An electric heater, like any other device, needs maintenance, which is not limited to just washing and cleaning the tank when the heating element burns out. Inside the boiler there is also an anode, which is a thick rod and is installed next to the heating element. It is this that protects your boiler from corrosive processes and significantly extends its service life.

Anode rods come in a variety of sizes, materials and costs and, like changing the oil in your car, can make a significant difference in the life of your water heater. In this article we will tell you in detail about its features, types and give some tips on how to increase the service life of this device from experts in the field of plumbing.

What is an anode rod?

Every owner of a water heater should know about the anode in the boiler and its operating principle, because it is this that affects its service life.

The anode is a gray metal rod that has a smooth surface and is located inside the tank next to the heating element. It is made of a specialized magnesium alloy and is attached via a threaded rod to the hole in the heating element flange.

The anode performs several functions inside the boiler tank.

The first function can be considered its direct purpose, namely the protection of the device and its constituent elements from corrosion. The second function is more of a bonus: the anode makes the scale looser, allowing you to remove it from the surface much faster and without spending a lot of effort on this task.

Wear criteria

If the boiler body is heavily contaminated, it may begin to receive an electric shock or will not turn on.

There are several easily identified indicators that it is time to completely clean the unit and then change the magnesium anode:

- when you turn on a household device, after some time the protection is triggered, which is explained by the presence of a thick layer of scale on its heating element;

- The previously observed water heating is completely absent when the boiler is operating in normal mode;

- the equipment body begins to periodically “shock” with current, which is a sign of poor insulation quality due to the destruction of individual parts.

One of these manifestations is a reason to immediately stop using the boiler and begin examining it. Only a thorough study of the condition of the electric water heater and anode allows us to make a final conclusion about the need to replace them.

Why do you need an anode rod?

The operating principle of the anode is quite simple. Due to the fact that the rod has the lowest electrochemical potential, all oxidative processes that occur during multiple heating cycles of water inside the device affect it, but not the walls of the tank. Over time, its surface ceases to be smooth and becomes overgrown with corrosion, which is how it protects the heating element and the surface of the tank from destruction. It is necessary to change the part on time so that the water heater tank remains intact and can serve you for many years.

Principle of operation

The operating principle of the electrode is based on its activity , since magnesium in all compounds is a divalent metal, and the iron from which the tank is made is trivalent. In addition to corrosion, when heating water, scale forms due to settling salts of heavy metals.

Since magnesium has increased activity, the salt atoms interact with it, and not with iron. Therefore, the magnesium anode binds oxygen atoms and attracts iron salts as a magnetic material. At the same time, the formation of calcium carbonate salts sharply decreases, and carbonic acid salts are formed from magnesium.

As a result, the scale becomes looser and can be easily removed when cleaning the unit. This prevents corrosion of the tank and the coating of the heating element. This process is called sacrificial protection, and the electrode is called anode-protector.

Types of anodes for water heaters

All water heater anodes serve the same basic purpose, but there are several types of rods on the market made from different materials. Let's figure out how they differ from each other.

Aluminum anode

An aluminum anode is a traditional metal rod often found in older water heaters. It was used for a long time before other types of devices were invented.

As knowledge of the toxic effects of aluminum has become more widely known in the 21st century, the use of these rods in hot water tanks has become much less common, although they are still found in areas with very hard water. Water from a tank with such a rod usually tastes strangely like hydrogen sulfide or rotten eggs. That is why, back in the USSR, parents did not allow their children to drink water from a hot tap.

The rod itself is made in the form of a standard threaded rod. The aluminum anode does not allow the boiler elements to oxidize, but has a sophisticated design and is easily damaged by mechanical stress.

Magnesium anode

One of the most popular metals for anode rods today is magnesium. Statistically, it is the most widely used metal in modern water heaters, although it is not recommended for areas with hard water.

It is a regular rod with a steel pin inside. It is quite large in size and can reach a length of up to 1 meter. Therefore, we recommend that when purchasing new anodes, pay attention to the length of the old one so as not to make a mistake in size.

If you live in a hard water area and are considering replacing the magnesium anode, make sure the hot water tank lining has not been corroded. Installing magnesium anodes in a corroded tank may cause an electrochemical reaction to produce hydrogen gas, causing water leakage.

Titanium anode

This anode for a boiler functions a little differently. It supplies a stable current, which prevents corrosion. Electrical control occurs externally thanks to a special power supply.

The current supply is periodically interrupted. At this time, the anode “checks” the inside of the equipment for damage. And then regulates the strength of the current supply.

The most important feature of a titanium anode is that it is not subject to destruction at all, so it does not need to be replaced. This is not only its main advantage, but also its disadvantage. The price of such anodes is more expensive than other types of anodes.

Errors when replacing heating elements

1

As discussed in this article, this method will lead to bending of the flange and subsequent leakage. That is, you will have to remove the boiler from the wall again, unscrew everything and reassemble it again.

2

No sealants should be used when replacing heating elements. Tightness should be created only by uniform pressing of the gasket material.

3

No matter how intact it may seem, in any case, every time you open the heating elements, be sure to replace the sealing elements.

4

Even if you don’t find a suitable anode in your store, never install heating elements inside the tank without it. Not only does this reduce the service life of the heating elements, but ultimately it all ends in burning out the body of the boiler tank.

Then a leak appears, without the possibility of recovery or repair.

True, some expensive boiler models have titanium anodes with electronic potential removal.

They just don't require replacement. Therefore, before unscrewing anything, carefully study the product data sheet.

5

When washing the tank and draining the water, be very careful; you can accidentally flood the electronic control board with the display, which is located on the side of the housing, with water. In this case, the boiler simply will not start after switching on.

You will search for the cause for a long time, ringing all the terminals, but it will lie literally on the surface. You can soak this board even with the boiler upside down.

Look closely at the hole where the lone control wire goes.

Water can simply flow through it directly to the electronics. So, it is best to close this hole initially, even before pulling out the heating elements, by pushing any seal there.

https://youtube.com/watch?v=_77LiS7L90A

Which is better: magnesium anode or aluminum anode?

Let's look at the two most popular types of anodes - magnesium or aluminum. Which one is better and more effective? Let's start with the aluminum rods:

For limited space, manufacturers often use flexible aluminum rods, which fit perfectly where others do not fit. They are installed directly to water heaters located in low ceilings, attics, basements, under stairwells and in storage rooms. To attach such a rod, you will have to bend its flexible parts, slowly inserting it into the water heater through the top hole.

Aluminum anode rods

- This is an excellent option if the water contains a lot of sulfates.

They work better when converting sulfates into hydrogen sulfide. Magnesium anode rods are known to increase hydrogen sulfide levels to extreme levels. This causes a faint rotten egg smell in the water, which can be quite unpleasant. Advantages:

- A small amount of zinc is often added to aluminum rods. This increases their lifespan;

- They are cheaper;

Flaws:

- The corrosive material created by reacting with water can fall and end up in your faucets and water supply. This can cause plumbing problems;

- Being less active than magnesium, aluminum reacts slowly with water elements. This means that it is not able to completely prevent corrosion;

- Aluminum produces by-products that are a thousand times its volume. They usually settle at the bottom of the tank as a jelly, promoting sediment accumulation;

- Certain byproducts sometimes rise to the top of the water heater, forming a sticky substance that can clog water filters and aerators;

- Aluminum rods expand over time as they corrode. This makes it impossible to remove them after prolonged use due to their increased diameter;

- The rods are known to detach from the core. They fall to the bottom of the heater and after a while stop participating in the corrosion process. This turns them into trash. Sometimes the aluminum rod may split into two parts when removed;

- The accumulation of aluminum deposits on the bottom of the heater causes noise. People using aluminum anodes often report noise from their water heater at night;

- Aluminum deposits are harmful to the liver, kidneys, brain and spleen.

In turn, magnesium alloy rods

They are excellent at protecting the inside of water heater tanks from corrosion. They do this by diverting corrosion towards themselves. Like their aluminum counterparts, they are also known as sacrificial rods. Typically used where softer water is available. Also, according to statistics, they last slightly less than rods made of aluminum and titanium.

This is due to their high reactivity and higher voltage. Despite the fact that they wear out faster than other anodes (it is recommended to change 1-2 times a year), they are considered the safest for humans.

Modern manufacturers of water heaters use this type of anode!

Advantages:

- Best protection against corrosion;

- Unlike aluminum, dissolved magnesium has health benefits.

Flaws:

- Magnesium rods are more expensive than aluminum rods.

Conclusion:

Aluminum anode rods are cheaper than magnesium anode rods. This is a great option if you live in an area with hard water. But unfortunately, their use is unsafe and is associated with many problems. For this reason, magnesium rods are considered the best option in terms of health safety and price/quality ratio.

Recommendations

- It is necessary to carefully monitor the operation of the boiler. If extraneous noise occurs, inspect the condition of the anode device and heating element.

- Constantly check its condition.

- Do not use water heating equipment without a safety rod installed inside.

- You can replace the used part yourself; calling a technician is not necessary.

- Salts will always form inside the container. It is recommended to descale the internal cavity at least once a year.

The versatility of some rod options allows you to install a magnesium anode for an Ariston, Electrolux, and other popular brands of water heater. They are also suitable for a Russian-made Thermex water heater. The price range depends on the dimensions of the anode rod and the manufacturer's brand.

How long does the anode last?

The anode rod should be checked at least once every 1-2 years depending on the hardness of your water. However, in our practice, the rods usually last around 4-5 years before they need to be completely replaced.

Therefore, we recommend checking every 1-2 years and ensuring that the anode is in its place. Different homes and different regions of Russia experience different conditions and properties of water, including the presence of minerals in the liquid, the level of acidity and the presence of softener.

Regular inspections will help you prevent potential leaks and breakdowns. By spending 10-20 minutes checking and 100-1000 rubles if you buy a new anode, you can save significantly on the purchase of a new water heater, the price of which can reach tens of thousands of rubles.

We service the indirect heating tank

Let us note right away that the replacement operation here is much simpler than in electric boilers. Since the anode in an indirect water heater is located at the top and is in no way connected with other elements - a heat exchanger or an additional heating element in combined models.

Combination heating apparatus design

How to change the anode in a floor-mounted indirect heater:

- Turn off the cold water supply.

- There is no need to empty the tank, you just need to relieve the pressure. Open the “hot” valve on the mixer and drain 2-3 liters of water through the drain valve of the device, then cut off the DHW line.

- Using an open-end or spanner wrench, unscrew the plug on the lid of the container and pull it out along with the old anode.

- Unscrew the rod with pliers, screw a new one in its place and tighten it by hand.

- Insert the element into the tank and tighten the plug with a slight force so as not to squeeze the rubber sealing ring. It is advisable to check the latter after disassembly and, if necessary, replace it.

Advice. Before disassembling, it is worth turning off the boiler circulation pump so that the coolant does not circulate through the coil.

The rod is changed in a similar way on stationary water heaters equipped with a gas burner. The work order is shown in the video:

If it is necessary to service the wall-mounted version of the “indirect”, the water will have to be drained. The protective rod is removed using the technology described in the previous section about electric models.

How to check the serviceability of the anode

Besides manually turning off the water supply to the water heater, unscrewing the anode rod from the tank, and visually checking to see if the rod has failed, there are several other methods for determining if your rod has failed.

- If you notice that your hot water has an unpleasant rotten egg smell, this may be the first sign that the anode is starting to fail. The unpleasant odor occurs because water and oxygen begin to react with the lining of the tank and spoil it. Of course, if you have an aluminum anode installed, then a slight unpleasant odor will be the norm.

- The boiler took much longer to heat up;

- The device often turns off and turns on on its own;

- During operation, noises are heard from the tank.

- If you have a water softener, running it can also cause the rod to break. The fact is that the softener can negatively react to the operation of the anode itself and cause its wear. In this case, we recommend checking the rod every 6-9 months.

If you smell a smell when cold water is supplied, it may indicate problems with the plumbing. In this case, it is best to seek help from a plumber to properly find and solve the problem.

If you need to unscrew the rod, pay attention to the following things:

- Calcium accumulation.

There can be a large amount of calcium in the water that builds up on the anode rod itself, making the rod significantly less useful and corroding your tank faster. - No corrosion.

If this is the case, it is possible that you have installed a rod that simply does not work. If, after a month of use, the anode looks like you just took it out of the box, then it is not doing its job and the boiler is suffering because of it.

Filling with water and checking functionality

Hang the electric titanium in place.

Connect the hoses and open the cold water and begin to fill the tank. The hot water tap must also be open to allow air to escape. At the same time, make sure that there are no leaks anywhere. As soon as water comes out of the “hot” tap, the boiler is full. There is no need to close the tap immediately; let all the “slurry” spill out and finally flush the tank and pipes.

Only when clean water comes out do you turn off the mixer.

After this, the water heater must stand for at least half an hour or an hour so that condensation leaves all surfaces and there is confidence that there are no leaks.

You can then apply voltage by plugging the titanium into an outlet. To check the operation of the thermostat, use the control knob to force the adjustment to maximum and minimum.

In this case, the boiler on/off light should light up.

If the boiler operates quietly, without making any sounds, and it is not clear to you whether it is heating or not, you can check the energy consumption using the meter.

At maximum heating power of the heater, the counter will spin or blink much faster. This means that the heating elements work as they should.

So self-repair can save you a significant amount of money, the main thing is not to make some mistakes.

How to replace a magnesium anode in a boiler

Replacing the anode in a water heater does not require special skills and almost any owner of the device can handle it. But when replacing, you must take into account that each manufacturer has its own modification and before purchasing, be sure to check which anode is right for you.

If you have difficulty choosing an anode in a store, the easiest way is to take the old one with you. The parts differ in thread diameter. The most popular anode mounting sizes are M4, M5, M6. The size of the anode itself is of secondary importance. The main thing is that it fits into the tank without effort.

The replacement procedure itself consists of several stages that must be completed:

- Disconnect the boiler from the network and drain the remaining liquid. To simplify this procedure, you can use a check valve by first connecting the hose;

- Unscrew the casing located at the bottom of the tank to get to the thermostat and flange and remove them;

- Remove the heating element by slightly shaking it. The element may be subject to salt deposits, so act extremely carefully so as not to damage the part;

- Remove the anode, which is located next to the heating element;

- Remove all scale from the heating element using special brushes or a regular screwdriver. In case of severe contamination, you can use a solution of citric acid (40-50 grams of acid per 1 liter of clean water, then leave the heating element in the liquid for 48 hours);

- Put everything back together and check the functionality of the new element.

Scale and cleaning of heating elements

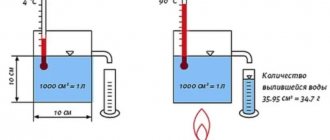

Scale forms primarily in the presence of hard water. Just 1mm of scale gives 75% additional thermal insulation. Thus, the heating element under such a large layer of salts simply begins to overheat.

The first sign of scale formation is a distinct hissing or whistling noise.

Disassemble the boiler, as shown below, and begin cleaning. This can be done in two ways:

a regular knife or wire brush

if the scale is very hard, then use citric acid or special products

Cut off the neck of a 1.5 liter plastic bottle and dilute the solution in it:

warm water 60 degrees

7 teaspoons citric acid

Soak the heating element in it overnight. After which, in the morning you clean off all excess. The result is sometimes simply amazing.

Ways to eliminate the smell of hydrogen sulfide from boiler water

A water heater tank may contain sulfate-reducing bacteria in both the sludge and water at the same time. But usually, one type of bacteria is the most active. Depending on what type of sulfate-reducing bacteria in the boiler tank is causing the smell of hydrogen sulfide, the method of getting rid of the smell is chosen.

Eliminating bacteria that live in the sludge layer

It may be enough to do at least one of the following:

- The easiest way is to raise the water temperature above 70 o C and use this water for three days until the smell disappears. In the future, constantly keep the water temperature in the boiler above 55 o C. Periodically it is recommended to increase the temperature above 70 o C.

- Regularly clean the boiler to remove scale and sludge deposits on the bottom.

- Take measures to reduce the amount of organic contaminants in tap water. To do this, you can change the water intake horizon - instead of a well, take water from a well or deepen the well. Install filters to purify tap water from mechanical and organic contaminants.

Eliminating bacteria from boiler water

To suppress sulfate-reducing bacteria living in boiler water, it is often enough to do the following:

- Try raising the water temperature above 70 o C and using this water for three days until the smell disappears. In the future, constantly keep the water temperature in the boiler above 55 o C. From time to time it is recommended to increase the temperature above 70 o C. But this method does not always help. Bacteria living in boiler water are often resistant to these temperatures.

- The activity of sulfate-reducing bacteria is suppressed if the molecular hydrogen content in water is reduced. For this purpose, the operating mode of the tread protection is optimized. Replacing a magnesium anode with an aluminum one eliminates “overprotection,” which reduces the hydrogen content in water. Read about replacing anodes at the beginning of this article.

General measures to combat bacteria in the boiler

The following measures can suppress the development of bacteria in both water and sludge:

- Aeration, saturation with air, of tap water leads to an increase in the content of free oxygen in the water. As a result, the anaerobic habitat of bacteria changes to one less favorable for their life.

- Disinfect tap water using methods whose antibacterial effect persists for a long time after treatment - chlorination, etc. Ultraviolet water treatment is not suitable for this.

- Take measures to reduce the amount of soluble sulfur compounds in tap water. To do this, you can change the water intake horizon - instead of a well, take water from a well or deepen the well. These measures should be selected after testing the water source for sulfate content.

Source of the article: https://domekonom.su/anod-dlia-vodonagrevatelia-boilera.html

Why does hot water from a boiler smell like hydrogen sulfide?

After some time, the water from the boiler may begin to smell terribly of hydrogen sulfide. The reason is the growth of bacteria in the water heater tank. This happens especially often if water is supplied to the water supply from a local well or well. Water from the city water supply is usually specially prepared, highly disinfected, chlorinated, and such cases rarely occur with it.

Large amounts of hydrogen sulfide gas (H2S) are released and accumulated as a result of the activity of sulfate-reducing (sulfate-reducing) bacteria in water.

Products for construction and repair

Sulfate-reducing bacteria use organic matter (CH2O) or hydrogen (H) as an electron donor and sulfate (SO4) as an electron acceptor to obtain energy

Simply put, there are two types of sulfate-reducing bacteria. Both varieties require sulfates - sulfur compounds - as well as hydrogen to survive. But one species of bacteria extracts hydrogen from organic matter in the sludge . Other bacteria use molecular hydrogen , which is found in water.

It is important that the development of sulfate-reducing bacteria occurs under anaerobic conditions , in the absence of free oxygen in the water.

Sulfates are salts of sulfuric acid H2SO4, for example, potassium sulfate K2SO4, sodium hydrogen sulfate NaHSO4. Sulfates are widespread in nature, forming a whole group of minerals. Many sulfates are soluble in water and are found in natural water.