Modern solid fuel boilers are very different from their predecessors. Simple design and stable operation make them indispensable elements of autonomous boiler houses. It is believed that cast iron devices last the longest. Such equipment is produced by many domestic and foreign manufacturers. Among them is the Beaver solid fuel boiler of the Proterm brand.

The popularity of solid fuel boilers has increased ↑

Oddly enough, this is really today's trend. Some time ago, it began to seem that solid fuel boilers would leave their “palm of championship” in the 20th century, as they were actively being replaced by automatic gas and electric heating systems. But the high cost of electricity and the inaccessibility of gas energy for quite a few remote settlements contributed to the maintenance and even some increase in the popularity of solid fuel boilers. Probably, the increase in their rating is also associated with an increase in the quality of equipment.

Firewood, charcoal and coal continue to be a viable alternative to gas. The market offers a wide range of models. So today's users are faced with more headaches when it comes to choosing.

Reviews of the 60DLO boiler

An alternative solution is the 60DLO model, which consumers consider equipment with high heating power. The latter parameters reach 48 kW. The device is used in closed heating systems. The combustion chamber has an increased volume, which, as buyers emphasize, allows you to extend the operating time of the heating system.

The design provides for a thermomechanical power regulator, which is required to adjust the heating temperature. Operation requires the use of solid fuel, it can be wood or coal. To maintain a certain heating temperature, the manufacturer equipped the installation with a thermostat.

Buyers like that overheating of the coolant is eliminated due to the presence of a cooling circuit in the design. If you wish, you can separately order a boiler, which is used to prepare hot water.

Boiler Proterm Beaver 20 dlo ↑

On our website you will find articles offering a comparative analysis of brands and models of heating equipment from different manufacturers.

Since the request from our reader from Izhevsk concerns a specific boiler: Proterm Bober 20 DLO , we will dwell in more detail on its technical characteristics, and also evaluate the advantages and disadvantages.

General characteristics of the heating boiler Proterm Bober

IMPORTANT: The Protherm Beaver 20 DLO is optimal for heating rooms with an area of about 200 square meters. m.

Table Technical characteristics and diagram of Protherm brand boilers

Solid fuel boiler Proterm Beaver

The brand has been known to customers since 1996. There are many devices in the company’s assortment, but there is only one series, including Protherm floor-standing solid fuel boilers - the Beaver series.

These boilers are designed specifically for heating houses and cottages; they operate on wood or coal. The difference between these units is the ability to replace sections to increase power in connection with the needs of the owner. The cooling circuit, which protects the structure from overheating, prevents the temperature from rising above 110 °C. Due to the heat exchanger material, devices in this series boast high performance. The cost of Protherm solid fuel boilers is higher when compared with models from other companies, but the price is determined by the quality, durability and long service life of the devices.

General description of the model, purpose ↑

Proterm Bober 20 DLO (Slovakia) is a modern solid fuel boiler for autonomous heating and operation of a hot water supply system, equipped with a spacious combustion chamber, widely used for heating residential and industrial buildings with natural/forced coolant circulation systems.

Designed for heating residential, utility and industrial premises with an area of up to 200 square meters. m. With the help of an additionally installed boiler, it allows you to obtain hot water supply. Equipped with a cast iron sectional heat exchanger. Service life under intensive use is up to 10-15 years. Attractive appearance - the body is painted with heat-resistant bright red enamel.

Works on different types of solid fuel (wood, coal). By the way, the recommendations advise using wood with a moisture content of no more than 20%, and using coal with a grain size of up to 40 mm. These are not mandatory conditions, but if they are met, the operation of the boiler will be more efficient);

IMPORTANT: The Proterm Beaver 20 DLO boiler assumes the technical ability to combine operation with a gas or electric boiler.

Functional

- Cast iron body with four ergonomic sections equipped with built-in sensors.

- Thermal manometer on the front casing of the unit to monitor the temperature of heating water in the system.

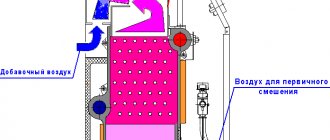

- Thermo-mechanical power regulator at the outlet of the housing, reading the water temperature and regulating the supply of primary air, which is important for combustion intensity.

- The chimney damper regulates the draft force.

- Maintaining a uniform temperature in the heat exchanger will prevent thermal shock and corrosion.

- Efficiency class according to EN 303-5 standard – first.

- Emission class according to standard EW 303-5 – first.

- The STN EN 303 - 5 standard implies the installation of a storage tank (tank) with the boiler.

Review of model range and prices

The DLO series is represented by five models with a power range from 19 to 48 kW. The operating principle of the boilers is identical. Products differ in technical parameters and cost.

20 DLO

Model 20 DLO is suitable for heating domestic and industrial areas up to 190 m² in size. Unit power: 19 kW for coal and 18 kW for wood.

The design is based on a prefabricated cast iron body. Front panels with thermal insulation are placed on top of it. There are two doors at the front. Behind the top is the combustion area. Behind the bottom is the ash compartment. The exhaust gas escape routes are fenced with an anti-smoke protection plate that prevents smoke from entering the room. The supply and return pipes, as well as the chimney outlet, are located at the rear.

When burned, fuel releases heat that is transferred to water. The remaining fuel material falls into the ash box. Flue gases go through channels into the chimney.

The cost of the model is 67,600 rubles.

30 DLO

The model has a similar structure to the previous one. Differs in higher output: 24 kW. The firebox accommodates logs 37 cm long. The unit is capable of heating a room up to 240 m².

Price: 81,500 rubles.

40 DLO

The heat generator is designed for large quadratures up to 320 meters and has a power of 32 kW. The loading chamber can accommodate firewood up to 43 cm in length.

You can buy a solid fuel boiler Bober 40 DLO for 88,800 rubles.

60 DLO

The most powerful option in the line: 48 kW. Designed for heating buildings up to 480 m² in size, equipped with a forced circulation heating system.

Not suitable for gravity flow circuits.

The spacious firebox allows you to burn logs up to 68 cm in size.

Cost of the device: 124,300 rubles.

Comparative technical characteristics of the models are presented in the table.

| Model/Specifications | 20 DLO | 30 DLO | 40 DLO | 60 DLO |

| power, kWt | 19 | 24 | 32 | 48 |

| Type | Solid fuel | |||

| Number of circuits, pcs. | 1 | |||

| Mode | Heating | |||

| Installation method | Floor | |||

| Electrical independence | Eat | |||

| Number of heat exchanger sections, pcs. | 4 | 5 | 6 | 10 |

| Combustion chamber type | Open | |||

| Material | Cast iron GG20 | |||

| Coal power, kW | 19 | 24 | 32 | 48 |

| Wood burning power, kW | 18 | 23 | 29 | 45 |

| Working time on wood, h | 2 | |||

| Coal burning time, h | 4 | |||

| Firewood length, cm | 32 | 37 | 43 | 68 |

| Efficiency, % | Up to 80 | |||

| Temperature range, °C | 30—85 | |||

| System pressure, atm | Up to 4 | |||

| Indication | Thermal manometer | |||

| Safety | Thermostat | |||

| Chimney diameter, cm | 15 | 18 | ||

| Height, cm | 93,5 | |||

| Depth, cm | 64 | 74 | 84 | 124 |

| Width, cm | 44 | |||

| Weight, kg | 230 | 262 | 305 | 455 |

| Warranty period, months | 24 | |||

Prices for the range of solid fuel boilers Protherm Beaver DLO

solid fuel boilers Protherm Beaver DLO

Specifications ↑

- Efficiency – from 90% and above;

- Power 19 kW (power varies depending on air supply)

- The diameter of the firewood is about 18 cm, length – up to 32 cm;

- Installation type: floor;

- Heating water temperature – up to 90 degrees. WITH;

- Pressure – up to 3 bar;

- Storage tank volume 800 l;

- Water volume in the boiler – 19.9 l

- The heating temperature of combustion products is up to 250 degrees. WITH;

- Dimensions (width/length/height): 44.0/64.0/93.5 cm;

- Weight (without water): 230 kg.

- Chimney diameter 15 cm, draft – 230 mbar

Installation and Maintenance

For a long service life and stable operation of the Beaver Proterm boiler, it requires proper installation and connection, as well as periodic cleaning. Experts recommend:

- Install the heating unit in a non-residential premises or a room specially equipped for it, where a flow of fresh air is ensured.

- Mount the device on a lining made of non-combustible material or on a special foundation when installing in a basement.

- At least a minimum distance of 600 mm must be left at the front and rear. On one side, it is necessary to provide the same distance for passage and unobstructed access to the rear of the boiler equipment.

- The cross-section of the chimney must be equal to or greater than the cross-section of the outlet pipe. The smoke exhaust pipe must be without bends, and parts of the structure in the unheated area must be insulated. If several solid fuel boilers are used, it is prohibited to connect them to the same chimney.

In addition, you also need to service the Proterm boiler from time to time. It is recommended to observe the following points:

- Monitor and regularly clean the ash pan. If the niche is overcrowded, air access to the combustion chamber will decrease;

- before starting the kindling, you should remove all solid fuel residues from the grate;

- at least once a month it is necessary to clean the surface of the cast iron heat exchanger from soot and ash deposits. When the carbon layer is too thick, heat exchange becomes lower and, as a result, the performance of the solid fuel boiler decreases.

Proterm Beaver solid fuel boilers are designed for those who value simplicity and efficiency. They will work perfectly where most analogues of solid fuel units, which require an electrical network, are not able to function.

Pros and cons ↑

Among the main advantages, it should be noted high operating efficiency and efficiency in the use of coolant, low heat loss with high inertia and high efficiency. Natural removal of combustion products occurs here. Loading firewood can be done twice a day. The equipment will last a long time, since, being made of cast iron, it has high wear resistance, does not deform and corrodes little. Among the advantages, owners also note a large fuel chamber with convenient loading. As for the shortcomings, users in their reviews note the peculiarities of draft regulation, which they have to adapt to, as well as not very convenient cleaning of the boiler. The cast iron unit Beaver 20 DLO is difficult to move from place to place; there are a number of analogues that are significantly lighter in weight.

Reviews of positive features

"Proterm Beaver 60DLO" is popular among consumers for the reason that it has many positive features, namely:

- reliability;

- quality work;

- open combustion chamber;

- delivery of the boiler assembled;

- factory warranty for 2 years.

Reliability is ensured by a pressure gauge, with which you can monitor the pressure inside the device. High-quality work, according to users, is ensured by a mechanized operating process. The boiler operates with high efficiency. Its efficiency exceeds 90%.

With the help of air supply and regulation you can control the boiler power. It is very easy to care for the equipment; maintenance is also not accompanied by difficulties, as is installation.

Installation: specifics and nuances ↑

Installation of the Protherm Beaver 20 DLO is possible not only in a residential area, but also, if necessary, in a utility room. It is installed in the basement, boiler room, corridor (at worst). The main thing here is to ensure the flow of air necessary for free combustion and to check the presence of a combustion product removal system. For safety reasons, the equipment must be installed on a fireproof base.

IMPORTANT: Installation of the boiler should be entrusted to specialized organizations that have the appropriate licenses.

Recommendations for installation and maintenance

Boiler equipment will last as long as possible, provided it is properly selected and used.

Choice

The power of the Beaver boiler must correspond to the area of the heated building. It is believed that heating ten square meters of a room requires 1 kW of thermal energy.

When purchasing a unit with a lower output, it will not be possible to achieve a comfortable temperature in the home. If the slope is greater, prerequisites for premature failure will arise: the formation of condensation and resin in the cavities of the device. In this case, the contaminated heat exchanger will not cope with its function.

Installation rules

Installation work must be carried out by an organization that has the necessary permits.

Features of installing Beaver equipment:

- a place for the boiler room is selected with a functioning ventilation system in residential and non-residential (corridor, basement) premises with a temperature of 5-35 ° C;

- the heat generator is installed on a non-flammable, level base: floor or foundation;

- the combustible base is first covered with a sheet of steel on the sides and front, placing a fire-retardant gasket under it;

- a free space of at least 0.6 m is left on the front side for ease of use;

- from the rear and side, for access to the nodes, an interval of 0.6 m to the wall is also used;

- connections of the chimney and heating system elements are made according to the instructions;

- carefully check the tightness of connections with heating pipes and chimney.

Recommendations for use

Maintenance of Protherm Beaver heating devices is carried out by the user himself and service specialists.

Basic rules of daily care:

- use small wood chips and paper for kindling, do not use flammable liquids or explosive substances;

- do not overheat the coolant above the maximum permissible parameters;

- the water temperature on the return line should not be lower than 50 °C;

- before adding a new portion of fuel, shut off the air supply to the fireplace and wait for the smoke to clear by opening the chimney damper;

- When manipulating a working boiler, use protective thermal gloves;

- do not store fuel material near the heating device at a distance of less than 0.8 m;

- clean the ash box several times a day so that the mass accumulated in it does not interfere with the flow of air under the grate;

- to collect ash, use containers made of non-combustible materials;

- once a month, clean the internal surfaces and chimney of the boiler from soot;

- if resin accumulates on the walls, burn it out by heating the coolant to maximum temperature;

- When turning off the unit, clean it, lubricate the rotating parts and close the doors.

In addition to the above, it is necessary to carry out maintenance (maintenance) of the unit once a year. It is performed by a representative of the service company.

During the maintenance process the following is checked:

- functioning of control and protection units;

- performance of dampers;

- tightness of joints. Read our article about the Grundfos circulation pump.