When installing autonomous heating for a private home, the owner has to choose a boiler in accordance with the type of fuel, its piping scheme and the need for additional hot water supply. When connecting the boiler to the heating system, its functional purpose is taken into account and the necessary components and pipeline fittings are selected in accordance with it.

Most consumers use natural combustible gas as a source of fuel for boiler equipment as the cheapest, most accessible and practical type. In addition to connecting the gas boiler to the heating system, the consumer must strictly fulfill a number of requirements for choosing a room, installing a chimney and connecting to a source of electricity.

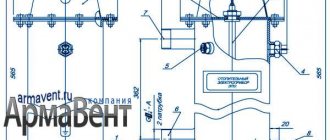

Rice. 1 Connecting the boiler to a heating system with piping in private houses

What it is?

An autonomous heating system involves a complete rejection of central heating.

That is, it will be necessary to dismantle the radiators and pipes related to this system. The basis of individual heating in this case will be gas or electric boilers. And to them, in turn, new pipes and batteries should be attached. The principle of operation of boilers is quite simple - they heat water and send it to circulate through the created system, thereby heating the premises in the required mode.

DIY connection diagram - if you are confident in your abilities

Installation of boilers is divided into several stages. First of all, you need to decide on the installation location. Next you need to install the fastenings for the boiler. It is different for each type. Installing a mount for a boiler is not a complicated process in itself - at this stage, the main thing is to correctly mark and calculate the pipe supply and connection system, as well as take into account the dimensions of your boiler in the room. The next stage is connecting the heating system of your home and looping the pipes with the boiler circuit according to the connection diagram.

The last stage, which is relevant only for the installation of gas and solid fuel boilers, is the supply to the chimney system. Well, and, of course, checking the heating system after all types of work have been carried out. Now in more detail. After marking and securing the boiler, we begin to determine the location of the chimney. If you do not have a chimney system in your house, then you will have to punch a hole in the ceiling and install it. In houses with ready-made chimneys, you need to make a hole in the wall; such systems are usually called turbocharged. The most reliable chimney system is the so-called “pipe in pipe”.

Particular attention should be paid to the angle of inclination of the pipe. If it is placed incorrectly, condensation may form in it, which, if it enters the boiler, can lead to failure of the entire unit.

If your chimney system is located in the ceiling, then you need to provide a special condensate drain for it. This process is labor-intensive, but it will save you from possible breakdowns.

The heating boiler connection diagram is described in detail in the installation instructions, and during operation you must follow all the points. Even if this is not indicated in the connection diagram, it is necessary to install filters for water purification in the boiler piping circuit. This is especially true for an electric boiler, since the presence of filters significantly prolongs the operation of heating elements. Filters also prevent pipes from becoming contaminated with various materials.

When connecting a gas boiler, it is necessary to install a shut-off valve, with which you can shut off gas access to the installation if you need to leave the house for a long time. After it there must be a gas filter, the installation of which is required by all authorities. All gas pipe connections must be carefully sealed. Regular tapes and other materials used for other pipe connections will not work here.

You can install an electric boiler yourself if you have sufficient technical skills. Connecting this type of heating will not take much time. For installation and further use of the installation, it is best to connect yourself to another power supply line. Grounding must be done to prevent electric shock.

To correctly connect the power supply circuit and grounding connection, it is necessary to invite special services or an experienced electrician. Among the main devices in the power supply network, in addition to the stabilizer, there is also an automatic switch, which will protect the system from sudden voltage drops, and will also allow you to turn off the boiler for future work. The circuit breaker must be selected depending on the voltage supplied to your boiler.

Features of connecting boilers to a source of electricity

For the electronics of a heating boiler to operate correctly, energy is required; usually the power consumed by it is small and averages about 100 watts. Connecting a gas boiler to a source of electricity is done by simply plugging the electric cable into a socket, and no additional operations are required.

The disadvantages of living in a suburban area include instability of the voltage in the network, which often goes beyond the normalized GOST limits of +6% -10% of 230 V.

And since gas boilers may not work correctly or electronics may fail due to significant voltage drops in the house, choosing a suitable voltage stabilizer becomes important.

The most acceptable option for the user is to purchase a relay-type stabilizer. Its design includes a transformer with a number of secondary windings, which are connected to the unit when the relay is activated. And the relay itself, in turn, responds to the external voltage through an electronic circuit. As a result, the stabilizer output will have a stable voltage that does not exceed the maximum permissible standards according to GOST.

An inexpensive standard stabilizer has four relays, that is, if the input voltage is exceeded, it can drop by two steps. A similar situation will occur when the input voltage decreases; a two-stage rise is possible at the output.

Since most stabilizers supplied to the domestic market are made from 99% Chinese components, it makes no sense to pay attention to the manufacturer’s brand.

The only factor that should be taken into account, besides price, when choosing a stabilizer is the convenience of its placement in the boiler room, that is, it is more practical to choose a suspended device.

If the user's area of residence frequently lacks electrical power, an uninterruptible power supply should be considered.

Rice. 12 Popular brands of voltage stabilizers for boilers and their placement

Components

After all, to install it, it is enough to fix it on the wall, after which it is connected to the heating system, supplying cold and discharging hot water for double-circuit types, as well as supplying electricity. As a rule, a circulation pump is used for these purposes, but an ordinary centrifugal pump, only of low power, is quite suitable.

Power supply from V is acceptable for them. They are used only for heating warehouse and industrial premises where people stay for a short time. Don't forget to ground.

If we install an induction or electrode boiler, temperature sensors are additionally installed, which are connected by wires to a remote control unit.

Air heating, based on the operation of air heat collectors, is considered no less effective, but practically unknown. If you want to create heating for a private house with your own hands, the schemes are selected based on the possibilities. You can increase or decrease the temperature in each room as needed

Therefore, before assembling the system, it is very important to choose not only the power, but also the type of heat source

Related article: Standards for testing and measuring electrical equipment

Forced movement of coolant in the house

The difference in coolant temperature in the first and last batteries is significant. The diagram for connecting the electric boiler to the heating system in such cases is as follows: The diagram for connecting the electric boiler to the heating system It is recommended to connect the electric boiler to the heating system using metal steel, copper or metal-plastic pipes, which are characterized by a low coefficient of thermal expansion. When cold water enters the unit's tank, condensation usually appears. On the market you can find different types of boilers for heating an apartment or private house.

General diagram of the implementation of a heating system in a house. Therefore, it must be performed at a professional level and taking into account the design features of the system and boiler. Installation of floor-standing electric boilers is carried out using a standard stand or they are installed on a specially prepared site. Heating of small houses is successfully provided by the Leningradka heating scheme, which has as many as four varieties.

Forced circulation. Gas boilers Heating systems with gas units are popular for use in a private home.

They are considered one of the most durable and economical boilers. In order not to get confused, you need to have a minimum of knowledge about each of them: Electrode boilers. Connecting the boiler The connection diagram of the unit to the heating system is quite simple, it consists of the following elements: a filter that works in tandem with a circulation pump; temperature sensors installed on the pipeline; expansion tank; Radiator; drain and shut-off valves. The door needs to be bypassed somehow. Heating with a solid fuel boiler, piping a floor-standing boiler in Orekhovo Zuevo

Requirements for boiler rooms

SNiP 2.04.08.87 provides the following standards for the placement of boiler equipment:

- It is not allowed to install more than two boilers (water heaters) in one room.

- If it is necessary to locate a boiler room outside a residential building, the decision is made by an architectural design organization or gas operating service. The requirements for these premises are similar to those for residential buildings.

- Installation of water heating boilers is permissible in kitchens and other non-residential premises with the exception of bathrooms.

- It is prohibited to place any gas-consuming equipment in basements, with the exception of individual housing, if these premises are illuminated by natural light and the fuel is natural gas.

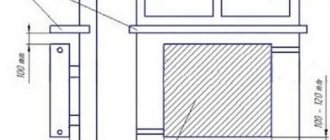

- Hanging gas boilers should be placed on walls with a non-combustible coating or insulated with sheet steel over a 3 mm asbestos sheet.

- The insulating coating must extend beyond the overall dimensions of the unit by 100 mm.

- When placing heating equipment on the floor, the gap to the wall is taken to be 100 mm.

- If heating equipment is placed in the kitchen together with a gas stove, its volume is taken 6 cubic meters more than the norms for gas-consuming stoves.

- When placing a heating unit with a chimney, the ceiling height in the room must be at least 2 meters with a total volume of 7.5 m3. If two boilers are installed in a private house, the volume of the room should not be less than 13.5 m3.

- The boiler room must be equipped with a standard sized ventilation duct facing the street.

- At the bottom of the wall partition or door leaf there should be an opening (grid) with a total area of 0.02 m2.

Parallel operation of wood and gas boilers

This option for heating a house from two boilers provides for their separate connection to the circulation system. Each heat source must have its own circulation pump installed at the return line inlet. There is no need to do this for a wall-mounted gas boiler; the pump is already installed by the manufacturer. If solid fuel burns out, the temperature of the coolant will decrease and the gas boiler will automatically turn on.

An important design point is the piping of the solid fuel boiler with metal pipes and the presence of an emergency discharge device with the simultaneous supply of cold water to the return line.

1 scheme (open and closed systems)

This method is convenient because the liquids of the two systems do not mix. This allows the use of different coolants.

Advantages and disadvantages

| pros | Minuses |

| Possibility to use different coolants | A large number of additional equipment |

| Safe operation, the reserve tank will release excess water in case of boiling | Efficiency is lower due to excess water in the system |

| Possibility of use without additional automation |

2 scheme, two closed systems

It uses a closed system, which eliminates the need for a heat accumulator. Control is carried out by thermostats and three-way sensors. Operational safety is ensured by automation.

Here we use the battery for excess heat. Thus, we increase the efficiency of the system and eliminate the need for temperature sensors and automation.

Heat supply via 3-way valve

Each boiler must be equipped with its own circulation pump, and another pump will be required to ensure circulation through the heating system devices. An automatic air vent should be installed at the top point of the hydraulic separator, and a tap for emergency drainage of water at the bottom.

System with a heat accumulator, why is it used?

The heat generated by the wood-burning boiler enters this container. From not, through a coil, heat exchanger or without them, into a gas boiler. The automation of the second understands that the water has the required temperature and turns off the gas. This will continue as long as there is enough temperature in the heat accumulator.

A heat accumulator or a heat-insulated container with a built-in coil, designed to accumulate heated coolant and supply it to the heating system. In this scheme, the gas boiler, heating devices and battery are connected by pipelines into one closed system. The solid fuel boiler is connected to the built-in battery coil and thus heats the coolant in a closed system. The organization of heating operation in this scheme occurs in the following order:

- In a solid fuel boiler, wood burns and the coolant is heated from the coil in the container;

- solid fuel has burned out, the coolant has cooled;

- the gas boiler turns on automatically;

- the firewood is laid again and the solid fuel boiler is ignited;

- The temperature of the water in the battery rises to the same temperature as that set on the gas boiler, which stops automatically.

This scheme requires the greatest costs for the purchase of materials and equipment, but has a number of advantages:

- the solid fuel boiler can operate in an open circuit;

- highest level of security;

- no need to constantly replenish the firebox with wood or coal;

- coolant circulation through a closed system;

- the possibility of simultaneous operation of two boilers simultaneously and each separately.

Additional costs include the purchase of an accumulator tank with a coil, two expansion tanks and an additional circulation pump.

calculate the required volume of container

How to choose strapping elements

When choosing a pump, you need to pay attention to the thermal load on the circuit. Here it is important to calculate the difference between the supply and return water temperatures.

The formula is as follows:

- Q=0.86xR/Dt,

- where Q is the pump performance indicator (cubic meters per hour),

- R - boiler power,

- Dt is the temperature difference.

For example, with a boiler power of 20 kW and a heating system temperature of 80/60oC, a pump is needed with the following performance characteristics:

- 0.86x20(80-60)=0.86 m3/h.

A pump with stepwise power adjustment performs well. It will be able to provide such a level of performance that the radiators throughout the circuit are evenly heated.

A parameter such as coolant pressure, which is measured in meters of water column, can be ignored. In a heating system, the number of floors in the building or the floor on which the circulation pump is located does not matter. The minimum pump value is 2 meters. Devices with this parameter cope well with the movement of coolant in the water circuit of an apartment building with high hydraulic resistance. When piping a heating boiler, these points need to be remembered.

What to pay attention to when installing a membrane tank:

- First of all, it is important to choose the volume of the tank. It should be 1/10 of the volume of coolant in the water circuit. There is an easy way to calculate this. If the heating system has aluminum or bimetallic radiators, then 1 kilowatt of boiler power requires 15 liters of coolant.

- The tank can withstand temperatures up to +120 C.

- The operating pressure of the device often does not exceed 1.5 bar. Sometimes there is a need to increase it. To do this, pump air into the tank using a bicycle pump.

How to select security group elements:

- The valve has an upper limit of permissible pressure of 2.5 bar.

- A pressure gauge must be selected with a pressure of 4 atmospheres.

How to arrange the strapping elements:

- The circulation pump is placed in front of the combustion chamber (in front of the heat exchanger), where the temperature is lower.

- The valve and pressure gauge are mounted at the outlet of the heat exchanger, in the place where the pressure begins to increase.

- The expansion tank is mounted in any part of the circuit, but not next to the pump (pressure fluctuations will lead to wear of the tank).

Connecting an indirect heating boiler

If the heating system is built on the basis of a single-circuit boiler, it is necessary to determine the source of hot water. The simplest solution is to install a regular electric boiler in your home. But it will consume expensive electricity, which is not very profitable. It is much cheaper to connect an indirect heating boiler to the heating circuit.

The easiest way to connect a boiler to a boiler is to install small collectors and connect to them a pipe with a circulation pump and a check valve, which will go to the water heater, as well as a return pipe. By controlling the operation of the circulation pump, the boiler will turn the coolant supply on and off, regulating the temperature in the built-in tank. It is also possible to implement this circuit without a collector.

If, in addition to the boiler, additional circuits and heated floors are connected to your heating system, then you cannot do without collectors or a water gun.

Electrical connection

There are two ways to connect a gas boiler to the network:

- Plug into the socket.

- Cable with three cores.

The choice is determined by the equipment model. But you always need to work through local protection. Connect to the panel. And don't forget to ground. It would be great if there were stabilizers or backup sources if the plugs suddenly went out.

The circuit breaker must be located next to the equipment. In any case, there must be a local outlet. And she must eat through a machine.

Building a ground connection on a gas pipeline or battery is prohibited! According to gas service standards, the resistance does not exceed 10 ohms.

Dual fuel heating boilers

The scheme in which gas and firewood are used to heat the coolant is considered the most popular and convenient, as it works with an open heating system. If you want to install a closed system, then it is recommended to install an additional circuit for the heating system in the tank of a universal boiler.

Manufacturers of heating boilers produce several types of dual-fuel combination boilers:

- gas with liquid fuel;

- gas with solid fuel;

- solid fuel with electricity.

Solid fuel boiler and electricity

A combination boiler runs on only one type of solid fuel. The water in the circuit begins to heat up when the loaded raw material burns. As soon as the fuel burns out, the thermostat activates and the electric heaters turn off, and the water begins to cool. As a result of a decrease in temperature, the heating element automatically turns on to heat the water. The heating and cooling process is cyclical, so the house is constantly maintained at a comfortable temperature.

heating systems

To summarize, it can be noted that to reduce the cost of heating a private home and ensure uninterrupted and stable operation of the heating system, installing a dual-fuel boiler is the best and proven option.

Pipes

What pipes can be used to connect the boiler to the heating system?

Forced circulation

Typical parameters for a circuit with a circulation pump are:

| Parameter | Meaning |

| Pressure | 1-2.5 kgf/cm2 |

| Supply temperature | 70-75С |

| Return temperature | 50-55С |

Autonomous heating operates in a pipe-friendly mode. In the photo, the electric boiler maintains a supply temperature of +65 ºС.

In normal mode, these parameters cannot be exceeded at any point on the circuit. What happens when the pump stops?

- Gas, electric, diesel boilers : the thermostat will turn off the heating and keep the circuit parameters within acceptable and safe limits;

- Solid fuel boiler : the thermostat will close the damper, but the fuel will continue to smolder for some time. The temperature of the water leaving the boiler heat exchanger will increase noticeably.

A solid fuel boiler is a device with high inertia. With the vent closed, it will heat the coolant for another 15-30 minutes.

That's why:

- For boilers of the first three types, you can safely use any plastic and metal-plastic pipes with an operating temperature of 80C and above declared by the manufacturer;

- At least the first 1-2 meters of the pipeline from the nozzles of the solid fuel boiler (or, better yet, all the spills) must be laid with metal pipes - steel, stainless or copper.

The section between the heat exchanger of the solid fuel boiler and the three-way valve is mounted with a steel pipe. The rest of the filling is polypropylene.

Natural circulation

In a gravity system, the coolant moves much more slowly than in a forced circulation circuit. When kindling, the hydraulic resistance of the entire circuit will prevent the start of circulation, and the water temperature at the outlet of the heating boiler can reach 90 degrees or more.

That is why the section of the circuit connecting the boiler and the expansion tank (what it is - I will explain a little later) is laid only with metal pipes. For all types of plastic, temperatures above 90 ºС are abnormal conditions.

The consequences of operating pipes in this mode are predictable:

- Multiple reduction in resource (from 25-50 years to several weeks, or even hours);

- Softening of plastic shells and the appearance of leaks (at temperatures above 130 ºС).

Rupture of a reinforced polypropylene pipe due to overheating.

When installing the circuit yourself, please note that in a gravity system, the internal diameter of the filling should not be less than 32 mm. A large pipe cross-section means minimal hydraulic resistance. Don't forget: gravity heating operates with minimal hydraulic pressure.

Main stages of boiler installation

In order to install a heating system based on the use of a solid fuel boiler, you will need the heating unit itself, pipes and heating radiators, an expansion tank, a circulation pump, a heat accumulator, and components of the automatic boiler control system.

The latter include:

- safety valve;

- air valve;

- pressure gauge;

- Temperature regulator.

All manipulations associated with the installation of a solid fuel boiler and the connection of peripheral systems and devices are carried out in accordance with a strict step-by-step algorithm. So, on the eve of installing the boiler, a specialized foundation is erected at the site of its planned location.

In this case, it is imperative to maintain all the required dimensions of the indents and correctly position the body of the heating unit both vertically and horizontally.

Next, electric heating elements are installed if they are included in the boiler package. As a rule, solid fuel boilers are equipped with mounts for mounting heating elements, next to which a temperature regulator is installed.

The next stage involves installation and connection of heating system pipes

It is important to close all connections using intermediate shut-off valves, and seal the butt joints with plumbing tape or material consisting of flax fibers. This will make it easier to access for future repairs.

Installation of thermal communications is done so that during operation of the heating system it is possible to easily carry out maintenance and repair work

In the case when the heating system involves the use of connections to the home’s electrical network, at this stage it is necessary to make all the necessary wire connections, their insulation and grounding.

Next, the security group is installed. Its configuration depends on the model of the solid fuel boiler, but, as a rule, it consists of: a safety valve, an air valve, a temperature regulator, a draft sensor, a pressure gauge and other devices. All these devices are installed before all locking devices.

The next step will be the installation of the chimney pipe. At the junction points of the smoke exhaust system elements, sealing is carried out with a sealing substance that is resistant to high temperatures.

The installation method, the height of the chimney duct, as well as the cross-sectional area are calculated in such a way as to further ensure the process of natural draft at the proper level. And to do this, you must strictly follow all the instructions in the operating instructions for the boiler model being installed.

Next, the thermal circuit of the solid fuel boiler is filled with water. At first, the water pressure level should be slightly higher than the working one. This stage involves testing the system for leaks.

Then you need to check all the internal elements of the solid fuel boiler firebox: plugs for cleaning, ignition valve, fireclay stones, grate bars, etc.

And finally, you should release the pressure in the boiler to operating values, put the dampers in the firebox and in the chimney in the position prescribed in the instructions, and put solid fuel into the boiler.

Having completed all the above manipulations, you can proceed to starting the heating system based on the use of a solid fuel boiler

To start the heating process, simply load fuel into the boiler and set it on fire. Then, after 10-15 minutes, you need to tightly close the kindling damper.

After the temperature is established at 80-85 degrees, you will need to set the temperature controller to the desired heat supply mode. Subsequently, you will simply need to supply the boiler with solid fuel if necessary.

Switching methods

There are two ways of piping boilers operating in pairs:

- sequential;

- parallel.

When implementing serial piping, the boilers are connected one by one; installation and arrangement of additional nodes and lines is not required. The first device warms it up as the coolant moves, the second one brings the water to the required temperature.

This option is rarely used and only for low-power heaters. It is considered irrational, since it is impossible to dismantle one boiler for repairs without turning off the other. The circuit is inoperative if even one of the two units malfunctions. To modernize and improve efficiency, additional fittings are used and a bypass line is installed.

Serial wiring

With parallel piping, two flow connection points are arranged on the direct coolant supply and on the return. The boilers operate independently of each other. In this case, it is possible to install an automatic control unit and a hydraulic switch.

Parallel harness

Types of solid fuel boilers

These devices differ in the types of fuel used, the number of fireboxes and combustion chambers, the method of fuel supply, and the material from which they are made. There are several types of solid fuel boilers.

Continuous combustion heaters

They are made of cast iron or steel, contain one or two fireboxes, run only on coal and wood, the operating cycle is 4–6 hours, the fuel is supplied manually. The control circuit for such equipment is mainly mechanical, the boiler temperature is 60–70 degrees, the difference between the flow and return is 20 degrees.

Power consumption is from 7 to 50 kW, and efficiency is 80–90%.

Long burning devices

Steel single-fuel units - the firebox is located on top, which ensures longer burning of one load (wood for more than 24 hours, coal for up to 144 hours) and uniform heating of the coolant.

Works on firewood and its derivatives (briquettes, sawdust, shavings, etc.), as well as on coal. Boiler temperature 70–80 degrees, power up to 50 kW, efficiency – 90–95%. Fuel is supplied manually.

Pyrolysis solid fuel

They are made of steel and have two chambers connected by a nozzle. The technology is that the main fuel (dry firewood with a moisture content of no more than 25%), burning in the first chamber, releases flammable wood gas, which ignites in the second chamber.

The operating cycle if a buffer tank is connected is possible from 6 hours to a day, the operating temperature of the boiler is from 70 to 95 degrees, power consumption is up to 120 kW, efficiency is 90–95%.

Pellet

Steel units operate on granules (pellets) made from wood waste - sawdust, shavings, etc. If there are removable grates, it is possible to use coal and firewood.

The achieved temperature is 70–80 degrees, power up to 400 kW, operating cycle from 24 to 144 hours.

The fuel supply circuit in such boilers can be automated and controlled electronically. This type of equipment is used for heating large areas.

How best to connect a gas boiler - choosing a circuit

There are several boiler connection schemes: the connection may also include a DHW circuit for heating hot water. In the simplest version of installing a gas heating boiler, a dead-end circuit is used. This connection diagram for a floor-standing gas boiler is also suitable for wall-mounted models, providing for switching heating devices between spills. The disadvantage of this option is the unevenness of the temperature regime in different parts of the circuit: nearby radiators will always be hotter than distant ones due to the passage of the main volume of coolant through them. The problem can be solved by balancing (throttling) the connections of the batteries closest to the boiler.

In the schematic diagram for connecting a double-circuit gas boiler, domestic hot water is prepared in a separate heat exchanger. In general, DHW is implemented very simply: cold water is supplied inside the heat exchanger.

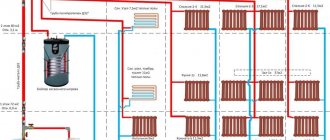

The diagram on how to properly connect a double-circuit gas boiler is much more interesting:

- Circulation inside the small circuit is ensured by a pump built into the boiler, which closes the heat exchanger and the hydraulic valve.

- Behind the hydraulic valve there is a manifold wiring for 6 autonomous circuits: 2 for standard sectional radiators, and 4 for a heated floor system. Each pair of underfloor heating combs is able to provide 2 circuits.

- It is imperative to synchronize circuits with different temperature conditions. For this purpose, the movement of the coolant through the tubes of the water heated floor is used.

- Connecting a gas heating system is only possible after obtaining the appropriate permit.

To organize DHW in a private home, a separate heater is often used, since connecting a single-circuit gas boiler is much easier. The preparation of hot water here takes place in an indirect heating boiler, with further partial transfer of energy from the coolant to the heat exchanger. To make it possible to organize a heated floor system, a connection diagram for a single-circuit gas boiler with a three-way valve and recirculation is provided here. In summer, water is supplied only through the boiler and boiler.

After the heater stops, water circulation between the heat accumulator and the heating radiators continues. The temperature control of the batteries here is also ensured by a three-way tap and a thermostat. For these purposes, a certain volume of water or antifreeze from the return line is circulated again.

Results

As a conclusion, we can say that the connection diagram for a gas boiler in a private house largely depends on the method of circulation of the coolant inside the heating system. The simplest in terms of organization are single-circuit gravity schemes, where the coolant moves by gravity due to the creation of the necessary slope of the pipes. However, forced systems that include a circulation pump are considered more effective: it ensures more intensive movement of the heated coolant through the pipes. The presence of excess internal pressure in closed circuits requires the mandatory use of additional control devices and safety valves.

Top 5 mistakes when installing boiler equipment

What mistakes are most often made by non-specialists who plan and equip the heating of a private house with a gas boiler with their own hands:

- incorrect calculation of the required power of heating equipment (especially if it is a double-circuit boiler);

- violation of the requirements for thermal and waterproofing of objects when organizing chimneys (a very dangerous mistake);

- operation of equipment without grounding and a surge voltage protection system (automation will quickly fail - one of the most expensive parts of the installation);

- the use of antifreeze concentrates diluted with tap water (scale forms very quickly in the radiator tubes and system wiring);

- careless installation and connection of control valves (threatens pressure losses in the network, leaks, and rapid failure of radiators).

Parallel and series connection of boilers

Parallel connection

Advice: before calculating the savings, you need to take into account the high cost of such systems and the installation, in combination with an electric boiler, of additional equipment on the circuit: shut-off valves, expansion tank - safety group.

Note that a parallel type system can operate in two modes: manual and automatic, in contrast to a sequential one. In order for the system to operate only in manual mode, it is necessary to install shut-off valves/ball valves or a mortise By-Pass system.

To organize automatic operation of an electric boiler with a gas or solid fuel, you will need to install a servo drive and an additional thermostat, a three-way zone valve to be able to switch the heating circuit from one boiler to another. This connection option is appropriate when the total displacement of the system coolant is per 1 kW of boiler power.

Serial connection

In order to save on components and increase functionality when connecting an electronic boiler paired with a solid fuel or gas boiler, it is necessary to take into account the volume of the tank. Connection recommended for sizes up to 50 liters.

Important: the use of a safety group and an expansion tank when connecting the heating system of a gas and electric boiler is a key point when connecting to an existing circuit.

To summarize, we can say that each of the schemes has the right to exist and has proven its effectiveness. And yet, what should you choose and how to correctly organize the connection of boilers in pairs: in series or in parallel? The answer will vary depending on your individual requirements:

- physical capabilities of the room for installing two boilers;

- well-thought-out ventilation and sewage system;

- ratio of thermal and energy parameters;

- choice of fuel type;

- the ability to control and prevent the heating system;

- financial component when purchasing boilers and additional elements.

Required tools and supplies

Materials and tools

- A set of adjustable wrenches for gas and water pipes, dowels for fastening the mounting strips of a wall-mounted boiler and parts of the chimney.

- A level at least 1 meter long for precise installation of wall-mounted and floor-standing boilers.

- A hammer drill or drill for drilling a wall for mounting planks and other fasteners.

- Brackets from the boiler kit and a pre-prepared set of spare parts.

- Metal shears for cutting pipes and a calibrator for flaring.

- Shut-off valves, control devices, kit for installation of piping.

- Galvanized steel sheet for thermal insulation of the wall and floor near the boiler.

Scheme with an additional heat exchanger

This boiler connection scheme is in demand when there is a need to completely waterproof individual circuits of the heating system. This need arises when using various coolants in circuits. That is, water can move in one, and antifreeze in the other.

The harness shown in various photos looks like this:

- Boiler.

- Heat exchanger.

- Various heating circuits.

- Safety elements installed on each circuit, a circulation pump, a drain valve and a make-up valve.

The heat exchanger is a heat accumulator with at least three coils. One circulates water heated in the boiler, and the other two circulate various types of coolants. Heat from the first coil is transferred to the others through the water in which they are located.

The benefit of an additional heat exchanger also lies in the ability to combine open and closed systems. The first is safer for the operation of the boiler, the second is more gentle for radiators.

A little theory

One of the characteristics by which autonomous heating systems can be classified is the method of inducing circulation in them. According to this parameter, the heating system can be:

- Gravitational (with natural circulation). The coolant is driven only by natural convection:

- heated masses of liquid are displaced into the upper part of the circuit by cooler (and, accordingly, denser);

- after which they return back by gravity under the influence of gravity;

The hot coolant is forced into the upper part of the circuit and returns to the boiler heat exchanger by gravity.

- Forced . In this case, the coolant drives the circulation pump.

Forced circulation ensures faster and more uniform heating of heating devices. The advantage of the gravitational system is energy independence. It will work in the absence of electricity or during frequent power outages.

Gas release

The second part of the start-up is the release of air from the pump, for which the heating regulators are brought to the operating position. The circulation pump turns on, which is accompanied by a faint hum and gurgle of water. To eliminate noise, you need to bleed air from the heating system: the cap in the center of the pump is slightly unscrewed, and when water begins to come out instead of gases, the cap is screwed back.

https://youtube.com/watch?v=taQJKUjiso8

After this, the noise will stop, the electric burner will start working, and the boiler will start working. You should also check the pressure and add more water if necessary. To set up a working system, you need to screw the batteries closest to the boiler, and start the distant ones using control valves, which are located in the water supply section to the radiators.

You also need to take care of the sewage system: during installation, you need to calculate the volume of condensate at the rate of 1 liter per 1 kW of equipment power per day.

Ventilation is located 25 cm from the ceiling with a diameter of 10 cm. Date: September 25, 2022

Unit installation features

There are no difficulties at all with a floor-standing boiler. The main thing is to strictly follow the instructions and take into account the features specified by the manufacturer. If the boiler is wall-mounted, then installation is carried out using special brackets (they are usually included in the kit). Installation is best done by two people. This will prevent damage to the equipment during the installation process, and will also speed up the installation process without loss of quality.

The most difficult thing in installing a gas boiler is choosing a location. What is important here is not only ease of use, but compliance with all standards for gas equipment. Basic rules for installing a gas boiler:

- the room for its installation must be ventilated and have good ventilation (ideally, forced ventilation should be installed, or the installed equipment should be equipped with a turbine);

- there should not be any devices nearby;

- the wiring in the room must be in full working order;

- Installation of equipment in damp or flooded areas is not allowed.

A wall-mounted gas boiler should be located at a height of 80 cm from the floor or more and at a distance of 50 cm from the nearest walls. This allows for maximum operational safety.