Gas convectors are modern devices for autonomous heating, representing an alternative to traditional central heating batteries. They are able to provide an automatic mode with a sanitary temperature inside the room. The great thing is that the devices do not require connection to either electrical or heating networks. They are very economical because during their operation they do not have losses along the length of pipelines, which are present in traditional heating schemes and sometimes reach 20% of the total load of the facility. The gas and products leaving the device do not enter the room, but are released through the smoke exhaust to the street, and therefore do not pose a danger to others. The units have a modern automation and protection system, maintain the set temperature, and almost instantly supply heat to consumers. They are universal, operate on 2 types of gas and are irreplaceable for heating residential and public premises in areas where there is no central heating supply. To correctly select a gas heater, you will need to know the consumption of the gas convector.

Operating principle and application of gas convector

Convection is a well-studied physical phenomenon of flow movement due to the difference in the masses of cold and heated air. The first one enters the room, moves through doors, windows, cracks to the floor. Heating devices are also located here, heating cold air by passing it through its structural heating surface. Heated air with a lower density rushes upward, and new cold air layers move in its place, the process continues until temperature equilibrium is reached.

This is a very effective method of heat exchange, since it does not require a source, such as a fan, to move masses. In addition, the advantages of this type of heat exchange are:

- Simple design;

- developed heating surface;

- absence of overheated heating surfaces above 45 °C;

- mobility, the ability to change the location of the device;

- No need for piping.

What does a gas convector look like?

The main components of a convective gas heater:

- Protective metal casing with grille to ensure speed of entry and exit;

- gas heating component;

- automatic temperature maintenance system.

Gas convectors using bottled gas are divided according to the installation method into floor/wall-mounted, built into the floor or into the baseboard. They work with flammable energy, so when using it you must follow the rules for the safe operation of gas installations.

Operating principle of a gaseous fuel convector:

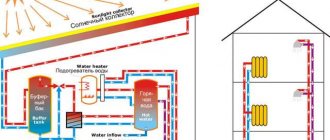

- Air is taken from the atmosphere through a coaxial flue laid in the wall. It is made of two concentrically located pipes, flue gases exit through the central one, and air enters through the interpipe space.

- Gas is supplied to the chamber from a main line or a gas cylinder.

- Cold air enters the convector from below due to natural circulation. For powerful systems, fans are sometimes installed for intensive air intake.

- The waste burnt gas is released into the atmosphere. The movement of cold air and hot flue gases occurs towards each other, that is, according to the counterflow principle, which allows the air entering the combustion chamber to be heated, thereby increasing the efficiency of the thermal process of the installation.

- Flue gases give off heat energy through convective heating surfaces to cold air, which, when heated, rises to the top, sucking cold air into its place. The positive thing about this process is that the two air environments do not come into contact with each other, that is, the process occurs without mixing the media.

Operating rules

In order for the device to serve for a long time, it is necessary to adhere to certain rules during operation:

- The distance from the heater to any object must be at least 500 mm.

- The unit cannot be placed under a window opening.

- Experts do not recommend leaving the device turned on overnight; this can only be done if there is a thermostat inside it that regulates the frequency of operation.

- You should not dry things on a heater.

Energy efficiency is now considered one of the most important criteria when choosing heating devices, so you should carefully approach the purchase of heaters. Unlike convective heating (central heating, oil radiators), inverter devices allow you to warm up that part of the air mass where people are, which is very convenient and profitable.

Methodology for calculating the power and consumption of a gas convector

In order for the equipment to be effective, it must be correctly selected for the specific conditions of the heating facility. The consumption of a gas convector is not easy to achieve, since the work is based on complex thermal processes that depend on many factors: ambient temperature, heating area, ceiling height, heat losses, wall and roof material, number of windows and many other parameters. Experts have simplified the calculations and derived the dependence of the device’s power on the heating area. This is, of course, an approximate calculation and can be applicable for heating objects in central Russia and with a ceiling height of no higher than 2.5 m, however, many successfully use this ratio:

1 kW of power per 10 m2 of total area.

For the northern regions of the country, due to lower winter temperatures, a correction factor of =1.5 must be taken into account.

When calculating the flow rate of a gas convector, it is necessary to take into account correction factors

For example, to heat a 4-room house with a total area of 150 m2 in Voronezh, you will need 4 convectors with a capacity of: 150:10:4 = 3.5 kW per installation or 15 kW of total power.

You can make a more accurate calculation if you perform it for each individual room and taking into account the insulation level of the object.

Correction factors for power calculations:

- Without insulation – 1.1;

- single-layer windows – 0.9;

- corner room – 1.2;

- ceilings with a height of 2.8 to 3 m - 1.05.

Organization of the heating system

Depending on the power, all inverter boilers can be divided into the following types:

- Industrial. They have large dimensions, a rather complex current conversion system (carried out by an inverter for a heating boiler), and volumetric heat exchangers.

- Household. This type of model is characterized by relatively small dimensions, as well as the ability to operate on mains power or batteries.

When the boiler is operating, the overall load in the electrical network of the premises will increase, so the wiring will need to be laid with a larger cross-section.

An important aspect is the safety of the boiler. And this nuance must be properly ensured. So, you will need to install a protective electrical unit that will automatically de-energize the boiler if there are voltage drops in the network.

Calculation of power by volume

This type of calculation is more accurate because it takes into account the height of the ceilings. The ratio that is taken when calculating the heat load is that to heat 1 m3 of the total volume of the room, 40 W of heat will be required.

Algorithm for determining power by room volume:

- Use a tape measure to measure the height, length and width of the room and determine the volume.

- Multiply the resulting value by 0.04 and get the recommended thermal power.

- Correction factors for insulation, glazing, and type of room are taken into account.

By performing the calculation, you can make sure that the efficiency and economy of heating largely depends on the level of insulation and glazing of the house, so the owner should be interested in carrying out insulation work and replacing double-glazed windows with energy-efficient ones.

Calculation of gas consumption

After determining the thermal power, they begin to calculate gas fuel for heating needs, on natural gas, they perform it according to the formula: L = Q / (qH x 0.90), where: L is the volumetric indicator of hourly gas consumption per 1 m3/hour; Q – design power of the convector, kW; Q ng – lower calorific value of natural gas, for main gas it is equal to 10.2 kW/m3; 0.95 – convector efficiency. For the above example, heating a house with an area of 150 m2 and a maximum thermal load of 15 kW, the calculation is:

15 / 10.2 x 0.95 = 1.54 m3 / h of natural gas.

Gas consumption per day is 1.54 x 24 = 36.96 m3, and

Monthly consumption – 36.96 x 30 = 1081 m3.

Karma BETA 2 Comfort 02

If necessary, this device can be easily integrated into a smart home system.

The design includes an electronic thermostat, thanks to which the temperature is maintained with an accuracy of one tenth of a degree. The creators tried to give this device maximum resemblance to a real fireplace. In particular, they equipped it with a window made of heat-resistant glass through which the flames can be observed. The power of the device is only 2 kW, however, this indicator is quite enough for high-quality heating of a room up to 40 square meters. m. The convector is very technologically advanced, equipped with a GSM module. Through it, up to three similar devices can be connected to one thermostat. The design does not have an igniter, which makes it possible to reduce the amount of fuel consumed by approximately 30% when comparing the products with standard mechanical devices.

Advantages:

- Low consumption of natural gas;

- Stylish appearance;

- High quality assembly and workmanship;

- Able to fit into any interior of the room;

- Long period of operation.

Flaws:

- A power of 2 kW is not enough for all consumers.

Nuances of calculations

Knowing the monthly gas consumption, you can determine the annual need for gas fuel. These calculations are valid for main gas and will differ slightly for liquefied gas. The heating season depends on the geographical location of the installation. It is determined in a tabular manner according to SNIP 01/23/99 “Construction climatology and geophysics”. For example, for the city of Moscow – 214 days.

Calculation of gas for heating: 36.96 X214 = 7909 m3, although in fact this is the maximum possible consumption, since the minimum outdoor temperature in winter will only be a few days, and the average temperature will be much higher. And it is she who will determine the actual fuel consumption. But to select equipment, the maximum calculation is taken to ensure reliable operation of the heater at the lowest temperatures.

Convector using bottled gas

This gas convector has its own characteristics that must be taken into account when choosing a model. The most optimal version of the device with a cast iron heat exchanger and control unit.

Similar to natural gas, power is also taken into account here, but you need to understand that these units are space efficient, so a separate one is installed for each. For apartments, devices with a closed chamber with a coaxial chimney are recommended, but even then it is not allowed to be installed in a multi-storey building due to the high explosion hazard of cylinder installations.

Convector using bottled gas

Many home owners equip such heating along with the installation of gas tanks that are filled with gas for the entire heating season.

Calculations for determining the volume of required gas are similar to those above, except that the lowest specific heat of combustion of liquefied gas is assumed to be 12.8 kW/kg, and the efficiency is 0.92. For the above example, heating a house with an area of 150 m2, calculation of the need for liquefied gas:

15 / 12.8 x 0.92 = 1.27 m3 / h of liquefied gas.

Daily consumption is 1.27 x 24 = 30.57 m3, and

Monthly consumption – 30.57 x 30 = 917 m3 As is obvious, in the case of using liquefied gas it will be required less per month by almost 170 m3. However, this does not mean that in general such heating will be cheaper, since its cost is much higher than main gas. In addition, liquefied gas is inferior to natural gas in many other respects, so liquefied gas convectors are installed only in areas where there is no central gas supply.

Gas convector on natural gas

This model is preferable for autonomous heating, but in order for it to work effectively, you need to know the differences and advantages of the modifications that are sold through the distribution network. After determining the required power of the unit, the next thing you need to pay attention to is the installation method, which can be wall-mounted or floor-mounted. The former are small in size and weight, while being quite efficient, but are limited by a productivity of 10 kW.

For heating large industrial premises, such as garages or repair shops, it is recommended to choose floor-mounted options. These models have a large weight and size due to the developed heating surface of the heat exchanger.

Modern gas convectors are equipped with closed combustion chambers. They are mounted together with a coaxial chimney. Due to the fact that air is taken from the street, they do not burn oxygen during the heating process, which creates positive sanitary and hygienic conditions in the room and is a huge plus, despite the increased cost of installation, up to 30% compared to open ones combustion devices.

Alpine Air NGS-20F

Alpine Air NGS-20F is a gas convector with wall mounting, equipped with a reliable and durable (rated for 50 years) cast iron heat exchanger. Other features of the device are non-volatile automation and reliable operation even at extremely low temperatures. In a particular model, only the operation of the built-in fan, used for faster heat distribution, depends on the electrical network. The Alpine Air NGS-20F uses a closed combustion chamber. A telescopic coaxial pipe is included in the kit to allow air to flow in and combustion products to be removed outside. The convector uses a gas burner and fittings made in Italy. The heater in different configurations can be connected to network (natural) gas or bottled (liquefied) gas. When purchasing, it is better to clarify the configuration option for a specific instance or obtain information about the availability of an additional kit. The Alpine Air line of gas convectors includes models NGS-20, 30, 40, 50 (2, 3, 4, 5 kW) and analogues with the addition of a fan (indicated by the letter F).

Main advantages:

- Cast iron heat exchanger;

- Reliability;

- Fan.

Minuses:

- Requires a hole in the wall.

Models in the line:

- Alpine Air NGS-30F

- 3 kW, thermal ventilation (convectors); - Alpine Air NGS-40F

- 4 kW, thermal ventilation (convectors); - Alpine Air NGS-50F

- 4.9 kW, thermal ventilation (convectors); - Alpine Air NGS-20

- 2.2 kW; - Alpine Air NGS-30

- 3 kW; - Alpine Air NGS-40

- 4 kW; - Alpine Air NGS-50

- 4.9 kW.

Advantages of a gas infrared heater: consumer reviews

According to consumer reviews, the first and main advantage of heating with infrared gas heaters is the absence of requirements for connecting to any networks. In fact, such a heater can be installed anywhere.

All you need for the device to fully operate is a cylinder filled with liquefied gas. If you believe the reviews, gas infrared heaters for summer cottages may well work if they are connected to a centralized gas supply system.

Outdoor gas infrared heaters

Manufacturers claim that such equipment can be used anywhere: in an apartment in a multi-storey building, in a private house, in a garage, in a greenhouse, etc. At the same time, the device is quite mobile and, if necessary, can be easily transported. In addition, there are several types of heaters, allowing you to choose the most suitable option.

All gas heaters can be of two types:

- those that heat surrounding objects;

- those that release heat into the air.

If we talk about infrared heaters, they work on the following principle: objects are subject to heating, which, in turn, release heat into the air. This method is considered the most effective, but it has a significant drawback: objects that do not fall within the range of the device remain cold. It is pleasant to sit near such a heater, for example, while reading a book, but to heat the entire room you will need sufficient power from the device.

An infrared floor heater heats objects that release heat into the air

How to choose?

Now let’s try to figure out how to choose a good gas convector for a private wooden house so that its efficiency is maximized. To do this, you will need to answer a number of questions. It is necessary to find out whether such a device is needed in the house. The fact is that it competes with a heating boiler. A convector would be preferable if there is a need to heat a building that is not very large in area, because such a device should be placed in every room. This means you can save a lot.

In addition, such a need for dacha owners may not arise if they do not live there permanently. That is, when they arrive, they can immediately turn on the convector and start heating the room. The power of this device will also be an important factor. The norm is about 1 kilowatt of heat per 10 square meters of room

When calculating power, you should take into account:

- insulation of the room;

- the presence of one or another type of window;

- the presence of cracks, doors and ventilation - factors that cause heat loss.

Note that it is best if, when carrying out power calculations, another reserve kilowatt is added, which will be spent on compensating for heat losses. Another important selection criterion will be the material of the heat exchanger. As already mentioned, they most often are:

- cast iron;

- steel.

The first category of devices is very durable, because a cast iron heat exchanger can operate for about 50 years. But it needs to be cleaned and maintained periodically. The structure of the metal itself allows for uniform heating, which increases the efficiency of the converter. But as mentioned, the mass of such a converter will be greater.

The second type of heat exchangers is cheaper in cost and is installed in most models that are on the market. Steel construction allows converters to be equipped with heat-resistant glass windows

Attention should also be paid to the type of chimney. There are 2 options:

- coaxial chimney;

- vertical.

Most models equipped with a coaxial pipe are easy to use. If desired, you can easily adjust their length, and this design looks quite aesthetically pleasing. At the same time, installation of a coaxial chimney is relatively simple. But if a gas convector is installed in place of a boiler or wood-burning stove, then a vertical chimney will be installed in the house, which will require its own model of gas convector. Typically these are heaters with an open combustion chamber.

Features of operation

Heaters powered by bottled gas can differ according to numerous criteria

It is necessary to pay attention to the characteristics of the equipment, which will allow you to choose the right heater for the characteristics of a particular building and private home.

Main characteristics:

- Availability of automatic control.

- Type of convention.

- Presence or absence of a fan.

- Energy carrier used.

- Combustion chamber type.

- Installation power.

- Heat exchanger material.

Depending on the design, such heaters can be installed on the floor or mounted on the wall. Wall-mounted models are highly efficient and light weight. The power of wall-mounted liquefied gas convector heaters can reach 10 kW, which allows them to heat large rooms. Floor-standing units can be equipped with a larger heat exchanger, but their performance usually does not exceed 5 kW.

When running a propane boiler is already dangerous:

Combustion chamber type

The combustion chamber can be closed or open. In recent years, models with a closed combustion chamber have become the most popular, which ensures the highest possible efficiency and complete safety of equipment operation. Convectors with a closed combustion chamber can have a coaxial pipe instead of a classic chimney, which simultaneously takes in fresh air from the street and effectively removes combustion products outside. The only drawback of convectors with a closed burner is their high cost.

Heat exchanger material

The material from which the heat exchanger is made will directly affect the durability, efficiency and reliability of the equipment. Today on the market there are convectors with heat exchangers made of cast iron and steel. The most durable, reliable and durable devices are those made with a cast iron heat exchanger. If used properly, they will last for 50 years. The disadvantage is the high cost of models with cast iron heat exchangers.

Some convector models will last you longer than others

Convection type

Depending on their type, thermal installations can use forced and natural convention. Heaters operating with natural convection make virtually no noise, which allows them to be used in residential areas. The advantage of devices with forced convection is their improved performance and the ability to use such equipment to heat large areas. Fuel consumption in a bottled gas convector can vary significantly depending on the power of the equipment and its type of convection.

Control automation

The gas convectors we offer can be equipped with both simple automation, which includes only thermostats and control relays, and advanced logic, which ensures maximum automation of equipment operation. Depending on the automation used, the cost of heating installations will differ.

Correct power calculation

The universal formula for calculating power is 1 kW of thermal energy per 10 square meters of room area. However, such calculations will be averaged and will not always allow you to choose the right converter for a specific room. It is necessary to take into account the structural features, ceiling height, the presence or absence of windows, high-quality wall insulation, as well as the climate in the region.

When choosing a convector, you need to calculate its power

When choosing fully automated installations that have a forced convention, you can proceed from the calculation of 0.7 kW of thermal energy per 10 square meters of room area. They can be used as the main heating method only in small buildings. A propane gas convector is an ideal solution for a wooden or brick cottage.

Gas infrared heaters using bottled gas: prices for popular models

Due to its fairly wide popularity, buying a gas infrared heater from a cylinder is not difficult.

Prices for some popular heater models:

| Name | Power, W | Heating area, m² | Size, mm | Weight, kg | Average price, rub. |

| Floor-standing gas infrared heater Ballu Bigh 4 | 4500 | 60 or more | 270 (length) | 2,8 | 2800 |

| Gas infrared heater Ballu Bigh 3 | 3000-4500 | 45 | 338x278x372 | 2,3 | 2400 |

| Gas infrared heater Pathfinder Hearth with cooking capabilities | 1500 | 15 | 275x275x180 | 1,8 | 3000 |

| basic infrared heater NeoClima UK-02 | 2500 | 25 | 192x150x86 | 1 | 1300 |

| Outdoor gas infrared heater Master 34 CR | 3400 | 160x350x460 | 2,6 | 2200 |

Using reviews as a guide, the Ballu Bigh 55 Gas Infrared Heater is also a very good option. It has a high power of 4200 W, and also provides the ability to install a cylinder directly inside the device itself. Of course, this is reflected in its size.

Helpful advice! If you want to purchase a gas infrared heater for a greenhouse, then you need to choose among outdoor models. Room heaters will not cope with this task.

Cylinder connector type

To connect the cylinder to a gas heater, you need a hose with a reducer that equalizes and stabilizes the pressure. The pressure gauge sets the optimal gas flow rate corresponding to the burner’s nameplate data.

The gearbox is connected by screwing it onto the thread. In such cylinders it is always on the left, i.e. You need to turn the union nut to the left, counterclockwise. To prevent the user from getting confused, the nuts have transverse notches that serve as a symbol of a left-hand thread.

Gas cylinders have one of two types of connectors: LPG or KLF. The first option is the most common and universal. Most gearboxes fit it. KLF is a European standard, the connector is narrower. To connect a regular gearbox to such a valve, you will need to buy an adapter.

Pipe diameters in inches and millimeters

The description of pipe diameters contains data on all parameters - internal, external, conditional, nominal. Knowledge of the characteristics is required when installing the network and selecting fittings. Otherwise, incorrectly assembled communications threaten loss of tightness and a short service life due to breakdowns. Next, consider the pipe diameters in inches and millimeters.

Dimensional characteristics of pipes

They are reflected in the relevant GOSTs and TUs and contain the following definitions:

- The outer diameter is the main characteristic of the pipe.

- Inner diameter.

- Nominal.

- Conditional pass.

More details about the differences:

- The outer diameter is classified into small, medium and large values - which is why the pipe is used in the appropriate conditions. Small diameter is used in residential and private water supply systems, medium diameter is used in city communications, large diameter is used in industrial ones. The outer diameter is the most important characteristic of the pipe, since it determines the required fitting thread. Designation – Dн.

- Inner diameter or true. It depends on the thickness of the wall and can differ strikingly from the external one, even if the dimensions of the latter remain unchanged. Designated as Din. It is calculated mathematically (Dн – 2S), where S is the thickness of the pipe wall. Example - the outer diameter of the pipe is 60 mm. Minus the 4 mm walls, its internal diameter will be 52 mm. As the wall thickness increases, the internal parameter decreases.

- The nominal bore or diameter of the pipe lumen is marked as Dу. This is the average internal diameter, rounded up to the standard value. For example, the outer diameter of the pipe will be 159 mm. The true internal diameter after subtracting the wall thickness of 5 mm is 149. Then the nominal diameter after rounding is 150 mm. This parameter is considered to select suitable fittings and fittings.

- Nominal diameter. The concept was introduced to standardize the marking of pipes made of different materials. The value is equal to the nominal diameter and is marked in inches. This allows you to correctly select pipes from various raw materials for combining in a network - steel and plastic are marked in inches, copper and aluminum - in millimeters.

Thus, the correct selection of components for home communications in accordance with the described concepts is not difficult. Tables for converting sizes from inches to millimeters and vice versa will help in self-repair and replacement of defective sections of networks.

Table of diameter sizes in diameters and millimeters

Nominal diameter (Dy) of the pipe, in mm

The diameter of its thread (G), in inches

Outer diameter (Dh), pipes, mm

Steel seam pipe, water and gas supply

Pipe diameter in inches and millimeters are very important indicators. Many have faced the problem of replacing or installing a pipeline, and finding the appropriate materials for the job.

It is difficult to understand the huge number of proposals on the construction market, so before purchasing you should study in detail what the volume of pipe rolling is and how it is used in practice.