- Labor-intensive operation for loading and cleaning from ash and soot.

Reviews of household solid fuel boilers: advantages and disadvantages

| Advantages | Flaws |

| Cheapness and availability of both boilers and fuel, “omnivorousness” of most models. The operating costs of solid fuel boilers are also among the lowest, lower only for gas and some liquid fuel boilers | The need to organize a seasonal warehouse for fuel storage, which means additional space, effort and expense |

| Reliability and simplicity due to the simple design, in which most often there is simply nothing to break | The need for constant monitoring and management. Even long-burning boilers require regular refilling of firewood, manual ignition and constant monitoring, not to mention classic inexpensive models |

| Installation of a TT boiler does not require approval or permitting documentation, as is the case with gas or electricity | Transportation, storage and combustion of solid fuels involves increased indoor pollution and a characteristic odor, especially when burning coal. |

| Prices for the most budget wood-burning models start from 12-14 thousand rubles | According to owner reviews, the prices for more technologically advanced and automated models are quite high, paying off for at least 5 years. |

| Independence from external factors, most models are non-volatile | |

| A huge selection of models for any budget and functionality, the availability of single-circuit and double-circuit models, as well as automated boilers that practically do not require human intervention | |

| Easy to use and maintain. Heating and cleaning modern solid fuel boilers is much easier and more comfortable than older models |

Criterias of choice

Before considering purchasing options, you need to determine:

1. Who will be the stoker and with what frequency will manually load fuel:

- three to five times a day;

- one to three times a day;

- once every three to six days;

- no more than once a week.

2. What to heat with:

- dry firewood or briquettes - an option that is not suitable due to the high price and humidity requirement of 20-25%;

- ordinary logs with a humidity of up to 40%, lying under a canopy until mid-autumn - a really applicable situation;

- wood waste - an undesirable option due to significant underestimations of power characteristics and the need for frequent cleaning of the product;

- coal is not a very suitable choice due to the high price, unpleasant odor, dirt, ash, etc.;

- pellets - a good option if you use only wooden ones, which you need to find and figure out where to store the seasonal supply, because purchasing in small quantities is not a very pleasant experience.

After answering the questions, you can start exploring your options. What you should know:

1. When selecting a manual loading product:

- There are no universal boilers; the design of the firebox and heat exchanger is developed for a specific material, the use of which will achieve the best result;

- the larger the volume of the firebox, the longer the boiler operates on one load;

- power depends on the fuel used due to differences in combustion temperature;

- the larger and heavier the unit, the longer its service life and higher efficiency due to the large heat exchanger area;

- the possibility of easy cleaning without extra effort and the use of special tools that are not commercially available;

- frequency of replacement of consumables - grates, seals, their cost and availability for sale.

2. When choosing a product operating in automatic mode:

- can work unattended for a long time, and one load is enough for five or more days;

- equipped with a “scoop” type burner, where the flame burns in a horizontal plane;

- equipped with automatic ignition;

- Only pellets are suitable;

- the need to break the loading flow to prevent a possible fire in the bunker during reverse draft;

- possibility of use in manual mode;

- higher price than models with automated loading.

3. When choosing a product with automated loading:

- mandatory presence of an operator up to twice a day;

- equipped with a retort type burner;

- continuous loading flow for more than five days with automated supply of pellets from a large bunker;

- lack of automatic ignition, which requires supervision for manual ignition when extinguished;

- possibility of use in manual mode with loading coal or firewood;

- mandatory presence of a bunker or constant purchase of pellets during the heating season;

- the need for regular cleaning of the heat exchanger (once every two weeks) to maintain efficiency at levels up to 85%;

- requirement to take special measures to ensure fire safety.

It should be remembered that models from branded manufacturers will be higher in price than products from unknown companies. However, if you are determined to buy a high-quality, long-lasting product, you need to choose a proven brand, and not just look at the price.

A unit from a reliable brand will create a cozy atmosphere in a country house or cottage during the unfavorable period of autumn-winter cold.

Steel or cast iron - which is better?

Solid fuel boilers are made from two types of metal alloys - steel and cast iron, and therefore there are ongoing battles on forums about which of these options is better.

Cast iron model

Opinions, as usual, are the most contradictory, and it is simply impossible to make an unambiguous verdict here.

Steel model

Let's still try to understand this issue, relying on the opinions of experts.

Table 3. Experts' opinion.

| Evaluation criterion | Pros and cons |

| Weight and transportation | A boiler with a steel body is lighter, so it is much easier to transport and carry it by hand. Cast iron is generally very heavy, and also fragile. Such a boiler must be moved very carefully, since after an impact it may not survive to the first fire. |

| Maintainability | The most common problem that occurs with cast iron boilers is a burst section that needs to be replaced. And here you can expect difficulties associated with ordering it and waiting for delivery - as well as with finding a technician who can replace it so that in the future the boiler, which needs to be completely disassembled, does not leak. On a steel boiler, at most, you may need to weld a seam, and any welder can do this. |

| Price and durability | If we compare two models with a similar design and power, then the cast iron one will be twice or even three times more expensive. Manufacturers and sellers explain this by a longer service life, which many experts strongly disagree with. And even if so, then for the amount you need to pay for a cast-iron model you can buy at least two steel ones, which in total will amount to the same period. And it is still unknown how many times during the entire life of a cast iron unit you will need to change its sections. So here the advantage definitely goes to the steel boiler. |

| Efficiency | About the same. However, cast iron is more massive and retains heat longer, while steel, although it heats up faster, also cools down faster. |

| Difficulty of installation | A cast iron boiler is more complex in installation, and any connection error can cost it its “life.” So here too it loses to its steel brother. |

The best manufacturers

Solid fuel boilers are widely represented on the market. Among the recognized brands are both foreign and Russian companies.

Teplodar

The Russian company has been designing and producing heating equipment since 1997, having patented 50 unique developments. Product production is carried out at three production sites with a total area of over 20 thousand square meters. meters.

The annual renewal of the technological park with modern machines from the world brands Safan and Trupf ensures high quality. Automated assembly is actively used under the constant supervision of the quality control department.

Zota

Despite the fact that the trademark was registered in 2007, the company’s products have been known since the 90s. last century. The manufactured equipment is developed taking into account the climatic conditions of countries where it is not always possible to carry out regular maintenance.

Along with heating equipment, the company also produces instruments and accessories, incl. automation systems, heating elements.

Kiturami

The history of the South Korean company as a manufacturer of heating equipment begins in 1962. Currently it is the largest manufacturer with its own research center. In total, more than 650 patents have been registered.

Branded products not only heat the premises, but also provide hot water. The most high-tech equipment and materials are used in production, increasing the service life and increasing the reliability of products.

Stropuva

The Lithuanian company began work in 2000 with the registration of a patent for the top-down combustion method, providing a long combustion time for one load, high efficiency and ease of operation. Since 2012, production has also been carried out in Russia at the joint venture Stropuva Baikal Service.

Along with the sale of products, a range of activities is also provided, from service maintenance to installation and commissioning.

Burzhuy-K

Registered brand of one of the leading manufacturers of heating equipment since 2006. Over 50 specialists work in two production workshops equipped with the necessary machines and lifting devices. The monthly production of goods includes at least 200 products.

How to choose a good solid fuel boiler for your home?

Actually, this list is unlikely to be enough to solve all sorts of questions from different users who visited our resource. Considering this and the fact that many potential buyers of heating equipment do not know how to choose a solid fuel boiler for their needs, we suggest you look at the aspects you should know:

- Installation method . Based on the type of installation, such equipment is divided into wall-mounted and floor-standing boilers. The first ones need to be mounted on the wall (relevant if there is little space), while the second ones are easy to install, but take up more space. There are also parapet ones, but this installation is applicable exclusively to gas models.

- Heating area . This is a key characteristic that can always be found in the description. But it should be understood that the designation of a particular model does not indicate that the indicated value is applicable to certain climatic conditions, which must be clarified with the manufacturer, speaking about specific operating conditions.

- Fuel bunker . Solid fuel boilers cannot do without such a design unit. We are essentially talking about a large container, the size of which determines how large the firewood can be placed inside. It is worth adding that modern models often support setting a number of parameters, including a full daily operating cycle. It is also possible to install automation in the bunker, which provides for minimal control by the user.

- The combustion chamber . If you don’t know the difference between boilers with open and closed combustion chambers, try to pay more attention to this issue. We will only reveal the key features. Open or chimney boilers require the absorption of air from the room to operate. The combustion products are discharged outside through the chimney. This argues for an affordable price, but also certain difficulties. For example, you need to make sure there is good ventilation in advance. It is advisable to think about having a humidifier to restore a favorable climate in the house. Closed or turbocharged models are completely isolated from the internal space, so they use air from outside.

- Protection systems . Modern equipment has many sensors and technologies that argue for a high level of safety, and their presence cannot be ignored. It is important that the equipment maintains a protection system against water overheating and fire extinguishing. When choosing a boiler with an open chamber, it is worth paying attention to the presence of draft protection to ensure constant control over the proper quality of exhaust of combustion products to the street. If the equipment operates on the basis of electricity (controlled), then it is advisable to ensure that there is protection against power failure. Otherwise, the equipment may break due to power surges.

Where can I buy

It is advisable to purchase boilers in specialized departments of heating equipment stores, as well as in representative offices of heating equipment manufacturers.

Now you can order online a suitable unit from an online store that specializes in selling similar products. In addition, on the pages of popular aggregators “Yandex.Market” or E-catalogue, you can always get acquainted with the required information - how much the required boiler costs, study the description, compare parameters, find a store and place an order.

When purchasing, you need to pay attention to the characteristics, especially the efficiency, which should not be hidden.

Manufacturers often try to overestimate the efficiency of the boiler!

What to burn, from sawdust to anthracite

Materials of plant origin are used as fuel for this type of boiler, even peat and coal are essentially plants that existed many thousands or millions of years ago.

Firewood

Firewood is a classic solid fuel; its use dates back as many years as people have been familiar with fire. Firewood from various types of wood is used for boilers; the efficiency of the heating system and its uninterrupted operation largely depend on the type of wood and humidity. As for humidity, it is clear that the lower it is, the higher the heat transfer, since energy is not spent on moisture evaporation, and the properties of various types of wood when used as fuel deserve more careful consideration.

The most suitable option is considered to be deciduous trees, among which the record holders for heat transfer are: oak, beech, hornbeam and ash; birch is not far behind, but if there is insufficient air supply to the combustion site, birch begins to release tar, which is deposited on the walls of the smoke removal system.

Hazel, ash, yew, pear and apple have proven themselves well; they split easily and burn hot, but elm and cherry emit a lot of smoke when burning. Poplar and linden, familiar to city dwellers, are not the most suitable option for a firebox; they burn well, but quickly burn out and spark strongly during the combustion process; aspen and alder are a completely different matter, which not only do not emit soot, but contribute to its burning on the walls of the chimney .

Coniferous trees are characterized by the presence of resins in the composition of the wood, which is ultimately deposited on the inner surface of the pipe; the process of deposition of resin and soot is especially relevant for boilers in which the combustion process occurs at a not very high temperature. The heat transfer of conifers is noticeably lower than that of deciduous trees.

Briquettes

This type of fuel is made from wood chips, shavings, peat, as well as agricultural waste - sunflower husks, straw, etc. Briquettes are produced by pressing, the binder is ligin - a natural mixture of aromatic polymers, no synthetic materials are used in production, so they deservedly considered a clean fuel.

Briquettes are produced in the form of a cylinder or parallelepiped; cylindrical products from some manufacturers have an internal hole along the entire length. Briquettes are not susceptible to fungal attack, have a high calorific value and are very convenient to use, as they have a low ash content of no more than 3%.

Pellets

Pellets are a granular type of fuel that greatly facilitates the task of automating solid fuel heating devices. The material for production is waste from woodworking and agricultural production - sawdust, bark, wood chips, shavings, flax waste, sunflower husks, etc. The material is processed into flour and pressed into cylinders under high pressure, the diameter of the pellets is 5–8 mm, and the length is not exceeds 40 mm. As in the case of briquettes, the binding material is a natural component – ligin.

Prices: summary comparison table

| Model | power, kWt | Efficiency, % | Combustion chamber volume, l | Cost, rub. |

| Week KO-60 | 60 | 92 (but highly dependent on fuel) | 160 | 130 000 |

| Teplodar Cupper PRO 22 | 22 | 85 | 35 | 39 000 |

| NMK KVO MAGNUM 20 TE | 20 | 80 | 79 | 62 000 |

| Bastion M-KST-20 P | 20 | 85 | 70 | 38 000 |

BoilersLong burning boilersRussian-made boilersBoiler manufacturersSolid fuel boilers