The Ukrainian brand Danko is known primarily for gas boilers. A clear advantage is their low cost. The range also includes parapet gas boilers, installed in private houses or apartments where it is not possible to install a chimney.

In the article we will look at the best models of Danko gas boilers, how they behave in practice, what advantages and disadvantages the owners note, as well as what malfunctions may arise during the operation of boiler units in real conditions.

About the manufacturer

The Danko trademark is managed by PJSC Agroresurs; the first batch of boiler units was produced in 2002. The company is represented in the markets of Ukraine, Russia, Belarus and Moldova, where it has established itself as a manufacturer of relatively reliable and efficient gas boiler units for their price. It’s not uncommon to find the first batches of 2002 in homes.

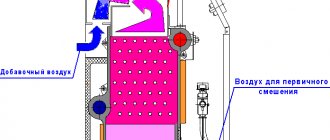

The design and principle of operation of Danko gas boilers in a section using the example of a double-circuit steel model 12VSR.

Heating boilers are produced using modern foreign equipment, automation is imported from Italy in finished form. Almost all boiler units have high efficiency - over 90%. However, there are also disadvantages - the assembly is of insufficient quality, problems with the automation are possible during operation, due to the simplicity of the device and low cost, the boilers do not have a wide range of functionality or a set of protective systems. Installers note the relative complexity of installation and connection.

In practice, during strong gusts of wind in versions with a horizontal gas duct, the burner often blows out and the flame goes out, but the automation does an excellent job and turns off the gas supply. After this, the boiler must be ignited manually. The above-described disadvantages are typical for any inexpensive boilers of Russian, Ukrainian or Belarusian production.

About the company and boiler products

Danko is a company that positions itself as a manufacturer of high-quality boilers at an affordable price. Since cast iron is considered a reliable and durable material, the developers from Ukraine decided to place all the elements and components made using modern technologies in a cast iron body. The result is a Danko gas boiler with a long service life. When properly operated, the unit will effectively provide heat to a room for 25 years, which is ten years more than its steel counterparts.

It is worth saying that the cost of models from this company is quite low. The manufacturer is constantly improving its products, their quality characteristics and appearance.

An overview of Ukrainian-made boilers is presented here

Interesting design and compact dimensions allow boilers from the Ukrainian manufacturer to fit perfectly into any interior.

Reviews of Danko gas boilers are mostly positive; many owners note the possibility of combining the heater with cast iron radiators. Therefore, when the old batteries are still functioning, there is no point in replacing them.

To manufacture equipment, the company purchases only modern parts and devices from Finland, Denmark and Japan. All models have independent temperature control systems and are equipped with safety devices. There are many people who want to purchase a boiler from this company, including residents of the Ukrainian territory, as well as many CIS countries.

Owner reviews of Danko gas boilers: advantages and disadvantages

| Advantages | Flaws |

| Affordable, not high cost | Noisy operation, especially in comparison with models from foreign manufacturers |

| Reliability - in practice, it is not uncommon to see cases of operation for more than 8, 12 and even 15 years | Modifications with a horizontal flue suggest the possibility of flame extinction in strong winds |

| High technical characteristics and efficiency | Regular cleaning and maintenance required (at least annually). If there is no cleaning, problems with the automation may occur. |

| Energy independence – equipment operates regardless of the availability of electricity. | According to reviews from owners, double-circuit models, with high water consumption, do not always cope with its heating |

| Economical - in models with a power of up to 20 kW, gas consumption is in the range of 0.8-1.7 cubic meters. m/hour | |

| The range includes models with a cast iron heat exchanger, the service life of which is more than 25 years. In other models it is made of stainless steel | |

| Due to the simplicity of design and automation, they are easy to use |

Popular models

Danko Rivneterm heavy-duty model for heating rooms up to 900 sq.

m Floor-standing models of Danko brand boilers are presented in the following series:

- Danko-10 with a power of 10 kW are intended for heating and hot water supply; they require a chimney.

- CP or VSR refer to single- and double-circuit models with a stated power from 8 to 24 kW. Equipped with metal heat exchangers with a wall thickness of 3 mm.

- SN and VSN are units with increased power from 30 to 48 kW with the same steel heat exchanger.

- Rivneterm belongs to a series of ultra-high power units and is designed for heating large areas.

The latest models are represented by single- and double-circuit boilers with a declared power of 30 to 96 kW, having a steel heat exchanger and capable of heating rooms up to 900 m2.

The series of wall-mounted boilers from the same manufacturer includes products with the indices US and UVS - single- and double-circuit boilers with a power from 7 to 18 kW. They have the same steel heat exchanger with three-millimeter walls. A separate series includes floor-standing boilers with a capacity of 16-50 kW, equipped with a cast iron heat exchanger. They have large dimensions and weight, which is explained by the different sizes of individual components and assemblies.

Cost and completeness

Automation for boilers is produced in Italy, Poland, and the USA.

The cost of Danko boilers is determined by the type of design, its functionality and ranges from 8 to 109 thousand rubles. The delivery set traditionally does not include a chimney and other components. Each series of products differs in its configuration, so before purchasing, the user will need to clarify its composition and purchase the missing elements.

The following sets are common on the domestic market of components for such boilers:

- A set of parts from Kare (Poland), manufactured specifically for Danko: valves, thermostat, reducer and a set of pressure and draft sensors.

- A selection of components from Honeywell (USA): electromechanical flow control units installed in particularly “advanced” models.

- Components from Sit (Italy): automatic units used in models of gas boilers made in Europe.

The range of products themselves and components for them is very wide. The user can always choose the best option taking into account the specific conditions of their operation.

The best and most famous models: characteristics and prices

8C

Low-power 8 kW single-circuit floor-standing boiler, one of the most inexpensive in price. Designed for a house with an area of up to 70-80 m2. The design and principle of operation of the model are as simple as possible: open combustion chamber, steel heat exchanger (C in the name), SIT automation (Italy).

The boiler has a high efficiency of 92% and a particularly low gas consumption - 0.9 cubic meters. m/hour. Unlike other models, it is equipped with a vertical gas duct, which prevents the burner from being blown out by the wind. The only protection is to prevent overheating and gas control.

Cost on average 18,000 rubles.

12VSR

A double-circuit floor-standing boiler with a power of 12 kW, designed for heating a house with an area of up to 120-130 m2. This is one of the best Danko boilers for heating a private home.

It is distinguished by the presence of a second circuit, that is, water heating (B in the name), hot water productivity at a temperature of 35°C is 4.93 l/min. The volume of hot water supply is sufficient for a single consumption; for more intensive use (eg bathing and kitchen tap at the same time), the power may not be enough. It has a steel heat exchanger and is capable of operating not only on natural gas, but also on liquefied bottled gas (P in the name).

Efficiency is 91.5%, and natural gas consumption is 1 cubic meter. m/hour. The boiler is energy-independent, the gas outlet is organized vertically, which greatly reduces the risk of blowing out and subsequent attenuation. The disadvantages are also the loud ignition sound, lack of auto-ignition and flame modulation, however, for such a price, these functions are rarely found on dual-circuit models.

Cost – 24,000 rubles.

Review of Siberia gas boilers One of the most reliable among domestic boilers

12.5US

An improved parapet boiler with a power of 12.5 kW is designed for installation not only in private houses, but also in apartments.

Parapet boiler systems have a closed (sealed) combustion chamber and do not require connection to a traditional chimney. They can be installed in any room where there is at least one external wall, through which a side coaxial chimney (pipe within a pipe) is subsequently discharged. It is installed in the apartment in the window sill and requires only a gas pipeline, since it is energy independent.

Gas consumption 1.4 cubic meters. m/hour is optimal for this power and price category, although higher than the classic convection models 12BP or 12P. One of the few truly quiet Danko boilers. Apart from the dubious build quality and narrow functionality, no shortcomings were found due to the practice of use.

Cost – 24 thousand rubles.

Is it worth considering parapet gas boilers for heating a private home?

16HP

Cast iron single-circuit boiler with a power of 16 kW, designed for heating a house with an area of up to 150 sq. m. A cast iron heat exchanger is usually used in more expensive modern models and has a significantly longer service life - over 25 years. It takes longer to heat up, but it also takes much longer to cool down, continuing to give off heat even after the burner is turned off.

Gas consumption is not outstanding, but optimal 1.9 cubic meters. m/hour, and efficiency is 90%. The disadvantages are the absence of any automatic protection systems and the significant weight of the heating unit - 97 kg. The cost of a boiler is on average 34-37 thousand rubles. , which is still significantly lower than foreign analogues, prices for which start from 45-49 thousand rubles.

Specifications

Gas floor-standing boiler Danko from a Ukrainian manufacturer

The technical characteristics of Danko boilers include:

- type of combustion chamber - turbocharged or atmospheric;

- average fuel consumption does not exceed 1.9-2.7 m3/hour;

- Efficiency – 92%;

- heating area – from 70 to 300 meters;

- power supply 220 Volt 50 Hertz.

These same indicators include a set of additional functions available for each specific model.

Official website: where to view all models and operating instructions

A snapshot of the website of the official representative in Russia.

In Russia, the official website is located at https://www.danko-rus.ru/.

By going to the Product Catalog you can see all available models, sorted by type. Each model is accompanied by a detailed description of the device’s features and technical characteristics, as well as an electronic copy of a full operating manual, which describes the installation diagram, the algorithm for switching on and adjusting the operation, maintenance features, and contains clear schematic images.

Which boiler model is ultimately better to choose?

If you decide to opt for Danko, it is not difficult to decide on a model; we recommend choosing from the most successful models described above. The main selection criteria are the minimum required power, the need for a second circuit for hot water supply and the budget.

One of the most budget-friendly gas boilers on the market as a whole is Danko 8C, which has enough power to heat a house with an area of up to 70 m2. For average house sizes (100-120 m2), models 12CP (single-circuit) or 12VCP (double-circuit) are suitable. With an area of 120-140 m2 or more, it is better to choose a model with a more efficient and reliable cast iron heat exchanger - 16HP or its more powerful versions.

Parapet models are intended, as a rule, for installation in an apartment; their choice is limited only by the minimum required power (simplified - 1 kW for every 10 m2 of area + 10-20% power reserve).

How to calculate the required boiler power for heating a private house

Types of Danko boilers

Wall-mounted boilers with a steel heat exchanger have power limitations.

Danko boilers on the heating equipment market are represented by a large assortment of models, differing in the following characteristics:

- according to the type of installation within the premises they have a floor, wall or parapet design;

- according to functionality they are divided into single-circuit and double-circuit systems;

- According to the type of combustion chamber, there are open or atmospheric and closed (turbocharged) types.

Danko floor-standing gas boilers for heating a private home are installed on a special stand made of non-flammable material or directly on the floor. For their wall-mounted analogues, hinged installation is provided using metal support structures (ramps) mounted on load-bearing walls. Parapet boiler samples are products with a hinged installation type. They differ from wall-mounted models in the way they connect to the chimney. In addition, this difference is caused by the need to create a slope for the heating system pipelines, ensuring natural circulation of the coolant.

Single-circuit units are designed only to heat liquid and transfer it to the heating network. Dual-circuit systems simultaneously heat the coolant and prepare hot water used for domestic needs. There are the following differences in the design of the combustion chamber:

- In open (atmospheric) models, to obtain normal combustion, air is taken directly from the room in which the boiler is installed. Combustion waste along with smoke is removed naturally due to the draft generated by the pressure difference.

- In closed-type units, air enters the system and smoke is removed from it through a powerful turbocharger fan.

Turbocharged units are much more stable in operation than conventional ones. The reason is the high pressure under which the fuel is supplied to the burner. The flame in it is more stable and does not die out due to drafts or strong gusts of wind.

From the point of view of the reliability of the boiler unit, the user may be interested in models with a steel or cast iron heat exchanger. In addition, it is possible to select samples with different configurations of control systems.

Possible problems during operation

The most common and almost the only problem with Danko gas boilers is the burner (pilot) going out. The cause is usually strong gusts of wind, icing of the chimney or its contamination with combustion products. To prevent blowing, we recommend installing a check valve in the chimney. To prevent clogged chimneys, it is important to have your chimney cleaned annually (or do an unscheduled cleaning to deal with the problem now).

A more rare problem that occurs in severe frosts (-15°C and below) is icing of the chimney. In addition to mechanical elimination, there are chimney designs that prevent icing.

Ready-made design of a side chimney that prevents icing.

There are also complaints about excessive smoke production during operation. Typically, a gas boiler smokes when there is a significant layer of soot in the chimney, formed due to untimely cleaning. Combustion products settle on the chimney especially quickly when using liquefied gas. Also, the reason may be that a cold boiler is started immediately at maximum power; we recommend increasing the temperature gradually.

If parapet models knock when heating or cooling in a certain temperature range, check the slopes, the pipes may have sagged and air has formed in the CO.

Please note that after extinguishing, unlike more expensive models with advanced automation, the burners of Danko boilers do not light up on their own and require intervention.

Device

It must be said that the design of Danko gas boilers is almost similar to units from other manufacturers. The design includes the following elements:

- smoke valve;

- blower fan;

- gas burner device;

- connecting fittings;

- automation unit for monitoring all equipment components;

- hydraulic unit;

- primary and secondary heat exchanger;

- forced coolant circulation pump;

- expansion tank.

Wall-mounted gas boiler Danko-23

All structural elements of the Danko gas boiler for heating are produced in European countries. This fact may indicate the practicality and reliability of the equipment of this brand.

Additional devices

In addition to the above structural elements, Ukrainian heaters are equipped with additional devices. These include:

- liquid temperature sensor, which reacts to boiling of the coolant in the system and corrects the operation of the boiler;

- a flame control system that shuts off the gas supply when the burner wick goes out;

- draft control system in the chimney, when air flow enters, the operation of the entire system stops;

- a draft control unit in the chimney that adjusts the burner flame level depending on the draft force of the flow;

- protective block with many functions. In the event of a certain type of threat, all boiler systems are stopped.

You can learn more about the draft sensor for a gas boiler in this article

From the above, we can conclude that all boiler blocks and systems once again prove the innovation and modernity of Ukrainian heating equipment.

How to light a Danko gas boiler

Identification of boiler control elements.

- Turn the mechanical temperature regulator counterclockwise until it stops.

- Make sure that the tap on the gas pipeline inlet is open.

- Press and hold the start button, then press and release the piezo button (several clicks may be required, repeat until the pilot burner lights up). Hold the start button for at least 30 seconds until the burner goes out when it is released. If the boiler has not been adjusted previously, it may be necessary to adjust the air supply by turning the nut on the ignition burner until the burner flame turns blue.

- Turn the thermostat knob clockwise until the main burner turns on, then set the desired power.

The startup process differs slightly for configurations with different automation; the algorithm is described in detail in the operating instructions, an electronic copy of which is attached in the description of each model on the official website.

Features of operation and setup

Annual cleaning of the chimney is recommended so that the quality of work does not decrease.

The requirements are set out in the user manual, which should be carefully studied before starting to work with the unit. During the operation of boilers, the following unforeseen situations are possible:

- The product does not turn on.

- The boiler starts to turn off randomly.

- In strong drafts, the burner may go out.

- The draft is noticeably reduced (for products with natural ventilation).

To eliminate the first two malfunctions, you should invite specialists. During operation, it is important to remember the need to periodically clean the chimney, which over time becomes clogged with combustion waste.

The need to adjust the boiler’s functionality may be required when it is necessary to increase the efficiency and stability of its operation. To do this, you will have to invite a service center specialist or representatives of the warranty workshop. Self-tuning can lead to complete failure of the equipment.

Prices: summary table

| Model | Number of circuits | power, kWt | Efficiency, % | Gas consumption, cubic meters m/hour | Cost, rub |

| 8C | single-circuit | 8 | 92 | 0,9 | 18 000 |

| 12VSR | double-circuit | 12 | 91,5 | 1 | 24 000 |

| 12.5US | single-circuit | 12,5 | 90 | 1,4 | 24 000 |

| 16HP | single-circuit | 16 | 90 | 1,9 | 35 000 |