Even though we live in the 21st century, periodic water outages still haunt us. These days, an electric water heater or boiler is becoming an indispensable assistant. This product is also very popular among summer residents if there is no centralized hot water supply in the house. The undoubted leaders in the Russian water heater market are 2 companies Thermex and Ariston.

Any water heater has several consumables, the periodic need for replacement of which is prescribed by the manufacturer. This is a heating element and an anode.

Description and classification of tubular electric heaters

The heating element externally is a tube that contains a resistive heating element. It is through this element that electricity passes. The heater body is made of metals capable of transmitting heat and electricity well. Commonly used copper, stainless and carbon metals.

Two main types of heating elements are used to heat liquids:

- Open/wet heaters. Installed directly into the liquid and in contact with it. As an example, consider the spiral in an electric kettle.

- Closed (“dry”) are placed in a special protective flask, which prevents direct contact of the heating device with the heating medium.

When choosing a heater, it is important to clearly understand which type is best suited to the existing operating conditions.

Difficult choice

When purchasing a water heater, users naturally face the question of what type of heating element will be best for the boiler. To do this, you must, at a minimum, become familiar with their performance characteristics.

The standard installation of all heaters in products is of the flange type. In this way, full contact with the heated liquid is achieved, but during operation deposits and corrosion products appear on the body, which significantly slow down the heat transfer effect.

The heating process increases over time, which leads to increased energy consumption. Designers from different manufacturers use various modifications that slow down the formation of deposits and scale, but wet heating elements tend to quickly fail, and their maintenance is quite complicated.

Dry heaters have a longer service life due to the fact that their body almost never comes into contact with the heated water. The inside of the tank, as well as the heater mounting flanges, are coated with special enamels based on titanium or glass porcelain - such corrosion protection prevents the occurrence of deposits and scale.

During long-term operation, wet-type thermal heaters become overgrown with scale, which can lead to breakdown and the user will receive an electric shock through the body of the product. In the dry version, this negative possibility is eliminated, because a ceramic bulb, which is a dielectric, is installed between the liquid and the heater body. In addition, this option completely eliminates overheating of the heater housing, service maintenance is reduced to a minimum, but periodic replacement is not excluded, although many times less often.

Many manufacturers have launched the production of large-capacity water heaters using two types of heating elements at once, which contributes to high reliability and increased service life.

Statistics confirm that closed heating elements last three times longer than their open counterparts - wet ones last no more than 5 years, and dry ones no less than 15 years. The cost of open heaters is much lower, they are more practical for repairs, but if you do not plan to maintain your water heater, then it is better to opt for the dry option.

"Wet" heating element

The open type heater has direct contact with water. Thin nichrome wire wound in a spiral type is an excellent conductor for electric current. First of all, it transfers heat to quartz, which fills the voids inside the case, and only then the heat passes to the case and warms up the environment. Such heating elements are classified according to the following technical principles:

- The shape of the heater can be straight or concave. Determined by the type of storage device in the boiler.

- By type of fastenings. There are heaters mounted on a flange or nut. The first ones are produced by casting or stamping.

- The presence of an anode socket or its absence.

In the production of open-type tubular heaters, stainless steel or copper alloys are used. These materials are less susceptible to oxidative processes. The advantages of such a heating element include ease of installation and replacement. And also the market price. Only due to continuous exposure to water, the heater quickly becomes covered with salt deposits and fails. Plus, an open heating element consumes a lot of electricity.

The best submersible heating elements for water heaters

Such equipment is installed directly into a container of water, and is therefore considered submersible.

The wet type of operation is optimal for accelerated heat transfer from the heating element to the liquid, but is more susceptible to the negative influence of suspensions and is considered more dangerous. When choosing, you should pay attention to compatibility with boiler models and tank size.

Thermex 2.0 kW RGS YH 1.2 mpA -TW - also suitable for other models

This is the best heating element for water heaters, since it is suitable for various devices, not only the Termex brand. Compatibility with the main brand is represented by more than 20 models. But the heating element is also designed for all round boilers with a volume of 30 liters or more produced by Ariston, Timberk, Garanterm.

The external design is equipped with everything necessary for full operation: two empty pipes for installing temperature sensors, terminals for connecting contacts, two brackets for passing current and heating.

Recommendations: 11 best instantaneous electric water heaters

12 best water heaters

14 best storage electric water heaters

Pros:

- the element is capable of operating in two modes with a power of 700 and 1300 W, as well as in a maximum mode of 2000 W;

- the 64 mm flange is stamped and matches the mounting hole of most boiler models;

- installation of the anode is simple due to the threaded fastening;

- tubes made of pure copper, which protects against corrosion;

- Convenient wiring connection via plug-in terminals;

- original Italian production.

Minuses:

- cost from 1350 rubles;

- 6 month warranty.

Heating element Electrolux EWH Centurio Digital, Royal 2.0 kW - with choice of power sharing

This is the best heating element for a water heater from a Swedish manufacturer, which you can buy for a boiler and pre-select heating modes according to the user’s needs. The model has a maximum rating of 2000 W, and there are operating modes to choose from: 1300+700, 1500+500 or 1000+1000 W.

To heat water, two stainless steel tubes are used, differing in length. They are coated with an anti-corrosion compound. The connection terminals are bent 90 degrees, making it easier to connect the contacts.

Pros:

- standard mount with 64 mm flange;

- anode socket with already threaded 6 mm;

- the screw method of fastening wires does not require a soldering iron;

- two hollow tubes for installing the operating and emergency thermostat;

- light weight 334 g;

- The heating element can withstand current surges up to 230 V;

- copper plating;

- the short tube length of 34 cm allows it to be installed in most boilers.

Minuses:

- cost from 1450 rubles;

- due to stainless steel pipes, they are more suitable for houses with water intake from a well rather than tap water;

- Anode is not included.

READ ALSO

12 best geysers

TEN ARISTON 2000W RCF 48mm - short but powerful

This is the best heating element for a water heater from the Italian company Ariston, which is suitable for all models of the RCF series. Its length is 280 mm, which allows installation even in small boilers.

The short length is ensured by the curved shape of the heating element. The longest part is the thermostat tube, which remains straight. All immersion parts are made of copper, which ensures long-term resistance to wet environments.

READ ALSO

14 best indirect heating boilers

Pros:

- Fits all models with 48mm flange hole;

- Italian production;

- 2000 W power ensures fast heating;

- convenient connection of terminals due to the “female” design;

- pressure flange made of brass;

- outside there is a plastic lining, an insulating surface and contacts;

- prepared hole for the anode;

- tube for the sensor.

Minuses:

- cost from 1250 rubles;

- You can install only one thermostat (without an emergency one);

- Anode is not included.

"Dry" heating element

A closed heating element is an insulated heating element and is located in a closed ceramic flask. The quality of the flask directly affects the strength of the entire heater structure and its service life. Heater manufacturers use magnesium silicate or steatite for the protective shell. The heating device itself is made of stainless metal. The water is heated due to the thermal conductivity of the protective flask. The production technology ensures safe operation due to the absence of the risk of short circuits. In addition, a dry heating element lasts longer compared to a wet heater and is more economical to operate. The only disadvantage is that each heater of this type is manufactured for specific models of water heaters and cannot be used for other boilers.

Types of heating elements for heaters, taking into account the spiral material

Most manufacturers of heating elements use fechral or nichrome to make coils. You can rarely find parts from Eurofechral.

Nichrome spirals remain plastic after heating and cooling cycles. Also they:

- have the highest possible resistivity;

- do not heat up during heating;

- withstands long-term use without deformation;

- do not burn oxygen during operation.

Heating elements with nichrome spirals can be removed, rearranged, repaired, and their sizes adjusted. They are used both in domestic and industrial heaters.

Fechral spirals can withstand high temperatures while simultaneously possessing significant resistivity. They are not destroyed under the influence of aggressive environments. Scale does not form on them. At the same time, they have good resistance to external mechanical influences and bending strength. They are mainly used in electric furnaces and heaters.

Dry ceramic heating element

For boilers and water heaters, you can also use dry ceramic heating elements in a stainless steel flask. Soapstone ceramic heaters are more expensive than metal tube heaters, but they last much longer. The Polimernagrev company produces dry ceramic heating elements with diameters of 42 and 34 mm. The length of the heaters, type of connection, flask and other parameters are made to order with individual requirements. You can order the production of even one heater from us, and when ordering several heating elements, a discount is provided. Please check with our managers by phone or email for the cost and production time.

What kind of heaters are produced?

Different models of water heaters differ in heating devices, so you need to know their features in order to choose an identical heating element for your boiler.

Ariston

The famous concern from sunny Italy prefers heaters made of stainless steel with a chromium-nickel composition, but with a copper shell. The flange is made of brass - this helps to increase the thermal power of at least 1.5 kW. Heating elements of this design are used in all water heaters, both small-capacity types and volumes designed for hundreds of liters. The cost of a new similar element is in the range of 1.5-2.0 thousand rubles.

Thermex

Another Italian company supplies its products with two types of heaters at once, which significantly reduces the time for heating water - one with a power of 1 kW, and the other with a power of 1.5 kW. They work together or separately, which allows the user to adjust the heating process at their discretion. The body is made of an alloy for which there is a registered patent; the composition is kept secret. A big plus is that instead of them you can install heating elements from other manufacturers, for example, Atlantic or Garanterm.

Combustion

The Slovenian company uses tubular-type heaters, but covered with a glass-like glaze or glass porcelain protection, similar to the enamel that covers the inside of the container. In this way, developers successfully combat the appearance of scale and limescale, which leads to frequent breakdowns of this part. The water heats up to an optimal temperature of 900C, so when replacing or installing a heater from another manufacturer, the user must reduce it to 60 degrees so that the heater does not burn out.

How to choose?

The operating time of the heater depends on many factors: operating conditions, power surges, etc. An open heating element operates on average for about 5 years, and the operating life of a wet heater reaches 10-15 years. When choosing a heating device, it is important to take into account the operating mode, frequency of technical work, volume of heated liquid, heating time, etc. etc. You can always get information on questions of interest from Polymernagrev specialists using the contacts on the website. We will carry out all the necessary calculations specifically for your water heater. You can also compare several types of heating elements and choose the best option for yourself.

Problems that occur

Here is a short list of common malfunctions in the operation of heating elements.

- When cold water runs out of the tap, this is a signal that there has been a violation in the connection between the heating element and the thermostat.

- If the product turns on and then turns off, this is the first signal that a rather thick scale or layer of limescale has formed on the heater.

- When, during self-installation, the user made various mistakes due to inexperience, a very impressive air cushion may appear in the container, which prevents the heating element from heating the water.

It is much easier to prevent any malfunction than to fix it later, with some effort and financial investment.

Design Features

The standard design of a wet heater consists of the following elements:

- hollow copper or stainless steel tubes bent in different ways;

- inside there is a spiral of nichrome thread;

- The insulator is a heat-conducting substance - quartz sand or magnesium oxide.

A dry or closed heating element for a boiler is distinguished by the presence of an insulating flask made of high-strength ceramic. Sometimes its body is made of magnesium silicate or inorganic steatite, but not of metal. Heating occurs through this protective flask, and the tubular element itself does not come into contact with the aqueous environment, and therefore lasts a long time.

If we are discussing which types of heating elements are better, then we should immediately note that there are very significant differences in power and configuration - for wet elements there are differences in the fastening used, bending shapes and materials for making the housing. The type of tank used in the boiler determines the shape of the heater - according to this characteristic, the electric heater can be made straight or bent in different directions. In the main body, wet heating elements are made of copper and stainless steel. A dry heating element for installation in a boiler is made in the form of a straight rod of different lengths and diameters - this depends on the volume of the tank, the body is made of stainless steel, and the soapstone coating is made specifically for each model.

Basic information about the procedure for replacing heating elements

Any manipulations with the water heating device are carried out only when it is completely disconnected from the power source. Before replacing, be sure to drain the water from the tank. The water heater itself is removed from the mounting bracket on the wall and placed on a table or floor to make it convenient to work.

The main lower bar of the boiler is unscrewed to gain access to the heating element. In order not to make a mistake when installing a new part, it is better to take a couple of photographs of how the old one was located.

Afterwards, you need to disconnect the wires going to the heating element and remove it from the tank.

Advice! It is not always necessary to change a part; sometimes to restore its properties it is enough to simply clean off the scale.

The procedure for replacing the heating element in this short video course:

Why is it important to monitor the condition of the heating element?

So, the heating element is something without which your water heater will not be able to do its job. Failure of this part threatens not only with unnecessary expenses for electricity, but also with an immediate danger to life, since the element comes into contact with water. It is necessary to periodically analyze the operation of the device and check the condition of the heating element. The resulting scale is removed, and if it is not present, but the device operates intermittently, then the part should be replaced with one that is suitable for the design.

Which heating elements do you consider the most effective? If you can recommend any specific models, please write about it in the comments!

Replacement algorithm

Replacing a heating element in a water heater is a very labor-intensive operation and is carried out strictly according to certain regulations:

- disconnect the product from the electrical network;

- drain the water completely;

- remove the water heater from its mounts and turn it over for ease of carrying out all work;

- Unscrew the fastening of the bottom panel, photograph the location and order of wiring;

- disconnect the wires from the heating element and remove it from the tank body;

- clean the plaque and scale; if no damage to the housing is found, then install the heating element in place;

- in case of replacement, install a new heating element and reassemble in the reverse order.

Especially for inexperienced users, to help them carry out this operation correctly, there is a video where an experienced technician replaces the heating element in a boiler:

Tubular heating elements for boilers

The tubular electric heater - heating element was invented in the middle of the 19th century; over the 158 years of its existence, it has become an indispensable element of many household appliances associated with active heating of water. The heating element for a water heater is the main part - without it, normal operation of washing machines and dishwashers is impossible, not a single electric boiler will be able to heat water in the absence of this component.

Heating elements for electric heating boilers

Previously, I wrote a separate article on electric boilers, which I also recommend reading.

Well, okay, let's get down to business. Blocks of heating elements are used as heating elements for electric boilers.

They consist of several heaters, which are combined together with a nut.

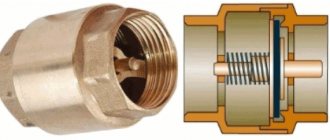

To make it clearer, look at the picture below:

Heating element block

The nut is available in the following diameters: 1.25 inches, 2 inches and 2.5 inches.

Such a block is sealed using an annular rubber seal (if it is provided structurally) or by winding with thread or FUM tape.

As for the tubes, they can be made of carbon or stainless steel.

Stainless steel is more expensive, but lasts much longer than black steel.

With powers up to 9 kW, units with a supply voltage of 220 V can be installed inside the boilers.

With higher power, units for a three-phase voltage of 380 V are installed in the boilers.

Purpose and type

For any water heating product, heating elements are the main part. They operate from the electrical network, so designers use them when developing various electric heating devices, from a regular kettle to large-capacity automated boilers.

The heating element for a water heater is structurally a hermetically sealed copper tube with a nichrome spiral inside, which is usually located in the lower part of the product or, in exceptional cases, on the side. The lower location is more acceptable because it ensures uniform heating of the entire volume of water.

Depending on the design, heaters are divided into “dry” and “wet”. The first are so called because they do not have contact with water - their body is hidden by a hermetic flask. Water heaters with dry heating elements are used for modern models. Manufacturers consider this design to be more durable, since the body of the heating element is not constantly exposed to water - the absence of lime deposits and scale significantly extends the life of the heating element. They will not burn out if the user accidentally turns on the boiler without water.

However, the most common model is considered to be wet or submerged heating elements. Some users believe that this is already an outdated model and is completely in vain - they continue to be used everywhere in various water heaters. The main disadvantage of such a heater is considered to be the tendency to frequent breakdowns due to scale and deposits, but compared to their dry counterpart, they are easier to find on sale, easier to replace and, naturally, they are cheaper.