Updated: 01/06/2022 15:04:55

Expert: Bogdan Shevchuk

*Review of the best according to the editors of expertology.ru. About the selection criteria. This material is subjective in nature, does not constitute advertising and does not serve as a purchase guide. Before purchasing, consultation with a specialist is required.

A gas boiler is one of the most cost-effective ways to heat and provide hot water indoors. Expertology specialists examined the market at the beginning of 2022 and selected for you options for single-circuit gas boilers that received the best reviews and recommendations from experts and ordinary users.

Boiler design without electricity

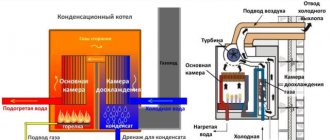

The gas boiler, independent of electricity, has:

- 2 gas burners – pilot and main;

- Combustion chamber - in such devices it is open for better traction;

- Automation;

- Boiler safety system - temperature sensor, backdraft valve (it is needed to regulate the operation of the chimney);

- Heat exchanger.

The system of a non-volatile gas boiler must have an open expansion tank, since when the coolant heats up, the liquid expands. And this is what promotes coolant circulation. But during expansion, excess is formed, which enters this tank.

Ignition in such gas boilers occurs using a piezoelectric element, which operates when a button is pressed. With its help, the pilot burner is ignited, and from it the main gas burner is ignited, thanks to which the heat exchanger is heated and the desired temperature of the liquid is maintained.

After some time, the gas does not flow and the burner goes out, after the heat exchanger has cooled down the process repeats.

Expansion tank for open system

An indispensable element that ensures the movement of the coolant, responsible for preventing its leaks and rupture of the pipe system as a result of a rapid increase in pressure, is represented by an expansion tank. In an open heating system there is no tightness, and the main requirements for such tanks are their sufficient volume and the presence of a supply pipe.

The most important function is, of course, compensation for the thermal expansion of the coolant of your open-type heating system. Thermal expansion occurs when the coolant is heated. The volume is increasing and it needs to go somewhere. There is room for this in the expansion tank.

Even if the tank is full, a drain pipe is cut into it so that when the coolant expands, it does not flow through the top and flood your ceiling. In this case, excess coolant is drained through an emergency drain pipe.

Also, the expansion tank in the open heating system of the house serves to remove air when the heating system is filling and operating.

To protect the water from debris, a special grill is installed. There are no increased requirements for the shape of such an expansion tank, but round, cylindrical and rectangular tanks are most often used. As a manufacturing material, it is advisable to give preference to metals that are as resistant to corrosion as possible (stainless steel and sheet steel) or heat-resistant durable plastics.

The expansion tank must be installed at the highest point of the heating system. When choosing an installation method, the best option is selected:

- on supply - the reservoir is located above the boiler;

- on the “return” – prevents water from boiling;

- combined method - installing a pair of tanks (supply and return).

During the installation process, an emergency drain pipe should be inserted, the tank body and pipes should be insulated, which will prevent the heating system from freezing and failing.

Types and types of heating boilers

Today, everyone has appreciated the convenience of an individual heating system - a non-volatile gas boiler is found in residential buildings, high-rise buildings, cottages, and small buildings in the private sector. The production capacity is also heated using similar but much more powerful systems. Gas boilers can be divided into industrial and domestic.

When considering the operating system of a gas boiler, we can conclude that this system includes technological as well as technical support for obtaining and then using heat energy for a wide variety of purposes. This is a powerful heating of industrial and domestic premises, heating of water for economic, hygienic, and heating purposes. The basis of this effect is the combustion of fuel, that is, natural gas.

Non-volatile gas boiler Buderus Logano plus SB745-1200

In industry, this heating using a natural resource becomes desirable because the cost is very low. The structure of this heating device is quite simple: a gas heater that heats the water, as well as a special heat exchanger that transports it through the system.

At the moment, the industry is producing the following designs of boilers for water supply and heating:

- Single-circuit non-volatile boilers that perform only heating functions.

- A non-volatile double-circuit gas boiler, in addition to its main functions, provides hot water supply.

Nowadays, models equipped with a broiler are also produced. This creates advantages because such devices have a reserve of water in case of a gas supply interruption. In addition, there are double-circuit boilers, the water in which is heated during movement.

Model of a gas non-volatile boiler equipped with a boiler

In addition to the listed models, the following types can be distinguished according to the method of placement: gas non-volatile floor heating boilers and wall-mounted ones. A non-volatile floor-mounted gas boiler is more popular than a wall-mounted, non-volatile gas boiler because it is the most reliable and easy to operate. Gas floor-mounted single-circuit non-volatile boilers are usually installed in a separate room or room in order to be able to hide the supply ventilation.

But, if you do not have the opportunity to allocate a room for the boiler, then it is better to pay attention to the wall-mounted option. It does not take up much space and has almost the same advantages as the floor-standing option

These design solutions help you choose the most suitable option, primarily in terms of technical parameters.

Single-circuit non-volatile gas heating boiler

Open system with heat storage

The multi-circuit heating scheme with heat accumulators includes special square or cylindrical containers, which are equipped with pipes of different levels. The volume of such a tank most often varies between 0.3-2.0 m³. Any heat accumulator must be installed taking into account the hydrostatic pressure of the coolant on the walls. When making calculations, you should add the height of the water column from the reservoir to the expansion tank installed at the highest point of the diagram.

What documents will the developer need to install the boiler?

Despite its apparent simplicity, it is hardly possible to carry out installation without the involvement of specialized organizations. Moreover, before starting the installation of a floor-standing gas boiler, it is necessary to prepare a number of documents.

You will need:

- Agreement for the supply of natural gas for an individual developer.

- Technical conditions for connection.

- Equipment installation project agreed with the gas service.

After the installation company completes its work, the facility is handed over to the gas service engineer. The correct connection is checked and the equipment complies with the design and standards. Upon successful completion, the consumer receives permission to use the system.

Pros and cons of energy-independent gas boilers

Energy-independent units have many advantages:

- The main advantage is the lack of dependence on electricity supply.

- Light weight and compact dimensions that will allow them to fit into any interior.

- High efficiency, which contributed to increased demand for these models.

- Work safety.

- Easy installation and low cost.

- Mechanical control of all functions ensures energy savings and autonomous operation.

These units are perfect for regions where power outages are not uncommon, and, thanks to their compact size, they will fit into small spaces. Non-volatile boilers can be installed at a facility where an autonomous power supply is used, which must be used sparingly.

The disadvantages of the presented boilers include:

- Some requirements for the heating system: pipes must be mounted at an angle; it is necessary to avoid a large number of bends in the highway; pipes must have sufficient diameter.

- The need for a good chimney that provides high-quality draft.

- It is necessary to ensure high-quality ventilation.

- The need for sufficient gas pressure in the gas pipeline to maintain the combustion process.

Features of gas heating

Despite the presence of a large number of alternatives (electricity, diesel, diesel, fuel oil, firewood, coal), gas heating is still the leader in the world. And there are serious reasons for this:

Economical. Compared to other options, gas is relatively cheap and has high efficiency. In this case, not only the cost of the fuel itself is taken into account, but also additional expenses for its storage (for the consumer), maintenance of the entire system, etc. Thus, parts for rare types of boilers can be difficult to obtain, and sometimes you have to overpay. This is also taken into account.

Minimal human involvement. Heating a room using wood or coal requires mechanical addition of fuel. Here everything is automated, including gas supply and flame control.

Cleanliness, absence of soot, soot and other things. Boilers can be easily installed in the kitchen.

Possibility of heating large rooms. One powerful boiler can handle a building with several floors.

At the same time, gas heating also has its disadvantages. Or rather, specificity.

Installation should only be carried out by specialists

In particular, the installation of a boiler requires approval from Gaztekhnadzor. Installation can only be entrusted to an organization with a license giving the right to provide such services.

Do not forget that gas is explosive. Therefore, saving on automation is extremely undesirable: it monitors, among other things, its leakage (we are talking about modern technology).

In addition, you need to take care of ventilation. Combustion products can be removed from the building naturally. But if problems arise with draft, you need to change the installation location of the boiler (which is not always possible) or provide it forcibly.

Types of non-volatile gas boilers

The vast majority of boilers of this type are floor-standing. If the boiler is non-volatile, then it is quite logical to assume that the heating circuit should function independently of electricity

Only heating systems with natural circulation work this way, and for them the location of the boiler is important, because To create pressure, the expansion tank must be raised as high as possible

In a natural circulation circuit, you can also install an energy-independent double-circuit gas boiler, which will provide the home with hot water.

In design, a floor-standing, non-volatile gas boiler is not much different from a conventional one; it has the same two burners - the ignition and the main, usually an open combustion chamber for good draft, a combustion product exhaust system (chimney or coaxial outlet) and an automation system that does not require electricity. A characteristic difference is the presence of a button for ignition using a piezoelectric element.

Floor-standing gas boilers can be single-circuit or double-circuit.

Gas boiler PROTHERM

An example is the energy-independent gas boiler Protherm, which is produced by the famous European company PROTHERM from the Czech Republic. It has been part of the German concern Vaillant Group since 2001. The Proterm Medved TLO model line is floor-standing, energy-independent gas boilers with a cast iron heat exchanger. Four models are available with powers ranging from 17 to 44 kW.

Main characteristics of PROTHERM boilers:

- classic non-volatile gas heating boilers of floor stationary type;

- cast iron heat exchanger ensures durability and reliability;

- safety is ensured by a thermocouple that controls the operation of the torch;

- ignition using a piezoelectric element was applied;

- average efficiency – 91%;

- removal of combustion products through the chimney;

- to control the coolant temperature, a thermostat is used, which sends a signal to a mechanical controller to turn the main burner on or off;

- the water temperature in the circuit is displayed on the panel using an overhead thermometer with a bimetallic spiral;

- An overheating alarm sensor is installed.

You can order or buy a non-volatile floor-standing gas boiler PROTHERM Bear in any specialized store, but first you need to calculate the required power of the boiler and select a suitable modification. In the PROTHERM series, Bear KLZ is the only gas-fired, dual-circuit, floor-standing, energy-independent boiler with a two-inlet cast iron heat exchanger with a built-in boiler. Power range from 18 to 49 kW in four modifications. The kit includes two expansion tanks for hot water supply and heating.

Floor-standing gas boilers of the Zhukovsky plant

Zhukovsky Mechanical Plant (ZhMZ) produces popular energy-independent floor-standing gas boilers with a power of 11.6 kW, which provide heating of 110 m2, and a model with a rated power of 29 kW will easily heat a home of 250 m2.

Floor-standing single-circuit gas boilers AOGV are manufactured in three main modifications:

- ECONOMY - boilers of this configuration are equipped with a mechanical automation controller made in Russia.

- UNIVERSAL - equipped with automatic equipment mainly made in Italy, for example 630 EUROSIT, 710 MINISIT.

- COMFORT – is also equipped with European-made mechanical controllers, which make the manufactured devices safe and reliable.

It is important that you can buy a non-volatile floor-standing gas boiler for little money, and in return you will get a reliable heating unit that is practical and durable

What it is?

A heating unit designed to heat the coolant and supply it to the heating circuit.

Wall-mounted models are mounted in a hinged manner on solid walls. Since the load on the supporting structures should not exceed a certain limit, wall-mounted models are not too large. Their power is limited to 40-50 kW, and the most popular are models from 15 to 16 kW, designed to heat rooms from 150 to 260 m2.

Such units have an attractive appearance, which allows them to be installed in kitchens or hallways. Installation is allowed only on sufficiently strong walls - a plasterboard partition cannot be a load-bearing surface. Separate premises are not required for them, but installing gas equipment in living rooms is prohibited by the rules. If the model is equipped with an open type burner, then installation is allowed only in rooms with a closing door (for example, in the kitchen).

Types of non-volatile boilers and their design

Based on the installation method, non-volatile boilers can be divided into two types:

- floor;

- wall-mounted

According to their functionality, boilers are divided into:

- single-circuit;

- double-circuit.

Let's consider the design of energy-independent floor-standing boilers.

Non-volatile floor-mounted gas heating boilers, like many other boilers, use water as a coolant. The water is heated in the boiler heat exchanger. The gas ignites in the combustion chamber and the pilot lights. The floor-standing gas boiler is energy-dependent to increase traction and is equipped with an open combustion chamber.

In addition, the components of a non-volatile gas boiler are: a chimney, a reverse draft valve, and a sensor to maintain the temperature in the desired mode. Non-volatile floor-mounted gas heating boilers use a manual piezoelectric element for ignition.

Video description

Additional food for thought about choosing a gas boiler in the video:

From domestic producers it follows about. The company's boilers are universal, suitable for most heating systems. Manufactured from high-strength steel. Many people are also well aware of the Zhukovsky boilers. Produced in the Moscow region, they attract with a surprisingly affordable price and simple design.

It is difficult to say which option is better here. Much depends on what exactly you are counting on.

Which gas boiler is better to choose for heating a private house: price

Prices for boilers, in terms of American dollars, start around 250 dollars and reach up to several thousand. Moreover, this amount does not always include delivery, and installation in most cases is paid separately.

In general, a double-circuit boiler is more expensive. But if you compare it not with a single-circuit one, but with a set of a boiler and a boiler, then the calculations are no longer so clear-cut. You will have to spend more money on the option with a chimney. And the most affordable one is a floor-mounted single-circuit boiler with natural draft of domestic production.

Single-circuit floor-standing boiler

True, paying less for a product does not mean that the issue of saving is finally resolved, because if in a few years you have to undergo serious repairs or a complete replacement, then the benefit is frankly dubious. Therefore, it is not advisable to focus solely on the issue of price when purchasing a boiler.

The gas boiler is the heart of the heating system. It largely determines whether your house (or apartment) will warm up normally, how much you will have to pay every month for utilities, whether there will be a problem with dampness, etc. Therefore, when buying a gas boiler, there is no need to rush. Moreover, there are many types of gas heating boilers on the market for a private home - for every taste and budget. This means you have the opportunity to choose the truly optimal option. We have looked at the main criteria for choosing a boiler for heating a private home, and we hope that you will not have any problems when choosing this important equipment.

Gas boilers are available in two common versions - with an open and closed chamber. What are both types of device?

Application and operation of a non-volatile gas boiler

Non-volatile floor-mounted gas heating boilers are used for heating the premises and supplying hot water. Most often, such boilers are used to service residential buildings and apartments, but sometimes they are used in commercial facilities.

Due to the difference in the specific gravity of cold and warm water, natural coolant circulation occurs.

The non-volatile floor-standing gas boiler uses an atmospheric burner as a burner.

Non-volatile gas boilers are produced both abroad and in Russia. The best floor-standing gas heating boilers are considered to be boilers from manufacturing countries such as France, Germany, and Belgium. Non-volatile gas heating boilers use automatic units and an automatic mode is designed that regulates the burner power.

This power control mode significantly saves fuel. Russian non-volatile heating boilers are inferior to foreign ones in quality and service life, but have a more attractive price.

What to look for when choosing

So, having considered what are the best floor-standing gas heating boilers, their scope of application and the design of a floor-standing gas boiler, let’s come to the question of their main characteristics.

It is best to purchase an energy-dependent floor-standing gas boiler at the stage of building a house. Since at this stage it is possible to design a heating system specifically for this type of boiler.

Non-volatile floor-mounted gas heating boilers have pros and cons. Positive characteristics of energy-independent gas boilers:

- do not require electricity;

- safety. The boiler runs on gas, not solid or liquid fuel;

- almost silent.

Disadvantages of such boilers:

- requires labor-intensive work to install the chimney, since for these types of boilers it is necessary to use a chimney with good draft;

- complex installation.

- If the boiler is installed incorrectly, the rooms may not heat up completely or the rooms will be heated unevenly.

Taking into account all the disadvantages of this type of boiler, it can sometimes be extremely problematic to install them in a house with more than two floors.

For example, if there is no good draft in the chimney, the valve will constantly operate, and this will lead to the boiler going out.

Advantages and disadvantages of double-circuit boilers with an open chamber

Purchasing a double-circuit gas boiler with an open chamber for a private home provides the following advantages:

- due to the absence of a fan for forced air supply to the burner area, the operation of the boiler is practically inaudible;

- heating of sanitary water and heating coolant is carried out in one housing;

- compact dimensions to save space;

- complete automation of the work process.

The disadvantages of this type of boiler include:

- the inability to simultaneously obtain good pressure and optimal temperature when using several water intake points in parallel;

- high probability of scale formation inside heat exchangers;

- dependence of automation on the availability of electricity.

If purchasing an uninterruptible power supply (UPS) will help you cope with the last point, then only installing a single-circuit boiler + indirect heating boiler system can solve the first two shortcomings. In this case, the boiler heats not tap water, but the prepared coolant, which eliminates the appearance of scale inside the heat exchanger. At the same time, there are no restrictions on connecting water intake points. And thanks to the implementation of the recirculation mode, there is no need to wait until the hot water from the double-circuit boiler reaches the tap.

Determining the appropriate model for an installation such as a gas boiler without electricity

The main guideline for determining the appropriate model of such an installation as an autonomous gas boiler without electricity is the correspondence of its heating power to the required area, and this characteristic must also correspond to the load on the installation. The double-circuit type of boiler, manufactured mainly by foreign companies, is often determined more serious price category. This is explained by the increased quality, design and more advanced functionality of the device compared to domestic analogues. At the same time, the manufacturer of the gas installation should be determined with special diligence; it is especially worth considering the presence of service centers of the represented company in the city or nearby, because the device requires maintenance and sometimes repair.

The most popular and high-quality manufacturers of gas autonomous boilers include the following companies: Italian manufacturers Alphatherm and Beretta - Italy, Slovenian company Attack, Czech-made Protherm and Swiss-made Electrolux.

Although models from domestic manufacturers are more attractive in terms of price, their reliability does not always correspond to the level of foreign analogues. Although they have their own special advantage - the models are produced according to all parameters corresponding to the use of boilers under local temperature conditions.

It is better to give preference to a gas boiler with heat exchangers for the manufacture of which cast iron or steel was used, and special attention should be paid to the first version of the material

. Such preferences can easily be explained by the impressive service life of the cast iron element, because a coolant of this type can last up to three decades, while a steel part will last no more than twenty years. In addition, cast iron coolant has high strength characteristics, since walls made of cast iron will be much thicker than those of steel, and practice shows that such a device will last much longer and more efficiently.

In addition, after many years of using a gas boiler, the heat exchanger tends to corrode. At the same time, cast iron is more advantageous than steel. Corrosion on this element of the device can occur as a result of a drop in temperature, which leads to the formation of condensation. Corrosion processes in such cases are provoked by released moisture.

In addition, the design of the heat exchanger provides for the presence of sections. If one of them is unsuitable, it is not advisable to change the entire heat exchanger; replacement is sufficient. At these production stages, all sorts of impurities are added to the cast iron, which significantly increase the strength characteristics of the boiler as a whole, which provides it with additional safety during transportation.

Rules for safe use

Natural draft gas boilers are quite popular due to their low price and other advantages. But when operating gas boilers, we must not forget about the safety rules:

We will send the material by email

When choosing a gas boiler for your home, you need to take into account a number of nuances related to the technical characteristics of the building, the installed heating system, the actual need for heat and hot water supply.

Domestic and foreign manufacturers offer a wide range of products. So finding a suitable copy is not a problem. You just need to know what to look for in order to understand how to choose a gas boiler for heating and not make a mistake. It is also advisable to understand how the presented options differ from each other, and which boiler to choose for a private home.

There are very few external differences between boilers of various modifications

Rules for installing a gas boiler

It is better to install a gas boiler independent of electricity in separate rooms with a good ventilation system, and also ensure air flow there. Because due to the open combustion chamber, air is constantly “eaten up” by the boiler. Combustion products are discharged through the chimney.

Rice. 3 Location of the boiler in the house

When installing a wall-mounted independent gas boiler, a coaxial chimney is installed, the design of which is called “pipe in pipe”. A coaxial chimney is not suitable for all devices and requires specialist advice.

If necessary, you can install a circulation pump. Mount it via bypass. It is recommended to install taps near it: 1 at the entrance and 1 at the exit. A tap is placed separately on the main line, which must be closed when the pump is running. If such taps are available, if necessary, you can repair the pump without draining the water from the system. It is recommended to install a filter in front of the pump.

There are certain conditions that must be maintained:

- the boiler room must have a positive temperature;

- fire safety. The walls in the boiler room must be equipped with non-flammable material. Typically, asbestos or metal sheets are used.

- The first start-up of the boiler after installation should be carried out under the supervision of a specialist.

A specialist should also check that the chimney is installed correctly. It is necessary that it corresponds to the power of a gas boiler without electricity and to the standards established by competent organizations. It is better to have a separate pipe for each heating device. According to the standard, the chimney should be straight; if it is impossible to make it this way, then there should be no more than 3 turns.

The length of the chimney should be about 5 meters. The heating unit must be selected and installed in accordance with the pressure in the gas pipeline, usually it is 1.270 MPa. The documentation that comes with the device (passport) always indicates the acceptable limits of this indicator. Sometimes gas pressure readings decrease in winter. Knowing this feature of the region, you need to select a device without access to electricity accordingly.

https://youtube.com/watch?v=whyv3CUO1mc

Can a gas boiler work without electricity? This question often arises among owners of private houses, who constantly have to deal with significant bills related to paying for electricity, because in addition to household appliances and light sources, sometimes you have to pay not as little for an electric boiler as you would like. Therefore, it is advisable to become familiar with the operating features of such an installation as a gas non-volatile boiler.

Device selection

When choosing a specific gas boiler model, you should consider the following characteristics:

- power;

- location method;

- number of circuits;

- features of burners;

- built-in automation.

The power of the gas boiler determines how much room can be heated. If there is not enough of it, it will be too cold. And if you work too much, not only will it be too hot, but your fuel costs will also increase.

To determine the required power, do a heat calculation . This is a calculation of heat loss through the roof, walls, windows and doors, etc. They largely depend on the materials used and the quality of insulation. And approximately the power is determined by the following formula: is enough to heat a 10 m2 room with a ceiling height of about 2.5 m .

Low-power models of gas boilers are available in wall-mounted versions. They take up less space and do not require a separate room. Such boilers are suitable for an apartment or small cottage.

How to choose the right model?

First you need to decide on the purpose of the purchase. If the boiler is purchased for personal home use, then you should not buy expensive large devices. For heating an apartment or a small private house, a mid-price product with a power of 10-15 kW is suitable.

Then you need to estimate the budget, which will include purchase, delivery, installation

The last point is often not taken into account in calculations, but in vain, because when purchasing an expensive boiler, you need to connect it correctly, otherwise breakdown is inevitable. Pay attention to reviews on the Internet to find out how easy the selected boiler is to operate and how difficult it is to find spare parts.

Consult your equipment supplier regarding this issue. Almost all modern companies offer the service of a technician visiting the installation site. The specialist will assess the area and furnishings and offer several options for the buyer.

Well-known companies and manufacturers

Single-circuit wall-mounted gas boilers are popular devices that are in high demand. For this reason, such designs are produced by all well-known manufacturers of heating devices.

Recognized leaders in this field of technology are German companies:

Italian companies practically do not lag behind them either in quality or in price:

Gas boilers from Czech and Slovak companies are distinguished by high quality and affordable prices:

In addition to them, Korean boilers from Navien or Kiturami, as well as Russian Lemax, Aton, Siberia, ZhMZ, are widely known. All these models are of high quality, capable of working in different conditions and performing their tasks in residential, public or industrial premises.