Why does the Conord gas boiler turn off?

Usually the culprit is a blockage - a fallen brick, a bird falling inside or a cobweb. Simply put, you need to clean the pipe to improve draft. If, after inspecting the chimney, you find that it is very dirty, this is probably the reason why the gas heating boiler turns off.

Interesting materials:

How to call Alfa Bank from a mobile phone for free in Ukraine? How to call Asia Pacific Bank? How to call Home Bank Astana? How to call Home Bank for free in Kazakhstan? How to call Home Credit Bank Kazakhstan? How to call otp bank for free? How to call Post Bank for a loan? How to call Raiffeisen Bank from abroad? How to call Rusfinance Bank for free? How to call the Cetelem Bank hotline?

Basic problems

A modern heating unit running on natural gas is equipped with a self-diagnosis system. Therefore, in case of any problem, the display automatically displays an error code. Special technical documentation contains decoding of such messages and recommendations for troubleshooting. However, events can often develop in several directions:

- The information board shows the fault code.

- There is no indication at all and the display does not light up at all.

- There is no ignition.

- The unit stops working in one of the modes.

In this case, the reasons why the gas boiler does not turn on are divided into two types:

- External . These include insufficient supplied gas pressure, malfunctions of the smoke exhaust system, interruptions in the power supply, violation of climatic operating standards in the boiler room itself (temperature, humidity, ventilation).

- Internal . Failures are associated with malfunction of electronic circuits and individual components - sensors, boards, wiring, pumps, circuits, etc.

Internal factors cause boiler malfunctions no less often than external factors Source ooo-konditsionery.ru

Note! If there is no indication of the boiler, first of all it is necessary to check the serviceability of the power supply circuit. The unit must be connected by a separate branch and have its own machine. For one reason or another, he may simply be knocked out. Then, after checking, the shield must be switched to the on state.

Reduced pressure in the line

The first obvious symptom of this problem is the burner turning off. In this case, the pilot light does not go out, and the boiler turns off.

Here the movement of fuel through the pipeline is studied: the hose coming from the pipes is unscrewed and the valve is opened to the limit:

- If there is a strong hiss and there is a smell of methane, the gas is supplied normally.

- If these signs are weak or absent, there is a problem in the gas supply network.

After examining the picture, close the valve, place the hose in the primary position, and check the tightness of the joint areas using a soapy mixture. The presence of foam and bubbles indicates a leak.

Immediately block the gas supply, open all windows and doors, leave the room and call a special service. Eliminating such difficulties is the job of gas workers.

If there is no leak, inspect the meter for rust or scale. Because of them, the fuel flows poorly and incorrect indicators are displayed.

Federal Law No. 261 prohibits cleaning the flow meter yourself. This is the work of licensed technicians from the gas company.

Pressure testing and washing

Pressure testing of the system is not the most necessary preparatory stage, but it is desirable, since it will show defects and leaks in advance, if any. Pressure testing is not always done due to the lack of a special pump and the reluctance to call a team, but if the heating fails in the midst of cold weather, the costs can be much higher!

It is especially important to check a new system and one that, on the contrary, has been in use for several years.

The cost of crimping in construction companies is from 3,000 rubles. Additionally, they may charge a fee for visiting the site (about 2 thousand rubles). By the way, a manual pressure testing pump will cost 4.5 – 6 thousand rubles.

Preventive recommendations

We must remember that timely preventive maintenance is better than any repair. Therefore, it is worth servicing the boiler both at the beginning of the heating season and at the end. Moreover, before the start of the heating season, it is necessary to carry out test firing several times, and only after that start the boiler at full power.

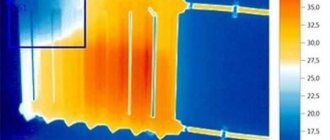

It is necessary to check all elements of the boiler for serviceability, especially if there are places where rubber is used. You also need to first fill in the coolant liquid and check for leaks from the circuit and radiators.

It is worth remembering that a gas heating installation is, first of all, a very dangerous equipment, which, if treated carelessly, regardless of the initial price, can simply explode if the user does not monitor its condition or does not hire people who are specialists in this areas.

It should also be remembered that when carrying out any work on the boiler - preventative or repair, it is necessary to completely turn off the power to the boiler and also turn off the fuel supply. Because otherwise the consequences can be more than sad.

Model Atem Zhytomyr 3

Of course, the company’s product range includes many models with different characteristics. However, the sales driver is the Zhytomyr 3 gas boiler, so it’s worth examining it in more detail.

The model is distinguished not only by its attractive price, but also by its excellent technical parameters.

The power of the unit is 10 kW. It is capable of heating an area of more than 100 m², which is quite enough for a country house. As for gas consumption, we can say with confidence that the equipment is economical.

Efficiency - 92%. Owner reviews of the Zhitomir 3 gas boiler are mostly good. Almost all users note the compact size, convenient operation and reasonable cost.

Oxygen deficiency

This phenomenon is usually caused by poor ventilation. It is determined by the following factors:

- window sealing,

- interior doors equipped with dense insulation and no gaps,

- a kitchen hood that is too powerful,

- unnatural ventilation.

The boiler may go out due to a powerful kitchen hood directing air through its channel.

The solution to the dilemma lies in installing supply valves on windows and walls. In the second case, ventilation devices are installed. They forcefully draw in air from the street.

Design Features

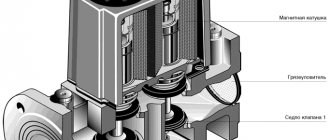

You can see the general structure of the Zhytomyr unit.

Construction of a gas boiler Atem Zhytomyr

The design features of the water heating boiler ensure independence from electricity for all models of the company. The burner is atmospheric and single-stage, with a simple design, brand POLIDORO, purchased in Italy, very reliable and durable.

The automation for Zhytomyr gas boilers is also reliable; it is also produced in Italy. The EUROSIT valve is automatic, does not depend on energy, is in great demand among boiler equipment manufacturers, it is installed in their own devices by production leaders in domestic and foreign countries.

To transfer heat energy in the heating system of the boiler, a fire-tube heat exchanger made of steel is used. This means that high temperature smoke gases pass through several pipes immersed in a water jacket. They transfer their own heat to the liquid and come out at a temperature of 110-150 °C. The pipes have a rectangular cross-section, and this makes the exchange surface area larger and makes the boiler operate more efficiently. In dual-loop models, there are copper coils around the heat exchanger tubes to heat domestic water.

Flue gas movement

To slow down the movement of flue gases in smoke pipes, turbulators are used in heat exchangers of mounted and floor-mounted units. Their backup function is to collect soot deposits remaining on the planes of these parts, which are located perpendicular to the gas flows, and soot deposits almost do not linger on the walls of the pipes.

In the future, soot can be easily removed from the turbulators, since when dismantling the heating device they are removed from the smoke pipes. This feature allows the surfaces of the smoke pipes to remain clean from the inside and effectively transfer heat energy to the water jacket. Otherwise, the soot layer that settles on the walls can greatly reduce their thermal conductivity, and the temperature of the outlet gases will increase, and the heat will go outside.

It is best to calculate the power of a gas boiler using

calculator

.

Atem Zhytomyr gas boilers will work properly with low draft chimneys. For this purpose, the equipment has a direct damper, which opens the way for smoke gases to escape without affecting the heat exchanger.

It works like this:

- Before ignition, the damper is opened. There is insufficient draft in the chimney.

- The valve adjustment wheel and the piezo ignition button are gradually pressed, the igniter lights up.

- The wheel is turned a couple of notches, gas is supplied to the burner and it ignites.

- High temperature gases (up to 200 °C) begin to flow directly into the chimney. Due to the temperature difference in the chimney, the draft increases and the boiler enters operating mode.

- After about 6 minutes, the damper is closed and the liquid begins to heat up, but the high traction force remains.

A mounted gas Zhytomyr boiler without a chimney is almost identical to the design of floor-standing equipment. The difference is in the design of the chimney; in mounted units it is coaxial. This is a double-walled pipe through which combustion products circulate, and air from the street moves towards them between the walls of the outer and inner pipes.

The burner takes oxygen for its own operation not from the room, but from the street, despite the combustion chamber being a closed type. In imported similar units, a ventilation device is built in for air circulation; in Atem boilers, the entire process is independent of energy and operates with natural draft.

Owner's review of the Zhytomyr heating boiler

The burner does not ignite

One of the most obvious disadvantages of atmospheric-type gas boilers (with an open chamber), such as, for example, Danko, is the dependence of the flame intensity on the oxygen content in the room - this is why so often the igniter, after going out, does not ignite again. To eliminate the malfunction, the following series of measures must be taken:

- Ensure adequate ventilation of the boiler room.

- If there are installed sealed double-glazed windows on the windows, introduce ventilation valves into their structure.

- If necessary, create natural ventilation in the room - open a window or door.

The boiler room should be sufficiently spacious and with high-quality ventilation Source sewerge.ru

A similar situation is caused by a number of problems directly related to changes in the draft value or similar in results, but caused by incorrect equipment settings:

- Chimney.

The attenuation of the burner flame, as well as the automatic shutdown protection, occurs due to a malfunction of the chimney system. In this case, 3 scenarios are possible:

- Blowing out or backdraft. Occurs due to improper installation of the external part of the system. The height of the pipe must be selected in accordance with the distance to the ridge. Otherwise, gusts of wind will lead to constant flame extinction.

- Excess traction. Excessive traction force occurs when there are other exhaust devices operating in the room - for example, general ventilation or a kitchen hood. It is necessary to exclude their influence on the room in which the unit is installed.

- Lack or absence of traction. Caused by clogging of the chimney - leaves, ice, soot, as well as burnout or deformation of the pipe. The chimney needs to be cleaned or replaced.

The chimney of a gas boiler must be installed in accordance with special requirements Source prohlados.ru

See also: Catalog of companies that specialize in autonomous gasification of country houses and related work

- Fan.

Models with a closed combustion chamber are equipped with fans for forced exhaust of fuel combustion products. However, if it breaks down, traction will worsen or stop altogether.

Characteristic signs of a breakdown are excessive noise, or, on the contrary, its complete absence. Restoration will require repair or replacement of the mechanism.

- Pump.

If the pressure in the boiler suddenly drops without leaks, the circulation pump is most likely damaged. Until the device fails, it will still distill the coolant, but with less force.

In addition, another sign of its failure appears in the form of constant attenuation of the burner flame. The circulation pump needs to be repaired or replaced.

- Igniter.

Incorrect gas supply settings lead to a “flame blow-off” effect. As a result, automatic protection is triggered and the equipment is turned off. To set up, you will need to perform the correct settings.

- Burner

As the injectors operate, sooner or later - depending on operating conditions - they become overgrown with carbon deposits. As a result, the clearance decreases and the gas supply deteriorates. Therefore, the combustion is interrupted.

To clean a gas burner, it is better to use the most effective method and tool Source khersonci.com.ua

To restore normal operation, you will need to clean the elements from carbon deposits and accumulated dust. In addition, it would be a good idea to update the surface of the sensor photocell.

Advice! You can check the draft in the boiler by holding a lit match to the outlet of the chimney pipe or the control hole. If there is a traction force, the flame will noticeably deflect. If the draft is insufficient or completely absent, the direction of the flame will not change.

Situations with dual-circuit devices

This technique may fade due to the reasons mentioned above. But if none of the signs are suitable, then the difficulties are caused by the specifics of the boiler. This category includes the response of the protective system against water overheating.

Documents for devices with separate heat exchangers, for example Ariston Clas B Evo 24 FF, usually indicate prohibitions on the simultaneous opening of two taps.

And in the settings, the optimal temperature for heating water is initially selected. To do this, use the regulator on the control console. Example on the Navien Ace device:

It should be taken into account that when cold water is turned on, the consumption of hot water is reduced and heat is generated in an identical mode. As a result, the heat exchanger overheats. Then the automation reacts, shuts off the gas, and turns off the boiler.

If you operate the device strictly according to the instructions, but it still goes out, the gasket of the water mechanism must be changed. There is a high probability of it wearing out.

All identified problems can be avoided if you carefully monitor the boiler’s condition and regularly arrange its technical inspection.

If you find it difficult to identify the cause, or there is already a noticeable smell of gas in the room, call the experts immediately.