Having realized the dream of purchasing a country house, many buyers are faced with difficulties in choosing a suitable boiler for heating the building. How much power is enough to maintain a comfortable temperature level? What type of boiler will satisfy the buyer's needs? The purchase is important, so when choosing a gas boiler, you should carefully study all its characteristics.

What characteristics exist

First of all, gas boilers differ from each other in their circuit design. It is possible to install a boiler with one or two circuits. In this case, the main circuit provides temperature control in the building, and the second circuit maintains hot water supply (DHW). Accordingly, if the house has a boiler for heating water using other energy sources, then the need for a second circuit remains at the discretion of the buyer, because this will allow saving on water heating during the heating season.

It is also worth considering such characteristics as the type of chimney for exhaust gas removal and the installation method (wall-mounted or floor-mounted), since these parameters depend on the need to place the boiler in a separate room, observing fire safety rules. Another problem is that most of the heat is removed through the chimney into the atmosphere along with the spent fuel. This is inevitable, but efficiency can be increased by installing a coaxial chimney and a boiler with a closed combustion chamber.

The main defining characteristic of a boiler is its heating power, measured in Watts. The larger the area of the building that needs to be heated, the more power will be required. It is worth considering that over time, the efficiency of the boiler decreases if its maintenance is neglected - cleaning the combustion chamber and heat exchangers will get rid of carbon deposits and condensate, thereby increasing the quality of heating.

In addition, it is worth considering the many additional features provided by the manufacturers of such heating systems. Temperature control using a remote control or even a smartphone program, protection against temperature changes or automated indoor climate control - this is not a complete list of functions of modern boilers that may be of interest to the buyer.

Steam boilers. Technical characteristics of steam boilers

Our organization provides a full range of services for operational, commissioning and environmental-thermal testing of steam boilers of any type and volume

Steam boilers. Technical characteristics of steam boilers

A steam boiler is a device designed to produce steam at a pressure higher than atmospheric pressure due to the heat generated by burning fuel. The main elements of the boiler are the firebox and heat exchange surfaces.

Water is supplied to the boiler, which is called feed water. The feedwater in the boiler is heated and then converted into saturated or superheated steam of the required parameters. Steam parameters mean its pressure and temperature. The main consumer of water steam generated in boiler plants is steam power plants, and it can also be used for technological needs.

Steam boilers. Technical characteristics of steam boilers

Operating principle of steam boilers

The conversion of feedwater into steam occurs in the heating surfaces of the boiler. Boiler heating surfaces include evaporative, superheating and economizer surfaces.

Evaporative heating surfaces are usually located in or directly behind the boiler firebox. In them, water is heated to saturation temperature and a so-called steam-water mixture is formed.

Superheaters are designed to produce superheated steam. They are located behind the combustion chamber.

Economizer heating surfaces are designed to preheat feedwater using the heat of combustion products leaving the boiler.

Basic elements of the boiler

- drums - designed to separate saturated steam from water, remove excess moisture from it, and also as a device in which the amount of water necessary for reliable operation of the boiler is accumulated;

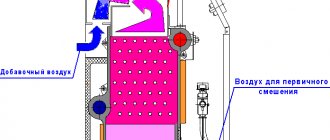

- air heaters - heating surfaces in which the air entering the firebox and necessary for burning fuel is preheated;

- burner devices - devices for burning fuel in the boiler furnace. The burner devices of modern boilers primarily ensure the most efficient combustion of fuel from the point of view of chemical processes and a reduction in the amount of harmful substances formed during the combustion process and emitted into the atmosphere.

- devices for regulating the superheating temperature of steam - heat exchangers of various types and injection desuperheaters.

Steam boilers. Technical characteristics of steam boilers

Classification of steam boilers

Steam boilers are divided according to their purpose into three main types: energy, industrial and waste heat boilers.

Industrial steam boilers, unlike power boilers, produce saturated steam, which has the boiling point of water.

Waste heat boilers can produce both steam and hot water.

Steam boilers according to their parameters are divided into:

- low steam output – up to 1 t/h of steam;

- average steam output - from 1 t/h to 10 t/h steam;

- high steam output - over 10 t/h of steam .

Our contacts

The specialists of our organization will perform installation, adjustment, maintenance, and verification of gas-using equipment of any type and volume in the city of Dnepr and the Dnepropetrovsk region.

To carry out the work, we have all the relevant documents issued by government bodies, as well as laboratories certified by government control bodies.

+380 63-852-66-89 +380 96-669-11-03

Feedback form. (Ask a question, leave your contact details, send a message – and we will contact you as soon as possible.)

Floor and wall boilers. Differences

To choose a boiler installation method, you should familiarize yourself with the general requirements for the placement of the heating system. So, the boiler room must be a separate room with an area required by fire safety standards, the walls of which must be made of fire-resistant materials. An exhaust gas removal system is required, and the possibility of their accumulation in the room must be completely excluded. Based on these requirements, the buyer must provide appropriate premises or build an extension outside the residential building. For heating a small building, it would be optimal to purchase a wall-mounted boiler, which is easier to install and the requirements for it are not so significant. The height of the placement is at least 80 centimeters from the floor, and the space around it must be completely free. If wall installation is excluded for some reason or the required heating power is simply impossible given the dimensions of wall-mounted boilers, then a floor-mounted method of installing the heat source is assumed. In this case, the boiler must be placed on a concrete or metal slab that creates sides of at least 50 centimeters around the boiler.

Characteristics of wall-mounted boilers

Wall-mounted boilers are a ready-made heating system that is easy to install, takes up minimal space and is much easier to maintain than floor-mounted ones. Modern models assume control using a remote control to set temperatures and control additional capabilities (for example, protection against freezing of heat exchangers when the boiler is turned off). This is the best choice for heating an apartment or small house, and manufacturers take into account their location in the living space and try to give them an attractive design. But it is worth considering that such heating systems are very susceptible to changes in the power supply. This leads to their complete shutdown or switching to minimum heating mode, which entails damage to the heat exchangers (for example, the occurrence of condensation due to a sudden change in temperature). So, if the power lines in the building are unstable, it is worth taking care of an uninterruptible power supply.

The main characteristics that you should pay attention to when buying a wall-mounted gas boiler:

- Power. Here you can select without stock. If the heat loss of the house is 20 kW, then the boiler can be selected with the same power. If you purchase a boiler of higher power, then this is also not a big deal.

- Functions. Wall-mounted boilers are essentially all the same, plus or minus. They differ only slightly in the internals. So perhaps you might be intrigued by certain features of certain brands.

- Economical. Here, too, all boilers have the same efficiency, plus or minus.

- Noisy. If you install the boiler in a residential area, pay attention to the noise level of the boiler.

- Type of heat exchanger. Basically, all heat exchangers are copper. But some people use aluminum ones. They are slightly worse in performance.

- What are the internal parts made of? Budget models are made of plastic, more expensive ones are made of brass. Plastic is made naturally from the point of view of reducing the cost, but at the same time scale does not form on it.

Characteristics of floor-standing boilers

In the case of heating a large building (more than 300 square meters), it will no longer be possible to get by with a wall-mounted boiler and purchasing a floor-standing boiler becomes a necessity. Its installation is complex and quite costly, and incorrect installation can lead to problems in the form of dampness and insufficient heating due to loss of efficiency. But such boilers have significant advantages, not to mention greater heating power. This is significant design flexibility - the buyer can independently design a heating system based on the building layout and various needs. A tangible advantage will be independence from the stability of power lines. It would not be amiss to mention the durability of such heating systems and the possibility of freely replacing failed components, which significantly extends the overall service life (for example, heat exchangers of proper quality can last for several decades).

The main characteristics of floor-standing boilers that you should pay attention to when purchasing:

- Dimensions. Floor standing units have quite a wide range of sizes. Choose what suits you.

- Chimney requirements. Some boiler models may have greater requirements for the chimney.

- Efficiency If the efficiency of wall-mounted ones is similar, then the spread is a little larger. But it’s rare that a manufacturer writes an honest efficiency rating about their boiler. Pay attention to the recommendations of those who already use the same boiler.

- Heat exchanger type. Cast iron or steel.

- Energy dependence. Advanced floor-standing boilers have advanced automation powered by electricity.

- Power . A reserve is usually put in here, since the power of boilers decreases in cold weather.

TOP 5 double-circuit gas boilers

Double-circuit boilers are considered the most preferred option among users.

This is true, although for families with a high need for hot water it is better to use single-circuit models with an external storage tank. Double-circuit units are convenient for small families or for use in public buildings. Popular models:

Vaillant turboTEC pro VUW 242/5-3 24 kW

German boiler from one of the most reliable manufacturers. It has a power of 24 kW, allowing you to heat rooms up to 240 sq.m. with simultaneous supply of hot water.

Unit parameters:

- installation type: wall-mounted;

- power consumption - 220 V 50 Hz;

- heat exchanger type - separate (primary copper and stainless secondary);

- Efficiency - 91%;

- gas consumption - 2.8 m3/hour;

- dimensions - 440x800x338 mm;

- weight - 40 kg.

Advantages:

- fully provides housing with heat and hot water;

- reliable stable operation;

- developed network of service centers.

Flaws:

- needs power supply stabilization;

- high price for boilers and spare parts.

Vaillant units are considered the most stable and reliable in operation. This is confirmed by ordinary users and service specialists.

Buderus Logamax U072-12K 12 kW

Gas boiler made in Germany . It belongs to the elite examples of European heating technology. The power is 12 kW, allowing you to heat 120 sq.m.

Characteristics:

- installation type: wall-mounted;

- power consumption - 220 V 50 Hz;

- Efficiency - 92%;

- heat exchanger type - separate (primary copper, secondary stainless);

- gas consumption - 2.1 m3/hour;

- dimensions - 400x700x299 mm;

- weight - 29 kg.

Advantages:

- stable and reliable operation;

- no noise;

- Ease of Management.

Flaws:

- high price;

- the need to use a power supply stabilizer and a water filter.

If you do not immediately install the filter units and stabilizer during installation and first start-up, you can quickly damage the unit and incur unnecessary costs for repairs and restoration of the boiler.

Bosch Gaz 6000 W WBN 6000- 12 C 12 kW

Gas double-circuit convection boiler with electronic control. Designed for rooms up to 120 sq.m., since its power is 12 kW.

Characteristics:

- installation type: wall-mounted;

- power consumption - 220 V 50 Hz;

- Efficiency - 93.2%;

- heat exchanger type - separate (primary copper, secondary stainless);

- gas consumption - 2.1 m3/hour;

- dimensions - 400x700x299 mm;

- weight - 28 kg.

Advantages:

- reliability, stability;

- no noise;

- low gas consumption.

Flaws:

- high cost of spare parts and repair work;

- demands on the quality of water and power supply.

Bosch products are known all over the world and need no introduction . The quality and reliability of heating equipment are considered benchmarks and serve as an example for other manufacturers.

BAXI LUNA-3 240 Fi 25 kW

Italian double-circuit convection boiler. With a power of 25 kW it is capable of heating an area of up to 250 sq.m.

Options:

- installation type: wall-mounted;

- power consumption - 220 V 50 Hz;

- Efficiency - 92.9%;

- heat exchanger type - separate (copper-stainless steel);

- gas consumption - 2.84 m3/hour;

- dimensions - 450x763x345 mm;

- weight - 38 kg.

Advantages:

- reliability;

- high performance;

- high-quality components and parts of the unit.

Flaws:

- high cost;

- The boiler dimensions are too large for a wall-mounted model.

Italian boilers are famous for their quality and reliability. However, to work in Russian conditions it is necessary to use additional equipment - a stabilizer and filter units.

Navien DELUXE 16K 16 kW

Korean boiler, characterized by relatively low cost and high quality. With a power of 16 kW, it is capable of heating 160 sq.m. area.

Boiler characteristics:

- installation type: wall-mounted;

- power consumption - 220 V 50 Hz;

- Efficiency - 91.2%;

- heat exchanger type - separate (both units are made of stainless steel);

- gas consumption - 1.72 m3/hour;

- dimensions - 440x695x265 mm;

- weight - 28 kg.

Advantages:

- reliability, high build quality;

- relatively low price;

- adapted to Russian conditions.

Flaws:

- high noise level (relative);

- Some parts are made of unreliable plastic.

South Korean boilers belong to the budget segment of heating technology. However, their quality is not inferior to their European counterparts, and the price is noticeably lower.

Boiler power. How to choose it?

The heating power of the boiler is calculated based on the area of the heated building. The generally accepted figure is 1 kW per 10 square meters. This takes into account the power required directly for heating, with compensation for lost efficiency (efficiency factor) due to room ventilation, as well as taking into account a small power reserve. Thus, we can calculate that if the ceiling height is about three meters, then 10 square meters will require 0.6 kW of heat, which with an increase of 30% to compensate for efficiency losses from building ventilation and with a reserve of up to 30% of power will give us the same figure of 1 kW per 10 square meters. Too large a reserve of boiler power is also not desirable in order to save both on resource costs and on the cost of the boiler itself. Accordingly, an area of 200 square meters will require a heating system with a capacity of 20 kW. At the same time, it is worth taking into account the energy efficiency of the room - window area, insulation of walls and floors, as this significantly increases energy costs to create a comfortable temperature in the room.

TOP 5 gas boilers made in Russia

Russian gas boilers did not stand out too much among similar products in the budget segment. However, recently there has been a clear increase in the quality and capabilities of Russian heating engineering.

Successful and reliable designs have appeared, characterized by stable and durable operation . A separate advantage should be considered the low cost and availability of spare parts, which increases the demand for units. Several popular models:

Lemax Patriot-10 10 kW

The unit is of relatively low power, suitable for an apartment or cottage. It is capable of developing 10 kW, which allows heating 100 sq.m.

Unit parameters:

- boiler type - parapet;

- functionality - single-circuit;

- Efficiency - 90%;

- power - 10 kW;

- dimensions - 595x740x360 mm;

- weight - 50 kg.

Advantages:

- energy independence;

- reliability, stable operation without failures;

- low cost of the boiler and spare parts.

Flaws:

- difficulty of ignition;

- it is impossible to monitor the condition of components and parts without stopping the system and disassembling the boiler.

Low-power boilers work well in apartments or country houses, where they have optimal operating conditions.

Lemax Premium-30N 30 kW

Floor-standing non-volatile gas boiler with a power of 30 kW. Designed to heat an area of 300 sq.m.

Its parameters:

- boiler type - convection;

- functionality - single-circuit;

- Efficiency - 90%;

- power - 30 kW;

- dimensions - 470x961x556 mm;

- weight - 83 kg.

Advantages:

- high power;

- ease of setup and adjustment;

- For such power the cost is very low.

Flaws:

- high fuel consumption;

- large weight and size.

High-power boilers can be connected in a cascade, forming complexes for heating large areas.

Lemax Premium-12.5N 12.5 kW

Gas floor-mounted, non-volatile boiler for heating small houses or apartments. Designed to work in rooms up to 125 sq.m.

Unit characteristics:

- boiler type - convection;

- functionality - single-circuit;

- Efficiency - 90%;

- power - 12.5 kW;

- dimensions - 416x744x491 mm;

- weight - 60 kg.

Advantages:

- profitability, operational efficiency;

- it is possible to install a forced-air burner and an external turbofan to enhance traction;

- relatively low price.

Flaws:

- it is inconvenient to light the burner;

- you have to frequently clean the open combustion chamber.

Some users consider Russian boilers to be too simple and primitive. This belief changes after the first breakdown, when the cost of repairing an imported boiler forces you to look at domestic analogues with different eyes.

ZhMZ AOGV-17.4-3 Comfort N

Non-volatile convection gas boiler designed for heating rooms up to 140 sq.m.:

- boiler type - convection;

- functionality - single-circuit;

- Efficiency - 88%;

- power - 17 kW;

- dimensions - 420x1050x480 mm;

- weight - 49 kg.

Advantages:

- reliable and stable operation;

- good set of parameters;

- independence from connection to the power supply network.

Flaws:

- needs a separate room with a chimney.

Boilers from the Zhukovsky plant are known for their reliability and simplicity of design. They are in wide demand among buyers.

Lemax PRIME-V20 20 kW

Compact boiler for heating rooms up to 200 sq.m. and hot water supply.

Options:

- boiler type - convection;

- functionality - dual-circuit;

- Efficiency - 92.5%;

- power - 20 kW;

- dimensions - 430x770x268 mm;

- weight - 29 kg.

Advantages:

- optimal set of qualities;

- low price;

- simplicity and reliability of design.

Flaws:

- A voltage stabilizer is needed, since the boiler is volatile.

Domestic units seem inconvenient and difficult to use to many. However, these shortcomings are more than compensated for by the reliability and efficiency of the boilers.

Types of heat exchangers: copper, steel, cast iron

The heat exchanger is also a very important characteristic when purchasing. After all, it directly determines the reliability, convenience and energy efficiency of the heating system. Thus, copper heat exchangers, due to their lighter weight and better heat conductivity, have smaller dimensions and are installed on the wall, while cast iron, as the heaviest, offer only floor installation. But copper tolerates any mechanical stress much worse than cast iron, since this metal is very easy to damage. Cast iron boilers are generally recognized as more durable (the service life can exceed half a century), but when the heating temperature drops below 60 degrees, cast iron can produce condensation, which will cause erosion and cracks may even appear on the heat exchanger. Copper heat exchangers do not suffer from temperature changes and are easier to install, so they are often suitable for heating small rooms.

In addition, gas boilers with steel heat exchangers stand out on the market, which in some way occupy a position between heat exchangers made of copper and cast iron. They are even stronger than cast iron, which facilitates the maintenance process before the heating season and at its end, including removing condensate, carbon deposits, as well as checking the integrity of pipes and the tightness of joints, during which the heat exchanger, given its dimensions and weight, can be easily damaged. But at the same time, they are more at risk of failure due to temperature changes, since steel is subject to extremely rapid corrosion with increased moisture condensation. In turn, steel heat exchangers offer a wider range of models, offering different energy efficiency and mounting methods. They come in three types: bithermic (in which heat exchange occurs in a dual way), monometric (directly from gas to liquid), secondary/plate (heat is transferred from the coolant liquid to the hot water liquid). Copper heat exchangers are more popular, as they are more suitable for the needs of small mansions. But they are used mainly in wall-mounted boilers.

Heating electric boilers

In boilers of this type, tubular heating elements (heating elements) are used to heat the coolant. Essentially, these are electrical conductors with very high resistance. Electric current flowing through the element causes its heating, which is transferred to the coolant.

The heating element itself is surrounded by dielectric material and placed in a metal tube of various shapes. The connection contacts are located at the ends of the tube. The tube itself (heating element body) is electrically safe.

At the household level, heating elements are well known from old electric kettles and portable water heaters.

The disadvantage of this type of boiler is the same disadvantage as in a kettle - the formation of lime on the surface of the heating element and the walls of the boiler. This lime formation occurs when using so-called hard water. Therefore, when servicing the boiler, an element of cleaning lime deposits is introduced by adding various additives to the coolant. Or before use, water is artificially brought to a normal hardness level of 7–10 mEq. per liter

The main ways to soften water are pre-boiling, distillation or the use of special filters. This also needs to be taken into account before purchasing an electric heating element type boiler.

Another problem with the boiler heating element may be a coolant leak. A heating element that is not immersed in water overheats and, as a result, burns out, which in turn leads to a fire. Therefore, there is no need to skimp on boiler automation and pay special attention to its automation.

What does a boiler heat exchanger consist of?

The most popular materials for the manufacture of such an obviously important functional part of a solid fuel boiler as a heat exchanger are two - cast iron and steel. It is these devices that should be discussed in more detail:

- Cast iron units are characterized by high performance if they run on coal fuel, since the use of firewood can negatively affect the power of the equipment. The main advantages of products made of cast iron are their affordable price, the versatility of the fuel used for operation, as well as the ability to repair them quickly and without problems for the entire system. However, this technique also has disadvantages, the main of which are a small efficiency coefficient (about 65 - 75%), the need for regular cleaning of the heat exchanger, as well as high inertia rates.

- In steel mechanisms, the main fuel is firewood or briquettes created by processing wood waste (pro

Induction boilers

There are interesting parallels between household appliances in the kitchen and types of electric boilers. More recently, induction electric stoves appeared and induction boilers appeared almost simultaneously.

Both different devices have the same operating principle - for heating, it is not electric current as such that is used, but electromagnetic induction, which is formed in the coil when current passes through it.

Electromagnetic induction, surrounding another conductor with ferromagnetic properties, causes it to heat up. In a kitchen stove, this ferromagnetic conductor is the dishes; in a heating boiler, it is a pipeline with a circulating coolant.

The disadvantages are still the same:

- Hard water deposits sediment;

- Serious protection against coolant leakage is required.

Design of an induction heating boiler

Let's look at the design of an induction heating boiler using the SAV induction boiler as an example.

This is a single-section induction boiler, cylindrical in appearance, supplied with a control cabinet. It is recommended to supplement the system with: a circulation pump, a safety group, an expansion tank, a flow sensor and a strainer, as well as a thermostat and a thermal overload relay. Can be equipped with a programmer with GSM control.

In the photo we see how simple the induction boiler is.

To complete the first acquaintance, we look at the diagram of its single-phase connection, visual and fundamental.

Induction boilers can consist of several heater sections. Example, vortex boiler “Vikhr”. The design of the induction boiler consists of three sections of the induction heater, each of which consists of:

- induction coil;

- heat exchange metal body;

- with inlet and outlet pipes;

- terminal group in a protective metal box.

The boiler kit includes a control unit in the form of an electrical cabinet with circuit breakers. To protect the boiler from dry running, a flow switch is installed between the circulation pump and the boiler inlet pipe.

What does the market offer?

Below you can watch a video about the variety of types of heating boilers. The selection of boilers is simply incredible in scale. If the user is not a specialist, then it will be very difficult for him not to get lost in the variety of models. But there are a few tips that will help you avoid choosing the wrong boiler:

- If you choose a boiler, you should definitely make sure that it is a branded product. After all, such companies guarantee the quality of their goods.

- Make sure there is a quality certificate.

- Preliminarily evaluate the reviews about a particular boiler model - and it is better if these are reviews from acquaintances and friends.

- Find out if the company that manufactured your new boiler has a service department in your area. After all, in the future you may need maintenance, or even repairs.

The question of choosing equipment, heating in particular, has always been one of the most important. But also difficult. If we consider heating boilers, it is best to do it at a professional level. And if you are going to buy a boiler, be sure to consult with professionals. They will help you make the right choice to avoid problems in the future.