A long-burning heating boiler is designed to heat residential premises for a long time without adding fuel, as well as to obtain hot water for the needs of residents.

Most of these devices are capable of operating on a single addition of solid fuel for about 12 hours.

Some models can maintain heat for up to several days.

The choice of such equipment is huge; it is important to be able to distinguish an efficient high-quality boiler from less functional devices.

| Place | Name | Price |

| TOP 9 best long-burning solid fuel boilers with a water circuit | ||

| 1 | Stropuva Mini S8 8 kW | Find out the price |

| 2 | ZOTA Topol-22VK 22 kW | Find out the price |

| 3 | ZOTA Topol-16VK 16 kW | Find out the price |

| 4 | ZOTA Topol-32VK 32 kW | Find out the price |

| 5 | Stropuva S30 30 kW | Find out the price |

| 6 | Stropuva S40 40 kW | Find out the price |

| 7 | TEPLOV Universal TA-40 40 kW | Find out the price |

| 8 | SAS UWT 14 14 kW | Find out the price |

| 9 | TRAYAN TPG-15 15 kW | Find out the price |

Distinctive features

A long-burning double-circuit boiler operating on solid fuel is a modernized version of classic heating equipment.

It, among other things, also has a heat exchanger built into it, providing the home with a full-fledged hot water supply.

The design of the two-circuit model includes the following elements:

- Housing - can be made of sheet steel or cast iron. The thickness of the metal ranges from 4 to 6 mm.

- Fire chamber . Usually made from the same material as the body of the device.

- Grate type grate . It is located inside the combustion chamber; the material is cast iron. Enriches the fuel with the oxygen necessary to support combustion.

- Ash pan . Accumulates solid waste generated during combustion.

- Chimney - removes combustion products outside the room.

- "Water Shirt" . Most often it is built into the boiler body and filled with water, which receives heat from the walls, after which it enters the heating system.

- Additional heat exchanger coil - distinguishes double-circuit models from single-circuit ones. It is built into the water jacket of heating equipment to provide hot water supply to the house.

The main disadvantage of this design is the low degree of productivity . Therefore, models made of cast iron are more popular because they take longer to cool down.

Heating circuit with pump

The forced circulation circuit does not have the disadvantages of the gravitational system. The length of the pipes and their diameter can be any, you just need to install a powerful pump.

Tools and materials

Additionally you will need:

- phase indicator;

- wire cutters;

- stripper (device for removing the sheath from the conductors) or knife.

As for the tools, you will need a phase indicator.

The following materials and products are needed:

- copper wires with a cross-section corresponding to the current consumed by the pump;

- WAGO type terminals or self-insulating clamps;

- dielectric adhesive tape;

- cable box.

In addition to pipes, fittings and radiators, to install the circuit you will need:

- Diaphragm expansion tank. Due to the excess pressure created by the pump, the system is made closed, so the option for gravity heating is not suitable. You need a red membrane tank for process water. Blue for drinking is more expensive.

- Pressure gauge, air vent and safety valve. Together they are called a security group.

- Three-way valve with thermal head.

- Filter.

What to do with condensate

To avoid coolant with a temperature below +50...+55°C entering the boiler tank, causing the formation of acid on its walls, a mixing unit is installed near the heater.

The “supply” and “return” are connected by a jumper to a 3-way valve controlled by signals from a temperature sensor. When the coolant at the inlet to the unit cools below the critical temperature, the valve will change position, and a mixture of hot flow and cold flow will occur.

In this mode, the boiler is also started after a long period of inactivity. Until the coolant warms up, it circulates in a small circle through the jumper.

Instructions

The heating system is assembled according to the following rules:

- DN25 pipes are used; for long circuit lengths, DN32 pipes are used.

- Horizontal sections are laid with a slight slope, necessary only for drainage of the pipeline - 2-3 mm/m.

- They don't make an accelerating manifold.

- The safety group is installed on the side of the boiler supply pipe no further than 0.5 m from it. It is prohibited to place shut-off valves between the heat generator and the devices.

- A pump with a filter and a membrane expansion tank are connected to the “return” so that they operate in gentle conditions at a relatively low temperature.

- The pump is placed between the 3-way valve and the heater.

Heating diagram with a solid fuel boiler with a pump.

It is necessary to provide for the possibility of emergency discharge of excess heat.

For this use:

- a branch with radiators in unheated rooms (for example, in a pantry or on a veranda);

- a coil in the boiler tank, connected to the water supply on one side and the sewer on the other.

An automatically controlled valve is installed on the cooling element, which opens according to a signal from a temperature sensor.

Types of devices

According to the method of fuel combustion, long-burning boilers with a double circuit can be divided into:

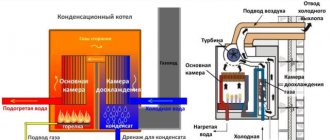

- Pyrolysis . Equipped with two combustion chambers. In one of them, the process of smoldering and the release of gas for pyrolysis occurs, in the other, the resulting gas is mixed with oxygen and burned. Equipment of this type is characterized by high environmental friendliness - a minimal amount of harmful substances is released into the atmosphere. The combustion process produces little soot. If the boiler is equipped with automation, power adjustment will be possible.

- With upper combustion chamber . Such boilers are very easy to maintain. The amount of automation required for their stable operation is minimal; it is possible to operate in autonomous mode without electricity. There are also disadvantages - a lot of ash is generated during operation, there is a list of requirements for fuel types. For example, small wood chips or sawdust are not suitable for kindling.

- Pellet . To kindle such equipment, special pellets or compressed fuel briquettes are used. Such boilers are environmentally friendly, economical and efficient, and have a long service life. One of the main disadvantages is the high price of the boiler and the special conditions that will have to be maintained for fuel storage. The room should be dry; high air humidity will contribute to the deterioration of pellets.

Optional equipment

To increase efficiency, a heat accumulator is installed between the boiler and the heating circuit - a water-filled container in a mineral wool shell. The solid fuel is constantly operated in nominal performance mode with maximum efficiency, heating the contents of the tank to +95°C.

A heat accumulator is installed to increase efficiency.

Hot water is withdrawn from the battery automatically as the medium in the circuit cools.

In a country house and other small buildings, a hydraulic arrow is used to connect the “warm floor”. This is a collector installed vertically. Thanks to this orientation, the temperature varies with height; the environment below is colder. Radiators are connected to the upper part, and “warm floors” are connected to the opposite part.

Advantages and disadvantages

Advantages:

- high level of environmental safety;

- increased heat transfer capabilities, which account for up to 90 percent of the generated thermal energy;

- the equipment is easy to install and maintain;

- for kindling, you can use various types of solid fuel, including inexpensive ones;

- the device can be used for both heating and hot water supply;

- compact dimensions of the boiler;

- there is no need for constant and frequent loading of raw materials to maintain combustion;

- the equipment can operate autonomously without the constant presence of a person.

Flaws:

- raw materials used for kindling in long-burning boilers must meet certain quality and humidity requirements;

- it is important to strictly follow safety rules at any stage of work, be it transportation and storage of fuel, its combustion, disposal of boiler waste;

- a significant level of labor costs when loading raw materials in non-automated boilers;

- high cost of such a unit in comparison with conventional boilers;

- automated equipment depends on constant access to the power grid;

- To store kindling materials you need to have sufficient free space.

How is the boiler power selected?

Accurate calculation of the required boiler power for heating a house is quite complicated. A simple technique is usually used: to heat an area of 10 m2, 1 kW of thermal energy is needed.

For unforeseen cases, a reserve of 10-15% of power is created. When using a water circuit or installing an additional boiler, additional energy of about 25-30% is required.

Climatic conditions make their own adjustments. In cold regions, where the air temperature can drop below minus 30 degrees, TKDG is selected at the rate of 1.6-2 kW per 10 m2 of room area. For the southern regions of the country, the requirement can be reduced: 0.8-0.9 kW per 10 m2.

How to choose and what to pay attention to?

The most important indicators when choosing long-burning solid fuel boilers with a built-in water circuit are:

- Availability of necessary fuel.

- The power level of the device depends on the area of the heated premises and the required temperature conditions of the coolant.

- The type of draft created inside the combustion chamber. Can be forced or natural. This parameter affects the possibility of placement in a particular room and the level of boiler performance.

- Efficiency. It will depend on the type of fuel used, design features and additional equipment used (presence or absence of exhaust hood, automation of fuel supply, etc.).

- The material of the heat exchanger - usually cast iron or steel - affects the reliability of the device and the characteristics of heating equipment.

- The type of location of the water jacket is important in order to correctly determine the installation location of the boiler from the point of view of fire safety rules.

- The weight of the unit is an important factor in determining the base where the boiler will be located. It must be strong enough and not subject to deformation.

- The method of loading fuel and the dimensions of the combustion chamber are important for determining the cycle of use of the unit and the possibility of setting up its automated maintenance.

- The design features of the ash pit and its accessibility will affect the ease of performing maintenance and maintenance work on the boiler.

- Cost level - depends on a combination of the factors listed above and the reputation of the equipment manufacturer's brand.

Operating principle of TKDG

Long-term combustion in a TKDG furnace can be ensured in 2 ways:

- Top combustion principle . In the combustion chamber, the fuel does not burn, but smolders with limited access to oxygen. The cylindrical firebox is located at the top of the unit and has a cylindrical shape. The gas released during smoldering enters the afterburning chamber, where a supply of atmospheric oxygen is ensured for its complete combustion. As a result, almost complete combustion of the fuel occurs with the active release of thermal energy.

- Pyrolysis principle . The combustion chamber is located at the bottom. Active smoldering of fuel also occurs here with limited access to oxygen. The combustible gas rises up and reaches the second chamber, where, enriched with oxygen, it burns completely.

Thus, the duration of combustion is ensured by the two-chamber design of the unit, when the fuel slowly smolderes in the firebox, and the released combustible gases burn in the second chamber.

Popular manufacturing companies

Heating equipment is always in high demand, which is why the majority of technically developed world countries are engaged in the production of such units.

Among the foreign manufacturers, the following brands are best known::

- Stropuva - produces long-burning boilers operating on solid fuel, chimneys and water heating systems, as well as shut-off and control valves (Lithuania).

- Buderus is a German specialist in the field of heating technology.

- WATTEK is a Czech company dealing with a wide range of issues - design, production, installation and maintenance of heating equipment.

- ACV is a Belgian manufacturer of heating and hot water equipment for domestic and industrial use.

- Wirbel is a company from Austria that produces various types of heating boilers, both solid fuel and electric.

Among Russian companies producing long-burning boilers, the following manufacturers are popular among users:

- NMK , full name - Novosibirsk Metalworking Company, is engaged in the production of various products, including solid fuel boilers of the Magnum series.

- ZOTA . The production is located in Krasnoyarsk and produces equipment for plumbing, heating units, including various types of boilers.

- TK TeploGarant LLC is a company from Kostroma that produces boilers for domestic and industrial use and various components for them.

Rules for arranging a boiler room

It is recommended to cover the floor with ceramic tiles and lay out the walls with refractory bricks. This measure will reduce the likelihood of a fire.

The floor with a wooden or other combustible covering within a radius of 1.2 m from the center of the boiler combustion door is protected by a 1.2 mm thick steel flooring on a thermal insulating substrate made of asbestos or basalt cardboard.

The walls are covered with fire-resistant plaster, for example, based on vermiculite. Layer thickness – 25 mm.

The following distances are maintained between the heater and the walls:

- from the combustion door side – 2 m;

- on the sides and back - 0.8 m.

The boiler room is equipped with emergency and emergency lighting. In case of depressurization of the circuit, it will be equipped with a ladder or pit 0.5 m deep connected to the sewer.

It is advisable to lay the walls of the boiler room out of brick.

With a heat generator power of up to 30 kW, firewood and coal can be stored near the boiler room in boxes made of fireproof material. The minimum distance to the firebox is 1 m.

If the boiler’s productivity is higher, an isolated, dry and ventilated room is allocated for the warehouse.

The best long-burning solid fuel boilers with a water circuit

Stropuva Mini S8 8 kW

Heating boiler running on solid fuel. capable of heating residential or industrial premises with an area of up to 80 m2 .

It is efficient and fully prepared for intensive operating conditions, including year-round use. A separate advantage is independence from electricity. The boiler can work with different types of solid fuel - coal, firewood, pellets.

Differs in compact sizes . Fuel loading is simplified by the vertical position of the firebox door. The ash pit is designed so that cleaning can be done only a couple of times a month.

The special combustion technology used in this model allows for long-lasting combustion of fuel with high efficiency.

One load of raw materials will provide you with warmth for at least a day. The burning time of pellets is up to 48 hours, depending on external conditions and fuel quality.

Characteristics:

- power - 8 kW;

- heated area - up to 80m2;

- purpose - heating;

- boiler volume - 40l;

- combustion chamber type - open;

- weight - 145kg;

- dimensions - 55.5*136.5x55.5 cm.

Advantages:

- high efficiency - up to 90%;

- safety;

- reliable design;

- built-in thermometer.

Flaws:

- significant weight;

- The door is difficult to clean due to the rough coating.

ZOTA Topol-22VK 22 kW

In this model, the configuration of the heat exchanger has been successfully changed and water-filled grates are used . The device body is reliably thermally insulated.

It has 2 combustion chambers, making both horizontal and vertical loading of fuel possible. The cell doors are securely locked.

The boiler combines a relatively budget cost with high device efficiency.

There is a separate door that allows you to remove ash even while the device is operating. One load of fuel will provide you with heat for 10-12 hours.

Additionally, you can install an external control panel to block the heating element and automate the combustion process.

Characteristics:

- power - 22 kW;

- Efficiency - 70%;

- non-volatile;

- heated area - up to 200m2;

- purpose - heating;

- weight - 128kg;

- dimensions - 90.5*47*87 cm.

Advantages:

- can heat a large area;

- easy to manage and maintain;

- vertical and horizontal loading.

Flaws:

- low efficiency.

ZOTA Topol-16VK 16 kW

Another representative of the line of boilers with a water-filled grate, which guarantees an increase in the heat transfer of the device.

Its pipe has a triangular shape, which eliminates blockages and increases service life. The boiler can consume pellets, wood or coal as fuel.

The boiler is convenient to operate, thanks to the large size of the firebox and two ways of loading fuel - it is convenient to load coal from above, and firewood - into the fire door.

The low cost is favorably combined with the efficiency of space heating.

Characteristics:

- power - 16 kW;

- Efficiency - 70%;

- heated area - up to 160m2;

- purpose - heating;

- weight - 108kg;

- dimensions - 80.5*44*87 cm.

Advantages:

- affordable price in its segment;

- efficiency;

- ease of use and cleaning.

Flaws:

- low efficiency.

ZOTA Topol-32VK 32 kW

The boiler, operating on various types of solid fuel, has a high level of performance, which allows you to make the heating system of your home high-quality and stable..

The equipment is considered very practical since it can be converted to natural gas consumption.

The equipment body has good thermal insulation, allowing it to be installed in any convenient place.

The efficiency of the device is quite high, given the low price among analogues . A single load of fuel allows you to maintain heat in the heating system for up to 12 hours.

Characteristics:

- power - 32 kW;

- Efficiency - 70%;

- non-volatile;

- heated area - up to 320m2;

- purpose - heating;

- weight - 143kg;

- dimensions - 87*44*100.5 cm.

Advantages:

- versatility;

- ease of management and cleaning;

- precise temperature control.

Flaws:

- No.

Stropuva S30 30 kW

Solid fuel heating boiler for installation in residential and commercial premises . Cost-effective, ready for seasonal or year-round use.

Does not depend on electricity, can operate on different types of solid fuel, and has high efficiency.

It is compact and does not require separate space for installation, and has an environmental safety certificate . The burning time for wood is up to 30 hours, for pellets – up to 2 days. No power required.

Characteristics:

- power - 30 kW;

- Efficiency - 85%;

- heated area - up to 300m2;

- purpose - heating;

- weight - 143kg;

- dimensions - 87*44*100.5 cm.

Advantages:

- high efficiency;

- safety;

- quality and long service life.

Flaws:

- high price.

Stropuva S40 40 kW

Long-burning solid fuel boiler with one circuit for heating rooms up to 400 m2. The fuel can be firewood or wood briquettes .

It has an open combustion chamber and is installed on the floor.

Characteristics:

- power - 40 kW;

- Efficiency - 85%;

- heated area - up to 400m2;

- purpose - heating;

- weight - 143kg;

- dimensions - 87*44*100.5 cm.

Advantages:

- reliability;

- attractive design;

- ease of maintenance.

Flaws:

- high price.

TEPLOV Universal TA-40 40 kW

Long-burning water heating and heating boiler, can heat residential and industrial premises and provide them with hot water.

Suitable fuels are briquettes, wood and coal.

You can choose an automated or non-volatile device option.

In the first case, you will receive reliable protection against overheating, freezing of liquid in the system, and the ability to adjust the temperature level for day and night mode.

Characteristics:

- power - 40 kW;

- Efficiency - 82%;

- heated area - up to 400m2;

- purpose - heating and hot water supply;

- weight - 390kg;

- dimensions - 147*48*77 cm.

Advantages:

- fuel versatility;

- heating and hot water;

- possibility of automation.

Flaws:

- large dimensions and significant weight of the installation.

SAS UWT 14 14 kW

The solid fuel boiler is made of steel and insulated with mineral wool to reduce heat loss . Can be installed as part of closed or open systems.

Equipped with an automatic control system.

It is possible to connect a hot water boiler.

The preferred fuel is coal, but wood burning is also possible.

Characteristics:

- power - 14 kW;

- Efficiency - 83.5%;

- heated area - up to 120m2;

- purpose - heating;

- weight - 310kg;

- dimensions - 54*141*101 cm.

Advantages:

- process automation;

- high level of efficiency;

- reliability and high build quality.

Flaws:

- high price.

TRAYAN TPG-15 15 kW

The boiler is equipped with one circuit and is intended for use as part of a central heating system with forced or natural circulation.

It is possible to connect a DHW boiler.

The unit differs from analogues in its low price while maintaining high performance.

The fuel can be firewood, peat or fuel briquettes.

Characteristics:

- power - 15 kW;

- Efficiency - 82%;

- heated area - up to 130m2;

- purpose - heating;

- weight - 270kg;

- dimensions - 72*73*160 cm.

Piping diagram without pump

In the absence of power supply or unstable operation of the network, a heating circuit with natural coolant circulation is constructed. Another name is gravitational. It does not require a pump, which means it is energy independent.

Principle of operation

The movement of the coolant through the pipes is ensured by convection - the tendency of a less dense heated medium to move upward under the influence of Archimedean force. Hot water is displaced from the boiler tank into the supply by colder water coming from the “return”.

Piping diagram for a solid fuel boiler without a pump.

Necessary tools and consumables

For installation you will need:

- perforator;

- levels – rack and spirit level;

- roulette;

- adjustable wrench "parrot";

- screwdrivers, pliers;

- for a polypropylene circuit - a special heater for welding plastic parts.

Materials needed:

- brackets for fastening pipes and radiators;

- dowels;

- tow or plumbing linen (FUM tape is not suitable due to the high temperature of the transported medium).

After heating, the volume of coolant will increase. To compensate, an expansion tank is inserted into the system.

Due to the absence of excess pressure in the gravity circuit, a cheap open type option is used.

Radiators, pipes, couplings and other fittings are also needed.

How to do

To create convection and minimize the hydraulic resistance of the circuit, it is built according to the following rules:

- The boiler is located at least 0.5 m below the radiators. In different rooms, marks at the same height are made using a spirit level.

- The first section from the supply pipe of the device is made vertical to the ceiling. This is an accelerating collector; it creates a strong convection pressure. The lowering is made along the corner of the room where the first radiator is located.

- Large pipes are used - with an internal diameter of 30-40 mm. As this parameter increases, the hydraulic resistance decreases.

- Horizontal sections are mounted with a large slope - 1 cm/m. This will make it easier for the cold liquid to drain back to the boiler.

The boiler is positioned to reduce hydraulic resistance.

The circuit must have a minimum of turns, fittings and other elements that increase hydraulic resistance.

The expansion tank is placed at its highest point. In order not to disturb aesthetics, the tank is often installed in the attic. In this case, the product must be insulated.

Minuses

The gravity system has a number of disadvantages:

- The length of the contour cannot exceed 30 m.

- Heat is distributed unevenly, radiators farthest from the boiler are colder than those closest to them.

- Due to the significant temperature difference between the “supply” and “return”, the heater experiences high loads.

- Large diameter pipes are needed, which increases the cost of the project and increases the volume of water.

- Through an open expansion tank, oxygen enters the working environment, causing corrosion of metal surfaces and airing of the circuit.

- It is impossible to operate the device in low-performance mode, which is required in the off-season.

Arrangement of a pellet bunker

There is a type of solid fuel boiler that does not require frequent loading of fuel. They operate on pellets - granules made from pressed waste.

You can make a bunker for storing them yourself from the following materials:

- tin;

- plywood;

- fabrics on a metal frame.

An electrically driven screw feeder is connected to the tank to automatically feed pellets into the burner. It is better to purchase a 2-screw model with an air gap, which eliminates the movement of fire into the bunker during reverse thrust.

Additional recommendations

To prevent the heat exchanger from becoming overgrown with scale, fill the system only with demineralized water. Often homeowners collect rainwater for these purposes.

For the same reason, it is better to purchase a model with a cooling coil in the heat exchanger, and not with water supplied directly to the tank.

Do not smoke in a house with an aluminum radiator system. Hydrogen is formed in them, which comes out through an air vent or Mayevsky valve.

During the period of inactivity of the heater, the heat exchange in its tank takes on the opposite direction. To ensure that the water in the circuit cools more slowly, it is recommended to create a bypass with taps through which the medium will move around the device.

By the way, it’s not difficult to make a solid fuel boiler with your own hands.