Izospan is an innovative material for protection against moisture and steam, designed to improve thermal insulation properties. This article will talk about laying the most popular film options and its application. Which side of the insulation is placed on Izospan A or its other modifications, how it is attached and other issues will be discussed in this article.

Izospan series A Source www.nostroma.ru

Features of the material

This is a special membrane that allows air to pass through. In addition, the film performs other functions that are very important during the construction of a building:

- does not allow the development of corrosion on metal surfaces and mold on wooden elements;

- two-layer structure, allows you to retain steam, does not allow moisture to penetrate;

- protects various materials from the destructive effects of moisture.

Such characteristics significantly improve the efficiency of the thermal insulation materials used. To get this result, you need to know which side of the insulation is placed on Izospan V.

Series B film Source img.bizorg.su

Advantages and disadvantages

Vapor barrier does not allow moisture to pass through to the insulation, increasing its service life.

Vapor barrier membranes are a more reliable way to protect structures and insulation from moisture. A conventional waterproofing film does not allow air and steam to pass in both directions. If placed outside the insulation, it protects against water entering from the outside. However, it is powerless against condensation from indoor air. At the same time, it is impossible to waterproof the insulation on both sides.

Izospan allows steam to pass through from the heat insulator, but protects against entry from the outside. This protection mechanism provides many advantages:

- Neither steam, nor condensation, nor moisture enters the heat insulator. Dry insulation lasts much longer.

- Walls, roofs, and frame structures protected from steam do not deform, do not rot, or become moldy.

- Izospan serves as a wind barrier - it prevents the penetration of cold or humid air.

- The film is light, elastic, durable. Installing a vapor barrier takes a couple of hours.

- Izospan is made from polypropylene. This is recyclable plastic - more environmentally friendly.

The disadvantages of the product include:

- installation is prohibited in conditions of high humidity, rain or fog;

- before laying, the material must be kept in a warm room for a couple of hours;

- the cost of Izospan is higher than that of conventional film.

The vapor barrier membrane is selected taking into account the purpose of the structure. To insulate the bathhouse, use foil material; Izospan group A is chosen for the ventilated façade.

Why is vapor barrier needed?

It is important not only to know which side to put Izospan on, but also why it is important in use. It’s very simple - inside any premises moisture gradually accumulates and escapes through the ceilings. In cold weather, steam turns into condensation, which settles on structures and gradually destroys materials, and mold begins to develop. Using a vapor barrier will help get rid of such problems. The film must be laid correctly, otherwise it will not give the desired result.

Among all protection options, the domestic Izospan is especially popular and of high quality. It is made from special materials that give it a number of properties, the main ones being durability and high strength. The canvases have certain sizes that ensure the simplest possible installation. At the moment, there are no analogues for this film; it is one of the best, performs all the functions assigned to it and has an affordable price.

Laying Izospan Source buildhome.semtex.ru

Why do you need vapor-waterproofing in a floor structure?

In some floor structures, a vapor barrier is required. If we talk about insulation from steam, then there are two types of Izospan for floors:

Where is vapor barrier required? For example, in the construction of a floor on the ground. The soil under the floor always has some moisture. It may be more/less depending on the season and groundwater level, but moisture is always present in the soil. If the room is warmer or drier, moisture will move from the ground into the room. If a vapor barrier is not installed in its path, it will end up indoors and then there will be constant dampness in the house that cannot be overcome by anything.

Izospan is used for waterproofing and vapor barrier

Sometimes a vapor barrier layer is also needed in interfloor ceilings, but not always. Only where there are conditions for condensation. In apartments and on the second and higher floors of cottages, it is needed only where there may be high humidity below. If the room is located above the bathroom, kitchen, above the staircase, etc., then we add a vapor barrier to the cake. Downstairs in a room with normal humidity? You can save money on this layer.

In houses with basements, vapor barrier is needed, but, again, not always - only if the temperature in the basement can be below freezing. Even if the basement is unheated, but does not freeze, you can do without a vapor barrier. It is necessary to organize ventilation (vents) and you can do without using a vapor barrier. If you want to play it safe, please. It wouldn't hurt, but it's not necessary.

Which floor structures require vapor-permeable types of waterproofing? Where mineral wool insulation is used. In this case, we choose Izospan for the floor, which allows steam to escape, otherwise the insulation will get wet and lose its properties.

Film types

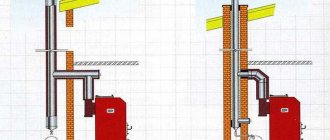

Izospan is presented in several options, which were developed for specific needs. The differences lie in a number of changes in the parameters of the scope of application, some characteristics and properties. At the moment, manufacturers produce materials that are divided into 4 groups, they include several types:

- A – used outside buildings;

- B – used only inside;

- C - for the roof, but provided that there is no insulation in it;

- D – designed specifically for concrete surfaces;

- AM – used at high humidity, has a reinforced structure;

- FB – high level of protection, for buildings with high humidity and temperature.

Izospan FB series Source teplotek24.ru

It should be noted that two-layer materials differ in structure and density, and have differences in purpose and application. A characteristic feature of such materials is heat retention and resistance to high temperatures.

Kinds

Some varieties of Izospan

Izospan is represented by a number of varieties, which differ somewhat in areas of use, characteristics, and capabilities. Essentially, any Izospan is a film or membrane. The entire variety of Izospan is divided into four large groups, but within these groups there are several more types of materials. There are about 14 in total.

| Izospan A | Izospan A. Designed to protect structures from the inside. This is a membrane. Its outer side does not allow wind and moisture to pass through, and the inner side removes steam, thereby eliminating the possibility of condensation. Mounted on top of insulation. |

| Izospan B | Izospan B. This insulation is vapor-tight. The side facing the inside of the room is fleecy and steam accumulates on the fibers. The smooth side should be adjacent to the thermal insulation. It is used for floors, ceilings, roofs and interior walls. |

| Izospan C | Izospan C. More durable material compared to Izospan B, but performs all the same tasks. Can be used in more “harsh” conditions. For example, to protect the walls of a frame house and cold roofs. Suitable for insulation in damp areas. The fabric is made from polypropylene and has excellent strength properties. Able to protect against moisture and atmospheric influences. |

| Izospan D | Izospan D. Distinctive characteristics are exceptional strength and resistance to UV radiation. This allows the material to be used as insulation for foundations, any roofs, floors and basements. |

Which side to lay Izospan

This material is today very widely used in the construction of various buildings. How to place Izospan correctly completely depends on the type of insulation used. These issues must be addressed before installation work begins. Particularly popular are the materials of the A and B series, which are distinguished by their high characteristics.

Installation is carried out using different methods, but the general rule is the same. The film is laid in such a way that the smooth surface is directed outward from the thermal insulation layer. On the other side there will be a fibrous side pointing inward. This allows moisture to be retained and prevents it from penetrating into the room. The rules for laying the material are described on the packaging.

Correct installation of Izospan Source dom.germanovich.com

Experts and the manufacturer recommend an overlap of the vapor barrier of at least 15 centimeters. All joints must be carefully sealed with tape or tape. Places of contact with structural parts are treated with a sealing strip. The tape is used at the junction of communications and structures.

See also: Catalog of companies that specialize in bath equipment, ventilation and air conditioning

The purpose of vapor barrier work

Wooden structures are very susceptible to moisture. This can cause the wood to swell and warp. The floor is an area that can come into contact with moisture on both sides. Soil moisture, as well as the constantly changing microclimate of the room, negatively affects the floor of the building.

In kitchens and bathrooms, water can often spill on the floor, although the humidity in these rooms is always high. This two-way bombardment of moisture can very quickly destroy the foundation or lead to the appearance of mold or mildew in the house.

In view of this, it is advisable to hydro and vapor barrier the floor in a wooden house. Thanks to such building material as Izospan for flooring, it is possible to qualitatively protect wood from moisture and condensation.

Installation recommendations

To get the maximum effect and effectiveness from using the material, you must adhere to a number of recommendations from experts. It is important not only to know which side of the insulation Izospan B is placed on, but also to follow the rules for attaching it.

Installation of film on the roof Source pravozem.ru

The vapor barrier installation diagram is as follows:

- Having opened and laid out the roll, it must be cut into strips of the required size;

- fastening parallel to the floor, you need to start from the bottom, the smooth side is directed away from the insulation;

- installation of the next tape should be carried out with an overlap of at least 15 centimeters;

- All panels are fastened with a regular construction stapler; galvanized nails can also be used;

- to seal all joints, you must use SL tape designed for this operation;

- a sheathing is mounted on top of the laid vapor barrier, the gap is within 40-50 mm;

- at the last stage, suitable finishing material can be mounted on wooden slats.

Lathing on Izospan Source pbs.twimg.com

Village Glazovo, house 7

In the picture from the instructions, everything is very simple: But in most cases it is not possible to actually implement the graphic instructions. The implementation may be essentially different, the main thing to remember is that the isospan B film is designed to protect the insulation from evaporation.

After going through several options, I settled on the following method of fastening the isospan:

The main thing here is to be careful, it is advisable not to leave folds when stretching the isospan and attaching it to the cranial bars with a stapler.

The most difficult thing is the beginning and the end:

You have to staple not in the most comfortable positions. And the effort required for a stapler is colossal, comparable to an expander.

Izospan must be attached with the rough side to the insulation. Afterwards, the boards of the lower subfloor are placed on it. Don’t forget to seal all joints with metallized tape:

Insulation is laid out on the lower subfloor, then everything on top is covered with isospan, which already protects against fumes from the room itself. You need to make a gap above the isospan; for this, slats are filled. And the upper subfloor - OSB-3 plywood - is already attached to the slats.

It will be possible to lay the main floor on top of OSB-3.

To work with isospan you will need very sharp scissors. My ideal is fiskars scissors. Cutting with knives, even sharp ones, is not very convenient.

Until the ceiling is sealed, a 5-meter space opens above your head:

Is there a lot of snow in the village? I answer:

If you don’t start it, you can drive it any day in any car.

Path to the well:

I doubt that the neighbors remember when there was a lowland here, what layer of snow they had to overcome to get to the well.

Expenses:

1) Paper clips, No. 42 (8mm) - 2 pieces - 418 rubles. I used to take 10mm ones, but I decided to try a little smaller one.

2) Ursa insulation - 859 rubles.

3) Ursa insulation - 644.25 rubles. OBI gave me a 25% discount because the pack of insulation was a little torn. My toad is absolutely delighted. Next time I'll take all the torn packs from them

Total: 1,921 rubles 25 kopecks.

glazovo7.ru

Advantages of film

This material is used directly for high-quality protection of various thermal insulation layers during the construction of buildings of various purposes and heights. The main qualities of the product are high strength, long service life, excellent reliability, simplest installation, absolute environmental friendliness, versatility, resistance to high temperatures.

The excellent versatility of the film makes it possible to use it for interior and exterior finishing work. But at the same time, you need to choose the right type of film for a specific job and also mount it correctly. Only in this case can we guarantee high performance and quality indicators of the material.

Izospan for outdoor work Source galich-dom.ru

Basement ceilings

Basement ceilings. Installation of vapor barrier

To preserve the hydro- and thermal insulation functions of the building structure in cases where a temporary rise in the groundwater level is possible at the site of foundation construction (during the autumn-spring period), it is necessary to ensure good ventilation of the underground space, as well as effective drainage of water from the foundation, i.e. .

It is necessary to carry out a complex of drainage works. 1. Floor 2. Vapor barrier Izospan RS, B 3. Insulation 4. Counter batten 5. Beam 6. Subfloor

Installation instructions Izospan RS, B

When installing basement floors, Izospan RS (Izospan B) material is used to protect all types of insulation from moisture, as well as to prevent the penetration of insulation particles into the living space. Izospan RS (Izospan B) is laid on the floor beams above the insulation (rough side to the insulation), with an overlap of 15-20 cm. It is recommended to create a gap of 4-5 cm between the finished floor and Izospan RS (Izospan B). Overlapping panels must be sealed with connecting tape Izospan KL, Izospan KL+ or Izospan SL.

Izospan C or Izospan DM can be used in basement structures . They are laid similarly to Izospan RS (Izospan B) , with the rough side facing the insulation.

Also in the construction of basement floors, Izospan FS, Izospan FD and Izospan FX , which are used as an insulating material that combines vapor barrier functions and the effect of heat flow reflection. The materials are laid on the floor beams over the insulation with an overlap of 15-20 cm ( Izospan FX - end-to-end) with a reflective surface inside the heated room. Overlapping sheets must be sealed using metallized connecting tape Izospan FL. It is necessary to maintain a gap of 4-5 cm between the reflective surface of Izospan and the finished floor.

In the case of erecting a basement floor on a concrete base , the installation of Izospan RS (Izospan B) vapor barrier is carried out according to a similar scheme.

Izospan D steam-waterproofing can be used, which is attached with an overlap of 15-20 cm from below to the subfloor using a construction stapler or antiseptic wooden slats . Overlapping fabrics must be glued using connecting tapes Izospan KL, Izospan KL+ or Izospan SL . When using this option on a concrete base slab, the vapor-waterproofing material is mounted on the concrete base of the basement floor, also with the obligatory gluing of material overlaps.

When using this option for installing a basement floor, special attention should be paid to careful sealing of material overlaps and to the junction of the insulation to the walls. We draw attention to the inadmissibility of installing wet materials (insulation and wooden structures). It is recommended to use materials that are resistant to moisture for insulation.

Places where Izospan materials meet wooden, concrete and other surfaces should be glued with Izospan ML proff .

Preparation for installation of a water vapor barrier layer

Laying a vapor barrier involves carrying out a number of preparatory works. First, you need to select materials for all layers, as they say, and also decide which vapor barrier is best for the floor. This “pie” consists of the following stages (starting from the top):

- Decorative floor covering.

- Plank floor.

- Vapor barrier.

- Counterrail.

- Thermal insulator (between the counter-batten boards).

- Water protection.

- Base floor.

We invite you to familiarize yourself with Insulation of floors in a bathhouse - All about the bathhouse

Preparation begins with the base floor itself. All boards, wooden blocks and other parts made of wood should be treated with a special disinfectant composition that prevents rotting, the formation of fungus, and also protects against insect attacks.

If we are talking about repairing the floor, and not about building a new building, then the finished floor boards, floor covering and existing vapor barrier on the floor must be removed in advance. All debris must be removed and then the wooden structure should be treated with an antiseptic.

Briefly about the main thing

To work correctly with Izospan, you must carefully study the instructions, as well as the product labeling. How fully the insulation will perform its functions will depend on which side the insulator is adjacent to the insulation. An error in location will cause the heat insulator to quickly fail.

Loss of the positive characteristics of the insulation will lead to the formation of an atmosphere in the room unsuitable for life. Expensive repairs will be required. After all, you will have to open the walls and completely change both insulators.