Modern, economical options for heating systems are becoming increasingly common in private homes and apartments. They allow you to provide a comfortable temperature while reducing heating costs.

One of the new products on the market that attracts the close attention of many homeowners is warm baseboards. Users are interested in many questions - from the principle of operation of such a system, to the possibility of using it as the main source of heat and calculating the parameters of the heating circuit.

Types of electric skirting boards

The issue of cost is one of the main ones that worries buyers of electric baseboard convectors not only in Moscow. Their prices largely depend on the type of construction. Today, baseboard convectors are available in two versions:

- Electric. It uses dry heating elements installed in copper tubes. This design provides more efficient and safe heating of the room. To connect such a system, you will have to lay powerful electrical wiring into the room. If necessary, you can achieve a more economical operating mode by additionally installing a thermostat.

- Water. The main working element is the heating boiler. According to the principle of operation, such a system is very similar to a standard scheme with radiators.

Systems of this type can be used as the main heating device.

The water system includes the following elements:

- a radiator made in the form of a box with a heat exchanger located inside it;

- a distribution manifold in which two lines are installed to ensure the supply and return of coolant;

- set of plastic tubes. They are installed in such a way that a part with a smaller diameter is located in a wider one.

Review of manufacturers

Currently, baseboard heaters are produced by a variety of manufacturers. In order not to make a mistake when choosing and to purchase a truly high-quality and durable device, you should first pay attention to products from well-known brands.

- Redmond. The product line of this manufacturer includes all types of warm baseboards. However, according to reviews from owners of heaters of this brand, it is best to choose infrared models.

- "Megador". In the assortment of this brand, infrared baseboard heaters occupy the largest part. During numerous tests, no significant deficiencies were identified.

- Dimplex is another leader in the sale of infrared heaters. The range of this manufacturer includes models for every taste and budget.

- Mr. Tektum - this manufacturer is rightfully considered the leader in sales of warm water and electric skirting boards.

- Best Board - the product line of this brand includes powerful baseboard heating systems that were specially designed for use in difficult conditions.

- "Teplin" is already a domestic manufacturer of electric and water heated baseboards. Buyers note not only the high technical characteristics of the models, but also their attractive decorative appearance.

All of these baseboard heater manufacturers have been on the market for quite some time. That is why their products meet not only all international standards, but also the requirements of even the most sophisticated customers.

Installation of a warm water baseboard system

Warm floors through heating.

Water heated floor as the main heating Installation of an electric heated baseboard is very simple: we fix it on the wall. That's it, the system is ready for use. All that remains is to plug it into the sockets. The main thing is that the cross-section of the wire is correctly calculated and that there are circuit breakers of the correct rating. This is the main problem when using an electric warm baseboard. The water one is much more difficult to install. Everything must be collected into a single system, and this is not easy.

Installation of a heating baseboard: you need to know the nuances

Calculation of baseboard heating

A complete thermotechnical calculation of heating is a long and complex matter.

The size and geometry of the room, the material of the walls, floor, and ceiling are taken into account, and the degree of insulation of all structural elements, including windows and doors, is taken into account. In general, the calculation is not easy at all.

Therefore, most often they take the average figure, which is derived as a result of the analysis of many calculations.

It is believed that to heat one square meter of room area with average insulation, 100 W of thermal energy is needed. That is, to calculate the power of a warm baseboard, you need to multiply the area of the room by 100. Get the required figure. This is exactly how much (or better, about 20-25% more) should be given in total by all the elements of the warm baseboard.

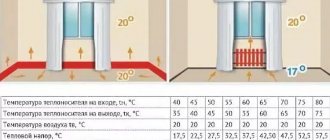

An example of the technical characteristics of the Best Board warm baseboard for different operating modes of the system

For example, the area of a room is 18 square meters. To heat it you will need 1800 W. Next, we look at how much heat is generated by one meter of heating. A water heating baseboard can operate in different modes; depending on the mode, it emits different amounts of heat. The table above shows data for one of the systems. For example, let's take the heat transfer of one meter of warm baseboard from this table (other manufacturers may have significant differences).

For example, the system will operate with a supply temperature of 50°C. Then one linear meter produces 132 W of heat. To heat this room you will need 1800/132 = 13.6 m of warm baseboard. When ordering, it is better to add a margin of 20-25%. This reserve is necessary so that the system does not work at the limit all the time. This time. And also in case of abnormal cold weather. That's two. So, we take 17 meters with a reserve.

Once again, please note: these are average data for some average house. Moreover, even the height of the ceilings is not taken into account. Again, it is taken as average - 2.5 meters. If your insulation is better, you will need less heat; if it is worse than “average,” you will need more. In general, this method provides only approximate calculations.

How to act

The first thing to do is to draw a plan on which to indicate the length of each heating device and the length of the connecting pipes. After all, the length of a warm baseboard is not always equal to the perimeter of the room. In this case, the sections of heating devices are connected to each other by copper or polymer pipes. It is undesirable to use steel ones, since they chemically interact with copper (it gradually collapses).

Preparation for installation occurs long before its actual start. At the very beginning of the repair, even before leveling the floor, pipes are stretched from the boiler or collector unit to the connection point for the warm baseboard. The pipes are laid, tested for integrity, filled with screed under pressure (working pressure in a private house is 2-3 atm, in a multi-storey house you need to find out from the housing office). Then all repair work is carried out and only after the walls and floor are finished, the installation of warm baseboards begins. Here's the order:

- Heat-reflecting tape is attached along the perimeter of the walls.

It prevents heat loss to heat the wall. Thermal insulation tape is attached, and fasteners are placed on top of it - Fastening elements are installed on top of the tape in increments of 50-60 cm. They are fixed to the wall using dowels or self-tapping screws (depending on the wall material).

- According to the plan, sections of the heating baseboard are fixed in the fastening elements and connected to each other with copper or polymer pipes.

We install the pieces and connect them into a single whole - The tightness of the system is checked using pressure testing.

- If everything is normal, pipes from the collector unit or from the boiler are connected, the system is filled with coolant and tested.

This is what it looks like when it's done - After successful tests, decorative covers are installed and the baseboard heating system is ready for operation.

Actually, installing warm baseboards is not too complicated. But the tightness of the connections is important and special attention must be paid to this.

Step by step guide

At the first stage, preparatory work is carried out:

- Preparing the wall surface next to the floor, including dismantling old regular baseboards and gluing this area with special insulating tape.

- At the same time, the power cable outlet locations are planned and marked, taking into account the fact that the power of all wires taken together should not exceed the power of the selected thermostat.

- Next, using a tape measure and a pencil, mark out the same installation level for all the walls of the room.

- Then, placing the back panels of the heating elements at the line level, mark the places for fixing the fasteners.

When the entire perimeter is marked, all the necessary tools and the required number of plinth elements are available, you can proceed to the direct installation stage:

- Using a puncher or drill, holes are made at the marked points into which dowels will be inserted and the plinth strips will be fixed.

- After fixing the profile, the holders of the heating panel are attached at intervals of 40 cm, which should not be in direct contact with either the wall itself or the insulation to prevent overheating.

- Thus, all modules are sequentially fixed one after another around the perimeter of the room, but it should be remembered that there cannot be more than 17 of them in one circuit, since the wire used in them with a cross-section of 2.5 squares will not withstand a larger load.

- The crucial point is the installation of power jumpers and ensuring the device is grounded.

At the third stage, the thermostat is installed, the power cable is installed and the heating system is tested:

- Using complete fasteners, similar to baseboards, a thermostat is mounted on the wall at a height of about 1.5 m above the floor, preferably near sockets and switches.

- After installation, the thermostat temperature sensor is calibrated.

- Now you can connect an electrical wire to it, the cross-section of which is selected depending on the total power of the system.

- All wires can be hidden either inside the wall or using special boxes.

- The system is connected to the network via a thermostat and a distribution box, in accordance with the passport instructions for the equipment.

- The final step is to plug the thermostat into the outlet, check the operation of the unit and, if necessary, decorate its elements.

When installing a traditional heating system, problems with radiators constantly arise.

I would like to hide them somewhere away so that they do not stand out and spoil the interior with their appearance. What if we initially made a system in which batteries would not be needed at all? And we are not talking about heated floors here.

It looks quite a bit different from the usual one. Its height ranges from 14 to 20cm, width about 3cm. With such dimensions, such a system will fit into any interior without any problems.

Is this heat source enough to fully heat a house or apartment? Quite. Despite its small size, do not forget about its length.

So, in a room up to 20 m2, when installing a plinth along three walls, the total area of such a heater reaches 2 m2. At the same time, it is not these square meters that emit heat, but something else.

To find out what exactly, let's take a closer look at the operating principle of a warm baseboard and find out all the details about its effectiveness.

A warm baseboard differs from heating radiators in that it heats up the entire wall and thus forms a thermal curtain or screen.

The heat is instantly distributed evenly throughout the room, and not just near the windows.

The design and principle of operation of a warm baseboard

How to make air heating of a private house with your own hands

A warm baseboard is a fairly simple device, consisting of an electrical module and a natural shell that does not emit foreign odors when heated.

Electric baseboard diagram

What is a warm baseboard? In general, there is no new word of technology in this device. Just the same principles of electric heating, only in a new design.

Inside the device there are heat exchangers mounted on copper tubes. The whole peculiarity of this device is its compactness. The entire structure fits into a narrow box about fourteen centimeters high and three centimeters wide. Such heaters are installed around the perimeter of the room and can serve as the main and additional means of heating.

Electric baseboard installation

Heated baseboard design:

- tube convector;

- a box with fasteners for attaching heating elements;

- rotating parts.

All these parts of the device are easily assembled into one whole and their installation does not create any problems. The principle of heating a room using this design is also primitive. A heat flow is created along all the walls, which prevents the cold from penetrating into the room. The walls become warm and release thermal energy to the air in the room.

The principle of heating with a baseboard system

Application area

Today on the market you can easily buy an electric baseboard for heating. It significantly surpasses in its performance characteristics all conventional heating options, which are not applicable everywhere. For example, in country houses, in the absence of heating plants, and sometimes even a gas pipeline, the only source of heating can be only firewood and electricity. In this correspondence competition, of course, the victory is at the baseboard, because it is much easier to turn on any electric heating device than to light the stove.

The plinth system operates similarly to electric floors; it also has a temperature controller for individual adjustment of the microclimate in the room. Temperature data comes from sensors placed on the walls, at human height level. You can connect such a device to a regular household outlet; professionals recommend not to overload the electrical wiring of the house and connect the heating device directly through a separate branch of the electrical wire to the distribution panel with the provided automatic circuit breaker.

Baseboard heating

Do-it-yourself heating from polypropylene pipes in a private house

Despite the fact that in our country what a warm baseboard is became known not so long ago, in Europe premises have been heated using this method for several decades. This technology is very simple, but at the same time quite convenient. The basis is metal (most often copper) pipes, which are also the heating element. The pipes are installed in the same place where the baseboard usually runs, that is, along the perimeter of the room. Then they are covered with a metal box made of plates with a corrugated surface. Due to this design, the box acts as a heat exchanger, thereby increasing the efficiency of the structure.

In general, a water baseboard consists of the following elements:

- front panel with holes that ensure air flow (standard size: width - 3-4 cm, height - 15-20 cm);

- rear panel - facilitates installation of the structure and protects the wall from constant exposure to high temperatures;

- heating radiator that performs the heating function (standard dimensions - 1 m x 0.4 m x 1.6 m);

- rotating side plugs;

- a heat exchange module consisting of two tubes through which water circulates.

Currently, there is a variety of warm baseboards (electric.) They differ from warm water baseboards only in the type of heating element.

Due to the fact that the baseboard is installed around the perimeter of the entire room, the heat gradually rises, and then the entire room is evenly heated. As a result, this technology does not cause temperature changes. Since the heating element is hidden under the front panel, it is not noticeable, which distinguishes it from massive ones. As you can see in the photo, the warm baseboard looks very neat; it can be additionally decorated so that it better matches the overall style of the room. The system is effective, but at the same time quite simple to install. Having minimal skills, you can carry out installation without involving professionals.

Conclusion

The choice depends on financial capabilities and the specifics of the premises. Since warm baseboards appeared relatively recently, they have not yet been thoroughly studied by consumers, so people often choose the “warm floor” system.

average rating 0

more than 0 ratings

Share link

Comments

Olga 01/15/2019 07:46

Hello. Are there any contraindications to installing a warm electric baseboard for any type of floor (parquet, laminate, etc.) Thank you in advance for your answer. Olga

How to make a warm baseboard with your own hands

Even if made in Russia, this pleasure is not cheap. But what if you want to try such a system, but don’t have a lot of “extra” money? Do it yourself. There are two working options.

Option one

Used with a diameter of 12 mm, sheets of roofing copper 0.4 mm thick. The order of work is as follows:

- Cut a strip of roofing copper (60 cm) with a grinder into strips of 15 cm.

- The edges of the full length strips should be beaded at an angle of 90o and the flange length is 7-8 mm. The length of the strips is no more than 3 meters - it is inconvenient to work with large pieces.

- Solder copper tubes to the back side of this plinth. To do this you need solder (plumbing solder containing 3% copper) and a torch. When soldering, point the torch at the tube: the strip is thin and will warp if overheated. The tube can withstand heat normally.

- Bend the ends of the tube slightly before soldering. This will make it more convenient to put adapters on them.

- For assembly, oil and petrol resistant hoses were used that can withstand working with coolant up to 120 oC (internal diameter 12 mm). At the connection points with the pipe they were secured with ordinary clamps.

- To regulate the temperature, a manually adjustable thermostat is installed.

- The joints are covered with similar inserts/plinths made of copper, but without pipes.

- The panels are attached directly to the wall using standard mounting clips (by the pipes). Do not insert them into the recesses - most of the heat is lost.

This system has worked in a wooden house for 9 years. There were no problems or need for repairs. The coolant temperature at the inlet is from 50 oC to 70 oC. In a room, 20-21 oC when rising is too hot.

Second option

In this case, aluminum profiles for working with drywall were used to make a warm baseboard with your own hands. Holes are cut (sawed) in them with a grinder at the top and bottom, after which they are attached to the walls. Two copper pipes are laid on a thin aluminum ceiling profile, screwed with aluminum wire. This entire structure is laid inside and fixed to the wall so that the pipes are one above the other. The pieces of such a homemade plinth were assembled by welding with copper pipes and fittings. “Front panel” is the same profile, only painted with radiator paint to match the walls (floor). This homemade warm baseboard is less effective and more difficult to clean, but it is also very functional.

Economy and the laws of physics

However, not everything here is as rosy as it seems at first glance. If your entire wall is heated, then heat loss from it increases.

This means that it must initially be made heat-intensive and strive for maximum heat resistance.

Here, for example, is the formula for calculating heat loss known from a physics course:

Where:

- S - wall area

- T = (Tinside - Toutside) - the difference in wall temperatures inside the house and outside

- R – surface heat transfer resistance

From this formula it becomes clear what heat loss primarily depends on. R - both with batteries and with the baseboard you do not change. The wall is the same.

But the parameters in the numerator will be different. The greater the temperature difference (T), the greater the heat loss. Let’s say that when heated by batteries near a window, the wall will conditionally have t=20C.

The temperature along the wall from the radiator to the farthest point (in the corners) is distributed along a gradient. The sections of walls to the right and left of the windows do not warm up at all.

If the entire wall inside the house is heated with a warm baseboard, from the same boiler with the same coolant temperature, then the wall will warm up more. Conventionally, up to +25C, which means, according to the formula, the difference in the numerator will increase, and heat transfer through the walls will increase.

It turns out that the more heat you lose, the more you will have to replace it. It doesn’t matter how this heat is pumped into the room - radiators or thermal baseboards.

As a result, there will be no significant savings and super energy efficiency here.

The same applies to the area - S. The surface heated by the baseboard is much larger than the surface located directly behind the radiator.

The situation can be improved a little if the heating baseboard is placed not only on the external walls of the house (as with radiators), but also on its internal partitions.

Most of the heat generated in this case will remain in the house, rather than trying to immediately escape outside. A little heating of the external walls is useful not only as a source of heating, but also for the building itself. Dampness as such completely disappears.

Considering all of the above, many therefore perceive such innovations with skepticism. There are long-proven and understandable methods - the same radiators under the windows, or heated floors in a screed.

All other tricks are too expensive either at the construction stage or during operation and repair.

For a room of 16 m2 you will need from 10 to 12 meters of plinth. Its price today averages 4000-5000 rubles per meter and more. And this is in addition to the cost of components. Add here the work itself (in Moscow they charge about 1,400 rubles per linear meter), all the rooms in the house and calculate your expenses.

Not everyone can afford such heating.

Is it possible to fully survive the winter with such thermoplinths? Yes, definitely. If there is sufficient linear footage and appropriate coolant temperature.

And numerous reviews on the forums confirm this. To warm up the house on the coldest winter days, the temperature of the coolant extraction in the warm baseboards collector will need to be kept around 75C. On normal days, 50-70C is enough.

Detailed review of thermal skirting boards from forumhouse

The higher the temperature, the more radiant energy you will receive. When it decreases to a level of 45C and below, the warm baseboard turns into a kind of mini-convector, which heats mainly with air flows.

Therefore, do not expect any unrealistic savings from thermal skirting boards. She won't be there. Warm floors are much more profitable in this regard.

However, the system has become widely used and some consumers actively use it both as the main and additional source of heating for their apartment or individual rooms in the house.

Types of heating baseboards

The baseboard heating system can be of two types: with electric and water heaters. At the installation stage, a system with warm water baseboards is more complicated (a collector or radial connection is required), but during operation it is more economical. An electric warm baseboard can be installed quickly - you just need to fasten the heaters to the wall, and immediately after installation it is ready for use. But heating costs, like any electric heating, are high.

One of the most inconspicuous heating systems is a warm (heating) baseboard

Heating device with warm water baseboard

The water baseboard heating system differs only in the non-standard shape of the heating devices. The key components do not differ from the standard ones: you need a hot water boiler, a collector unit and a pipe system with which the warm baseboard is connected.

There is also a combined warm baseboard - with an electric heating element and pipes for coolant

Please note: the optimal operating mode of the system is low temperature. Supply 40-50°C, return about 5°C lower

Therefore, you need to select a boiler or build a system based on this. If the boiler is gas, the best choice is a condensing boiler. When installing any other, the system requires a heat accumulator and/or a mixing unit to reduce and stabilize the temperature.

Connection method

There are also features in choosing the connection method. Connecting all baseboard heaters in series in a room is ineffective: by the time the coolant reaches the last ones in the heater branch, it will cool down greatly and they will remain cold almost all the time.

The radial connection diagram looks something like this

For a water heating baseboard, a radial system is used: devices are connected one at a time or in pairs. To do this, a collector unit is built into the system, to which the pipes that go to the heating devices are connected. The disadvantage of such a system is the high consumption of pipes. After all, each device (or small group) has two pipes - supply and return. The pipe flow rate is much higher, but the heat distribution is more uniform and the system itself is more reliable. Why is it more reliable? If pipes or radiators in one group are damaged, all others work normally.

Installation features

When installing water baseboard heating, the pipes are usually hidden in the floor. It will not be possible to lay them along the walls, since the space is occupied by heating devices. That is, installation of warm water baseboards is possible only at the renovation stage - the floors will have to be raised.

Very attractive when assembled

It is recommended to lay special polymer pipes in the screed - they are not subject to corrosion and have low heat transfer, that is, heat loss during transportation of the coolant will be small. But since these systems have limited availability for repairs, you need to buy high-quality products from well-known manufacturers, and this is not cheap.

Electric warm baseboard

An electric heated baseboard differs in appearance from a water baseboard only in the presence of terminals for connecting power. Otherwise the view is the same. These are two tubes with perpendicularly fixed aluminum/brass/copper plates. In the lower tube there is a heating element - heating element, in the upper tube there are wires for connection.

General design of a heating baseboard

Installing and connecting an electric heated baseboard is much easier. You just need to secure it, stretch the wires and connect them to the terminals. To maintain the set temperature, a thermostat is built into the system, which turns the heaters on and off. The use of thermostats is desirable, as it optimizes operation and saves electricity.

Installation is really simple, but you need to connect the electric warm baseboard to a dedicated line with a correctly selected circuit breaker rating and single-core copper wires of the appropriate cross-section. So in this case, repairs are required - it is customary to lay the wiring in the wall, and for this you need to do it, that is, break the walls.

Calculation

The main task of calculating a warm baseboard is to determine the required length of the heating circuit.

The power it delivers should compensate for the heat loss of the room and warm it up in conditions of low outside temperatures.

For calculations, you can use the standard simplified method.

Determination of heat loss

A simplified method involves calculating heat losses by room volume, taking into account correction factors.

For calculation:

- The serviced volume is determined by multiplying the area of the room by the height of the ceilings.

- The loss power is calculated - the resulting volume is multiplied by the average specific (per 1 cubic meter) loss rate for a given area. So for the middle zone it is 40 W/m3, for the northern regions it is taken twice as much, and for the southern regions it is 40-50% less.

- Amendments are made to the calculation - the power obtained in the previous paragraph is multiplied by correction factors that take into account:

- Losses due to windows are 1.27 for a regular window, 1.0 for a double-glazed profile, and 0.85 for a triple-glazed window.

- The area of windows relative to the area of the room is no more than 30% -1.0, and then +0.1 for every 10%.

- Material and thermal insulation of the walls - panel with standard thermal insulation - 1.27, with additional thermal insulation materials - 0.85.

- Ceiling height - 2.5-2.7 m - 1.0, 3 m - 1.05, and then +0.05 for every 0.5 m of height.

- Location of the room. Each external wall increases the standard factor of 1 by 0.1 (for two external walls the result is 1.2). The floor and ceiling are treated similarly.

- The obtained result is increased by 20-30% in order to have a power reserve of the heating system in case of abnormally low outside temperatures.

The calculation without taking into account correction factors gives the average heating power, which appears in many sources - to heat an area of 10 sq.m with a ceiling height of 2.5m, 1 kW of power will be required.

Water calculation

To calculate the water-heated baseboard, tables provided by equipment manufacturers are used. They link:

- Coolant temperature in the circuit.

- The difference in coolant temperatures between the supply and return (as a rule, all models are designed for a difference of no more than 5°C).

- Room air temperature.

- The resulting thermal pressure of the system (in °C).

- Power delivered by 1 linear meter of heating module.

Knowing the latest power required for heating, the required total length of the heating modules is determined.

At the last stage, the exact number of modules of different lengths is calculated based on the layout of the system on the walls of a particular room.

Electrical calculation

When calculating a heating system with electric heating elements, everything is somewhat simpler.

Manufacturers provide the power output from each module (depending on length).

All that remains is to arrange the system (count the required number of modules of different lengths) along the length of the walls of the room and determine whether there is enough power for heating.

If reduction is necessary, some modules are replaced with an empty box.

To increase the performance of the heating circuit, it is necessary to install modules in 2 tiers.

Operating principle and differences

Manufacturers of baseboard heating claim that the system is more economical than all other types of heating. Savings are 20-30%. This happens because lower temperatures are required to achieve a comfortable feeling. This is because most of the heat is transferred by radiation rather than by convection.

Almost all existing heating systems do not create the best thermal picture: warm air accumulates at the top, while cold air remains at the bottom. If the room does not have very high ceilings, the situation is tolerable, but in rooms with large heights this is critical. To equalize the temperature picture, forced convection is used: fans are built into heating devices that more or less effectively mix the air masses. But active air movement carries dust and germs. At the same time, stagnant zones still remain in the corners of the rooms, in which cold air accumulates.

When using baseboard heating there is no thermal cushion at the top, the air is fresh and the feeling is comfortable

Uneven temperatures and dust in the air are not all the troubles of convection heating. There is also dampness that appears on the walls. The fact is that convection heats the air. The walls remain cold. When warm air comes into contact with cold walls, condensation occurs, the walls become wet, and fungi and mold develop. Moreover, this picture is typical for houses and apartments with good insulation.

Baseboard heating works differently

The first important difference: the lower layers of air immediately heat up, which is already comfortable. Gradually and slowly rising up along the walls, the air cools, transferring heat to the walls

Therefore, it turns out that the top is not warmer (or not much warmer) than the bottom.

Only about 20-30% of the heat is spent on heating the air by convection. Everything else goes to heating the walls. And this is the second important difference. The heated air rises along the walls, rather than mixing with the rest (this effect was noticed by the scientist Coand). Therefore, the rising warm flow cuts off the cold from the walls and heats them. Yes, while the walls heat up and dry out, a lot of energy (and fuel) is consumed. But after that the entire surface begins to radiate heat.

This is where the savings zone begins: a person feels comfortable if the wall temperature is 36-37oC and the air temperature is 16oC. We simply feel the heat emanating from the walls with the entire surface of the body. At the same time, the cost of maintaining the temperature of dry walls is low. After all, it is the water contained in the materials that is the best conductor of heat, and the air that replaces it, on the contrary, conducts heat poorly.

This is what one of the options looks like up close

That is why with such heating it is not so important whether there are pieces of furniture along the walls or not: it is mainly the walls that are heated, not the air. Let them take away some of the heat, but then they themselves will begin to give it back. But the walls will heat up anyway.

What it is?

A warm baseboard is a distributed modular heating system with the so-called.

"floor" installation. The term “floor” does not mean at all that the elements of such a system are mounted on the floor covering - the fasteners are made on the wall in its lower part in close proximity (at a distance of no more than 1-2 cm) from the floor.

The system received the name “plinth” for the modest dimensions of the modules (up to 3 cm thick and 10-24 cm high), excellent decorative properties and the possibility of installation indoors instead of a standard plinth.

The air is heated by heating modules - water or electric.

Is the price per meter justified for installing a warm water baseboard?

The data from this table will be useful for calculations.

| product name | Unit | Price per m.p./piece, rub. |

| A heating element | m.p. | 2010 – 2120 |

| Front Panel | m.p. | 670 – 720 |

| Top mounting strip | m.p. | 360 – 400 |

| Bottom mounting strip | m.p. | 190 – 230 |

| Bracket for mounting the heater | PC. | 70 – 90 |

| Inner corner cap | PC. | 70 – 90 |

| External corner cap | PC. | 50 – 60 |

| End cap | PC. | 100 – 120 |

| Fitting for straight sections | PC. | 170 – 200 |

| Flexible tube with seals for 90° and 180° rotation | PC. | 415 – 440 |

To analyze the parameters of a warm water baseboard, the price and reviews should be studied together. The approximate cost of one linear meter of the system is 3,600 rubles. To equip a room of 20 sq. m. when installing a plinth along only two walls, you will need to spend 32,400 rubles. The price of standard aluminum radiators for such a room, together with Mayevsky taps and regulators, is about 8,500 rubles. According to construction forums, ordinary users do not experience significant installation difficulties in both cases.

When painting the outer surface of a water heating baseboard in a certain color to better match the interior, you will have to pay from 900 to 1,400 rubles. for 1 m.p.

Popular models and estimated cost

Buying one of the popular models of warm baseboards, for example, Melodie or Verlys Evolution, today is not a problem even if you order online. But the cost, depending on the store, salon or company where it is purchased, can vary significantly, which makes the search for the optimal option far from a waste of time.

On average, the estimated cost of a linear meter of the system starts at $30. When choosing between a more or less powerful system, you must take into account the fact that it can consume a significant amount of electricity, for which you will have to pay every month.

It is difficult even for a specialist to roughly estimate the cost of purchasing and installing such equipment, because this is a whole system that has a large number of components: aluminum profiles, heating elements, thermostats, sensors and power cables, the number of which may vary for each individual room.

The only criterion that gives a more accurate idea of the cost may be the area of the room planned for heating and, accordingly, the power of the equipment required for this. So the Melodie Evolution model with a power of 500 W will cost 23 thousand rubles, and the 1000-watt Verlys Evolution version costs 41 thousand rubles.

Advantages and disadvantages of warm skirting boards

Next, we will consider the pros and cons of warm baseboards, both water and electric. Let's start with the positive features:

Skirting radiators are an excellent choice for rooms with panoramic windows.

- The miniature size of the equipment is perhaps the most important advantage characteristic of any warm baseboards, including electric ones. Thanks to this, we have the opportunity to have at our disposal an extremely compact heating system that is not conspicuous;

- Possibility of heating rooms with panoramic windows - warm baseboards will provide reliable protection from cold air flows and prevent the formation of condensation;

- Low temperature of the housings - as a rule, it does not exceed +40 degrees, so accidental touching the baseboard radiators does not lead to burns;

- Uniform heating of air masses throughout the entire volume - you will not feel discomfort or cold feet;

- Warm skirting boards (including electric ones) are suitable for use in any premises - kitchens, living rooms, bedrooms, corridors, loggias, covered balconies, terraces, retail premises, entrances, halls and much more;

- Possibility of simultaneous operation with any other heating devices. For example, electric convectors can be used together with electric warm baseboards, and classic batteries are often installed together with water appliances.

There are also some disadvantages:

There are some difficulties when installing warm baseboards in a room with built-in furniture.

- The high cost of warm baseboards is typical for any equipment, including electrical equipment;

- Lack of efficiency - many manufacturers claim that baseboard heating allows you to save money, but these claims can be questioned;

- High energy consumption is typical for electric models. Even if your area has rural rates, the costs will be very high;

- It is impossible to lay warm baseboards where built-in furniture is installed - it covers the space necessary for installing equipment.

However, baseboard heating continues to grow in popularity. Where just recently there were bulky cast iron radiators, today extremely compact warm baseboards are appearing - electric and water. Thanks to their thoughtful design, they provide quick and uniform heating of rooms, giving people warmth.

Reviews

Melodie Evolution:

- It heats well, definitely no worse than apartment heating systems.

- Hooray, you no longer need to carry a foot warmer around the room with you, this system copes 100%.

Verlys Evolution: I have small children, a girl and a girl, who used to constantly catch colds and get sick, although the room seemed even stuffy. The thing is that there were very strong drafts on the floor, and the children often played while sitting on the rug. We wanted to make a heated floor at first, but then we were told that it would be much cheaper to buy a system of mini-plinths with electric heating. It didn’t cost us much, without unnecessary hassle, and most importantly, it solved the problem of the microclimate in the children’s room.

Choosing a baseboard infrared heater

In order not to make a mistake when choosing an electric baseboard convector, you first need to get acquainted with the existing varieties. The most in demand both in Moscow and in other cities are infrared devices. Such designs have an operating power of no more than 150 W. They can be used as the main heating method, since they are able to generate 5 times more heat than similar devices.

The design of such a system includes anodized aluminum lamellas, which ensure strong heating of the walls and nearby surfaces. By installing such skirting boards, an effective curtain is created that perfectly protects the room from cold air.

Cable heater device

Skirting boards of this type can be used to heat any premises, except those where high humidity prevails. The advantage of these heating systems is a more simplified assembly scheme. The heating elements are mounted in a box; there is no need to install a manifold or lay supply lines.

Operating principle of a plinth convector

During operation of heating baseboards, maintaining a comfortable temperature in the room is ensured not only by influencing the air in the lower part of the room, but also by transferring heat to the wall surfaces. In order to heat the air by convection, you have to spend about 30% of the total energy, and the rest of it goes to warming the walls.

After the air warms up to the required temperature, it begins to rise up along the walls, where it mixes with warmer air currents. As a result, an air cushion appears. After the walls warm up to a temperature of 37 degrees, they begin to release the resulting heat into the room.

When choosing the best option for a warm baseboard, you need to pay attention to its price. The cost of such a system may vary

Much depends on the features of the device and the characteristics of a particular model. The design of the baseboards has a heating element, which is covered with a light metal strip. This element includes copper tubes to which the radiator plates are connected.

Installation Features

effectively

Installation of warm Megador plinth is carried out in two stages. It all starts with preparing the terminals for connecting the structure, then the supply lines are laid and the cable is connected.

The second stage begins only after finishing the room. When using a water-type heating baseboard, all its elements are first installed, modules are connected to the output elements, after which the circuits are adjusted and the system is pressure tested. In the case of an electric warm baseboard, you first need to install all the elements of the housing, connect them to the circuit terminals, and then take insulation measurements. At the final stage, the thermostat is adjusted.

Particular attention should be paid to calculating the number of sections where it is important to avoid mistakes. Here you need to pay attention to the power of the system and possible heat loss

The final results will differ in each case. It all depends on the quality of thermal insulation of walls, window structures and air temperature. I would like to draw your attention to the fact that when using electric type skirting boards on an area of 10 m2, 0.5 kW will be required. If the water option was chosen, then this figure is doubled.

Rating of the best models with water coolant

A high-quality device that makes it possible to create a compact heating system for any room. Air flows are distributed evenly, which creates an optimal microclimate. The box is made of durable aluminum, it prevents negative effects on the walls. The heat exchanger is made of durable stainless steel. The main advantage of the device is its ability to withstand pressure up to 16 atm. The positive side is simple installation, which takes a minimum of time and allows you to install the product in every room. Sold at a price of 3,300 rubles per meter.

- Uniform heat distribution;

- High-quality insulating material;

- Sold in several colors;

- Strength characteristics;

- Low cost.

Installation nuances

The installation process must be completed in several steps. The first step is mounting the frames. Using fittings, individual parts are assembled into a system. After this, the assembled circuit is connected to the collector. The next step is to check the connections for sealing. The final stage is fastening the decorative elements.

The heating system has significantly fewer disadvantages than advantages, which is why baseboard heaters continue to gain popularity. During installation, you need to remember some features:

- Select a minimum installation height of 15 mm. If it is less, the efficiency of the system will significantly decrease.

- It is forbidden to install heating baseboards behind furniture, especially upholstered furniture, since it dries out and becomes unusable due to such proximity, because it takes away most of the heat energy.

- A standard socket is not suitable for convectors. An electric heater must have a circuit breaker and grounding.

- It is better to supplement the thermostat of the IR heater with electronic control with special programs.

If we consider the sequence of necessary actions, then installing a baseboard heating system is not such a complicated process. For electric convectors, a separate circuit for electrical power is required. The installation of water heaters and conventional batteries has much in common.

When choosing a heating device, you need to take into account the ceiling height, installation power and temperature options. It is better to prefer a system in which the temperature can be adjusted.

Infrared models are more suitable for private homes. However, the price of an IR convector is higher, especially if it is equipped with a carbon heater.

Installation of warm baseboard:

Purely masculine and purely feminine

Installing a warm baseboard

“I installed both floors and skirting boards - I can say that the heating quality of the skirting board is better, and the price is cheaper,” comment from an installer from the Rmnt forum.

And a very feminine one on ForumHouse: “In my opinion, this is an excellent solution for electric heating... I found several manufacturers on the Internet. Domestic ones are not expensive, but somehow they don’t look presentable. Imported ones are beautiful, but more expensive,” - that’s why they are imported, so that they are both more beautiful and more expensive!