Home page » Articles about boiler equipment. Reviews. Comparisons. Ratings.

Heating

Editor Kotlotorg 05/18/2020

227 Views

SaveSavedDeleted 0

In our country, heating of suburban housing is given special importance, and during construction it is very important to think through the heating system of the house. As a rule, in suburban settlements there is no centralized heating, as in the city, so each building must have its own heat source. Most often, a gas boiler is installed in a house, but not all regions are gasified; moreover, even in a gasified region there may be places where it is very difficult to supply gas. Therefore, solid fuel boilers are quite popular among country residents, which, as their name suggests, operate on different types of solid fuel - coal, wood or pellets. The latter deserve more detailed consideration than firewood or coal, because they have many varieties and are quite available in almost every region.

What are pellets

So, pellets are special fuel granules, which are made mainly from industrial and agricultural waste, are of organic origin, and when burned in stoves do not emit as much smoke as coal and even firewood. In addition, they are cheaper than these two types of fuel, however, different types of pellets also have different sizes, so one or another size is not suitable for every type of boiler. There are stoves in which large pellets can be burned, and there are those that can only work effectively with small ones, and if you purchase this fuel not according to the instructions of the boiler manufacturer, then not only its efficiency will decrease, but also the service life of the equipment.

The most common type of pellets is 5-7 mm in diameter and about 2 centimeters long. Large pellets can reach 10 mm in length, and the smallest ones have a diameter of 3 mm. However, pellets that are too small are used more in industrial stoves; they are not suitable for domestic boilers.

Pellets are made mainly from wood waste - shavings, sawdust, small chips, but pellets from straw, plant husks, peat and even chicken droppings are quite common. The heat transfer parameter for different types of pellets is different, but in any case it is very high, the ash content is relatively low, and it is easy to work with them - they do not generate dust like coal, and they are easy to load into the firebox, unlike the same firewood.

About biofuel production

It can be roughly divided into seven stages. Let's look at the example of wood pellets.

Coarse crushing

Raw materials are divided into two groups - pure dense wood and unpeeled wood. (This will allow us to further classify the product according to the quality of raw materials).

The raw material enters the crushing machine and is crushed. As a result, the material that comes out is reminiscent of large sawdust, whose size is ≈ 25 by 25 mm. This fraction allows them to be effectively dried and subsequently crushed to smaller sizes;

Drying crushed material

For the further process, the coarsely chalked granules must be dried. This will reduce the humidity level to the specified value. On average, the figure should be ≈ 10%.

Drying technologies can be different (belt, drum, etc.), but in any case, this is the most energy-intensive process, since it is necessary to ensure an ambient air temperature of ≈ 400°. This stage is important because if you make pellets from overdried sawdust, you will not get durable granules;

Fine crushing

The raw material from which the granules will be produced should not be more than 4 mm. For this purpose, special crushers (such as hammer mills) are used to grind the material to the desired fraction.

The weight of a standard product after fine crushing is ≈ 150 kg per 1 m³.

Humidity regulation

Sometimes material that has passed the drying stage loses moisture excessively (i.e. less than 8%). This does not allow the pressing stage to be carried out efficiently (dried granules become brittle and destroyed, in addition, their calorific value decreases).

To increase humidity, different methods are used - short-term immersion in a container of water (usually for soft wood) or steam saturation (for old or caked wood).

Pressing

The material, prepared in size and moisture content, is passed through a press (granulator), in which there are many cylindrical depressions (matrices). The compressed material noticeably decreases in volume and at the same time its temperature increases.

As the temperature rises, the crushed mass releases a substance called lignin. It is a natural adhesive ingredient. The granules become strong due to the polymerization of lignin.

You can change the geometric shape of the pellets using dies of the required diameter and an automatic knife that cuts the pellets to the required length.

Cooling

With press pressure and friction of material particles, the temperature of the extruded granules increases to 90°. Therefore, they need to be cooled. This does not require special equipment; the granules cool naturally. After which, they gain the appropriate hardness.

Packaging of finished products

The customer can receive the goods in packaged form or in bulk (shipment from bins). In order to eliminate the risk of quality degradation from environmental influences, pellets are packaged in waterproof bags. Large bags, so-called big bags, holding from 500 to 1000 kg or small consumer packaging of 15 - 25 kg.

That's probably the whole process. Let me remind you once again that we looked at the production of wood pellets. Production of other materials may vary.

How to store this fuel? Recommended in dry, ventilated or ventilated areas. Optimal placement is on wooden boards (or pallets). In a word - not damp.

Wood pellets.

This type of pellet is the most common; pellets are made from small fractions of wood – sawdust, shavings, chips, bark – pressed under high pressure. There are several types of such pellets by color - from white, yellow and light orange, to brown and gray. The color depends on the amount of bark in the granules, which somewhat reduces the quality of the fuel, although not much. Basically, dark pellets have an increased ash content and a slightly reduced efficiency, that is, heat transfer, but this is not of fundamental importance, especially considering that their cost is somewhat lower than that of white pellets.

Area of use

Pellet boilers have high technical properties. This explains their widespread use in various fields. Today, experts distinguish between two main areas of application for such heaters:

- Industrial enterprises, restaurants, shops and other institutions and buildings that require heating and hot water supply.

- Such boilers are very popular among owners of country houses. With their help, you can create a productive heating system, the maintenance of which does not require large costs.

Before installing a pellet boiler, you need to familiarize yourself with the different types of boilers and choose the best option for yourself.

Straw pellets.

Straw is practically a waste material; it is not reused in any way, so pellets made from it have a noticeably lower price than wood pellets. They are common in the southern, agricultural regions of our country, where there is many times more straw than wood waste. Of course, the heat transfer properties of straw are inferior to wood fuel, however, given that straw pellets are much cheaper, and also that there is little wood in the regions, this is the most suitable material of this kind for conditions characterized by a warm climate.

Introduction

Pellets are solid wood pellets made by pressing waste from various industries. Heating with pellets is much more economical than many other types of fuel, since they provide high heat transfer and the price does not tend to increase. Pellets are environmentally friendly; they do not contain a large amount of chemical additives. Often the consumer asks himself the question, which pellets are better?

It is not necessary to burn pellets in specialized boilers. They will burn in the stove, in the fireplace, and in the camp fire. But it should be taken into account that for proper combustion a constant flow of air is required, which is maintained automatically in pellet boilers.

This is due to the combustion process of wood pellets, as a result of which they release pyrolysis gas. At the proper level of boost, it does not go into the chimney, but burns, releasing additional heat and increasing combustion efficiency.

If you want to achieve the required efficiency, then you cannot do without purchasing automatic heating equipment. However, with the low cost of fuel, the boiler will cost much more than its conventional counterparts, and the use of low-quality pellets can lead to its failure. So which pellets should you buy?

Sunflower husk pellets.

Sunflower is also a very common agricultural crop in the southern treeless regions of the country. The heat transfer of pellets from the husk of this plant (husk) is very high, literally at the level of white wood pellets. However, they have a fairly high ash content due to the increased oiliness of the material, so a boiler fired with sunflower husk pellets must be cleaned very often. However, the very low cost of this fuel makes it quite popular. The same can be said about fuel pellets made from the husks of other agricultural plants, for example, buckwheat or corn husks. Buckwheat and corn pellets have the highest thermal output of all pellets made from vegetable husks.

Mistakes when using pellet stoves

A pellet boiler can be expensive and of high quality, but if the choice of the device was wrong, disappointment is inevitable. The main mistake lies in the general incompatibility of the boiler with the goals of consumers. It is necessary to clearly understand your needs and how much the oven can satisfy them. First of all, equipment must be assessed in terms of its type and selection criteria.

A common mistake is incorrect calculation of boiler power and room heat loss. The result is too low or too high a temperature. It is better to spend more time, but make the right calculations. It’s even better to entrust this to a specialist.

Poor furnace performance is another annoying problem. It is usually connected (if we are not talking about low-quality equipment) with the typical realities for Russia - mentioned by the poor quality of electrical networks and fuel.

Let's briefly list three more possible troubles:

- chimney sparking; the reason is the wrong choice of the latter;

- wood dust flying around the room; the reason is an incorrect choice of location for the stove;

- increased frequency of filling the ash pan; The reason is incorrect setting of the pellet burner.

Peat pellets.

This fuel is made from dried peat and is the least quality type of pellet, however, due to its low cost, due to the truly huge reserves of peat in our country, it enjoys a certain popularity. In fact, peat pellets are more often used in industry, but in principle they are also suitable for household fuel boilers, although their ash content is quite high.

Popular models

The most famous suppliers of solid fuel units are the following brands:

- Lithuanian Stopuva;

- German Buderus;

- Czech Wattek;

- Belgian ACV;

- Austrian Wirbel;

- Russian NMK, Zota and TeploGarant LLC.

Among the models on the market from various companies, there are several popular devices.

Stropuva Mini S8

A power-independent unit serving an area of up to 80 square meters. m. Works with three types of fuel and is distinguished by its small size. Equipped with a convenient vertical firebox door.

The special design of the ash pan allows you to reduce the need to clean it to twice a month. One bookmark is enough for daily heating; the pellets burn out in 48 hours.

Advantages:

- high efficiency;

- quality of construction;

- safety;

- presence of a thermometer.

Flaws:

- heavy weight;

- The rough surface of the door makes it difficult to clean.

| Roman Oborin: | Igor Falaev: |

| “Economical and compact unit, burns for a long time. It consumes little fuel, heats the house well, and does not produce soot. The only negative is that it’s a bit heavy.” | “A small, convenient barrel, the device is immediately ready for use, you don’t need to assemble or screw anything in. The door handles are of high quality and reliable, they do not open spontaneously. It takes a long time to heat, it can burn for up to 20 hours.” |

Teplodar Cooper Expert-15

Russian model with the ability to install a burner.

In the upper half of the housing there is a fitting for air outlet. Compatible with firewood, coal and briquettes. Three air entry zones and top combustion ensure long-term heat maintenance. At the bottom there is a water reservoir that prevents excessive heating of the floor. A steel plate protects the door from heat. You can additionally attach a draft regulator.

Advantages:

- possibility of installing a pellet or gas burner;

- convenient door placed at an angle;

- continuous burning for 24 hours.

Flaws:

- complexity of installation;

- small firebox.

| Oleg Egorin: | Semyon Ivin: |

| “It’s a convenient boiler, you can buy an additional burner, it works for a long time and even after switching off the house remains warm.” | “It’s not a bad unit, it’s enough for almost a day of heating, but it consumes a lot of fuel. Convenient door design for stowage." |

ZOTA Topol-16VK

A device with a water circuit at an affordable price. The triangular shape of the pipe avoids blockages and increases the service life of the device. To refuel the boiler, you can use firewood, coal and pellets.

The model is distinguished by a spacious firebox and the possibility of top and side fuel storage.

Advantages:

- low price;

- ease of use and cleaning;

- efficiency.

Flaws:

low efficiency.

| Vladimir Kharitonov: | Alexey Zaitsev: |

| “A high-quality device at an affordable price for its segment. Works flawlessly." | “The device is pleasant to use, cleans without problems, you can load different types of fuel, both briquette and regular.” |

Teplodar Cooper Expert-22

The device is small in size, capable of operating in 4 modes: fast heating, classic, medium and maximum.

Combustion from top to bottom ensures uniform and longer combustion of the material and good heat transfer. The upper cleaning hatch is protected by a steel screen that prevents burning.

Advantages:

- two hatches for cleaning;

- inclined door for top loading;

- top burning function.

| Evgeny Zherdev: | Ivan Alaev: |

| “Sophisticated heating adjustment, you can adjust the burning duration from 30 minutes to a day. Easy to clean, special cleaning accessories included.” | “A high-quality model, the design allows you to connect heating pipes from either side. The device comes with a heating element and a thermomanometer.” |

Stropuva S30

Solid fuel boiler for placement in commercial and residential premises. Equally effective for year-round and seasonal use. It is characterized by high efficiency, is independent of power supply and is compatible with a variety of fuel materials.

The device has compact dimensions and is environmentally friendly. The duration of firewood burning is up to 30 hours, briquettes can smolder for up to 2 days.

Advantages:

- safety of use;

- high efficiency;

- durability;

- build quality.

Flaws:

high price.

Litter pellets.

It may seem strange, but fuel is also produced from the droppings of farm animals - chickens, geese, cows, horses and others, in the latter case the droppings are called manure. The fact is that this droppings mainly consist of crushed plant remains that have passed through the stomachs of animals, which is why it burns just fine. When burned, droppings do not emit virtually any unpleasant odors, which is why they are excellent as fuel for home stoves and boilers, and in many regions of our country, pellets from droppings are made in factories. However, litter and manure are still more often used to fertilize agricultural crops than as raw materials for fuel pellets, but still such fuel today can also be purchased and used quite effectively.

There are also pellets made from many other types of raw materials. For example, fuel pellets are known from waste paper or coal dust, as well as from the remains of any combustible household waste. But some of them, due to odors or high ash content, are used only in industrial furnaces, while others are unpopular due to a lack of raw materials and relatively high cost.

Unit design

The pellet boiler itself consists of three main components:

- Furnace - equipped with a special burner (retort or torch) and two doors (control, cleaning).

- Convective zone - a heat exchanger is located in it: it can be vertical, horizontal or combined, tubular or plate type. In the convective zone, the coolant in the heat exchanger is heated by gases released during the combustion of pellets. Most units are designed only for heating and have one circuit, but some models have two circuits: heating and water heating.

- Ash pan - it receives combustion waste (insignificant during normal afterburning), which is periodically removed through the cleaning door.

However, the listed components are, although the main part, but only a part, the operation of which requires the APT attachment (automatic fuel supply). This attachment includes the following components:

- A hopper is a container for pellets of a certain volume, from which the pellets enter the combustion chamber; it can be built-in or external.

- Auger - portions feed granules to the burner as needed, driven by a gearbox.

- A fan is necessary to maintain the combustion process, since the boiler design does not provide for natural draft.

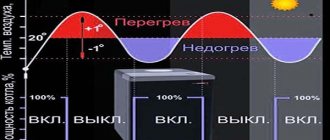

Since the pellet boiler is an automated system, its device also includes a control unit with a display, which displays information about the current state, and through which the main operating parameters are set. The controller regulates the ignition of the burner, the supply of pellets and air, and stops when the desired temperature is reached, maintaining the heating mode selected by the owner.

Depending on the capacity of the bunker and the selected mode, one filling can be enough for several days, a week or even more.

To make the heating process fully automatic, the boiler can be connected directly to the storage - a pneumatic pipe will supply granules to the bunker as it is emptied.

Requirements for pellets for boilers

You should also consider some of the requirements for fuel pellets, because very often the conditions for their production differ, and this, accordingly, affects the quality.

If we talk about humidity, then its level in the material should not exceed 8-10%. The only exception is peat pellets, their moisture content is allowed at 15%, and if this figure is higher, then this is a low-quality fuel.

A very important parameter is calorific value, that is, the amount of heat released during combustion. The standard option is when the calorific value is 5 kcal/kg (wood) and 4 kcal/kg (husk, husk). If the calorific value is lower, then it is a very bad fuel; if it is higher, it is excellent, but its cost also increases significantly with such indicators.

Ash content is the amount of solid waste that is formed during the combustion of fuel. For pellets it should not exceed 1%; if it is higher, then the boiler will have to be cleaned of ash almost every 2-3 days. If you use white wooden pellets, then their ash content is 0.5% or lower (up to 0.2%), which is considered simply excellent, and the boiler can not be cleaned for months.

Instead of an epilogue

An analysis of the Russian market for the goods in question has established that the middle and budget segments are completely occupied by domestic producers. However, such a product has a single and direct purpose - heating only. At the same time, reasonable prices and variability of supply indicate sufficient quality of products. The premium segment, as a rule, is entirely represented by foreign (primarily European and transatlantic manufacturers), is characterized by a high level of environmental friendliness and can be used in various fields. It is worth mentioning that the price of such quality and multitasking is very high, so the Russian consumer is unlikely to purchase premium samples for heating. They are ideal for grilling and other outdoor cooking tasks. In addition, it should be noted that the market for the goods in question in Russia is just beginning to develop and there is hope that domestic companies will soon begin producing multi-tasking granulates, and the prices for them will not be greatly inflated.

How to check the quality of boiler pellets

The chemical quality of the pellets is also very important; if they are made using chemical glue, then this is very harmful to health. This parameter is checked by placing the granules in water. If the granule sank, quickly became wet and disintegrated without precipitation (sand, stones, other impurities), then it is of high quality. If glue was added to the granule, then it will never get wet and will not dissolve in water; moreover, it will not even sink.

When purchasing pellets, you must ask the seller for a certificate that specifies all the necessary parameters of the pellets - this is the only way to be sure that you have purchased a quality product. Moreover, it is better to buy this product from a large, trusted manufacturer who never experiments and produces products from the same raw materials, dealing with the same trusted suppliers.

Selection by diameter

The diameter of pellets is 6 or 8 mm. One of the myths that surrounds pellet heating is that eight-millimeter pellets are of lower quality. The root of this misconception lies in the granulators in which they were produced.

According to a common statement, 8 mm have granules made on domestic equipment, which was often used in the past for the production of feed in agricultural production, therefore, the technology cannot be fully complied with.

However, the question of the dependence of quality on diameter does not have a final and comprehensive answer. When choosing the diameter of pellets, you must be guided by the passport data of the equipment in which they will be burned. This is due to the fact that the boiler automation is designed for a certain forced air supply, which will maintain optimal combustion. The use of unsuitable granules creates an increased load on the mechanics and leads to a reduction in its service life.

Prices and packaging

In conclusion, it should be said that today pellets are sold packaged in small bags - from 5 to 25 kg, as well as in large-capacity bags made of polypropylene (big backs), while the cost of fuel is much lower than if you buy fuel pellets in small bags. Today the price for white wood pellets is about 8 thousand rubles. per ton, gray - about 5 thousand rubles. per ton, and straw pellets or made from husks - about 3-4 thousand rubles.

- Product

- Characteristics

Final comparison table

The above calculations are relevant for a house of 100 m2. Costs do not reflect all options; actual figures are affected by the climate of the region, the severity of winter, and the level of thermal insulation of the house.

| Options | Pellets | LPG (gas holder) |

| Efficiency | 50-90% | 97% |

| Fuel cost | 48 thousand rubles. in year | 49-54 thousand rubles. in year |

| Cost of equipment | from 40 thousand rubles. | from 155 thousand rubles. plus gas boiler |

| Connection | Boiler installation | Installation of a gas tank on the site and a boiler in the house |

| Ease of use | Regular fuel loading is required daily or once a week. The quality of the pellets is important. | Full autonomy after refueling 1-2 times a year. |

| Reliability | High | High, problems can only arise if incorrectly selected and installed |

| Safety | Carbon monoxide danger | High, no risks |

| Electricity dependence | Yes | No |

| Fuel warehouse | Needed | Not needed |

| Service | Loading, cleaning | Tank refilling, technical inspection twice a year |

The combination of a gas holder plus a gas boiler provides ease of use and a certain independence from external factors (electricity, quality of pellet production). But it implies the presence of free space on the site far from residential premises and the implementation of such a project will cost more than the “competitor”.

Pellet equipment is cheaper, as is the fuel itself. But it requires high quality pellets, constant maintenance or additional costs for modernization. At the same time, it produces low efficiency when compared with a gas tank. But a gas boiler also requires annual maintenance.

We also recommend that you familiarize yourself with the comparison between a gas tank and main gas.

Structure

Pellet boiler design diagram

The diagram shows the components of a pellet boiler, which include:

- pellet bunker (place for storing fuel pellets);

- pellet feed auger (necessary for supplying fuel from the hopper to the burner);

- pellet burner (fuel is burned in it);

- components of the heat exchanger and grate cleaning system (compressor, auxiliary elements);

- security system (fire extinguishing sensors, auger overflow);

- control system (built-in and portable remote controls).

Manufacturers

The main manufacturers of pellet boilers that have earned credibility in the modern market are presented below:

- TERMODINAMIK (Türkiye);

- TIS (Belarus);

- FACI (Italy);

- D'ALESSANDRO (Italy);

- GRANDEG (Latvia);

- Metal-FACH (Poland);

- KOSTRZEWA (Poland);

- KITURAMI (Korea);

- GRANDLINK (China);

- KLOVER (Italy);

- TERMAL (Russia).

Each of the boilers from the presented manufacturers has optimal technical characteristics for use, an original design, and is also easy to use. The choice should be made based on your preferences and financial capabilities.

Which brands of pellet boilers are the best in quality and reliability?

- Lighthouse.

Long-burning pellet units are characterized by high productivity and heat transfer. The heat exchangers are made of high-quality boiler steel with a thickness of 6 mm. The devices are equipped with a highly efficient Polish-made Pellas-X burner and a hopper for storing wood pellets.

- Drew-Met.

The Polish-made automated heating system is characterized by its versatility (in addition to wood pellets, it is possible to use an alternative type of fuel (firewood, wood chips, peat briquettes, etc.)). The heat generators are made of high-strength boiler steel 6 mm thick and equipped with a PellasX pellet burner and LCD Pellas-X S automatic control.

- Tis.

Domestic manufacturer of reliable heating equipment, the efficiency of which reaches 92%. Ideal for use in cold climates. Some models (for example, EKO DUO) allow the use of other types of raw materials, such as firewood, coal or peat.

- Kronas.

The Ukrainian brand of world-class heating equipment is distinguished by economical fuel consumption and high performance due to built-in automation and a torch burner.

- Sas.

Polish manufacturer of solid fuel equipment, which is characterized by automatic control and loading of granular raw materials. All models are made of high-quality heat-resistant steel P265GH. The built-in flare burner ensures stable fuel combustion.