Here you will learn:

- How profitable are solar collectors?

- Classification according to temperature criteria

- Types of solar collectors

- What can you make a solar system from yourself?

- Polycarbonate manifold

- Solar collector made from a hose or flexible pipe

- Collector Stanilova

- Collectors from scrap materials

- How to connect a solar collector to a tank (shower) by gravity

- How to connect the collector to the hot water supply

A solar collector for heating water with your own hands can be made from plastic or copper pipes, from a hose, from bottles or cans. We offer simple diagrams of such structures.

How profitable are solar collectors?

The payback of such devices depends on the breadth of use. In the southern regions, where there is a lot of sun, they are beneficial. But at the level of the 52nd parallel, they no longer pay off if they are used for heating (there is little sun in winter), but they pay off further north if they are used for hot water supply in the off-season and in the summer.

In Europe, for example, where gas is expensive and equipment is cheap, collectors are definitely beneficial for heating, even in the northern regions.

Our cheapest summer solar collectors, which can be made literally from scrap materials, or which are made “semi-handicraft” in local factories, are definitely advantageous.

They are used for heating water in a swimming pool, summer shower, hot water supply in the house and heating houses in the off-season. In winter conditions, cheap (homemade) collectors cannot compete in efficiency with factory ones; they become more like coolers, and therefore are not used.

Spreading

Solar water heaters are popular in Malta.

Modern Israeli houses equipped with solar collectors.

The world leader in production and application is China. In 2007, about 40 million households with a total population of 150 million people used solar water heaters in China. By 2009, the total area of installed solar water heaters increased to 140 million m². This is enough to supply hot water to approximately 60 million households. By 2022, 300 million m² of premises in China will be equipped with solar water heaters.

In 2010, about 2,800 companies produced solar water heaters in China, of which 1,200 companies produced components. China's total solar water heater market was 73.5 billion yuan (approximately $11.5 billion) in 2010. The largest Chinese manufacturers: Sunrain Group, the Linuo Group, Himin Solar and Sangle Solar. Annual sales of each exceed 2 billion yuan (approximately $313 million).

Water heaters are also very widely used in Israel, where approximately 85% of apartments are equipped with this equipment [ source not specified 1206 days

].

This is due to a law passed in 1976 [ source not specified 1206 days

] and obliging the construction of housing with built-in solar water heaters.

The exception is [ source not specified 1206 days

] high-rise buildings (more than 9 floors), where the roof area is insufficient to accommodate solar collectors sufficient for all consumers of the building. This widespread use of solar water heaters saves about 8% of all electricity produced in the country.

Classification according to temperature criteria

There are quite a large number of criteria by which certain solar system designs are classified. However, for devices that can be made with your own hands and used for hot water supply and heating, the most rational option would be to separate them by type of coolant.

So, systems can be liquid and air. The first type is more often applicable.

In addition, a classification is often used based on the temperature to which the working components of the collector can be heated:

- Low temperature. Options capable of heating the coolant up to 50ºС. They are used to heat water in irrigation tanks, in bathtubs and showers in the summer and to improve comfortable conditions on cool spring-autumn evenings.

- Medium temperature. Provide a coolant temperature of 80ºС. They can be used to heat rooms. These options are most suitable for furnishing private homes.

- High temperature. The coolant temperature in such installations can reach up to 200-300ºС. They are used on an industrial scale, installed for heating production workshops, commercial buildings, etc.

High-temperature solar systems use a rather complex process of transferring thermal energy. In addition, they occupy an impressive amount of space, which most of our lovers of country life cannot afford.

The manufacturing process is labor-intensive, and implementation requires specialized equipment. It is almost impossible to make such a version of a solar system on your own.

It is quite difficult to make high-temperature solar panels using photovoltaic converters at home

Main manufacturers

Let's take a look at some of the major solar water heater companies. So, the top manufacturers on the world market:

- The Italian company produces vacuum-type manifolds KAIROS VT. There are modifications with 15 or 20 tubes;

- The German manufacturer offers three models SKR21, SKR12, SKR6;

- Another German company that produces models with 6 or 12 tubes. Moreover, they can be combined into blocks to increase the power of the system;

- Sunrain Solar Energy. This is a Chinese manufacturer that produces solar water heaters;

- And another German company that offers two water heaters under the brands Vitosol 200 and 300. These models differ in the design of the heating unit;

- Italian manufacturer producing the Ecotube model.

Water heater KAIROS VT

Here it is worth saying that the products of these companies are of the highest class and are provided with a guarantee, but not everyone can afford them for the money. Therefore, most of the demand on the market is covered by little-known manufacturers.

Types of solar collectors

The standard device has the form of a metal plate, which is placed in a plastic or glass case. The surface of this plate accumulates solar energy, retains heat and transfers it for various household needs: heating, water heating, etc. Integrated collectors come in several types.

Cumulative

Storage collectors are also called thermosiphon collectors. This DIY solar collector without a pump is the most profitable. Its capabilities allow you not only to heat water, but also to maintain the temperature at the required level for some time.

This solar heating collector consists of several tanks filled with water, which are located in a thermal insulation box. The tanks are covered with a glass lid, through which the sun's rays shine through and heat the water. This option is the most economical, easy to operate and maintain, but its effectiveness in winter is practically zero.

Flat

It is a large metal plate - an absorber, which is located inside an aluminum case with a glass lid. A do-it-yourself flat-plate solar collector will be more efficient if you use a glass cover. Absorbs solar energy through hail-resistant glass, which transmits light well and practically does not reflect it.

There is thermal insulation inside the box, which can significantly reduce heat loss. The wafer itself has low efficiency, so it is coated with an amorphous semiconductor, which significantly increases the thermal energy accumulation rate.

When making a solar collector for a swimming pool with your own hands, preference is often given to a flat integrated device. However, it copes just as well with other tasks, such as heating water for household needs and heating a room. Flat is the most widely used option. It is preferable to make an absorber for a solar collector from copper with your own hands.

Liquid

From the name it is clear that the main coolant in them is liquid. A do-it-yourself water solar collector is made according to the following scheme. Through a metal plate that absorbs solar energy, heat is transferred through pipes attached to it into a tank with water or antifreeze liquid or directly to the consumer.

Two pipes approach the plate. Through one of them, cold water is supplied from the tank, and through the second, already heated liquid enters the tank. Pipes must have inlet and outlet openings. This heating circuit is called closed.

When heated water is directly supplied to meet the needs of the user, such a system is called open-loop.

Non-glazed ones are more often used to heat water in a swimming pool, so assembling such thermal solar collectors with your own hands does not require the purchase of expensive materials - rubber and plastic will do. Glazed ones have higher efficiency, so they are able to heat the house and provide the consumer with hot water.

Air

Air devices are more economical than the above-mentioned analogs that use water as a coolant. The air does not freeze, does not leak, and does not boil like water. If a leak occurs in such a system, it does not cause as many problems, but it is quite difficult to determine where it occurred.

Self-production does not cost the consumer much. The sun receiving panel, which is covered with glass, heats the air that is between it and the heat-insulating plate. Roughly speaking, this is a flat-plate collector with space for air inside. Cold air enters inside and, under the influence of solar energy, warm air is supplied to the consumer.

A fan, which is attached to the duct or directly to the plate, improves circulation and improves air exchange in the device. The fan requires the use of electricity to operate, which is not very economical.

Such options are durable and reliable and are easier to maintain than devices that use liquid as a coolant. To maintain the desired air temperature in the cellar or to heat a greenhouse with a solar collector, just this option is suitable.

Operating principle and design features

Modern solar systems are one of the types of alternative sources of heat. They are used as auxiliary heating equipment that converts solar radiation into energy useful to home owners.

They are able to fully provide hot water supply and heating during the cold season only in the southern regions. And only if they occupy a sufficiently large area and are installed in open areas not shaded by trees.

Despite the large number of varieties, their operating principle is the same. Any solar system is a circuit with a sequential arrangement of devices that supply thermal energy and transmit it to the consumer.

The main working elements are solar panels based on photocells or solar collectors. The technology for assembling a solar generator on photoplates is somewhat more complicated than a tubular collector.

In this article we will look at the second option - a solar collector system.

Solar collectors still serve as auxiliary energy suppliers. It is dangerous to completely switch home heating to a solar system due to the inability to predict a clear number of sunny days

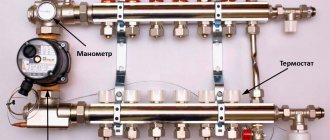

Collectors are a system of tubes connected in series to the output and input lines or laid out in the form of a coil. Process water, air flow, or a mixture of water and some kind of non-freezing liquid circulates through the tubes.

Circulation is stimulated by physical phenomena: evaporation, changes in pressure and density from the transition from one state of aggregation to another, etc.

The principle of operation of solar collectors is based on the receipt and accumulation of solar energy imparted to the coolant (+)

The collection and accumulation of solar energy is carried out by absorbers. This is either a solid metal plate with a blackened outer surface, or a system of individual plates attached to tubes.

For the manufacture of the upper part of the body, the lid, materials with a high ability to transmit light are used. This can be plexiglass, similar polymer materials, tempered types of traditional glass.

In order to eliminate energy loss, thermal insulation is placed in the box on the back side of the device

It must be said that polymer materials do not tolerate the influence of ultraviolet rays quite well. All types of plastic have a fairly high coefficient of thermal expansion, which often leads to depressurization of the housing. Therefore, the use of such materials for the manufacture of the collector body should be limited.

Water as a coolant can only be used in systems designed to supply additional heat in the autumn/spring period. If you plan to use the solar system all year round, before the first cold snap, change the process water to a mixture of it and antifreeze.

Air solar systems use air as a coolant. Channels for its movement can be made from ordinary corrugated sheets (+)

If a solar collector is installed to heat a small building that has no connection with the autonomous heating of the cottage or with centralized networks, a simple single-circuit system with a heating device at the beginning is constructed.

The chain does not include circulation pumps and heating devices. The scheme is extremely simple, but it can only work in sunny summers.

When a collector is included in a double-circuit technical structure, everything is much more complicated, but the range of days suitable for use is significantly increased. The collector processes only one circuit. The predominant load is placed on the main heating unit, running on electricity or any type of fuel.

To make a solar collector, you can use a ready-made circuit, you can build your own pilot model and test it in practice (+)

Despite the direct dependence of the performance of solar devices on the number of sunny days, they are in demand, and the demand for solar devices is steadily increasing. They are popular among folk craftsmen who seek to channel all types of natural energy into useful channels.

What can you make a solar system from yourself?

First, you need to understand what operating principle a solar water heater uses. The internal structure of the block contains the following components:

- frame;

- absorber;

- a heat exchanger within which the coolant will circulate;

- reflectors to focus the sun's rays.

The factory solar water heating collector works as follows:

- Heat absorption - the sun's rays pass through the glass located on top of the body or through vacuum tubes. The internal absorbent layer in contact with the heat exchanger is painted with selective paint. When sunlight hits the absorber, a large amount of heat is released, which is collected and used to heat water.

- Heat transfer - the absorber is located in close contact with the heat exchanger. The heat accumulated by the absorber and transferred to the heat exchanger heats the liquid moving through the tubes to the coil inside the heat storage tank. Water circulation in the water heater is carried out by forced or natural means.

- DHW — two principles of heating hot water are used:

- Direct heating - hot water after heating is simply discharged into a thermally insulated container. In a monoblock solar system, ordinary household water is used as a coolant.

- The second option is to provide domestic hot water with a passive water heater based on the principle of indirect heating. The coolant (often antifreeze) is sent under pressure to the solar collector heat exchanger. After heating, the heated liquid is supplied to a storage tank, inside of which a coil (playing the role of a heating element) is built, surrounded by water for the hot water supply system. The coolant heats up the coil, thereby transferring heat to the water in the container. When the tap is opened, heated water from the heat-storing tank flows to the water collection point. The peculiarity of a solar system with indirect heating is its ability to operate throughout the year.

The operating principle used in expensive factory-made solar systems is copied and repeated in do-it-yourself collectors.

The working designs of solar water heaters have a similar structure. They are only made from scrap materials. There are schemes for the production of collectors from:

- polycarbonate;

- vacuum tubes;

- PET bottles;

- beer cans;

- refrigerator radiator;

- copper tubes;

- HDPE and PVC pipes.

Judging by the diagrams, modern “Kulibins” prefer homemade systems with natural circulation, thermosiphon type. The peculiarity of the solution is that the storage tank is located at the top point of the hot water supply system. Water circulates through the system by gravity and is supplied to the consumer.

Installation

Since the equipment is powered by solar energy, the heater will be installed outdoors.

Installation is recommended to be carried out on the roofs of buildings, on balconies or other architectural protrusions. The water heater screen should be directed south. The installation is carried out at a certain angle to the horizon, which is equivalent to the geographic latitude of the area.

The water heater constantly absorbs energy and for obvious reasons the energy source cannot be turned off, therefore, in the case of low water consumption, the stagnation temperature can reach up to 300°C.

For this reason, the use of plastic and steel pipes with zinc coating is not allowed. Pipelines made of copper or stainless steel will be optimal for operation.

The hot circuit of a solar water heater must be insulated to avoid burns and fires. The operating temperature of the equipment should be taken into account when choosing thermal insulation and fasteners.

Manufacturers of solar water heaters indicate the exact stagnation temperature on the body of their products. The collector panels should be located in an open space so that there is open access to sunlight. It is necessary to exclude the presence of possible obstacles.

Most often, the angle of inclination of the collector will be the slope of the roof slope. In order to bring the water heater operating efficiency closer to maximum, it is better to follow the recommendations and use a special rack on which the collector will be mounted.

Those. The key to proper and efficient operation of the equipment are just a few rules:

- direction south;

- correct angle of inclination;

- unhindered access to sunlight;

Incorrect installation will reduce the quality of the water heater, and the investment will not be justified. The type of heater can also play a role in how it is installed. During installation, take into account the type of equipment used.

Passive

It implies the absorption and accumulation of energy that occurs naturally. Solar energy enters the heating object without controlling this process, i.e. There are no mechanisms or control elements. This is a simple system that does not require any special costs. However, the disadvantages are that the water heater operates unevenly and not at full capacity.

The most obvious example is a darkened tank, which is located above the outdoor shower. Single-circuit systems that use the natural circulation process operate in this passive mode. For full operation of the system, the receiving tank is placed above the collector, but this installation method is not always convenient. The issue can be resolved using another way of operating the system.

Active

Free from the disadvantages of a passive system. Its operation is based on the fact that the sun's rays, thanks to special devices, are converted into thermal energy, which is systematically transferred to the heating tank and the consumer. The operation of such a heater is achieved thanks to forced circulation, which can be maintained in single- and double-circuit systems. Also used and additionally installed are motors that rotate panels and pumps, measuring equipment, as well as devices for monitoring and controlling the operation of the system.

Polycarbonate manifold

They are made from honeycomb panels with good thermal insulation properties. Sheet thickness from 4 to 30 mm. The choice of polycarbonate thickness depends on the required heat transfer. The thicker the sheet and the cells in it, the more water the installation can heat.

To make a solar system yourself, in particular a homemade solar water heater made of polycarbonate, you will need the following materials:

- two threaded rods;

- propylene corners, the fittings must have an external threaded connection;

- PVC plastic pipes: 2 pcs, length 1.5 m, diameter 32;

- 2 plugs.

The pipes are laid parallel to the housing. Connect to the hot water supply via shut-off valves. A thin cut is made along the pipe into which a sheet of polycarbonate can be inserted. Thanks to the thermosiphon principle, water will independently flow into the grooves (cells) of the sheet, heat up and go into the storage tank located at the top of the entire heating system. To seal and fix the sheets inserted into the pipe, thermally resistant silicone is used.

To increase the thermal efficiency of a cellular polycarbonate collector, the sheet is coated with any selective paint. Heating of water after applying selective coating accelerates approximately twice.

Solar collector made from a hose or flexible pipe

Those who have a private house with a garden or a dacha, of course, know that the water remaining in the temporary light mains after watering the beds quickly heats up. This positive quality of hoses or flexible pipes was used by craftsmen to create solar heat exchangers from them. It should be noted that such a collector will cost many times less than one bought in a store, but for the manufacturing process to be successful, some effort must be made.

Such a manifold may consist of one or several sections into which hoses tightly coiled in a spiral “snail” are laid and secured.

This design can be called the simplest, both in design and installation. Its main disadvantage is that it practically cannot be used without the use of forced circulation, since if the pipe contours are too long, the hydraulic resistance will exceed the pressure force created by the temperature difference. However, solving the issue of installing a circulation pump is not at all difficult. And such a system installed in a country house will be an excellent help and will quickly pay for itself, including the costs (very insignificant) for powering the pump.

Similar collectors are also used to heat water in swimming pools. They are connected to a filtration system, which is necessarily equipped with a pump. Water, circulating through the collector pipes, has time to heat up before entering the pool.

In some cases, when creating an entire solar battery system, you can do without installing a storage tank. This is possible when hot water is used only during the day and in small quantities. For example, a circuit of 150 m of pipe having an internal diameter of 16 mm holds 30 liters of water. And if five or six such “snails” from pipes are collected into a single battery, then during the day each family member can take a shower several times, and there will still be a lot of hot water left for household needs.

Materials for production

To make such a solar water collector, you need to prepare some materials. It is not at all impossible that some of them will be found in a barn or garage.

A rubber hose or a flexible black plastic pipe with a diameter of 20 ÷ 25 mm is essentially the main element of the system in which heat exchange will occur during water circulation. The amount of hose will depend on the size of the solar panel - it can be 100 or 1000 meters. The black color of the hose is preferable because it absorbs heat more than all other shades.

It should be noted right away that metal-plastic pipes are not particularly suitable for making a collector, even if they are coated with black paint. The fact is that their plasticity in this case is insufficient - they break when bending a small radius and thus, even if the integrity of the walls is not violated, the intensity of the water flow will decrease.

Hoses are sold in coils of 50, 100 or 200 meters. If you plan to make a large-volume battery, you will have to purchase several bays. If you plan to use, for example, 50 or 100 m of hose in each section, then you should not buy a whole 200-meter coil, it is better to purchase a ready-made measured hose. This will help save time during installation.

The hose can be laid not only in a round spiral, but also oval, and also in the form of a coil.

As a good alternative, you can try modern PEX cross-linked polyethylene pipes. They have good plasticity, but it’s not hard to figure out how to give them black color if it’s not on sale.

- If the slope of the roof on which the collector battery will be installed is steep, then special boxes are made from bars, plywood or metal sheets for the hose spirals. To do this, you will need bars 40×40 or 40×50 mm, plywood 6 mm thick, or a metal sheet 1.5–2 mm thick. The blanks of the future module are treated with an antiseptic (wood) or anti-corrosion compounds (metal). Then a box is assembled from them into one or more spirals. By the way, you can use old window frames as the sides of the box, onto which the bottom part is simply mounted.

- For pre-treatment of metal and wood, it is necessary to purchase antiseptic, anti-corrosion and primer compounds.

- Hoses (pipes) will experience considerable loads both from the mass of the coolant and from temperature changes and internal pressure. Therefore, they will try to disrupt the installation, deform, and sag, so it is necessary to provide special fastenings to maintain them in the initially specified position.

This can be a metal strip that is secured between the pipes with self-tapping screws.

Another option is a loose bundle with a tight cord or a plastic clamp-“tie” with a cross or crossbar. But still, this fastening method is more suitable for a plastic pipe than for a hose, since it can sag on the cord when the rubber expands. If a reinforced rubber hose is chosen for the collector, then this method is quite suitable for fixation.

Another fastening option suitable for a plastic pipe or reinforced hose can be nails with wide heads. They can be driven either into the bottom of the box (in this case it must have a thickness of at least 10 mm), or onto a kind of cross made of a block.

- It will also be necessary to prepare connecting elements for the hose or pipes. There are quite a lot of varieties of such fittings, but you need to choose exactly those that are designed for the material chosen for the manufacture of the manifold. In addition to such connectors, threaded fittings will be required to transition from a plastic or rubber pipe to a common metal one. Such a connection will be necessary if the collector consists of several modules. To know how many connecting elements are required, you need to draw in advance a schematic diagram of the system being created and calculate their number on it.

- To combine all modules into a single battery, you will need two collectors - a piece of metal pipe. Through one of them, fixed at the bottom of the battery, cold water will flow into the heat exchangers, and in the second, fixed at the top, warmed water will be collected.

The upper pipe will connect to the storage tank, that is, go to the consumer. It should have a diameter of 40 ÷ 50 mm.

Battery installation

Having prepared everything you need, you can start working.

- First you need to treat all wooden parts of the future structure with an antiseptic.

- Next, if the bottom of the modules is made of metal sheet, it must be coated with an anti-corrosion compound. Typically, mastic designed to cover the undersides of cars is used for this.

- After the compositions have dried on the prepared elements, single or common modules are assembled from them.

- Then the hoses are laid in them, for which the holders are secured.

- To allow pipes to pass freely through the sides of the modules, holes are drilled for them - in the upper and lower parts. Accordingly, the cold water inlet pipe is led into the lower hole, and the heated water outlet into the upper hole.

- If several modules are mounted vertically, or one common one, into which several pipe “snails” are also placed, one above the other, then the lower end of each of the spirals is connected to the upper outlet of the underlying one - and according to this sequential principle, the entire “column” is switched. The lowest end is connected to a common metal collector through which cold water will flow. All adjacent vertical rows are mounted in the same way - with a common connection to the supply manifold.

- Accordingly, the upper ends of the hoses of the uppermost horizontal row of modules are connected to a metal collector pipe through which hot water is discharged for consumption.

- The spiral-shaped collector circuit can also be mounted on a metal sheet installed not on the roof, but near the house, on its southern side, or near the pool, if it requires heating. In this case, the metal base will contribute to faster heating of water and heat retention in the pipes, since it has good thermal conductivity and heat capacity.

- Another option for a thermal solar collector can be laying the circuit on the roof plane in special boxes in long parallel rows along the entire length of the roof.

Collector Stanilova

Engineer Stanislav Stanilov presented the world with the most versatile solar collector design. The main idea of using the device he developed is to obtain thermal energy by creating a greenhouse effect inside the collector.

Collector design

The design of this collector is very simple. Essentially, this is a solar collector made of steel pipes welded into a radiator, which is placed in a wooden container protected by thermal insulation. Mineral wool, polystyrene foam, and polystyrene can be used as thermal insulation materials.

A galvanized metal sheet is placed at the bottom of the box, on which the radiator is mounted. Both the sheet and the radiator are painted black, and the box itself is covered with white paint. Of course, the container is covered with a glass lid, which is well sealed.

Materials and parts for manufacturing

To build such a homemade solar collector for heating a house you will need:

- glass that will serve as a lid. Its size will depend on the dimensions of the box. For good efficiency, it is better to select glass measuring 1700 mm by 700 mm;

- glass frame - you can weld it yourself from corners or put together from wooden planks;

- board for the box. Here you can use any boards, even from dismantling old furniture or plank floors;

- rental corner;

- coupling;

- pipes for radiator assembly;

- clamps for attaching the radiator;

- galvanized iron sheet;

- radiator inlet and outlet pipes;

- tank with a volume of 200−300 liters;

- aqua chamber;

- thermal insulation (sheets of polystyrene foam, expanded polystyrene, mineral wool, ecowool).

Stages of work

Stages of making a Stanilov collector with your own hands:

- A container is made from boards, the bottom of which is reinforced with beams.

- A heat insulator is placed at the bottom. The base must be especially carefully insulated to avoid heat leakage from the heat exchanger.

- Afterwards, a galvanized plate is placed at the bottom of the box and a radiator is installed, which is welded from pipes, and secured with steel clamps.

- The radiator and the sheet underneath are painted black, and the box is painted white or silver.

- The water tank should be installed under the collector in a warm room. Between the water tank and the collector you need to install thermal insulation to keep the pipes warm. The tank can be placed in a large barrel into which expanded clay, sand, sawdust, etc. can be poured. and thus insulate.

- An aqua chamber must be installed above the tank to create pressure in the network.

- Do-it-yourself solar collector installation should be done on the south side of the roof.

- After all the elements of the system are ready and installed, you need to connect them into a network with half-inch pipes, which must be well insulated in order to reduce heat loss.

- It would be a good idea to build a controller for the solar collector with your own hands, since factory devices do not last long.

Structural drawings

Let's get started

Before building a solar collector, it is necessary to make the appropriate calculations and determine how much energy it should produce. But you shouldn’t expect high efficiency from a homemade installation. Having determined that there will be enough of it, you can begin.

The work can be divided into several main stages:

- Make a box

- Make a radiator or heat exchanger

- Make a front camera and storage device

- Assemble the collector

To make a box for a solar collector with your own hands, you should prepare an edged board 25-35 mm thick and 100-130 mm wide. Its bottom should be made of textolite, equipped with ribs. It should also be well insulated using polystyrene foam (but preference is given to mineral wool), covered with a galvanized sheet.

4 more effective ways to alternatively heat your home

Which you can learn about in our next article.

Having prepared the box, it’s time to make the heat exchanger. You should follow the instructions:

- It is necessary to prepare 15 thin-walled metal tubes 160 cm long and two inch pipes 70 cm long

- In both thickened tubes, holes are drilled with the diameter of the smaller tubes into which they will be installed. In this case, you need to ensure that they are coaxial on one side, the maximum step between them is 4.5 cm

- The next stage is that all the tubes need to be assembled into a single structure and welded securely

- The heat exchanger is mounted on a galvanized sheet (previously attached to the box) and fixed with steel clamps (metal clamps can be made)

- It is recommended to paint the bottom of the box in a dark color (for example, black) - it will better absorb solar heat, but to reduce heat loss, the external elements are painted white

- To complete the installation of the collector, it is necessary to install a cover glass near the walls, while not forgetting about reliable sealing of the joints

- A distance of 10-12 mm is left between the tubes and the glass

All that remains is to build a storage tank for the solar collector. Its role can be played by a sealed container, the volume of which varies about 150-400 l

. If you cannot find one such barrel, you can weld several small ones together.

Like the collector, the storage tank is thoroughly insulated from heat loss. All that remains is to make a fore-chamber - a small vessel with a volume of 35-40 liters. It must be equipped with a water-falling device (a swivel valve).

The most responsible and important stage remains - to assemble the collector together. You can do it this way:

- First you need to install the front camera and storage. It is necessary to ensure that the liquid level in the latter is 0.8 m lower than in the front chamber. Since a lot of water can accumulate in such devices, it is necessary to think about how they will be reliably shut off

- The collector is placed on the roof of the house. Based on practice, it is recommended to do this on the south side, tilting the installation at an angle of 35-40 degrees to the horizontal

- But you need to take into account that the distance between the storage tank and the heat exchanger should not exceed 0.5-0.7 m, otherwise the losses will be too significant

- At the end, the following sequence should be obtained: the front camera must be located above the drive, the latter - above the collector

The most important stage is coming - it is necessary to connect all the components together and connect the water supply network to the finished system. To do this, you will need to visit a plumbing store and purchase the necessary fittings, adapters, sockets and other shut-off valves. It is recommended to connect high-pressure sections with a pipe with a diameter of 0.5 inches, low-pressure sections with a diameter of 1 inch.

Commissioning is carried out as follows:

- The unit is filled with water through the bottom drainage hole

- The anterior chamber is connected and the fluid levels are adjusted

- It is necessary to walk along the system and check that there are no leaks

- Everything is ready for everyday use

Collectors from scrap materials

Assembling a solar collector for heating a house with your own hands is both cheaper and more interesting, because it can be made from various available materials.

From cans

The coolant of a solar collector made from aluminum cans is air. The cans are connected to each other to form a pipe. To make a solar collector from beer cans, you need to cut off the bottom and top of each can, dock them together and glue them with sealant. The finished pipes are placed in a wooden box and covered with glass.

Basically, an air solar collector made from beer cans is used to eliminate dampness in the basement or to heat a greenhouse. Not only beer cans, but also plastic bottles can be used as a heat storage device.

From the refrigerator

You can make your own solar water heating panels from an unusable refrigerator or the radiator of an old car. The condenser removed from the refrigerator must be rinsed thoroughly. Hot water obtained in this way is best used only for technical purposes.

Foil and a rubber mat are spread on the bottom of the box, then the capacitor is placed on them and secured. To do this, you can use belts, clamps, or the fastening with which it was attached in the refrigerator. To create pressure in the system, it would not hurt to install a pump or aqua chamber above the tank.

From plastic and metal-plastic pipes

How to make a solar collector with your own hands, having plastic pipes in your home arsenal? They are less effective as a heat storage device, but are several times cheaper than copper and do not corrode like steel.

The pipes are laid out in a box in a spiral and secured with clamps. They can be coated with black or selective paint for greater effectiveness.

You can experiment with pipe laying. Since pipes bend poorly, they can be laid not only in a spiral, but also in a zigzag. Among the advantages, plastic pipes can be easily and quickly soldered.

From metal pipes

This assembly option is similar to the Stanilov manifold. When assembling a solar collector from copper pipes with your own hands, a radiator is welded from the pipes and placed in a wooden box lined with thermal insulation from the inside.

Copper pipes will be the most effective; aluminum pipes can also be used, but they are difficult to weld, but steel pipes are the most successful option.

Such a homemade collector should not be too large so that it is easy to assemble and install. The diameter of the pipes on solar collectors for radiator welding should be smaller than that of the pipes for coolant input and output.

How to connect a solar collector to a tank (shower) by gravity

The weak point for summer solar collectors remains the need to use a pump. This dramatically increases the cost of the design or makes it completely unacceptable.

But you can make a heating tank connected to the solar collector so that the liquid moves by gravity. The principle of gravity flow is preserved - the heater is located lower than the storage tank (radiator).

According to this scheme, when using pipes from ¾ inches, water should move by gravity. The heated water from this tank can be drained into the pool.

How to connect the collector to the hot water supply

The best monetary benefit comes from the manufacture and operation of a collector made of aluminum or copper tubes on metal under glass, connecting it to the hot water supply system.

Since the collector and spiral in the boiler are a small-sized heated system, it must be equipped with an expansion tank and a safety valve. Circulation is carried out using a low-power pump. A good collector will provide the house with hot water even in the off-season...