A check valve is a type of pipeline fitting, the purpose of which is to prevent a change in the direction of fluid movement in the pipeline. The device automatically allows flow in one direction and stops flowing in the opposite direction. Refers to direct-acting protective pipeline fittings.

Before purchasing a 110 or 50 mm sewer check valve, it is important to understand the features of different types of locking mechanisms and their operating principles. It is also recommended to find out all the information about the existing sewer system.

Installation is quite simple; additional equipment is usually not required. It is important to purchase the device from trusted sales outlets, and also make sure that there is a warranty from the manufacturer.

Purpose of the locking device

The check valve is an important element of the “protective fittings” of any pipeline. Its main purpose in the overall technological system is to prevent a possible change in the direction of the flow of the working fluid. All valves of this type freely pass the working medium in the desired direction and prevent its movement in the opposite direction.

The purpose of check valves in sewer systems is similar - by releasing waste from the internal sewer system into the general house system, they prevent their reverse flow in the event of a plug, blockage or other problem on the subsequent section of the pipeline.

Additional functions of the products are to protect individual housing construction from wastewater that overflows the drain well; prevent rodents from accessing the sewer system (for this, a 50 mm sewer check valve is often used).

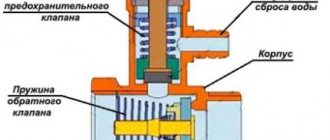

Check valve with electric motor

This modern analogue of a check valve runs on electricity; in case of frequent power outages, there are models with batteries. In this device, the locking membrane is always completely open, which prevents the formation of dirt build-ups on it, which prevent it from closing completely if necessary.

The device operates as follows:

- the liquid begins to move in the opposite direction and fills the pipes;

- when the pipe is filled to 70% of its volume, the probe installed inside sends a signal to the electrical unit;

- sound and light alarms are triggered, notifying you of trouble;

- the damper closes automatically.

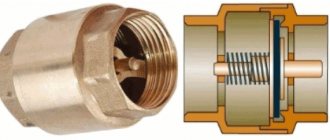

Design and principle of operation of the product

Check valve in operation

Standard check valve components:

- Housing with pipes (inlet, outlet) and inspection cover.

- A working shut-off element - disk, valve, membrane, ball - to shut off the pipeline over the entire internal cross-sectional area.

- Seal to ensure a tight fit of the working element to the body during reverse flow of drainage masses.

- Return spring of the locking element.

- Lever mechanism for forced opening of the valve manually. It makes it easy to adjust the position of the damper. It can be fixed vertically or horizontally.

The check valve works as follows. Initially, the damper blocks the entrance to the housing chamber. The pressure of the flow of drainage masses lifts it without obstacles, and the water or the contents of the toilet rushes to the sewer without delay. If there is a blockage or blockage in the pipes located behind the valve, a reverse flow of liquid occurs. Its pressure presses the working element against the support ring of the housing and reliably closes the passage - liquid waste does not return to the apartment or house.

Controls and technical characteristics

The device can be controlled in two ways:

- mechanical;

- in an automatic way.

The main technical characteristics of check valves include:

- nominal diameter (DN) - cross-sectional size of the openings of the connecting pipes (from 50 mm to 300 mm);

- nominal pressure (PN) - the value of the highest excess pressure of the working medium at a temperature of 20ºС;

- throughput coefficient (Kvs) - water flow (m³/h) with a temperature of 20ºС;

- operating temperature range - depends on the materials used and is indicated in the technical specifications for specific samples;

- installation type - horizontal or vertical;

- type of connection to the pipeline.

Classification of products used

Based on the type of working locking element, the following design options for sewer pipe valves are distinguished:

- Lifting . The principle of their operation is described above. The passage through them is blocked by a damper or disk.

- Rotary (petal) . A distinctive feature is that the locking membrane resembles a petal. They work similarly with lifting type products.

- Ball . The locking element is a balloon filled with air. With the “correct” movement of waste liquids, it rises and rolls into the recess provided for by the design of the housing. The flow passes freely into the common drain system, and the ball then rolls back to its original place under its own weight. In an emergency, the reverse flow, with its pressure, presses the sphere harder, which reliably blocks the passage.

- Wafer . These check valves are suitable for sewer pipes with a pipe size of 50 mm. Products in the shape of a low cylinder with a rotary valve are placed inside the pipe. They are capable of passing only water without any solid particles or inclusions - therefore they are designed for discharging liquid from sinks and bathtubs.

check valve types

How to clean, conduct an audit

The sewer system itself prevents the passage of clean water through it. Sometimes debris does not pass through the valve, getting stuck at the base of the plug cheeks. This problem often occurs if you do not monitor what goes into the drains.

Manufacturers of water seals have provided an inspection window in the device. It is located at the top of the shutter. Fastened with several bolts: three or four. Cleaning or inspection of unit components occurs through it.

We unscrew the bolts, first loosening each one. Remove the water seal cover. A round membrane and a chamber through which all the water passes will become visible. We remove all debris and large elements stuck in the chamber with a glove. We slam the plug several times, shaking it off. Now you need to rinse the device.

Clean water is poured inside the window. First, wash the chamber after the membrane, then the inlet compartment. After the inspection, we check the normal operation of the throttle by flushing the toilet or turning on the water in the sink. All this without closing the viewing window lid. You can see how everything works. Only after this close the lid and tighten the bolts. The rubber band also needs to be washed and returned to its place.

Important: you cannot immediately pull out all the pins and remove the cover. Residues of waste water can suddenly rush through the window.

The valve installation method allows us to distinguish the following designs:

- Flanged . Suitable for connection to large cross-section pipes that have a similar fastening element. The valve with flanges is conveniently mounted on pipeline sections with a vertical or horizontal arrangement.

- Bell- shaped The valve with a conical socket and a rubber sealing ring easily mates with other pipeline elements.

- Couplings . The products are designed to mate with pipes (mostly metal) of small diameters - up to 2.5 inches.

Flanged and Union Check Valve

The material for the manufacture of check valves is:

- Stainless steel . Used for the production of interflange products. Other types of valves can also be manufactured for inclusion in a metal pipe system. In products made from other materials, stainless steel dampers can be used.

- Polyvinyl chloride (PVC) . The most common material for large cross-section sewer valve bodies.

- Polypropylene . The sewer check valve 110-315 mm polypropylene remains operational at +95°C without deformation. The housing material includes components that can partially suppress the operating noise of the product.

- ABS plastic . This thermoplastic resin produces durable and impact-resistant housings for check valves.

- Cast iron . Such designs are recommended for installation in loaded systems (usually external) made of large-section cast iron pipes.

Step-by-step installation instructions

Most air valves are produced by manufacturers to connect to DN110 pipes. If the connecting size of the device does not correspond to the size of the pipe, a special adapter is used. For pipes DN50 or DN75, aerators with the corresponding diameter of the connecting outlet or equipped with a reducing insert are used.

It must be remembered that a valve designed for pipes with a diameter less than 110 mm can be installed for a maximum of two plumbing points.

In areas of transition from a pipe of a larger diameter to a valve with a smaller diameter, reducer inserts and various adapters are used. To install the aerator on a cast iron pipe, there are also special adapters that ensure a reliable joint between the plastic and the metal.

At the beginning of the work, the installation location of the valve is determined, taking into account the installation rules and its accessibility for further maintenance.

Next, perform the following steps:

- The water supply in the house is turned off.

- If the installation is carried out on a previously installed pipeline, then a tie-in is made and a special adapter is installed.

Most aerator models have a bell-type connection.

The assembly of such connections is carried out in the following sequence:

- The outer surface of the smooth part and the surface inside the socket are cleaned of dust.

- Wipe the sealing ring from possible contamination and place it in the socket groove.

- The surfaces that come into contact during connection are lubricated to reduce friction. To do this, use a silicone-based sealant or soap solution, glycerin.

- Place the smooth end of the valve into the socket up to the mark. The quality of the connection is checked by rotating the parts relative to each other, followed by returning to their original position.

If necessary, the area with the connected vacuum valve is secured with a clamp. Upon completion of work, it is necessary to check the joints for leaks.

The surfaces that come into contact during connection are lubricated to reduce friction. To do this, use a silicone-based sealant or soap solution, glycerin

For hidden installation, special models of vacuum valves are used. If the riser is hidden in a fine or protective box, then measures must be taken to ensure the flow of air into the sewer valve. To do this, a ventilation hole is made according to the size of the aerator mesh.

The aerator body is buried in the wall, the fastening element is adjusted so that its outer edge is flush with the wall surface. The only visible element remains the decorative grille, which can be attached using self-tapping screws or inserted manually. For aesthetic reasons, it is available in the most popular color options - white, gray, black and chrome.

Some valve models can be used as drain cleaning holes. To do this, remove the decorative cover, take out the internal mechanism of the fan valve and insert the cable inside.

Valve Selection Tips

- To install the valve, before connecting the apartment sewer system to the common house sewer system, select a product for a non-pressure system.

- Any type of valve can be installed in front of the bathtub or sink. The main requirement for it is compliance with the fastening and diameter of suitable pipes.

- When installing the valve in a vertical riser, use a product with the appropriate mark on the packaging.

- Valve models designed only for vertical installation should not be used on horizontal sections of the pipeline, and vice versa.

- You cannot install a valve designed for pressure in a non-pressure system - it works with crushed waste materials and will quickly become clogged with waste from the toilet.

- To install a plastic valve on a pipeline made of cast iron or steel, special plastic adapters will be required.

- Models of products with flanges must be placed on pipes with the same type of fastening.

- It is not advisable to install metal valves on plastic pipes.

- The cost of check valves can vary by an order of magnitude. However, expensive models do not guarantee great advantages during operation.

Before purchasing

Before purchasing a check valve for the sewer system, you need to decide on the exact location of its installation and know the type of sewer system - free-flow or pressure (with a pump in the pipe system).

When choosing the required model, they also take into account the dimensions of the product, the manufacturer’s warranty period, build quality, complexity of the upcoming installation, material, functionality, and recommendations of practitioners.

Why do you need a non-return valve for a sewer?

Determining the installation location

It is important to know! The air valve for sewerage is usually mounted 20-30 cm above the main pipe. During installation work, do not allow dust, dirt or liquid to penetrate the membrane. For optimal performance, a systematic supply of oxygen is necessary.

For installation in an apartment, the device is mounted on a pipeline in a vertical position. This method will not provide ventilation to the riser, but will eliminate odors in a specific area.

It is recommended to install a sewer air valve in a private house. In this case, it is possible not to carry the fan structure through the roof. But some experts argue that it should be mounted only as an auxiliary part to the riser.

In private houses and apartments, plastic sewers are installed. Air elements are also made from polypropylene or PVC.

The valve must be installed:

- In high-rise buildings that are connected to wastewater treatment plants.

- In waste disposal areas.

- When connecting sewerage to sanitary facilities.

- In systems that can be connected horizontally.

The nuances of installing sewer valves

- Before installation, you must perform a visual inspection of the purchased product. For further work, leave the structure without visible defects, chips, cracks and deformations.

- After this, the functionality of the valve in the bath is checked using water, which is alternately supplied from different sides through the body pipes. If necessary, at this stage it is easy to eliminate minor faults or replace the product under warranty.

- There is always an arrow on the body of any model. It helps to correctly orient the product during installation - with an arrow towards the common collector or drain well.

- Before work, you must definitely agree with the residents of your riser (from apartments on the upper floors) about a temporary refusal to use water supply and sewerage. Such forethought helps to avoid unexpected troubles.

- If the materials of the product and pipes are different or have different diameters, you will need to install special transition elements that are purchased in advance.

- Each connecting joint must be sealed.

- After installing the valve, the functionality of the drain system and the tightness of the connections are checked. Deficiencies are immediately eliminated. If there are no problems, the sewerage system is suitable for use.

For self-installation

Every home craftsman can independently install a valve of any type. You don’t need a professional or any expensive tool for this. The non-return valve for sewerage is not yet a well-known and widespread device. Therefore, for those who first encountered the product and decided to install it, the following tips will be useful.

Installation of a check valve is simplified if it is sequentially assembled together with all elements of the future sewer system into a common chain. This happens when the entire drainage system of an apartment or house is completely replaced during a major renovation or during the construction of a new home.

When installing the device in an operating sewer system, the role of preliminary marking and careful removal of the pipe section for inserting the valve in this place is important. Installation on metal and cast iron pipes is more complicated than on plastic ones - it may require the involvement of specialists with practical experience in performing such work.

You may also like - Slope of sewer pipes according to SNiP

Work progress

If you plan to install a check valve in a residential high-rise building, you must:

- 24 hours before the start of installation, notify all residents about the upcoming work;

- perform a shutdown using valves installed in the inlet section of the cold and hot water supply to prevent unauthorized entry of water into the sewerage system circuit;

- notify all neighbors immediately about the very beginning of work to replace the device;

- After completing installation of the product, turn on the water in the entrance.

The work itself on installing a device with a threaded connection type is carried out in the following sequence:

- choose a location for installing the device and cut out a part of the pipe there that is equal in size to the length of the valve;

- cut threads at the ends of the pipes;

- clean the remaining chips;

- take a strand of flax fiber of such length as to ensure the number of windings is 1.5 - 2 times greater than the number of thread turns and lay it clockwise, wrapping the entire length of the threaded section;

- apply a layer of sealant over the wound flax;

- Screw on the valve and tighten the fastening using a wrench or torque wrench.

A useful video on the process of installing a locking device in a bathroom can be viewed in the video:

Valve Maintenance

Timely inspection and periodic maintenance of the check valve increases the service life of the device and ensures its reliable operation.

Important! At the stage of designing the drain system and installing the valve, it is necessary to provide for ease of access to the product for the necessary maintenance.

The sewer valve is serviced quarterly. To do this, remove or unscrew the top inspection cover. Then a visual inspection of the condition of the product is carried out, the debris accumulated in it is removed, and, if necessary, the edging and/or damper is replaced. The reason for unscheduled maintenance of the check valve may be the deterioration of the drain system, the presence of additional unnatural noise and vibrations in the valve when draining waste.

When servicing the valve in use, you should also follow the manufacturer's recommendations specified in the product instructions.

Connection diagram

Schemes for installing check valves are developed in accordance with the technical characteristics of the device and a description of the conditions for its further operation. In the photo you can see examples of the location of the device:

- to protect the washing machine;

- on an external sewer pipe.

Causes and consequences of sewer blockages

Possible destruction or mechanical damage to pipeline elements creates an emergency situation. But most often, emergency situations in sanitary systems for the removal of products from human household activities are associated with the occurrence of internal blockages, which necessarily provoke a stop and reverse movement of the discharged wastewater.

A simple malfunction leads to serious problems, which usually affect the lower floor apartments of apartment buildings or the sanitary premises of the lower level of private buildings. The location of the blockage in these cases is in the horizontal sewer pipes passing through the basement. Residents of the upper floors can also suffer, which happens less frequently. To do this, it is enough to have a plug in the vertical riser between floors. Installing a sewer check valve eliminates the possibility of such domestic accidents in apartments. This device will also protect private homeowners.

Causes of plugs and blockages in drain pipes:

- Blockage of the drain pipe due to violation of the rules for using the sewer system. In this case, the traffic jam is created by large food waste, diapers, plastic bags, cotton wool, pieces of thick cardboard, rags and other bulky items that are not sent to a special garbage container.

- Long-term operation of pipes is accompanied by the gradual formation of sediment on their inner walls and a decrease in the working clearance (section). Subsequently, the rough inner surface of the pipes more easily retains solid particles, which settle and gradually form an impenetrable plug in the overall system.

- Incorrect pipeline slope allows solid particles to settle on its walls. To avoid this, the flow of discharged liquids must have a certain speed. To change the slope of the pipes, you will have to completely redo the problematic system.

- The formation of plugs is also facilitated by bends located perpendicular to the main pipeline. The flow of liquid in these areas slows down sharply, delaying large inclusions - the reason for the formation of plugs.

The consequence of an internal blockage of a sewer pipe that occurs for any of the reasons listed is the accumulation of liquid and its reverse flow. Immediately, the toilet bowl (closest to the plug site) accumulates with the contents of the waste system, with possible overflow of the liquid mass over the edge. In this situation, the unpleasant smell ceases to be a problem, in comparison with the upcoming cleaning, repairs and expenses for purchasing new things to replace the damaged ones.

Is it really necessary?

Installation of a sewer check valve 50 or 110 is not always required; there are certain situations when installing this device does not make much sense. For example, residents of apartments on the 6th floor of an apartment building do not have to worry about possible sewer flooding through the central blockage, because... the pressure of waste fluids will not maintain a high level when rising to the 6th floor.

In general, there are situations when it is strongly recommended to install the device:

- location of the apartment on the first/second floor of a multi-storey building;

- location of office space on the first two floors;

- private 1-storey house;

- cottage-type country house with 2-3 floors.

In the above situations, it is financially more profitable and easier to install a valve on plumbing fixtures in advance than to later repair the premises and deal with the negative consequences of a clogged and broken sewer. It is especially important to install the mechanism in houses with old pipelines. Pipes in such buildings usually have a layer of sediment on the inner walls, resulting in a smaller working area and an increased likelihood of clogging.

How to install it yourself

At the time of design, the risk of flooding should already be included in the system, so during this period it is necessary to work out the installation of the valve. Installation takes place in several stages.

Installation of a check valve can be done both on an external system and on an internal one.

The first stage is choosing an installation location

The location for installing the throttle must be easily accessible. The equipment must not be installed in the wall or floor, covered or cluttered.

Each device has a cover for cleaning and repair, so access to it is required at all times. If the sewerage system runs in the floor or concrete base, the locking mechanism is mounted in the pipe, and its upper part remains on the surface.

If the depth of the gasket is large and the headband is out of sight, we make a removable cover in the floor for inspection.

The second stage is choosing a device

Locks are classified differently, some are installed outdoors, in a well, others can only be installed indoors. It is necessary to choose the most suitable one for the installation conditions. If there is an error at this point, the shutter may subsequently collapse or crack.

- Grinder with cutting disc.

- A sharp, hard knife for chamfering.

- Oil, lubrication paste.

- Hammer and flat board.

- At the installation site, we clear the work area.

- We measure the length of the device so that it fits into the prepared space.

- Lubricate the end of the pipe generously with motor oil or plumbing paste.

- The O-ring should also be treated.

- Before inserting the firecracker into the pipe, having made the socket, we will turn the device several times (if possible).

- With a little effort, but sharply we stick the pipe into the throttle.

- Then we check to see if the rubber band in the device has pulled up.

- On the reverse side we continue assembling the sewerage system.

It is not always possible to install a throttle during the initial installation of the pipeline. This can be done in the current system.

- Having chosen a place, use a grinder to carefully cut out a piece of pipe. It is advisable to choose a place closer to the socket so that the piece can be removed.

- We make a piece of pipe slightly larger than the device itself. In order not to disassemble the entire thread, we will need a channel with a compensatory socket.

- We insert the compensator into the pipe, and the valve from the other edge.

- We insert the assembly onto the pipeline first from the side of the compensator, moving it until it stops, then, pushing it out of the socket, insert the valve on the other side.

Important: each cut point in the pipe must be processed by chamfering.

How to chamfer a plastic or PVC pipe

The end, if it is not fixed in the system, is pulled out and pressed between the legs or armpit so that the cut is in front of the eyes. Using a sharp knife, we begin to cut the edge in a circle. The result is a chamfer, a cone. We also remove all burrs in the cut areas.

How to place it at the outlet of a plumbing fixture

To install it to the toilet, you will need an external device without a stable housing, inside which the clapper moves. Instead, a cuff is placed on the back of the toilet, with a hard membrane attached to the end. The shutter is of a conical type. A serial connection allows you to insert the device inside the socket, where the plate will work. We coat each joint with oil or plumbing paste for better connection.

Installation goals

Why do you need a valve in the sewer?

To ensure that, if clogged, the drains from the upper floors do not enter the rooms below. The principle of communicating vessels works here: as soon as the outlet to the well or collector ceases to perform its functions, wastewater begins to pour out through the plumbing fixture located below the others. Once you install a valve in front of it, the sewage will have to find another way.

In addition to the reverse movement of wastewater, valve flaps prevent the movement of rats and mice through the sewer system. In the absence of drains, the valve is completely closed, and when water is drained, it is raised just enough to allow the flow to pass.

Air (vacuum) valves, which prevent the breakdown of water valves on devices connected to unventilated risers, are also reverse in design. They allow air to pass in only one direction - inside the riser, compensating for the vacuum that occurs in it during flushing.

Operation of a vacuum valve for sewerage.

Review of manufacturers

The most famous manufacturers of check valves:

- VIEGA/Germany . Devices for external sewerage made of polypropylene. The valve has two dampers, one of which has a manual locking system.

- CAPRICORN/Poland. Single valves for internal sewerage. Manufacturing material – polypropylene.

- McAlpine /Scotland. Plastic models for internal wiring. They are small in size.

- Polytron/Russia. Valves for outdoor installation with an emergency locking handle. Made from polypropylene.

Installation of the device in the sewer system

Choosing the appropriate check valve option is an individual matter, depending on financial capabilities and requirements for the device. Of course, it is better to choose a more reliable unit, but simple designs are also capable of performing the functions assigned to them. When choosing, you must take into account such a parameter as the diameter of the sewer pipes, so as not to encounter the problem of incompatibility. This problem can be solved with the help of adapters, but it is better not to make additional connections and immediately select the appropriate option.

To install a valve with a large diameter on a common riser, it is advisable to use a horizontal arrangement, which is much more popular than a vertical one. There are arrows on the body of any valve showing in which direction the fluid moves. These arrows (or arrow) must necessarily point to the sewer riser.

Aerator for sewerage

If the house has more than 2 floors and there is plumbing on each floor, then the system must be equipped with ventilation. Usually free air exchange is ensured by a fan pipe, but there are times when it is not possible to install it and then an aeration or ventilation valve is installed.

Important! If the sewer system is sealed and left without ventilation, then when a large amount of water is discharged, a pressure drop will occur, as a result of which water will be regularly sucked out of siphons and other water seals, which will lead to the penetration of sewer gases into the room.

An air check valve is easier to install than a liquid check valve. According to the rules, a valve with a diameter of 100 mm or more fits into the system 30 cm higher than the top outlet, for example, on a sink, but now there are a lot of small models that are installed next to the toilet or siphon.

How to install an aerator

How does the air drain valve HL 900NECO and similar ones work?

You can make an aeration valve with your own hands; the photo below shows instructions for making such fittings.

How to make a ventilation valve with your own hands

Study of samples

I told where and how sewer check valves are used, but did not mention what they are like and how much they cost. I will hasten to correct this defect. As an object for research, I will focus on the products of the company Hutterer & Lechner - not the cheapest, but certainly one of the highest quality in the post-Soviet space.

Shutter for washing machine HL3.

| Parameter | Meaning |

| Material | Polypropylene |

| Diameter | 3/4 inch |

| Connections | Union nut with gasket, hose fitting |

| Working temperature | 95C |

| Purpose | Prevents waste from entering the washing machine without its own valve |

| Retail price | 664 rub. |

50mm HL4 valve.

Design and dimensions of the product.

| Parameter | Meaning |

| Material | Polypropylene |

| Diameter | 50 mm |

| Connections | Smooth pipe, socket with O-ring, diameter 50 mm |

| Working temperature | 95C |

| Purpose | Installation in front of a washbasin or bathtub (works with wastewater without large suspended matter and feces), vertical or horizontal |

| Bandwidth | 1.36 liters per second |

| Retail price | 2412 rub. |

110 mm valve HL 710.0.

Device and dimensions.

| Parameter | Meaning |

| Material | Impact resistant ABS plastic |

| Installation | Horizontal |

| Compound | Socket with O-ring diameter 110 mm |

| Purpose | Installation in a well on the edge of the outlet |

| Working temperature | 60C (short-term 80C) |

| Counterflow operating pressure | Up to 5 meters |

| Weight | 720 |

| Retail price | 7257 rub. |

HL valve flaps with a diameter of 110 mm and larger are made of stainless steel and are capable of withstanding significant deforming loads. Its semicircular shape makes the valve more resistant to high backflow pressures.

Pass-through HL710.

Device and dimensions.

| Parameter | Meaning |

| Material | ABS |

| Connections | Smooth pipe and socket with O-ring diameter 110 mm |

| Purpose | Installation into a pipe rupture. Designed for wastewater without faeces |

| Working pressure | Up to 5 meters |

| Working temperature | 60C |

| Weight | 2.02 kg |

| Retail price | 7258 rub. |

HL710.1 with manual damper control.

The design and dimensions of the shutter.

| Parameter | Meaning |

| Material | ABS |

| Purpose | Installation into a pipe rupture. Not suitable for fecal waste |

| Connections | Smooth pipe and socket with a diameter of 110 mm |

| Working pressure | Up to 5 meters |

| Weight | 2.18 kg |

| Retail price | RUB 11,318 |

Double chamber shutter HL710.2.

Device and dimensions.

| Parameter | Meaning |

| Material | ABS |

| Purpose | Installation into a pipe rupture. Works with fecal wastewater |

| Connections | Smooth pipe and socket with seal with a diameter of 110 mm |

| Working pressure | Up to 5 meters |

| Peculiarities | Two service hatches, manual control of one flap |

| Weight | 3.23 kg |

| Retail price | RUR 15,798 |

Electrified valve HL710.2 EPC.

Device and dimensions.

The senior valve in the HL model range is equipped with an electric actuator powered by a 220-volt network and a battery that provides autonomy for up to 7 days. The connection is bell-shaped, with a diameter of 110 mm. In addition, the manufacturer offers valves with a diameter of 160 and 200 mm.

Here are the most interesting features of the device to consumers:

- The closing force thanks to a 300-watt electric motor reaches 50 kgf. Large fractions of waste water trapped between the valve and the seat cannot prevent it from closing: they are simply ground up;

- The damper closing time is 11 seconds;

- The control unit with a standard cable can be placed 6 meters from the gate;

- The damper can be closed forcibly not only manually, but also from the remote control;

- The valve design allows for horizontal installation only.

The retail price of the shutter is 102,970 rubles.

The cost of the products I cited as samples is, let’s say, far from budget. In order not to scare the reader with upcoming expenses, I will introduce him to a pair of domestically produced valves.

TP 85.100.

Device and dimensions.

| Parameter | Meaning |

| Material | PVC |

| Connections | Smooth pipe and socket, 110 mm |

| Purpose | Internal and external sewerage |

| Installation | Horizontal, vertical |

| Retail price | 1660 rub. |

A product with the laconic name “outer check valve 110 mm”.

This Novosibirsk-made valve is also intended for internal and external sewerage. Like the previous device, it provides for manual locking of the damper in the closed state and the possibility of servicing through the service hatch.

Unlike TP85, here you will need a tool to open the hatch - an open-end or socket wrench. The cost of the valve is even more attractive: it will cost the buyer only 1,500 rubles.

Types of how devices work

There are several types of sewer check valve. Depending on the installation location and the nature of the network.

1. Rotary , they are also called petal (clackers).

The body is square or oblong with a bell joint on one side and a blank end on the other. Inside, a round washer with a diameter larger than the through hole of the pipe by 2-4 mm is attached to the upper part of the wall.

A loose spring is installed at the fastening point, allowing the passage to be more tightly covered.

In a quiet state with horizontal installation, the firecracker is closed and opens when wastewater from plumbing fixtures enters the system. If there is a blockage, overflow and water rushes up, the throttle closes and blocks access.

Some models additionally have a manual hydraulic lock of the same operating principle. It is located on the same line, immediately after the first plug. Its task is to mechanically block the drainage passage if the first sewer valve does not work.

2. Lifting.

The main element blocking the passage is also a round disk. It is attached to the ceiling of the housing with a bolt, and a metal spring is wrapped around it. It creates tension to hold the membrane closed. The water pressure entering the system is enough to lift the washer with the spring and move on.

The throttle device allows you to stop the reverse flow, which presses on the disk from top to bottom. The design is used in any sewerage system. A distinctive feature of the housing structure is the flange connection of the top cover. By unscrewing it, you can easily clean and repair the device.

Installed only on internal networks. There are special recesses inside the body: water passes into one, and a ball is placed in the other. As the waste moves from the device to the receiver, the ball rolls into the cavity.

If the process occurs in the opposite direction, the ball blocks the passage.

The shutter has one drawback. There is no clean water in the sewer system, which means that the drainage is always mixed with dirt and sewage. Debris can get between the ball and the wall of the device and it will leak.

4. Wafer.

Mainly used in plumbing systems. Due to their compactness, they, of course, outperform the firecracker, but the installation conditions are very harsh.

The breather is mounted between two flanges and when opened, its moving part must fit inside the pipe.

A wafer throttle is a metal cylinder, inside of which a disk with a spring is fixed along the axis. The plate is always closed and opens when pressure is applied. The peculiarity is that the working pressure in the sewer is less than the water supply. Therefore, the drains cannot push through the spring.

What it is

It’s not hard to guess what a check valve is. Obviously, this is a device that allows the working medium to move in only one direction. Check valves are widely used in the installation of water supply and heating systems, so their concept will not seem unusual to the reader.

The use of this product for wastewater requires, however, some adaptation:

- The valve should open and close with minimal pressure . As you know, in most cases, domestic sewerage is gravity-flow;

Valves that require significant excess pressure to open (for example, ball valves) can be used in pressure sewer systems. They are installed at the beginning of the pressure section immediately after the pump and prevent the reverse movement of wastewater after it stops.

- Since the valve and seat will inevitably become overgrown with grease, sediment and other deposits, the valve must be easy to open for maintenance.

This is what the product looks like when opened for service.

Typical valve materials are plastics, primarily unplasticized polyvinyl chloride (UPVC) and polypropylene. As a rule, products are marked by color: valves intended for internal sewerage are gray, for external installation - orange.

The v115 sewer check valve for PVC pipes can be installed in a well.

Valves are single-chamber (with one damper) and double-chamber (with two dampers). For obvious reasons, the latter are more reliable: even if a dirty seat of one damper prevents it from closing completely, the second one will ensure tightness.

A check valve can often be found on sale under another name - a sewer valve.

Double chamber shutter device.

Many valves provide manual control: the damper can be forced into a fully closed state.

The red handle forces the device into the closed state.

In addition to mechanical ones, many manufacturers offer electrified devices. The servomotor, which blocks the path of the drains with a damper, starts after the filling sensor is triggered. Electrified devices are often equipped with batteries that provide long-term (up to a week) autonomous operation during power failures.