Today there are a large number of electric tubular electric heaters for heating on the market. The models differ in appearance, power, and degree of protection of the outer shell. But the principle of their operation has not changed practically since the middle of the 20th century.

Inside a metal tube with good thermal conductivity characteristics there is a wire (nichrome), twisted in a spiral and a coolant (periclase). Current is supplied to this element and the wire heats up.

It is used as the main component in many household appliances:

- washing machine;

- Dishwasher;

- boiler;

- electric kettle and many others.

But today heating elements for heating systems have become very popular. The device is inserted into the radiator, and the base with the connection point remains outside.

This system gives the owner a number of opportunities:

- Maintaining a comfortable temperature at any time of the year. This is especially convenient in the fall before the start of the heating season or in the spring after turning off the central heating;

- Organization of autonomous heating using a ready-made central heating system;

- Use for emergency heating of liquid in case of accidents during cold periods;

- Saving money on air heating due to high efficiency.

However, heating by direct convection has also not been canceled, so the heating tube is actively used in convectors, heat curtains or guns, and so on.

What is heating element and its pros and cons

Heating elements are electrical devices that, when immersed in a container of liquid, heat it up. These include heating elements for a heating radiator and a regular water boiler. As a rule, these devices are installed in radiators either as the main source of heat in houses with an autonomous heating system, or as an additional means that increases heat transfer and automates the entire process.

Typically, a heating element for a cast iron radiator is installed if:

- A transition to autonomous heating is required.

- The centralized heating system “does not exhaust” and the room is cold, then it is used as an additional source of heat.

- Installing a heating element in a cast iron battery as an emergency heater. It is able to save the heating circuit from freezing in the event of a power outage. It is enough to turn off the heating taps and plug in the electric heater.

These devices have their advantages and disadvantages. The first include:

- Quite high operating efficiency and cost-effectiveness. This is due to the fact that the transition of electricity into thermal energy occurs with virtually no losses.

- Easy to install and can be ridden by any beginner using the instructions included with each unit.

- They serve flawlessly for many years, provided they are installed correctly.

- Heating elements for heating radiators are compact and practically invisible.

- They are safe because they are equipped with control sensors.

- The cost of the device is low, but a thermostat, which is not included in the kit, can cost a pretty penny, depending on its design.

- Electric heating elements for cast iron batteries can not only regulate the heating of the coolant, but also save energy resources.

Among the disadvantages of the device:

- High electricity consumption if the heating element in the heating radiator is used as the main and only source of heat.

- These devices should not be used in homes with unstable power supply.

If you use a heating element for a cast iron battery with a thermostat in a house where people rarely live, then the anti-freeze mode will save the heating system from bursting pipes. It is able to maintain a minimum temperature of the coolant, which does not consume much electricity, but at the same time prevents it from freezing.

What are electric heating elements?

A heating element is a tubular electric heater. It is essentially a hollow tube made of stainless or carbon steel.

Inside there is a wire spiral, which has a high resistance value. For installation, a brass nut is provided, which is screwed into the heating device.

The heating element is installed in any radiators, suitable for both old cast iron batteries and modern aluminum and bimetallic ones.

The best option is a heating element equipped with a thermostat. This device will allow you to control the temperature and protect the heating element from overheating. Considering that the device will be installed in a heating radiator, water will play the role of coolant.

Electric heating elements work quite simply. After connecting to the home network, the coil installed inside the tube begins to heat up, transferring energy to the coolant.

If the device is equipped with a thermostat, the required temperature mode is set. After the batteries reach the set temperature, the electrical circuit will open and the heating element will turn off.

When the liquid in the batteries begins to cool, the device will turn on automatically.

The heating element with a thermostat has several additional modes:

- Turbo. In this mode, the heater turns on for a short period of time, but uses maximum power. Turbo mode is used to quickly warm up the room.

- Antifreeze. This function is relevant mainly for non-residential premises. The heating element operates at minimum power, preventing the system from freezing in emergency situations.

An electric heater for a battery allows you to turn a heating device into an autonomous system with minimal cost, time and effort.

Heating element in a heating battery: how to choose

When choosing a heating element for a radiator, several characteristics are taken into account:

- power;

- compatibility with battery type;

- element length;

- type of automation (internal or external).

The price of the heating element ranges from 750 to 1500 rubles. and depends on power, manufacturer and other parameters.

Power

The power of the heating element varies from 800 to 2,000 watts. When choosing, you can be guided by the following scheme:

- 20 W/m3. This power is suitable for new buildings that have excellent thermal insulation.

- 30 W/m3. Recommended for apartments with plastic windows, walls and floors equipped with reliable thermal insulation.

- 40–50 W/m3. Heaters with this power are recommended for use in older homes.

Battery Type

Electric heaters for different radiators differ in the shape of the outer part of the body, material, thickness and diameter of the plug. The product data sheet states for which batteries the heating element is intended.

On a note. Cast iron radiator plugs usually have a 32mm thread, aluminum radiator plugs usually have a 25mm thread.

Heating tube length

The length of the heating element must be sufficient to ensure circulation of coolant in all sections of the battery and uniform heating. The optimal size corresponds to the length of the radiator minus 10 cm.

Manufacturers

Italian heating elements Thermowatt, Ukrainian Electron-T, Polish and Russian models have good reviews. Products from China are not always of high quality.

Installing a heating element: important features

The heating element is installed according to the following scheme: one of the battery plugs is unscrewed, and a heating element is installed in its place using a threaded connection. To ensure the tightness of the joint, a rubber gasket is used.

Mr. Build recommends: it is best to screw in heating elements instead of the bottom plug. There is a logical explanation for this: heated water will rise and cold water will fall, which will ensure efficient operation of the heating element.

This procedure is repeated in each room of the apartment. We remind you that installation is carried out before the start of the heating season.

It is important! Shut-off valves and a bypass must be installed near the radiator to which the electric heater is planned to be connected. If there are no valves, all the heat will go to the neighbors. In the absence of a bypass, the general building heating system will be disrupted.

A few more important points:

- Do not use excessive force during the installation process. There is no need to forcefully tighten the contact nuts and the heating element fasteners themselves. Brittle material may burst.

- It is strongly recommended that after the shut-off valve, install a safety valve or a small expansion tank with a volume equal to 10% of the battery volume. This is due to the fact that when the coolant in a closed system is heated, it expands and increases the pressure in it.

Rules of operation and maintenance

In order for the heating element installed in the heating battery to serve as long as possible, the following rules are observed:

- The heater turns on only if there is water in the battery. If liquid gets on the already heated tube of the device, a small thermal explosion may occur. As a result, not only the heating element will fail: the heating battery may be damaged.

- During operation of the device, scale will form on its surface, which must be cleaned off periodically. The recommended maintenance schedule is once every three months. If the thickness of scale on the heating tube exceeds 2 millimeters, heat transfer will decrease and the device may fail.

- To eliminate possible voltage surges, it is recommended to connect the heating element through an uninterruptible power supply or stabilizer. When installed, the heater is grounded.

- Manufacturers recommend using only distilled water as a coolant. In apartment buildings with a common riser, it is unrealistic to comply with this requirement, so it is necessary to clean the heating elements from scale more often.

Conclusion

Installing a heating element is one of the ways to ensure comfort and coziness in residential premises.

This design can be compared to an electric oil radiator, but it provides faster and more uniform heating of all rooms in the apartment.

But you need to keep in mind that with constant use of such a device, electricity bills will increase very significantly. The installation sequence of radiator heating elements is shown in the video below.

The design of the heating element and its operating principle

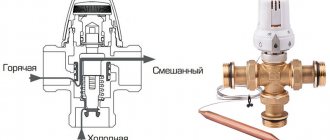

The design of the electric heating element is quite primitive. It is a metal cylinder, inside of which there is a spiral of copper or strong steel wire in a special insulator. Since the heating element for heating radiators has a thermostat, it is used not only as a heating element, but also to adjust the temperature of the coolant.

The cylinder with a spiral is protected by a housing equipped with control sensors. Their task is to ensure that the device does not overheat. The galvanization process to which it is subjected gives additional reliability to the device. Chrome and nickel plating enhance the strength of the heating element and create an additional protective barrier that protects people from contact with electricity.

In addition to heating functions and thermoregulation, modern electric heating elements for cast iron batteries are equipped with additional “responsibilities”:

- The “anti-freeze” mode is capable of maintaining a constant coolant temperature of +10°C, which is enough to prevent the water in the pipes from freezing. Having heated the liquid to the desired level, the heating element turns off and starts working again when it cools down.

- If the autonomous heating of a private house is equipped with cast iron batteries with heating elements, then the “Turbo” mode will suit perfectly. With it, the device turns on at full power, which ensures almost instantaneous heating of the system and heating of the air in the room. The subsequent operation of the heating element is to maintain the selected temperature of the coolant in the network, which ensures energy savings during heating.

Some consumers believe that the best coolant for radiators with heating elements is technical oil, since it heats up faster and cools down more slowly. This does not mean that it is not advisable to use it in a water heating system.

What are heating elements and their features

A heating element is a tubular electric heater that can be installed in any container filled with liquid. Many people are probably well aware of the heating element for an oil radiator, which effectively heats up this heating device. In fact, an electric water boiler is such a device.

Electric heating elements for radiators are special devices that can be installed in any heating radiator as a main or additional heat source. As a rule, they are mounted with thermostats that allow the heating process to be automated.

Scheme for using an electric heater as an additional heater

Advice! Heating elements can serve as an emergency source of heating in case of central heating shutdown. In such situations, you can turn off the taps and connect the heater to electricity.

The installation process of these devices is very simple - you just need to unscrew the plug and screw the heater in its place. After this, the radiator can be filled with both water and low-viscosity oil. The latter is best used for cases where the heating is turned on from time to time, for example, in a garage, so that the coolant does not freeze.

The heating element is screwed into the radiator instead of a plug

Advantages

Among the advantages of the device in question are:

- Low cost. however, the price of the heating element itself is usually added to the price of the thermostat, which is supplied separately.

- Easy installation - every home craftsman can install the heater with his own hands, spending only a few minutes of free time.

- If you have a high-quality thermostat, you can completely automate the heating process.

- Electric heaters are quite reliable, durable and absolutely safe. But for this, the connection instructions and safety regulations must be followed.

In the photo - a heating element isolated in a safe housing

Flaws

Along with the advantages, radiator heaters also have some disadvantages:

- High energy costs, especially if heaters are used as the main heater.

- Low heat transfer efficiency. The fact is that the battery heats up unevenly, as it is designed for constant circulation of coolant at high speed.

- A heating element for a radiator with a thermostat and other electronics is more expensive than an oil heater.

Thus, before installing this device, you should consider all its advantages and disadvantages. The fact is that in many cases it is more expedient to use other sources of electrical heating.

Note! Heating efficiency largely depends on the type of heating batteries themselves. For example, cast iron radiators with heating elements are less efficient than, for example, bimetallic or aluminum

Main functions and design of the heating element

The main functions of a heating element mounted in a battery: heating the coolant and, if the heating element is equipped with a thermostat, temperature control.

The heating element for radiators itself is so simple that even a schoolchild can understand its design. An insulated conductive thread is inserted into a metal tube. Most often this is a nichrome spiral. During the galvanization process, the metal tube is coated with chromium or nickel, which gives the metal special protection from the aggressive effects of water and ensures that there is no human contact with electricity. In addition, the housing of the heating element is equipped with control sensors that prevent the device from overheating.

As for the coolant heating function, there are no other options except one: the device is plugged in and the water (or other coolant) is heated. The principle is the same for all electric heating devices.

The thermostat functions are carried out by a heating element equipped with a thermostat. This allows you to set the heating element for radiators to a certain temperature. In addition, there are regulation modes that are simply necessary in certain conditions:

- “Anti-freeze” - maintains a constant coolant temperature of +10 ° C, which does not allow the heating system to freeze.

- “Turbo” is necessary for instant heating of the coolant in an autonomous heating system at maximum power. After reaching the required temperature, the mode automatically turns off and the device operates in accordance with the parameters set by the thermostat.

As for the coolant itself, there is an opinion that the most suitable for batteries equipped with heating elements is transformer oil. It heats up in a short time and gives off heat for a long time.

How to choose the right heating element for a cast iron radiator

For a heating element to truly become an effective assistant, you need to select it according to the following parameters:

- First of all, you should focus on the power of the heating device. To select the power of a heating element for a cast iron battery, you need to calculate what it should be. If we focus on SNiP indicators, then 1 kW of power will be required to heat 10 m2, but this is not the only indicator that should be taken into account.

- Of considerable importance is what metal it is made of and how the heating radiator works. There is a difference between heating elements for cast iron batteries and aluminum or bimetallic ones. For the former, heating elements of a different shape and with a larger plug diameter are produced.

When purchasing a heater, you need to clarify what type of radiators it is suitable for.

- To choose the correct heating element length, you need to focus on the number of sections in the radiator . As a rule, the optimal length of the device is 10 cm shorter than the battery. This will allow it to heat the coolant in the device evenly and quickly.

- You can install a heating element in a heating radiator with a thermostat if it will be used as an additional heat source. When its function is to heat a house or apartment, additional external electronics will be required to automate the heating process. This makes the device itself somewhat more expensive, but helps save on energy resources during its operation.

- The pressure in the central heating batteries should also be taken into account. If it tends to increase, then you should periodically bleed the air using a Mayevsky tap.

Heating elements for heating radiators: comfortable heating

What is a heating element for heating?

Electric heating elements for heating are heating elements that heat the coolant fluid circulating inside the radiator. They are installed on electric radiators made of different materials and alloys - cast iron, aluminum, etc.

Scope of application of heating elements

You can use a heating element for a heating radiator (shown in the photo) when installing autonomous heaters simultaneously with a centralized heating system in order to provide additional heating of the coolant.

Most often, the decision to install a heating element in a battery is made by property owners if the heating in an apartment or house is unstable or is often turned off. This heating device is a good alternative that prevents the building from cooling down and the batteries from defrosting.

Advantages of heating elements

Heating elements (heating elements) have many positive characteristics:

- economy and efficiency - when converting electricity into heat, there is practically no energy loss;

- simple installation - you can even install a heating element for a heating battery yourself and for this you do not need to obtain a special permit from various authorities. Each device is accompanied by detailed instructions from the manufacturer, explaining the connection procedure and operating rules;

- durability - it is achieved through chrome and nickel plating;

- compactness;

- safety;

- an electric heating element with a thermostat for capillary-type heating allows you to regulate the temperature with a high degree of accuracy;

- save energy consumption by allowing the device to operate in pulses;

- affordable price;

- availability of additional functions.

In addition to its positive qualities, a device such as a heating element for heating batteries has several disadvantages:

- high cost of electric heating of residential premises due to electricity prices;

- Not in all settlements throughout the country the electrical power from the substation allows the use of these devices.

Correct choice of heating element model

When going to purchase a heating element, the buyer needs to know a number of technical characteristics:

- required power of the device;

- length, diameter and shape of the tube;

- length of the insulating cap;

- overall length;

- connection type;

- method of fastening.

To calculate the power of a heating element intended for heating water of a certain volume, use the formula:

Solid fuel heating boilers with heating elements

Currently, boilers operating only on solid fuel are rarely used. Instead, the domestic market offers a wide selection of combined and universal heating units that operate not only on solid fuel, but also on other types of energy carriers. A wide range of electric solid fuel heating boilers is offered to consumers.

A heating element solid fuel boiler has the following advantages:

Some models have additional elements:

- A heating element for a 2 kW heating boiler, equipped with a thermostat and a temperature limiter;

- a draft regulator that allows you to automatically regulate the flow of air into the combustion chamber of the device.

In the event of a breakdown, heating elements for heating boilers can be replaced with new products.

Power calculations

To choose the optimal heating element for a cast iron battery, you will have to make some calculations.

- The power of the device is determined by the amount of heat that the room needs. So, to heat 1 m2 you will need 100 W, which means that for a room of 20 m2 you need 2000 W. Since cast iron batteries are used as heaters, the required amount of heat must be divided by the thermal power of one section of the battery, for example, 180 W. It turns out that this room will require 11 cast iron sections. The length of the heating element and its power must correspond to the size and needs of the radiator.

- Another parameter that should be calculated is the volume of coolant in the structure. This is important, since even a powerful device will not be effective if there is not enough liquid in the battery. Therefore, when purchasing a heating element, it is so important to consider what type of battery it is needed for. The volume of aluminum radiators is only 0.2 l, while in a cast iron battery it can be from 0.6 to 1.5 l, depending on the model and manufacturer.

Approximately 1 kW of heating element power per 15 liters of coolant is taken. Based on this and taking into account the number of radiator sections, it is easy to determine what power the device needs and how many of them should be in the heater.

Internal structure of electric heaters

It is convenient to consider the device using the example of a tubular model. An electric heater is a ceramic or metal tube filled with a thermal conductor with a spiral located inside. In the place where the tube is fixed to the flange there are insulating bushings that make it impossible for the conductive spiral to contact the heating element body.

Most models of heating elements use similar components, but their durability may vary depending on the build quality

The electric heater is mounted primarily with a flange connection, which allows the internal environment of the heating device to be sealed from the external space. The disadvantage of this design is the impossibility of replacing the spiral if it burns out internally.

Steps and rules for installing a heating element in a battery with your own hands

How to install a heating element in a cast iron battery will not cause problems even for a beginner. The only thing you need to do is follow the instructions and follow some safety rules:

- First of all, you need to stop the water supply to the cast iron radiator and drain it from the system.

- The lower plug is removed and the heating element is installed in the radiator instead.

- After tightening the plug, the electronics are installed and water is reintroduced into the system to check the tightness of the structure.

Basic safety requirements:

- Heating elements cannot be used if there is no high-quality ventilation in the room. Like any electrical appliances, they burn air, which needs to be taken into account, especially in small enclosed spaces.

- There should be no easily flammable elements near the device connected to the network.

- Before installing and connecting the heating element into a cast iron battery with your own hands, you need to make sure the quality of the electrical wiring and its ability to withstand additional load.

- Under no circumstances should you dry clothes or shoes on a radiator with a heating element.

Otherwise, this is an excellent way to additionally heat an apartment in conditions of unstable heat supply. If you need to heat your house with cast iron batteries with heating elements, then you need to make very accurate calculations regarding their power and quantity. Often, it is better to place the heating element directly into the boiler to increase the heat transfer of the entire heating circuit.

Modern electric heating elements are heating elements equipped with precise and sensitive electronics that help create the necessary microclimate in the room.

Today there are a large number of electric tubular electric heaters for heating on the market. The models differ in appearance, power, and degree of protection of the outer shell. But the principle of their operation has not changed practically since the middle of the 20th century.

Inside a metal tube with good thermal conductivity characteristics there is a wire (nichrome), twisted in a spiral and a coolant (periclase). Current is supplied to this element and the wire heats up.

It is used as the main component in many household appliances:

- washing machine;

- Dishwasher;

- boiler;

- electric kettle and many others.

This system gives the owner a number of opportunities:

- Maintaining a comfortable temperature at any time of the year. This is especially convenient in the fall before the start of the heating season or in the spring after turning off the central heating;

- Organization of autonomous heating using a ready-made central heating system;

- Use for emergency heating of liquid in case of accidents during cold periods;

- Saving money on air heating due to high efficiency.

However, heating by direct convection has also not been canceled, so the heating tube is actively used in convectors, heat curtains or guns, and so on.

Types of heating elements in heating systems

As a rule, heating elements for heating a house are used in systems where water or antifreeze becomes the temperature carrier. But there are also air systems with these elements. There are several types of them:

Tubular. The most common. The principle of operation is the exchange of temperatures by convection - the replacement of warm masses with cold ones. Used in electric boilers, water heaters, oil heaters and other units.

Not a single household heating device can do without this element - kettles, all kinds of steamers or washing machines. For clarity, you can see what it is.

Rib or needle heating element. The element has additional ribs along its entire length perpendicular to the axis. Such elements are used in thermal curtains.

As central heating for a residential building, it is too energy intensive. In addition, such elements are fragile compared to tubular options. If damaged, they can only be replaced.

Block and ring view. Their feature is the regulation of the power of the entire element. Designed for heavy industrial loads and inappropriate for a private facility.

You can assemble tubular heating elements yourself. The cost of such a product will be low compared to elements integrated into a factory-type system.

How to choose a heating element for installation in a homemade boiler

For independent work, it is better not to reinvent the wheel, but to buy a ready-made product right away - the price for them is unbeatable

So, what to look for when buying:

- Power. You need to immediately apply the formula - for 10 m², 1 kW of energy is required. Therefore, after making simple calculations, you need to purchase an element of such marking - 10, 20% of the total figure. You should not purchase an element larger than the calculated capacity. Firstly, it is economically unprofitable, and secondly, such power is unlikely to be needed.

- The design is not important. The main thing is that the element enters the heating tank freely, without contact with the walls.

The length is important - short heating elements will not cope well with large amounts of water. It is better if the element parameter does not reach the length of the radiator by 10 cm maximum.

Heating heating elements with a thermostat or control unit are available for sale. If the owners are satisfied with the price, then, naturally, such elements are preferable - they will optimize heating costs. You can set the specified parameters and the temperature will not have to be raised sharply during the peak of cold weather - the room will be sufficiently warmed up at low values. The manufacturer is not so important, unless the product came to us from China. As a rule, individual elements are produced by Türkiye, Poland, and Ukraine. European countries do not produce heating elements regardless of boilers, so if sellers try to sell a German or Italian heating element to a buyer, this is simply a deception.

However, our manufacturers make good options, the service life of which is estimated at tens of years. When producing a homemade installation, you should contact a domestic manufacturer

In general, going to the store unprepared is not a good idea. You should hire a person who understands the essence of the problem as an assistant. The same goes for the work of constructing a makeshift boiler as a whole.

Types of heating elements with thermostat

You need to understand that when current is applied to the coil inside the tube, it immediately begins to heat up and cannot turn off on its own. The thermostat monitors the media parameters, turning off the power when the required temperature is reached.

This saves electricity costs and extends the life of the heating element. In this case, there is no connection between the type of heating element and the manufacturer of the thermostat; these two components are packaged together based on economic feasibility.

Three types of heating elements are used for heating.

Tubular electric heater

The most common type, which is found almost everywhere where it is necessary to heat a liquid or the surrounding space.

Peculiarities

The outer tube can be coated with a special composition to resist corrosion and have a bizarre shape. It is possible to select a heating element to suit any request.

Specifications:

- tube diameter from 6 to 20 millimeters;

- length ranges from 0.2 meters to 6;

- metal workmanship:

- steel;

- stainless steel;

- titanium;

- almost any configuration, power and performance, selected by the buyer individually.

- high efficiency (about 98%);

- use without additional projects and permits;

- affordable price.

Advantages and disadvantages

The advantages include:

There was also some negativity:

- high cost of heating when using a heating element as the main heater;

- relatively short lifespan;

- the formation of an electromagnetic field that negatively affects human health.

Finned heating element electric heaters

Another type that is used to heat air or gas.

Peculiarities

Metal ribs are attached to a smooth tube, which are located perpendicular to the surface of the heating element. The easiest way to make such a design feature is from a metal strip, which is attached to the base with special nuts.

A heating tube of this shape allows you to remove more heat from the surface; it is often used with a fan that forces air passing through the heating elements.

Advantages and disadvantages

The pros and cons of the device are the same as in the previous version, except that the price is slightly higher. But the efficiency of fins in heating air pays for the costs.

How not to make a mistake in choosing

Radiators for heating elements are quite simple to choose, since they do not require a special variety of designs and technical characteristics. Please consider the following points before purchasing.

Electric heating element power calculation

In order to correctly determine the required power of the device, it is advisable to know the thermal standards in force in the given area. As a last resort, you can use the average indicator, which can be used in central Russia and make some adjustments if necessary.

Based on this, for 10 sq. meters of heated area, provided that the heating element will be used as the main heating, 1 kW of its power is required.

If heating elements for radiators are chosen as the main heating for the home, it is highly advisable to purchase models with a thermostat. In this way, it will be possible to regulate the power of the device and thereby reduce energy costs

If the device is used as additional heating, the required power will be 3-4 times lower. In addition, when choosing a device, you should take into account the specifics of the radiator heating element.

Due to its design features, it will be able to operate uninterruptedly only at 75% of the heat transfer from the radiator. With higher power, the device will overheat and it will constantly turn off.

Based on this, the power of the device is calculated. The exact heat transfer values of a particular radiator can be found in its technical documentation. However, on average, one section of an aluminum battery has a heat output of 180 W, and a cast iron battery has a heat output of 140 W.

Let us calculate, as an example, which heating element is suitable for a 10-section radiator. We multiply the data by 10 and we get that for an aluminum battery it is worth taking a heating element with a power of up to 1.35 kW, for a cast iron battery - up to 1 kW.

Design features of the device

For each radiator, you should select a heating element that is suitable for it in size and thread direction. The equipment has different shaft lengths, which may affect its performance.

If the length of the heating element is insufficient, the equipment is not able to provide a sufficiently high circulation rate of the coolant, as a result of which the heating of the radiator will be uneven and insufficient.

The length of the device is perhaps one of its most important characteristics, which directly affects its efficiency. Before purchasing, you should measure the radiator and calculate the required length of the built-in heating element

The optimal option is when the heating element rod does not reach the inner wall of the opposite edge of the radiator by 60-100 mm

It is also important to choose the right body shape and diameter of the device.

The material of the plug may vary between models. To make the right choice, you should study the manufacturer’s recommendations, where he describes the types of heating devices suitable for using a particular heating element.

Availability of automatic control

Devices are available for sale with or without built-in automatic control. The first variation is as convenient as possible and does not require the purchase of additional equipment. In this case, a thermostat with a sensor that measures the temperature of the coolant is built into the lower part of the heating element housing.

If there is no built-in automation, the electrical appliance does not have a thermostat. In this case, it is advisable to connect using a detector that measures the air temperature in the room.

It must be admitted that this equipment is not so popular and in demand for large European companies to start producing it.

In stores you can find radiator heating elements made by Turkish, Polish and Ukrainian brands. In terms of quality and functionality, they are approximately similar.

It is difficult to say which company's products should be preferred. But you need to be wary of Chinese heating elements, since you can often get a low-quality product.

Rules for choosing a heating element with a thermostat

The diversity on the market makes it difficult for the buyer to choose, so you need to decide in advance on the characteristics, appearance, and connection method.

A few features of the devices that you should pay attention to when purchasing:

- The diameter of a specialized hole in the radiator. Not every model will fit the heating device. This parameter needs to be known in advance;

- Thermostat quality. Ideally, a small control device should have a turbo mode for emergency heating and an economy mode, which prevents the system from defrosting. But a simple sensor with a temperature scale will do the job just fine;

- Heating element power. It is a generally accepted fact that 1 kilowatt is required per 10 square meters of room. If oil or antifreeze is used as a coolant, then a coefficient of 1.5 is applied, that is, for the same size of heated space, the heating element must have a power of at least 1.5 kilowatts;

- Metal tube. Titanium is an ideal and durable option, but extremely expensive. Regular or stainless steel is most often used. It’s not worth purchasing a Chinese heating element, because the thickness of the metal will cause it to burn out in a short time;

- Type. Based on the required power and heating method, you need to decide on the variety. The features of each are described above;

- Additional options. Shutting off when overheating will avoid many troubles. After all, even in a radiator filled with liquid, there are air pockets that cause the tube to heat up much faster.

Block heaters

Block options are several tubular-type heaters that are combined into one block and usually have one fastening element

When choosing a particular block heater, you should pay attention to the power ratings and the ability of the boiler equipment and pump to provide effective heat removal

It is recommended to give preference to these types if:

- you need to use a device with high power and heating rate of the environment;

- there is no way to quickly transfer heat energy from the working coil to the medium due to the small area of the heating element shell on the outside.

The advantage of the block solution is the ability to reduce the load on each tube, which simultaneously increases the uniformity of heating of the medium and causes little wear on the heating elements located inside these tubes.

View products

As for power, models can provide from 5 to 10 kilowatts. So, during the installation of equipment with block heating elements, you will have to take care of laying an additional electrical cable.

Installation features

Installation is not difficult at all. The heating element is mounted in heating radiators as follows:

- the equipment is turned on outside the radiator for a short time to check its functionality;

- water is drained from the system;

- a hole opens for the heating element, it is placed there and secured;

- the system is filled with water, after which voltage is applied to the tubular heater.

It is worth paying attention to the following nuances:

- If the product documents indicate the need for grounding, then this is necessary for long-term operation. Otherwise, the service life will be significantly shorter;

- You cannot wet a heated heating element with water; an explosion and destruction of the outer shell are practically guaranteed. Therefore, the water level must be monitored before power is supplied.

The air convector and other devices are simply connected to a grounded network. The only limitation is the wire of the required cross-section.

A hole for the heating element opens and it is placed there and secured.

Operating rules

A few simple rules for operation and maintenance will extend the life of the heating element and make its operation more efficient. Here they are:

- If water is used as a coolant, it must be distilled. This will protect you from scale;

- Frequent switching on and off leads to a decrease in service life, so the thermostat must be adjusted accordingly. The minimum difference in water temperature should be at least 5 degrees;

- It is mandatory to use an emergency power cut-off system. This way you can protect other household appliances in the event of a serious breakdown in the heating element;

- It is necessary to deal with voltage surges using a stabilizer or an uninterruptible power supply;

- The appearance of static electricity on the surface of the radiator indicates depressurization of the tube. The heating element must be turned off and removed, otherwise a short circuit is possible, and this means a higher level of problems or material costs.

Failed heating element

Types of heating elements

Can be domestic or industrial. The latter have higher technical characteristics. Manufacturers offer various types of products.

Each one has a built-in protective casing to prevent liquid from entering the heated heating element and causing electric shock to people.

Tubular type heaters

Tubular heaters are the most common type. During their operation, they convert electrical energy into thermal energy, heating the coolant inside the batteries due to thermal conductivity, convection and radiation. Tubular type heaters:

- have a length of 20 – 600 cm;

- made from a tube with a diameter of 6 – 18.5 mm;

- can have a variety of configurations;

- can be made of carbon or stainless steel or titanium. The last type is the most expensive;

- Available with different performance and power.

Tubular finned

Compared to conventional tubular ones, they have ribs perpendicular to the axis of the product. Metal tape is used to make them. The tube is made of carbon or stainless steel.

Tubular products are ideal for heating gas or air used as a coolant in a heating system. They are installed in thermal curtains and convectors.

Block electric heaters

Block products are used when there are increased requirements for the power of the product. The design features of the electric heater block can significantly increase the power of the device. This is especially true for batteries in which bulk material acts as a coolant.

It can be connected to the heating device via a flange or threaded connection. The first ones are the most popular among consumers.

Cartridge type models

Electric heating element with a characteristic cylindrical shape. Made from stainless steel. Has a perfectly flat surface. The cartridge type refers to products for industrial use.

Ring heaters

Heating elements for industrial use. They have a characteristic shape with a minimum twist diameter of 8 mm.

The maximum is limited solely by the characteristics of the equipment for which it is manufactured.

Heaters with temperature controller

Heating elements with a thermostat have become widespread. They are intended for heating systems in which liquid acts as a coolant. Can be installed on various equipment. Devices with a thermostat are capable of heating the coolant to +80 °C. With their help, if you have a thermostat, it is easy to maintain the room temperature within the specified limits.

The thermostat included in the product will disconnect the equipment from the network as soon as the temperature of the coolant exceeds the set value. When the coolant cools below the set value, the heating element with thermostat will reconnect to the network. This allows you to optimize energy consumption.

Models with a thermostat are made of nickel-chromium wire placed inside a tube filled with a special compressed powder. The powder is magnesium oxide, which is an excellent dielectric with high thermal conductivity.

average cost

Offers taken from online stores in Moscow:

- TEN1500W made in Slovakia. Includes thermostat, branded fittings, power 1.5 kilowatts. Cost 1930 rubles;

- Heating element with thermostat, made in Russia:

- power 4 kW – 1500 rubles;

- power 3 kW – 1350 rubles;

- power 1.5 kW – 990 rubles;

Devices made in China can be found for 500–600 rubles, but their quality is highly questionable. And a heating element with a price of 1000 rubles (or so) can be of high quality, provided it is produced in the Russian Federation.

TEN1500W made in Slovakia

Blitz tips

Here are a few recommendations from professionals that will help extend the life of your heating element or avoid mistakes when installing it. So:

- A good place to install a heating element in a radiator is the bottom. This way you can avoid possible air pockets, and therefore overheating;

- When purchasing a heating element, pay attention to the manufacturer’s recommendations for additional sealing;

- When securing the wires to the terminals, you must not apply too much force , otherwise the nut will burst or the tube’s tightness will be compromised;

- When using tap water as a coolant, the heating tube must be removed every 3 months and the deposits must be cleaned off non-mechanically.

A heating element is an electric liquid heater in the form of a metal tube, inside of which there is a spiral. There are many designs and varieties. Heaters are manufactured for both large and small industries.

These heaters are widely installed, for example, in electric boilers and electric boilers, and therefore are also produced by well-known manufacturers.

But in any market you can find heating elements intended for installation in heating radiators. These devices are often manufactured in Poland, Ukraine, and China. They can be equipped with built-in temperature sensors, i.e. work in semi-automatic mode, monitoring the degree of heating.

Based on such electric heaters, you can easily create a heating device with your own hands. This is what home craftsmen use, constructing the simplest heating and, as they think, “saving” a fair amount of money.

But is it really profitable to use heating elements? Where and in what situations are these electric water heaters usually used? How to install and use heating elements...

How big is the benefit from heating elements?

If you have an old battery, then why not use a heating element to turn it into a heating system for a small utility room - a chicken coop, a workshop, a garage...

There are even myths that heating with heaters is beneficial. But “dreams are shattered by harsh reality” - heating with electricity is the most expensive. Since the most expensive energy carrier is used.

Product types

Electric heating elements differ in:

- type of work environment. There are models for heating gas (air) and liquid;

- type of working surface. They can be tape, rod, ribbed, tubular;

- method of use. There are products designed for installation in radiators, boilers, boilers and other equipment;

- technical specifications. The power per unit surface is taken into account;

- functionality. There are models with a thermostat and automatic shutdown sensors when overheating.