The advantages inherent in aluminum radiators make them a good option for heating a city apartment or private house. They have a high heat transfer rate, are lightweight, equipped with regulators and are resistant to pressure surges.

When choosing a radiator it is worth considering:

- tolerance of water hammer of the heating system;

- its power;

- refrigerant heating temperature.

Aluminum quickly corrodes; if you follow the operating conditions specified by the manufacturer, you can ensure that the aluminum radiator lasts for a full period of 10 years or more.

Some features of aluminum radiators

The main advantage of this device is its operation. At any time when required, a person can add the number of sections, which will lead to an increase in the efficiency of the thermal system. It should be noted that aluminum radiators can be used both in closed and open heating systems. When using this equipment, the room temperature changes almost instantly. The main disadvantage can be considered an increased sensitivity to corrosion. The main features of the radiator include:

- Working pressure in the heating system.

Device lifespan.

Eyeliner sizes and options.

Appearance and painting.

The features of aluminum radiators are the main aspect of their price. The higher the price of a product, the more efficiently it works and the better quality it has.

Aluminum batteries can be used in heating systems that have a pressure of 6 to 16 atmospheres. In order to improve the sale of products and increase the possibility of their use at various facilities, some manufacturers have proposed developing units that can withstand pressure of up to 25 atmospheres. In an apartment, normal pressure is 6, maximum 8 atmospheres. In a private house this figure does not exceed 6 and can drop to 4 atmospheres. (See also: How to choose heating radiators)

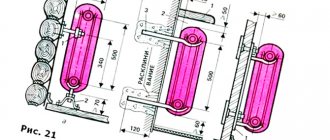

One-pipe system, bottom method

- On the riser, as close to the floor as possible, two tees are mounted in series, and locking devices are installed on both.

- From the tap of the supply side of the pipe, a branch is laid along the floor or lower part of the wall to the nearest lower inlet of the heater.

- As close as possible to the supply outlet, the far lower opening of the sections is connected to the return flow valve.

The three previous methods are acceptable only if the distance from the supply pipeline is short. For this reason, professionals use them to solve the problem of how to connect a heating radiator in an apartment where risers run through each room.

Assembling a cast iron radiator

This is done in the reverse order, the only difference being the change in the direction of rotation of the key. Do not forget about replacing gaskets; it is best to buy paronite gaskets in the store, they are stronger, more durable and can withstand aggressive coolants (antifreeze).

If you don’t find such gaskets, you can use plumbing flax. It is wound onto the right-hand thread clockwise, and onto the left-hand thread in the opposite direction - counterclockwise. Also, for reliability, you can apply a sealant (for example Unilock) to the threads of the nipple nut. If you plan to use antifreeze in the system, then you cannot apply paint to the winding - it will corrode very quickly and you will have to repack everything. And this is draining the system, flushing it, disassembling it, then assembling all the sections... a lot of work. So, under a system with antifreeze, use a chemical-resistant sealant and paronite gaskets.

Features of installation of heating radiators

According to industry SNiP, the following standards must be adhered to:

- between the radiator and the floor you need to maintain a distance of 10 cm, between the heating device and the window sill - from 5 cm, to the nearest wall - 3-5 cm;

- the length of the device fixed under the window should be no more than 50-75% of the width of the opening;

- the vertical axis of the battery (it is determined by eye in the middle) should continue with a similar parameter of the window. Here a deviation of no more than 2 cm is possible;

- installation of radiators is most appropriate in areas where there is intense air circulation - near doorways, under windows.

If you apply a heat-reflecting screen to the wall (in particular, attach foil material), the battery can be placed closer - at a distance of 2.5 cm. An additional finishing layer helps to reflect heat from the wall, which leads to energy savings and faster heating of the room.

The assembly technology is determined by the type of system being used and the selected equipment connection diagram.

Installation stages

The installation of an aluminum battery can be divided into three main blocks: preparation for installation, assembly of the radiator and connection to the water supply system.

Preparatory work

Before connecting the radiator to the system, you must do the following:

- Determine the required power of the device. The characteristics declared by the manufacturer may not correspond to reality if the coolant temperature is insufficient. To obtain the required amount of heat, a recalculation is made taking into account the temperature of the working substance and the required number of sections is selected.

- Select the optimal location for installation. Radiators give off heat to the environment in two ways: convective and thermal radiation. A window sill that is too close is unacceptable.

- Select the optimal fasteners. For thick walls, standard fasteners supplied with the radiator are suitable. Brackets will need to be purchased if mounted on a thin partition.

Radiator assembly

The device is assembled before its installation. Its sequence is as follows:

- Assembly of the required number of sections;

- Installation of plugs and plugs;

- Installation of thermostatic and shut-off valves;

- Installation of an air valve necessary to release accumulated air from the system.

The valve should be installed with the head facing upwards with a tightening torque not exceeding 12 kg. If this element is installed correctly, it is closed immediately after air is bled from the system.

Installation and connection to the riser

Immediately before installing the radiator, it is necessary to mark the brackets and install them. In this case, you need to take into account:

- The optimal distance of the radiator from the window sill, floor and walls (10 cm, 12 cm and 3-5 cm, respectively);

- Method of supplying the working substance;

- Installation option - special niche;

- The presence of a heat reflector (screen).

Holes are drilled according to the markings, the brackets are secured with dowels, and the radiator is installed on them. Use a level to ensure that the device is installed exactly horizontally. Next, the pipelines are connected to the device, at the inlet of which a thermostat, tap or shut-off valve is installed.

It should be remembered that with a rapid intake of coolant, the risk of water hammer increases. Therefore, the shut-off valves open smoothly.

Pros and cons of aluminum heaters

Aluminum radiators have become frequent “guests” of private houses and apartments in houses with centralized heating.

This was made possible thanks to the qualities that have won the hearts of consumers around the world:

- Aluminum is one of the best conductors of heat, releasing it into the surrounding space in two ways: radiation and thermal convection. This feature is especially in demand in heating systems with unstable media pressure.

- Assembly of aluminum radiator sections is possible without the use of additional forces. Since their light weight allows you to do everything yourself. They are easy to both transport and install.

- These batteries are capable of withstanding pressure from 16 to 25 atmospheres, which makes them desirable in the places that were occupied by cast iron “accordions”. There are 2 types of aluminum radiators. One of them is suitable for autonomous heating systems, where the load rarely exceeds 10 atmospheres. The second is for batteries connected to central heating, where differences of up to 15 atmospheres occur.

- Aluminum radiators are much lower in price than their steel or bimetallic counterparts. This is one of the most important factors that attracts consumers.

- They are easily adjustable, which allows you to create the necessary microclimate in the room and save money on heating.

- They have an attractive design that fits easily into any interior.

These qualities have made aluminum batteries in demand all over the world, despite the fact that they have minor disadvantages:

- Aluminum is not resistant to corrosion, but modern radiators are treated with special means that prevent its occurrence. But even after treatment, it is better to keep such heaters filled with coolant, which is difficult to do in a centralized heating system, where water is discharged after each end of the season. This is why aluminum batteries are more in demand in autonomous systems where there are no such discharges.

- Batteries of this type are prone to airing, so at the beginning of the heating season, excess air must be vented from them.

- The threaded connection in aluminum models is weak and if there is a strong water hammer, a leak may appear at the joint. This defect can be eliminated only by knowing how to assemble an aluminum heating radiator using additional gaskets.

This type of radiator is available in two types: solid and sectional. The second is most common in private houses and apartments.

Instrument design

Aluminum heating panels consist of sections that are made of metal alloys with silicon additives. This composition makes the device much more resistant to mechanical damage and exposure to hot temperatures. The metal alloy is not subject to corrosion damage. Often, to enhance the protection of the inner surface from the effects of heating fluid, a thin polymer coating of approximately 50 microns is used.

Radiator panels are usually produced in a standard white color. If desired, they can be repainted with enamel that can withstand high temperatures. Often the original photographic image is applied to the devices.

Also, most manufacturers produce equipment of any color and design upon personal order. In order to disguise them, you can use special decorative grilles.

Advantages of aluminum heating devices

The growing popularity of the devices is due to a number of advantages of their use in the design of a heating system:

- compact, take up little space;

- high heat transfer;

- light weight (does not complicate transportation, installation and connection of devices);

- rapid heating of equipment by coolant;

- the convection heating method prevents the accumulation of dust deposits between sections;

- favorable price-quality ratio;

- attractive appearance;

- the ability to select a custom radiator of any design;

- sections are powder coated to prevent corrosion.

Flaws

These devices, despite all their positive performance qualities, have their drawbacks. Poor quality coolant and water hammer resulting from increased pressure inside the heating system can lead to failure and rupture of the radiator. Also, low quality fluid causes metal corrosion.

Equipment is often connected to pipes made of metals that are antagonistic to aluminum - copper and steel. Their interaction provokes the formation of rust. To avoid this, experts recommend using pass-through plugs made of chrome-plated and nickel-plated metals when installing aluminum radiators indoors.

Radiator connection diagrams

Heating radiators are connected to the heating circuit according to several schemes, the choice of which must be approached very responsibly. The fact is that incorrect connection leads to loss of almost half of the heat.

Incorrect connection of sections leads to uneven heating of the system, and violation of assembly technology leads to the formation of leaks and ruptures

Therefore, it is important not only to choose a suitable diagram for how to connect the heating batteries to each other, but also to correctly connect the radiator sections. In any case, the work requires attention and accuracy

Radiators are connected to the heating system as follows:

- Consistently.

In this case, one heating circuit pipe is required. - Parallel. The work involves two pipes; the radiators are connected to each other by means of an upper and lower outlet.

- A through connection involves the passage of coolant through the heating device system.

Two-pipe system, side method

- Choose a convenient place on the supply pipe, preferably as close as possible to the radiator, on its outer side (to the left or to the right) for installing the tee. When determining the position of the tee, you should take into account the need to turn the tap in the direction of the entrance to the battery using an angle.

- A valve is mounted on the tee, as in the one-pipe system.

- From this tap a connection is made to the upper inlet channel of the radiator.

- The lower hole on the connection side of the sections, which in this case will serve as an outlet, is connected to the return flow pipeline according to the same principle. For the aesthetic component of the design, it is advisable to observe the analogy of a mirror image of the supply part of the circuit.

How to assemble an aluminum radiator

We assemble in reverse order. We place the sections on a flat surface (a suitable sized table or simply place it on the floor). If the radiator is not new, unscrew the end cap and Mayevsky tap.

Before installation, you should carefully examine the threads and grooves; they must be of high quality, without chips or changes. On the mounted section for testing, we “drive” the thread by screwing in and unscrewing the nipple

Here you need to pay attention to the fact that there may be a gasket under the layer of factory paint in front of the thread. Lightly rub the end with fine sandpaper; if it is found there, it must be carefully cut off with a knife with a sharp blade.

This is what an aluminum radiator looks like in cross section

Before adding sections of the heating radiator, be sure to clean the ends to a smooth surface. We even remove factory paint. It is not needed at the ends of radiators, but will only contribute to the early appearance of leaks. Sooner or later, coolant will begin to seep under the paint. In the case of non-freezing liquids, this will happen very quickly; if water is used in the system, then not very much, but it will definitely happen. And then coolant will begin to leak between the sections, although the gaskets are still in perfect condition. The whole point is that the paint on the ends has peeled off or been corroded, and microcracks have appeared. So we make sure to clean the ends to bare metal, but use fine sandpaper so that the surface of the metal is smooth and without scratches. This guarantees the operation of the system without leaks in the radiators.

For better tightness, the ends then need to be degreased (using gasoline). Gaskets are also degreased, but they need to be washed with ordinary soapy water. For a system that will be filled with water, degreasing is an optional procedure, but for systems that will run on antifreeze it is necessary. Antifreezes have high fluidity and seep into the smallest pores. After everything is dry, we begin to assemble the aluminum radiators.

Then tighten both nipple nuts half a turn. Heat-resistant paronite (silicone) gaskets are placed on top of the nipple to seal the joints. Now we take the section that needs to be screwed and place it tightly against the nuts, checking the tightness of their fit. Next, insert the key into the upper hole and tighten it 1-2 turns. At the same time, we do not use the lever yet. We twist our hands. Then we perform the same operation in the lower hole. We repeat several times, alternately tightening both nuts several turns.

We unscrew the sections gradually, one or two turns of the nut, either from below or from above.

Tighten as much as you can. Only after tightening by hand can the lever be used. This must be done in two stages on each nipple. It is better not to use excessive force when final tightening the nipples, since you can easily break the threads: aluminum is a soft metal, don’t forget.

If the section is completely assembled, screw a plug onto the unused holes on one side, and a Mayevsky valve on the other (to bleed air from the system). Now you know how to assemble sections of a heating radiator and, if necessary, you can add several sections.

Two-pipe system, bottom method

Two-pipe system, bottom method

- The supply and return pipelines are laid above the baseboard, along the floor or under it.

- The outlet through which the coolant flows is connected to any of the lower holes of the set of sections. The procedure for performing the work is the same as in the two previous options.

- A return flow of liquid is mounted on the lower opposite channel. The mirror principle with respect to the incoming pipes is observed.

Types of heating systems

There are 3 categories here - single-pipe, two-pipe and collector; they differ in the level of heat supply and the specifics of connecting structural elements.

Types of heating systems

Single-pipe

The equipment is combined into a bundle in such a way that the coolant moves through only one pipe, sequentially passes through each radiator and, already cooled, enters the boiler. This simple installation method is widely used in multi-storey buildings. Disadvantage of the solution: more and more cooling water passes through each subsequent battery, and accordingly the rooms are heated worse. There is no possibility of individual repair of one radiator; in an emergency, you will have to turn off the riser.

Two-pipe

Thanks to the parallel connection of the batteries, the hot coolant is supplied to each of them through one pipe separately. The entire complex of equipment is heated evenly, the cooled water flows into a separate return pipe, through which it is transferred to the boiler, where it is reheated. It is also not difficult to assemble the system; if replacement is necessary, you only need to disconnect one radiator.

Collector

This complex scheme is used for heating cottages: separate pipes must be connected to each radiator. Usually professionals are involved in its installation.

Single pipe system, side method

One-pipe system, side method.

- Two tees are installed on the supply line. The opposite terminals are oriented along the pipe, and the side ones towards the battery. Their locations are selected in such a way that they correspond to the inlet and return outlets.

- The American type valves described above are mounted on the tees.

- The outlet from the shut-off device located on the coolant inflow side is connected to the battery inlet.

- A pipe is laid from the outlet to the remaining tap.

Instructions for connecting aluminum radiators

Depending on the type of heating device and what kind of heating radiator piping is used, there are several installation options. It is impossible to describe all the options in one article, so we will briefly describe how to correctly install an aluminum heating radiator using the example of its sectional version.

Necessary components for the radiator

For installation you will need the following components:

- The manifolds are factory-made with right-hand and left-hand threads on the corresponding side. They are needed to add sections. To switch to right-hand threads, you will need adapters.

- To close the remaining two entrances, you will need plugs with external threads that match the purchased adapter.

- Sometimes on the upper manifold they do not install a plug, but a Mayevsky valve to release accumulated air.

Accessories can be purchased individually or as a set. For ease of repair and replacement of the device, ball valves can be installed. To simplify installation work, it is better to use an American one (these are taps with a coupling connection and a union nut). Sometimes, instead of ball valves, an angle or straight thermostat is installed.

To work you will need the following tools:

- adjustable wrench;

- sealing paste;

- open-end wrench;

- tow;

- building level;

- perforator;

- square;

- roulette;

- pencil.

Installation process

The installation sequence of the heating device is as follows:

- First you need to mark the installation location, drill holes and secure the brackets. Fasteners are leveled in a strictly horizontal plane.

- Proceed to assembling the plumbing parts. To do this, place the battery on a workbench and pack the device with purchased components.

- Then the battery is hung on the brackets. Check the horizontal and vertical installation, as well as the location of previously installed trim elements.

- On the threaded part of the faucet, which is located on the other side of the union nut, we attach elements that allow us to connect the device to the heating circuit. In the case of polypropylene pipes, these are fittings. For fastening to a steel pipeline, a threaded bend is chosen.

- The pipe line is connected locally to the battery.

- After cutting into the pipeline, sealing gaskets are placed in the union nuts on the American ones. The radiator is hermetically connected to the return and supply circuits.

- Finally, a pressure test of the system is performed to assess the tightness of all connections.

Removing air from radiators

When the system is filled, air accumulates in the upper corner of the battery not used for connection, which must be removed. To do this, you need to place a liquid container under the pre-installed Mayevsky tap and open this device.

After waiting until the output stream is smooth, without splashing or air bubbles, the tap should be closed. After this, go to the next battery in the chain and perform the same actions.

It is required to start from the radiator located first on the supply pipe. After finishing the round, go around the second circle, check that all the air has been removed. If necessary, duplicate the entire process several times.

Now, knowing how best to connect heating radiators in an apartment or house and paying attention to each stage of work, it is not difficult to provide the desired warmth and comfort in your home.

If you do not have sufficient experience in construction work, lack tools or confidence in your abilities, it is better to entrust such a responsible task to professionals.

Key rules for disassembling heating radiators

Depending on the condition and type of battery, you need to prepare the following tools:

- nipple key;

- grinder or autogen;

- sledgehammer, hammer;

- an adjustable wrench (it can be replaced with a set of wrenches with different heads);

- construction hair dryer;

- chisel.

It is important to find a high-quality nipple wrench: it looks like an iron rod, at one end there is a spade-shaped head, at the other there is a hole or an eye. The tool is equipped with serifs, the width of the radiator sections corresponds to the distance between them

When dismantling the old battery, dirty coolant leaks out; you need to protect the floor with oilcloth or a large amount of rags.

Dismantling of bimetallic and aluminum sectional products

Before dismantling the device with your own hands, you need to stop the coolant supply and relieve the pressure. The diagram shows a cross-section of a bimetallic radiator - it will help you navigate the sequence of work.

What does a heating radiator consist of?

How to disassemble a heating battery:

- you need to wait until the device cools down. To remove it from the system, unscrew the connecting input and output couplings;

- move the couplings along the pipe away from the heating element and remove it from the brackets;

- get rid of the liquid remaining inside, place the device on a flat surface face up;

- Remove and rinse the filter thoroughly, otherwise dirt will dry in it.

You can begin dividing the radiator into sections by understanding the direction of movement of the nipple nut (otherwise there is a high probability of equipment damage). The ring-shaped nut has internal grooves and external threads - right and left; when it is unscrewed, the sections move apart. Manufacturers of bimetallic batteries mark their products and indicate the thread direction: S – left-handed, D – right-handed

When unscrewing, it is important to follow this tip so as not to strip the threads on the heating device

The nipple key must be inserted into the radiator and directed towards the nut using the notches on the tool, use the lever and move the connecting element. An assistant will come in handy here - he will hold the battery in a level position. After disconnection, you need to inspect the metal gaskets placed between the sections - those that are in good condition can be reused, silicone gaskets must be replaced.

Why increase the number of sections on the battery?

If the room is not heated well enough during the cold season, first of all, you should think about thermal insulation of the windows. This is the most effective and cheapest way to keep warm. But if the expected effect could not be achieved, then it makes sense to replace the battery.

Stop! Today, sectional radiators have become widespread. These modern heating devices have one great feature - they can be expanded by adding new modules. This is their nature, because each such battery is a prefabricated structure.

Just buy as much as you need and invite master installers from our company. But how do you know how many sectional modules per battery you need? It's very simple! You need to look in the technical specifications section for the performance capacity of each module. It is given in watts. Based on the calculation that every 100 watts heats approximately 1.3 square meters of room. It’s cold in a room of 10 square meters, but the radiator only has 6 sections? No wonder - after all, you need at least an 8-section radiator! Buy what you are missing and order the addition service!