Cats don't sleep on cold radiators.

The efficiency of the entire heating system directly depends on the performance of the boiler. Malfunctions of the main heating equipment negatively affect the efficiency of the home heating circuit and lead to excessive energy consumption. That is why any breakdowns, even the most insignificant ones, are given special attention. People’s experiences are understandable if the boiler is working and the radiators are cold. After all, this not only reduces the level of comfort in the house, but also entails expensive repairs. To properly solve a problem, you need to understand its essence. Only a specialist can correctly determine the reasons why the boiler does not heat the batteries. Also read: “Why do radiators heat poorly?“.

What other selection criteria can you use?

In addition to the main classification of types of boilers for heating a private home, there are other parameters that distribute them according to the device:

- The number of circuits determines the purpose of the boiler. Single-circuit boilers are designed exclusively for heating the heating circuit, while double-circuit boilers have an additional hot water supply (DHW) circuit, in which sanitary hot water is prepared for domestic needs. DHW productivity is usually sufficient for 1-3 points of consumption.

- The energy dependence of the boiler determines the need to connect it to the electrical network. Non-volatile models do not require connection to the mains, but have simpler functionality, manual piezo ignition (button), and require a classic vertical chimney. Volatile models connect to a regular outlet (220-230 V), have higher efficiency and economy, expanded functionality, and are used in conjunction with a coaxial (side) chimney.

- The design of the combustion chamber in which the fuel is burned determines the boiler's efficiency, room and ventilation requirements, and the type of flue used. Boilers with an open chamber (atmospheric) are cheaper, they take air from the room, and the combustion products are discharged through a classic vertical chimney; the requirements for the room and ventilation in the case of an atmospheric boiler are increased. Boilers with a closed combustion chamber (turbocharged) are equipped with a turbocharging fan, which carries out forced air circulation, taking it from the street through a coaxial chimney. Turbocharged boilers are more economical, since the amount of air is clearly regulated by the turbine speed, installation of a coaxial chimney is easier, and strict requirements for room ventilation are eliminated, but they are more expensive and noisier.

- The installation method determines the design, reliability and price of the boiler. In fact, this criterion applies only to gas models, electric ones are exclusively wall-mounted, and the rest are exclusively floor-mounted. Gas wall-mounted models are more technologically advanced and efficient; they have all the necessary elements of the heating system in their housing: expansion tank, circulation pump, safety group, etc. However, in floor-standing models you can install a heavy, durable cast iron heat exchanger with a service life of more than 30 years; in extreme cases, a steel heat exchanger can also be made thicker and more durable. Budget atmospheric floor-mounted models are much cheaper than budget wall-mounted models.

The boiler does not heat water for hot water supply

In addition to the lack of heating of the heating system, it happens that the gas boiler does not heat the hot water supply circuit.

After all, scale has a structure that limits the passage of coolant and also takes away its heat. This is due to the thermal conductivity of salt deposits - it is much lower than the thermal conductivity of the metal from which the heat exchanger is made. Therefore, the boiler does not heat hot water well.

It is also possible that a piece has come away from the salt deposit, blocking the flow completely, which leads to a complete stop in the supply of hot water.

Structurally, the sensor is a paddle device through which water flows, which is the condition for its operation, because it sends a signal about the presence of a flow to the electronics, which, in turn, starts heating the water again. It happens that the sensor gets clogged, but it can be cleared of the blockage without removing it.

The device has the shape of a cylinder and is located near the circulation pump. To start cleaning, open and close the tap near the sensor. If this does not help, then it should be unfastened and removed, cleaned by hand and reinstalled. If this does not help, then the sensor is most likely faulty and needs to be replaced.

It is designed to shut off the heating system when the hot water tap on the mixer is opened. If the valve does not work, the boiler does not switch to heating water for DHW from heating water for heating. The first reason for its failure may be clogging with corrosion products, which needs to be removed.

If this does not help, the valve should be replaced. The hose system and filter may also become dirty. This problem is barely noticeable on the heating circuit, but on the hot water supply circuit it will be more noticeable. These elements need to be cleaned.

Electricity costs for heating a house

The boiler reaches its rated power mode only during the coldest five-day period of the year. The rest of the time it operates with reduced heating output. On average it is:

- in the winter months (December, January and February): 50% of nominal;

- in November and March: 30%;

- in October and April: 15%.

For example, a 10 kW boiler will consume during the heating season:

- During the winter months: 10 × 0.5 × 24 hours × 90 days = 10,800 kWh.

- For November and March: 10 × 0.3 × 24 × 61 = 4,392 kWh.

- For October and April: 10 × 0.15 × 24 × 61 = 2,196 kWh.

Total: 10,800 + 4,392 + 2,196 = 17,388 kWh.

In 2022, in the Moscow region, the tariff for houses with electric stoves and heating corresponds to 3.89 rubles/kWh. This means that the costs for the season will be 17,388 × 3.89 = 67,639.32 rubles.

Basic structure and principle of operation of an electrode boiler

It will be much easier for some readers to understand the structure and operating principle of an electrode boiler if they remember a simple way to quickly boil water using a simple device. In student dormitories, where commandants strictly enforced the ban on having electric heaters, such a device was probably hidden in every room. This is a cable with a plug at one end for connecting to the network. And on the other there are two razor blades, secured in one way or another, but always in such a way that there is a small gap between them. Instead of blades, other metal plates were also used: in army barracks, for example, shoe shoes were often used. The essence did not change from this.

“Student boiler” is the most intelligible demonstration of the principle of operation of an electrode boiler

After lowering such an “assembly” into water and connecting it to a 220-volt network, the water heated up very quickly. We didn’t have to wait long—it took less than a minute to boil a glass. The same principle is used in electrode, or, as they are often called, ion boilers.

What is the matter here, due to which such rapid heating occurs? To understand the principle, it is necessary to recall some physical laws.

Even ordinary water (unless, of course, distilled water is taken into account) has electrolytic qualities - substances dissolved in it acquire an ionic structure, that is, a combination of positively and negatively charged particles. If two direct current electrodes are lowered into such an environment, the directed movement of ions will begin: negatively charged (anions) - to the positive conductor (cathode), and positive (cations) - to the anode

This process is called electrolysis.

But in our case, an alternating voltage with a frequency of 50 Hz is used. This means that the polarity of the electrodes immersed in water changes at a rate of 50 times per second. Naturally, the movement of ions under such conditions is not directional, but turns into oscillatory, with a change in direction with the same frequency. Since such vibrations occur in a fairly dense water environment, which provides significant resistance to movement, the energy of movement is converted into heat. Very rapid heating occurs in the space between the electrodes, which leads to boiling of water.

An electrode boiler works in exactly the same way, only the generated thermal energy is already transferred by the coolant flow through the heat exchange points - radiators. In all other types of electric boilers, certain metal parts act as a “transfer link”. This can be the tubular body of the heating element, a labyrinth of internal channels, or the body itself - in induction-type devices. In any case, the coolant is heated only due to direct heat transfer. But in the electrode circuit there is no such “intermediary” in principle - the liquid medium itself, which is currently located between the conductors immersed in it, is heated.

They say, and this seems to be true, that such technology was transferred into human life from the military industry - this is how water is heated for heating the compartments of submarines and surface ships. This is supported by the combination of necessary qualities - compactness, speed, efficiency, fire safety.

A small digression so as not to return to the problems of terminology. Electrode boilers are sometimes called ion boilers - why is probably understandable. However, sometimes manufacturers focus on precisely this formulation, trying to draw some kind of boundary between these two concepts. They motivate it by the fact that their devices implement high-precision control at the level of “quantity and quality of ions” involved in the heating process. This can be perceived as a publicity stunt or taken seriously - in any case, such control is assigned to some electronic unit and requires the use of a precisely calibrated composition of the electrolyte-coolant. But the operating principle of the heating circuit itself does not change at all. So it won't be a big mistake to use either of these two formulations.

But the name “cathode” or “anode” boiler is completely incorrect, since in constant voltage mode such a circuit is simply inoperable.

Using boilers

As for gas boilers, there are no subtleties here, you need to set the temperature you need and turn on the device, after some time the heating radiators will begin to warm up the room.

The process of firing fuel-fired boilers includes the following steps:

- Cleaning the grates. Using a spatula, the ash is moved along the grates and it falls down.

- Cleaning the chamber where ash accumulates.

- Cleaning the walls of the furnace chamber from soot. Use a dry cloth to wipe the walls.

- Chimney cleaning is carried out regularly, once a year. If traction is impaired, clean as necessary.

If the fire is fired with coal, you need to make sure that a grate for burning with coal is installed in the chamber; when switching to another type of fuel, replace it.

Design and progress of work

Electric boilers "Evan" are in demand by modern people for a number of reasons. Their heating elements are made of high-strength and durable steel, electricity consumption optimally ensures economical operation of the entire home heating system, and a large range of models and low costs make it possible to easily select the right type of equipment. As a coolant, ordinary water or special liquids are usually used here, which will not freeze and are produced only for use in modern heating systems. Evan units can be selected as the main structure for heating a home or as a backup. The products are as simple as possible to maintain and can be easily controlled; they will not make much noise during active operation and make it possible to easily adjust their power

A very important feature is the impossibility of soot appearing on the product, which even the most popular liquid and solid fuel appliances and gas units cannot offer.

produces single-flange electrical appliances, except for “Professional” class products, using a container for heating the coolant, which is made of a specific type of steel and treated with a special anti-corrosion compound. The thickness of this heating container is only 0.3 cm. Comfort class electric boilers are made from special materials with an increased level of thermal insulation and a thickness of up to 2 cm. The service life of the unit is at least 25–30 years.

The Evan electric boiler has such characteristic features as:

- small parameters;

- installation in any place most suitable for its installation;

- automated system.

After the installation of the device is completed and after it is connected to the heating system, connecting to the electrical network will complete the entire preparatory process. Due to the ease of installation, the Evan electric boiler is often chosen for heating buildings ranging in size from 25 to 4,800 m². They are suitable for installation in country houses, private buildings, residential cottages, detached garages, and huge production workshops.

The design of an electric heating appliance of the Evan brand includes several main elements:

Czech heating elements from the Backer brand, which has an excellent reputation for producing high-quality products at affordable prices. These devices are assembled into blocks, thereby guaranteeing excellent maintainability, have a threaded connection and are protected from rust.

Even a non-specialist will understand the connection diagram of this heating boiler, so installing the device will not be difficult for any layman. During installation, you should study the electrical connection diagram as carefully as possible, which the manufacturer usually attaches to a large package of documents for their designs. Evan electrical devices include solutions that can significantly reduce electricity bills. Thanks to the operation of the device in auto mode (it warmed up - immediately turned off, as soon as the temperature decreased - turned on again for heating), electricity consumption will be only 60% of the possible power. A boiler with a power of 12 kW will consume approximately 5 kW over the entire heating season, on average. If you also purchase a temperature sensor, you will save another 10%, and if you install a two-tariff meter, you can add another 20% to the savings.

Incorrect boiler gas valve setting

In order for the burner flame to be intense and provide optimal heating power for the coolant, the gas valve must be adjusted correctly. If this is not done, the heating of the heat exchanger will be insufficient, which is why the boiler may stop heating water.

Gas valve assembly https:///image/cache/catalog/V95001111-1200×800.jpg

To adjust the valve, you must follow the following simple algorithm:

- First of all, you need to open the cover of the water heating unit to gain access to the valve.

- The valve adjusting screws are protected by a plastic cap on clips, which must be pryed off with a screwdriver and removed.

- Under the cover there is a special fitting intended for connecting a pressure gauge. You need to unscrew the locking screw and connect the measuring device to the fitting.

- The unit switches to room heating mode. If a gas boiler does not heat well, the reason may lie in incorrect valve settings, and this problem can be eliminated by adjusting it.

- By turning the second screw, the lower threshold of gas pressure in the system is set.

- Upon completion of the procedure, the locking nut is tightened on the screw in the specified position, after which the valve cover is returned to its place.

Despite the simplicity of the procedure, if the water column does not heat the water due to the gas valve, it is better to entrust its adjustment to installers from the gas trust. Tampering with gas distribution units is associated with an increased risk of fire or detonation.

Gas valve https:///image/cache/catalog/0.845.053_2-1024×768.jpeg

If the boiler does not turn on

The cause of this problem may be the burnout of any electronic part: control panel, power control board, or failure of the heating element. Failure can be determined by assessing the operation of the indicator lights. For this:

- Turn on the boiler and set the desired coolant temperature. The water in the tank should be cold. Current should flow to the heating element, and the electric boiler operation indicator should light up. It is often connected to the same cable that leads to the heating element. This cable comes from the power control unit.

- Check to see if the indicator lights up. If it burns, then there is a problem with the heating element. If not, then there is a breakdown in the electronic part.

Briefly about the main thing

To understand why a double-circuit boiler does not heat hot water well, you should diagnose not only the unit itself, but also the entire heating system. The most likely causes of such failures are scale on the walls of the boiler equipment, problems with the gas supply and burner operation, as well as violations in the automatic settings of the programmable module. If the boiler does not heat the heating well and the consumer has found out the reason, it is necessary to eliminate it.

Have you ever encountered a problem when the boiler began to poorly heat the water circulating through the heat exchanger? How did you solve the problem?

01.07.2021

Electric boiler for home heating Protherm

08 March 2012 News, Expert advice, Electrical for home, Electrical heating for home

In addition to homemade electric boilers, in my practice I also have to connect factory-made boilers, both domestic and imported, such as the Protherm boiler.

This is the brand of electric boilers I want to tell you about.

The price category for such electric boilers is quite high, about 20 thousand rubles. depending on the power there are plus or minus several thousand.

This is how the Protherm Skat 14K electric boiler impressed me in practice.

Boilers are made in Slovakia, in the city of Skalica.

It is made of very high quality and soundly, all parts are mounted very compactly and at the same time accessible for maintenance.

It is clear that manufacturers have puzzled over the internal structure of the electric boiler a lot.

All electrical wires and connections to them are also of very high quality, and almost all the internal contents of the electric boiler, from manufacturers of leading companies in the world, are at the highest level of quality.

To be honest, it’s nice to look at; a professional can immediately determine the high reliability of the operation of such a boiler, even from the component parts.

So, on the front, front part of the boiler there is a digital display with control buttons and indication:

The interface itself is very clear and it’s very easy to understand the settings.

The boiler does not turn off

As practice shows, there are quite a lot of situations in which the EVAN boiler does not turn off and begins to waste reserves. Without a diagnostic inspection, it is almost impossible to identify the cause of the damage, so we recommend scheduling repairs from a boiler specialist. Our technicians have state-of-the-art tools and practical experience at their disposal, which combine to help perform an effective inspection. By calling us, you will receive convenient service at a reasonable price, and if the Evan electric boiler does not turn off, we will help and set it up.

- Do you always arrive so quickly? Response time is on average within an hour. But if for some reason it is increased, we will warn you about it in advance.

- We purchase spare parts from a supplier with whom we have been working for more than 8 years. Not all brands have original spare parts, but we select high-quality analogues.

- All engineers are our full-time employees. We never involve third-party craftsmen.

Order repair:

- To place an order for the installation of household appliances, fill out the form on the website, or call us at 8 (495) 320-37-07.

- When confirming the order, it is advisable to name the type, brand and model of the boiler, describe the installation conditions (whether there are supply lines or not - water pipes, electrical wiring at the installation site).

- Installation can be done on the day of your request or at any other time. The operator will agree with you on a convenient time for the engineer to arrive.

For all types of services provided by the service center for the repair of boilers of any brand and model, an official guarantee with a long period is required. Qualified specialists will not only fix existing breakdowns, but will also prevent future breakdowns by replacing worn parts with new ones.

To ensure that boiler repairs are carried out reliably and their service life lasts for years, we use certified spare parts in our work, which are purchased from official suppliers around the world at cost.

The client himself chooses where the boiler repair will be carried out - at the installation site or in the service laboratory, and also indicates the time for the arrival of the technician or courier. We are always ready to listen to your wishes and advice to improve the quality of service.

For all types of services provided by the service center for the repair of boilers of any brand and model, an official guarantee with a long period is required. Qualified specialists will not only fix existing breakdowns, but will also prevent future breakdowns by replacing worn parts with new ones.

To ensure that boiler repairs are carried out reliably and their service life lasts for years, we use certified spare parts in our work, which are purchased from official suppliers around the world at cost.

The client himself chooses where the boiler repair will be carried out - at the installation site or in the service laboratory, and also indicates the time for the arrival of the technician or courier. We are always ready to listen to your wishes and advice to improve the quality of service.

The service employs high-level specialists who not only have the appropriate education, but also many years of experience in this field. They solve problems of any complexity in a short time.

To confirm our words about the high reliability of our repairs, we provide a warranty receipt certified by the service seal. This document entitles you to free boiler repair in our workshop without a queue.

If you want your home to always be warm, order our services. We have been repairing boilers throughout

10 years and we know everything about their internal structure.

Boiler repairs usually take no more than 3 hours. The period depends on the type of boiler and the breakdown. Specialists come to you with a full set of tools and can carry out repairs in the shortest possible time.

We accept both cash and non-cash payments. You can also pay for our services using a plastic card. Upon completion of the repair, we will provide you with all the necessary documents.

Connection

If we consider equipment such as electric heating boilers from the point of view of fire safety, then we note that they do not pose any danger to humans. Under no circumstances can an electric boiler cause a fire in a wooden house. However, there are nuances that you should be aware of

When calculating the wiring, it is necessary to take into account the power of the heating installation. If its cross-section is smaller than required for your equipment, then it will heat up

And this is no longer safe for both the house and the people living in it.

When determining the optimal wire cross-section, the following calculation is used: 8A per 1 mm 2 cross-section. If a 6 kW heating boiler is installed in the house, then the minimum cross-section of the wire leading to it should not be less than 3.4 mm 2.

A water heated floor is the optimal heating system for an electric boiler. Among all installations intended for heating premises, an electric boiler for heating private houses is the most expensive class. The cost of a kWh of thermal power when operating this equipment is 3-4 rubles. By placing the unit in the lower part of the room, it is possible to ensure the most efficient use of the supplied heat.

How to fix the problem yourself

Before buying a boiler, correctly calculate the power suitable for your room volume. If the problem is poor draft, it is necessary to clean the chimney, clean the chamber from which the air flows, and the combustion chamber itself. If these manipulations do not produce results, install the draft regulator.

If performance is poor due to fuel, you should first carefully study the instructions and clearly determine what exactly can be used to heat your model. When purchasing a supply for the heating season, first buy a small batch for a couple of days, and, after making sure of the quality, you can make a purchase for the season. If the reason is the volume of the chamber, make an incomplete bookmark.

Principle of operation

In heating equipment powered by electricity, heat is generated by heating a conductor through which a large electrical current flows. Exceptions include heat pumps and air conditioners, however, the working fluid in them is not electricity as such.

If in heating element or induction boilers the conductor and heater is a refractory metal wire or the body of the device, then in electrode boilers the current is passed directly through the coolant.

Water containing salts and other impurities is a good conductor, and when current is passed through it, as is the case with any conducting medium, heat is released in proportion to the strength of the current.

An electrode boiler is always a flow-type design. The electrodes are fixed inside the boiler in such a way that there is a small gap between them. Electric current passes only if the space is filled with a conductive liquid.

When the power is turned on, a potential difference occurs between the electrodes. Negative and positive salt ions present in the coolant rush to the correspondingly charged electrodes. Collisions of molecules during movement are accompanied by the release of heat, which heats up the solution.

The electrode boiler is powered by alternating voltage. The sign of the charge on the electrodes changes with a frequency similar to that of the supply line - 50 Hz. Changing the polarity protects the system from the formation of electrolysis gases, the stable splitting of water into hydrogen and oxygen, and the deposition of salt components on all conductive surfaces.

Boiler operation diagram

The bottom line is:

Heating the coolant without the use of intermediaries.

The correct choice of coolant with a conductivity of at least 1 kOhm/cm is important.

The boiler and heating require thorough grounding, otherwise users may be electrocuted when in contact with metal elements of the system and static discharge in the case of polymer surfaces.

Among the features of electrode boilers, it should be noted:

- The electrode deteriorates over time and requires regular replacement; if this is not done, the efficiency of the boiler decreases and the risk of arc breakdown increases. Which is dangerous for the entire electrical system of the house.

- Requires a powerful electrical input into the house, a separate power supply branch and always before the RCD (Residual Current Device).

The boiler manufacturer regulates the maximum permissible volume of coolant in the system. The approximate ratio is 10 liters for each kW of power. This is easy to achieve if the heating is designed from scratch. However, the inclusion of a boiler in an existing design, for example, with cast iron radiators with large sections, will lead to a significant decrease in the efficiency of the boiler or its incorrect operation.

The conductivity of the solution increases with its temperature, therefore the indicated rated power is only achieved at 70°C or 90°C.

The insertion was carried out poorly: the diameter does not match or there are narrowings in the gas pipeline

A common reason for a complaint that a gas boiler in a house does not heat well is poor-quality connection of heating equipment to the general gas supply system (gas pipeline).

Often, gas service workers weld an additional thread, screw a tap onto it and drill a small hole where the thread joins the gas pipe. The diameter of such a hole is much smaller than the diameter of the pipe, which leads to a drop in pressure. As a result, the gas boiler does not heat hot water well.

Correct connection requires compliance with certain rules and takes more time. Therefore, negligence occurs frequently.

You can determine this reason in the following way:

- there is a sharp decrease in the flame after ignition of the boiler;

- stops gaining temperature, or the flame goes out on its own.

Special calculators are used to calculate the required diameter of pipes in a particular room. The power of the boiler requires a larger volume of gas supply, therefore it is necessary to use pipes with a larger diameter. Before connecting the boiler to the gas pipeline, you must call a qualified specialist who will calculate the required diameter for the pipes, taking into account the characteristics of the room and the power of the boiler.

The following factors influence the choice of a larger cross-section in the connected pipes:

- low pressure requires connection to pipes with a large diameter;

- boiler power and room area affect the diameter;

- the longer the system, the larger the cross-section must be used;

- a reserve in diameter is necessary when there are many turns in the system (gas flow slows down at turns);

- number of consumed points;

- the required room heating temperature with the water heating temperature for domestic use;

- what pump is installed in the boiler.

Characteristics of the boiler EVAN S1 3

- Power - 3 kW

- Block heating elements made of stainless steel

- Smooth adjustment of coolant temperature in the range from 30 to 85°C

- Block for connecting the circulation pump and air temperature sensor/GSM-Climate module

- Overheating protection - emergency self-resetting sensor (operation temperature - 92±3°C)

- Efficiency - 99%

- Warranty - 18 months

Boiler design EVAN S1

|

The electric boiler EVAN C1 of the “Standard” class is intended for heating summer cottages, private houses, small retail and warehouse premises. Can be used as both the main and backup heat source. The boiler is a monoblock that combines the boiler and control panel in a single housing.

The required coolant temperature in the boiler is set by a built-in thermostat by smooth adjustment from 30 to 85 degrees. In addition, it is possible to connect an external thermostat, with which you can regulate the air temperature in the room. The GSM-Climate boiler remote control module can be used as an external thermostat, which allows you to regulate the room temperature from a distance, control the operation of the boiler and monitor its health.

To ensure safety when heating the coolant to the set temperature, the thermostat turns off the boiler and turns it on again after the temperature drops below the set point. For additional protection against overheating, the devices are equipped with a self-resetting emergency thermal switch, which, in the event of failure of the main thermostat, turns off the boiler when the coolant reaches a temperature of 92 degrees.

The heating elements of the EVAN C1 boiler, like all EVAN electric boilers without exception, are made of stainless steel, which increases their service life. In addition, EVAN S1 boilers feature a block design of a heating element with a threaded connection, which makes it significantly easier to replace.

To operate in systems with forced circulation, the electric heating boiler EVAN C1 has a connection block for connecting a circulation pump.

Evan NEXT - 5

Electric boiler Evan NEXT 5 is one of the simplest heating units made in Russia. It is used for heating private households, country houses, industrial and commercial premises. The model is easy to operate and has a long service life. Boiler features:

- Heating elements made of stainless steel;

- Universal power supply;

- Possibility of connecting a thermostat;

- Ability to work with heated floors;

- Monoblock design.

The boiler is made in a compact metal casing for wall mounting.

Boiler design

The wall-mounted electric boiler Evan NEXT 5 is built on the basis of Czech-made stainless steel heating elements. It is resistant to corrosion and low quality coolant. The temperature in the circuit ranges from +30 to +85 degrees with a permissible pressure of up to 3 bar. Water or certified antifreeze liquids are used as a coolant. With a boiler power of 5 kW, the maximum heated area is 50 square meters. m.

The boiler is made in the form of a monoblock. It combines blocks of heating elements and a simple mechanical control panel - here the power and temperature of the coolant are selected. To reduce heat losses, the housing is supplemented with a layer of thermal insulation. Due to its compactness, the boiler will not take up much space in the boiler room. There is no built-in piping, but the design of the unit provides terminals for connecting a circulation pump.

Microclimate control

The Evan NEXT 5 electric boiler is characterized by its simplicity of design, which has a positive effect on its reliability. The microclimate in the premises is controlled using a simple thermostat with an accuracy of one degree. A room thermostat - simple or programmable - will help automate the operation of the boiler. It is connected via a two-wire circuit and controls the operation of the heating elements. The user just has to choose a comfortable temperature - a boiler with a thermostat will ensure its stable support.

Power supply and options

The electric boiler is powered from a single-phase or three-phase electrical network. An emergency self-resetting switch is used as the main protection system. It operates at a temperature of +92 degrees, preventing overheating of the coolant in the heating system. After the coolant has cooled, the switch returns to its original position without user intervention.

The electric boiler is easy to operate and does not require frequent maintenance. It is mounted on the wall; pipes with a diameter of 1 inch are provided for connecting the heating circuit. An interesting option will be the ability to connect a GSM module for remote control of the boiler via mobile Internet or SMS channel - an excellent solution for country housing or a summer house. If necessary, the boiler can work with heated floors.

How to get rid of gas boiler clocking Some tips

Frequent operation and shutdown of the heating boiler is a fairly common problem. It occurs in different boiler models from different brands. The main thing is to detect and eliminate it in time. We suggest looking at why a gas boiler often turns on and off and what to do if the unit is not working correctly.

Malfunction is often the result of incorrect installation or failure to follow operating instructions. If you see that the equipment begins to randomly turn on/off at high frequency, you need to carry out diagnostics and repairs. Otherwise, the service life of the equipment will be greatly reduced due to rapid wear of parts.

The most common reasons for incorrect operation of heating equipment

Even systems from leading manufacturers can malfunction for various reasons: Navien, Ariston, Bosch, Vaillant, BAXI and others. A common reason why the Navien boiler often turns on and off (like models from other brands) is incorrect installation. The system starts turning on/off every 5-7 minutes or even more often.

If you see that the operation occurs more often than normal, this is a reason to contact a specialist. He will be able to more accurately diagnose the problem and find the answer to why the malfunction occurred.

Here are some more common reasons:

- The model was chosen incorrectly. For example, if a model with too much power is installed for such premises. We have repeatedly said that you need to choose units with a power reserve, but not too much. Usually +10% of the recommended power is enough.

- The circulation pump is not installed correctly. If the coolant does not move as expected, this can also cause operational errors.

- The specified temperature range is incorrect. Modern models of heating equipment make it possible to accurately indicate the temperature range that they must maintain - to prevent overheating of the room and its hypothermia. If the owner sets these values incorrectly and the temperature difference is too small, this may be the root cause why the boiler often turns on and off.

- There is no thermostat installed in the room, and the operation of the equipment is adjusted according to the temperature of the coolant. This solution does not provide an objective assessment of the room temperature and the system does not work correctly. It is more efficient and reliable to install a thermostat.

Most of these problems are not critical and difficult to solve. But if you do not pay attention to them, the system will wear out much faster due to incorrect operation and will require replacement. And this is already expensive. We will talk about these problems and their solutions further.

Excess power

A powerful wall-mounted or floor-standing gas boiler in a small room is overkill. First of all, it's expensive. And secondly, power must be calculated accurately, and not in excess. Too much power is not recommended, as is insufficient power. If you cannot perform power calculations yourself, we recommend contacting a specialist who will do everything.

By the way: if you install a unit of insufficient power, there may not be a problem with frequent switching on/off, but condensation will constantly collect in the chimney. Clogging and wear of system elements accelerates. Plus, it will be impossible to fully heat the premises.

We have already written how to calculate the power of a heating system for a home. The choice is influenced by many factors:

● climate in the region by season; ● total area of heated premises; ● materials used to build the house and the quality of insulation; ● type, sizes of windows and doors, etc.

Check the instructions for how often your boiler should be activated. These values differ for different models. You should be wary not only of too frequent shutdowns, but also of its different frequency - after five minutes, after three, then again after five (the intervals may be different).

If your boiler has excess power, this is not a reason to buy a new one. There are several ways to solve this issue:

- Install 4-way mixing valves in the hydraulic system. This is the most effective method, but it is also the most expensive.

- Lower the burner. This method is only applicable if a multi-stage burner is installed.

- Install and connect the boiler. This way you will reduce the boiler power and at the same time provide the house with hot water.

What happens if the boiler power is incorrectly selected?

In cases where a mistake is made and the choice of boiler unit is not made correctly, you need to understand how to get out of this situation correctly. In fact, there are 2 options for incorrectly calculating the thermal power of a heating unit.

The first is that the thermal performance of the unit in relation to the total heated area of the house is chosen to be very small in order to be able to compensate for the thermal losses of the object, and the second is when the heating unit is purchased with a significant margin. In the first option, even when the device is operating at full load, the temperature in the rooms remains unacceptably low and does not rise. There is no emergency here; the only negative is the cold in the house.

In order to solve this problem, you still need to calculate the required size of the heating output of the unit and only then will it be possible to choose the right solution.

If the power deficit is not large, it may be compensated by additional insulation of the external walls of the house by replacing window units.

If this is not enough, then you will have to buy a new device as the main one for heating, and leave the first one for heating hot water and “standby heating”, when outside temperatures are above zero or there are no residents in the house. This way you can get a very efficient heating system.

The situation is much worse when the calculation of the heating device is carried out with an excessive reserve of thermal power. First of all, this will cause a constant high and uncomfortable temperature in the room, even when the burner is operating at the lowest load, everything in the house will be unbearably hot.

Source: https://101studio.ru/teplyj-pol/pochemu-elektrokotel-ploho-greet.html

Repair and spare parts

For devices, the most common types of breakdowns are:

- destruction of the heating element inside the heating element due to burnout of the coil;

- breakdown of the heating element.

The occurrence of these malfunctions can be explained by the following reasons:

- a solid deposit of hardness salts is deposited on heating elements; it is this sediment that interferes with the removal of thermal energy from the heating element, which will quickly cause its breakdown;

- Voltage fluctuations in the power grid also lead to device failure;

- evaporation of the liquid can also lead to overheating and for this reason the heating element may burn out.

The negative features of electric boilers include their complete dependence on electricity. Power outages will threaten to stop heating, so experts advise purchasing an uninterruptible power supply in advance. Sometimes consumers complain that the boiler turns on only during the time period from 23:00 to 7:00. And this is despite the fact that there is an electronic thermostat in the home.

Sometimes in various models the room temperature sensor stops showing. This kind of malfunction can be explained by loss of contact in the terminal block, failure of the sensor itself (it can be replaced with a new one) and the presence of a fault in the board. And also, ordinary people often complain that the boiler stops responding to the set parameters of the thermostat: it constantly operates at full power. In this case, most likely, there is no temperature sensor in the room; it must be installed. If there is a sensor, it means it is broken - you will need to replace the burnt parts in it and reconfigure the automation.

A review of the Evan Expert electric boiler awaits you in the next video.

Other reasons

There are other reasons why the boiler does not take in water or it does not heat up enough:

- Pipeline blockage.

Poor quality water leads to the appearance of various deposits in pipe bends. Experts advise replacing communication systems made from old materials with polypropylene ones; it is additionally recommended to improve the water purification system.

To get rid of a clogged pipeline, you can use a regular brush, or special chemicals Source severdv.ru

- Damage to valves.

The water heater contains special taps that are responsible for the normal supply of water. The release of one of them (hot or cold water supply) can disrupt the normal functioning of the system as a whole. The broken part needs to be replaced and the problem will be solved.

- Broken pressure regulator.

The storage water heater simply produces the same level of pressure that it gains at the inlet. If the pressure in the central line is stable, and hot water does not flow well from the water heater, you need to check the functionality of the pressure reducer. If this is the reason, you need to check the device settings or replace it with a new one.

- Unstable system pressure.

One of the reasons why there is low pressure of hot water from the water heater is insufficient pressure in the pipeline. The liquid collects at the top of the boiler and begins to move only due to the pressure in the system. To check this, you will need to open the valve on the cold water mixer, and if this is the problem, then you need to contact the housing and communal services.

SNiP states that the water pressure in the central pipeline must be at least 1 Bar Source otoplenie-gid.ru

- Back pressure valve jammed.

This can happen due to foreign objects entering. To correct this problem, the valve must be completely disassembled and the stem redesigned. Before starting this process, you need to drain all the water from the heater.

What affects electricity consumption

All boilers convert the energy used into heat in a 1:1 ratio. With 100% efficiency, negligible losses in wires and connections are neglected. The exception is heat pumps, but they are still rarely used.

Thus, there are only 2 ways to reduce electricity consumption:

- Reduce heat loss. To do this, the home is covered with mineral wool or polystyrene foam, and the cracks are sealed.

- Optimize the operation of the boiler in order to eliminate excessive consumption of energy resources.

The second problem is also solved in 2 ways:

- Using weather-sensitive automation. Such a system promptly warns the boiler about the onset of warming, and it manages to reduce power without overheating the room.

- Programming. A model with this function, according to user settings, reduces heating output when residents are at work or sleeping. The rest of the time the device returns to normal mode.

It is possible, without reducing consumption, to reduce financial costs. They are switching to differentiated metering of electricity consumption with a big discount at night (RUB 1.68 instead of RUB 3.89). The heating system is equipped with a heat accumulator - a large capacity in which the boiler raises the temperature of the working environment to +98˚C within a grace period. During the day, boiling water is gradually supplied from it through the mixing unit into the circuit as needed; the heater does not work at this time.

In this case, you will have to pay 17,388 × 1.68 = 29,212 rubles for the season. But there is a nuance: the rated power of the boiler should be twice the design power, because at night it works both for heating and for “charging” the heat accumulator. For the example given, a 20 kW unit will be required.

How to avoid the problem?

You can avoid malfunctions if you follow a few simple recommendations:

- Be sure to contact professionals at the boiler room design stage. Incorrectly selected boiler power or insufficient volume of the heating system will negatively affect the operation of all equipment.

- Entrust installation to specialists. High-quality installation and connection of boiler equipment will eliminate most of the malfunctions that may arise during further work. In addition, this is a mandatory item to obtain a warranty period from the manufacturer.

- Perform regular maintenance on your equipment. Once a year, a technician comes to diagnose your boiler, clean all components, check operating pressure, check for leaks, and perform a test run.

- Follow all manufacturer's recommendations when operating boiler equipment. Carefully read the user manual for your equipment. Please comply with the specified requirements.

- Entrust the repair of your equipment only to specialists from specialized companies. Remember that independent repair of gas equipment is strictly prohibited! In addition, if you entrust the work to an unqualified specialist, there is a possibility that the boiler will fail altogether or an emergency situation will be created.

Thus, you will not only extend the uninterrupted and safe operation of the boiler, but also will not lose the warranty. And solving problems in a timely manner will help you avoid costly repairs and save your money.

Example of electricity consumption

For clarity, you can consider the organization of heating in a house with an area of 90 square meters. m, located in the Moscow region. There are electrical appliances with the following power consumption:

- water heater and washing machine: 1.5 kW each;

- 2 socket groups with 10 A circuit breakers, i.e. designed for a power of 220 × 10 = 2.2 kW each;

- internal and external lighting, supply and exhaust ventilation system with recuperator: total 1 kW.

The kitchen stove runs on bottled gas.

The total power consumption is 8.4 kW. 15 – 8.4 = 6.6 kW remains for heating.

The required rated power of the boiler corresponds to heat loss in the coldest week of the year + a reserve of 20%. To calculate them, a complex calculation is required, but a less accurate simplified version can be applied to a standard house: Q = S × K, where

Q – heat loss in the coldest week, W;

S – heated area, sq. m;

K – specific heat loss, W/sq. m.

Depending on the region, K is taken equal to a fixed value:

- southern regions: 60-80;

- central part of the country: 90-110;

- northern districts: 120-200.

According to the condition, the house is located in the Moscow region, we can assume that K = 100 W/sq. m.

Taking into account a reserve of 20%, the power of the heat generator in the coldest week will be:

W = 90 × 100 × 1.2 = 10,800 W = 10.8 kW.

Which electric boilers are most often used to heat a private home?

There are 4 varieties:

- heating elements;

- electrode;

- induction;

- heat pumps.

The first ones are the most common. Their advantages:

- affordable price;

- low requirements for the coolant: it only needs to be desalted once before the first use;

- simple and inexpensive repairs;

- soft start (prevents power surges in the network).

Electrode boilers are cheaper than heating elements and are simpler in design. But the user has to prepare the coolant according to the recipe. At the same time, its chemical composition is constantly changing, so every 1.5 months it is necessary to pour new liquid into the circuit. This makes operation difficult.

Both of the latter types have a common drawback: their design does not provide for a soft start, so when switched on, voltage surges occur in the network.

If funds allow, it is advisable to purchase a boiler that operates on the principle of a heat pump. It is beneficial to use it. For every kilowatt of electricity consumed, the device produces up to 5 kW of heat. But the system will require a lot of money: in addition to purchasing an expensive device, you will have to pay for the construction of an extensive external heat exchanger (a long circuit of pipes in the ground).

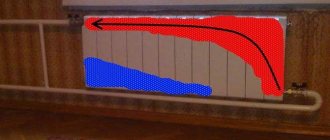

The boiler does not heat the radiators

Often, a two-pipe heating system does not heat due to the low heat transfer rate of the boiler exchange circuit. This leads to a decrease in temperature and, as a consequence, a loss of efficiency of the entire system. Not every boiler model provides an easy way to dismantle the heat exchanger. If the heating does not heat well due to the appearance of plaque on the internal elements of the boiler, you can perform flushing without this procedure. To do this you will need a pump with a filtration system. The cleaning procedure is as follows:

- Disconnecting the boiler from the general heating system;

- Connection to the inlet and outlet pipes of the pump hoses;

- Filling a special cleaning liquid into the boiler heat exchanger;

- Using a centrifugal pump increases the speed of fluid passing through the boiler.

After this, the radiators should not heat poorly

Particular attention should be paid to the flushing fluid. It should not harm the metal elements of the boiler and system. Therefore, at the end of the procedure, the entire system should be rinsed with distilled water.

Therefore, at the end of the procedure, the entire system should be rinsed with distilled water.

To avoid the appearance of scale, before pouring water into the heating system, you need to reduce its hardness level. The use of running water is not recommended as it contains large amounts of calcium and magnesium bicarbonates. They are the main source of limescale deposits not only in the boiler heat exchanger, but also in pipes and radiators.

Problems with the heating circuit

The pump must be selected according to the requirements of the heating circuit.

Malfunctions in the operating mode of the heating circuit are not always associated with a malfunction of the main heating element. If the boiler works, but does not heat the batteries, the reason must be sought in the wiring itself.

List of main heating circuit malfunctions:

- the filter on the return line or the needle tap (Maevsky tap) is clogged;

- insufficient power of the circulation pump;

- the rules for installing a heating circuit with natural circulation have not been followed.

Any of the above problems must be resolved before the start of the heating season. Otherwise, the room may be left without heat for several days, since the repair involves completely draining the coolant.