4.9 / 5 ( 14 votes)

A gas boiler is a device that we use to maintain heat. It serves as a heating device or a constant source of hot water. But in order for a gas boiler to properly perform its functions, it must be cleaned periodically. We’ll tell you how to do it correctly in our article.

- When is it time to clean a gas boiler?

- How to clean the igniter?

- Burner and nozzles

- Rules for cleaning the gas boiler filter

- How to clean the heat exchanger?

- How to remove scale?

- Firebox and chimney

Boiler cleaning frequency

How often should a gas boiler be cleaned? This depends on the quality of the water in the water circuit and the fuel that enters the unit. Externally, blockages and dirt appear as follows:

- when the unit operates in the usual mode, the temperature in the house is reduced;

- there was an increase in fuel consumption;

- there was a smell of exhaust gas.

To understand what exactly is clogged and how to flush a gas boiler with your own hands, you need to understand the structure of the unit.

Causes

So, as mentioned above, gas boilers are very popular among residents, and this popularity is growing rapidly. This growth is explained by the efficiency of the device, its cost-effectiveness, which is very suitable for providing heat to a house/apartment.

To ensure that a gas boiler does not fail, as with all other appliances, it must be maintained.

Most often, gas boilers suffer from soot, so in most cases, cleaning the device is done precisely because of it.

Which parts of the gas boiler need to be cleaned?

The main components require periodic preventive maintenance:

- igniter (its function is to ignite the burner);

- the burner itself with nozzles;

- gas filter (a device for purifying gas from impurities);

- heat exchanger (coil, inside of which the coolant is heated before subsequent distribution along the water circuit);

- combustion part;

- chimney channel.

Each unit has its own characteristics when carrying out preventive work. To know how to clean a gas boiler, you need to take these features into account.

Technical reasons

Gas boilers will need cleaning if the following phenomena related to the technical component occur to them:

- insufficient temperature in the room or space that the boiler should provide;

- increased consumption of electricity and gas;

- the appearance of a burning smell in a room or premises.

Such failures are usually caused by clogging. To get rid of the above problems, first of all try to clean the most important part of gas boilers - the burner.

Cleaning the igniter

When the igniter is clean and not clogged, the flame that comes out of it has the appearance of a bluish cone. A yellowish flame indicates that the igniter is clogged. Cleaning proceeds as follows:

- block the flow of fuel to the unit;

- the igniter is unscrewed;

- First, the removed part is cleaned with a wire brush;

- blow out the igniter;

- are installed in place.

The next stage of cleaning the unit will be devoted to the burner.

How to clean a burner with nozzles

The burner is the most important part; it must be perfectly clean, otherwise there will be no fuel savings. This applies to any type of boiler: wall-mounted or floor-mounted.

- the gas supply must be shut off;

- the burner is removed from the boiler;

- unscrew the nozzle (it’s convenient to take a photo before doing this so you know how to put the nozzle back);

- The nozzle is carefully cleaned with a soft brush;

- The burner is cleaned with a brush;

- The burner holes are purged with any pump (regular bicycle or car);

- the nozzle is inserted back into the burner (do not confuse its location);

- The burner and nozzle are put in place.

Important. The burner with nozzles must be cleaned regularly, before each heating season.

About the dangers of scale

Scale that forms in key components of a gas boiler leads to the following negative consequences:

- The thermal conductivity of the part deteriorates, since scale has high porosity.

- Scale deposits lead to uneven heating of the system, which can lead to ruptures at the welding points of various elements of the device.

- The information supplied to the liquid temperature control sensors no longer corresponds to reality. This will reduce the performance of the equipment.

- Partial or complete blockage of the working ducts will, in the long term, lead to breakdown of expensive equipment.

Gas filter

Equipment for cleaning the fuel entering the gas boiler also needs preventive maintenance before the onset of the heating season. Not only fuel consumption, but also the longevity of the main components of the boiler depends on its proper functioning. There are different models of filters; the filter material can be mesh or hair, so cleaning them depends on the design of the device.

How often should the boiler be cleaned?

There are many factors influencing this process, and they are all different:

- unit power;

- degree of purity of the coolant;

- gas quality;

- condition of pipelines;

- heat exchanger material;

- length of the heating line;

- radiator design;

- boiler operating mode;

- general age of the equipment.

In general, it is recommended to carry out cleaning once a year: this will be enough to bring the installation into working condition. Experts advise doing this before the start of the heating season. Of course, if before the start of the service unpleasant signs did not appear in the form of failures in the automation, the unpleasant smell of unburned gas and a change in the color of the flame on the igniter.

How to clean the heat exchanger

The heat exchanger (coil) is a very important part in the heating system. How clean its internal walls will be depends on the throughput of the coolant, and therefore the rate of heating of the water circuit as a whole.

Pay attention to the coil both inside and outside. It should not remain covered with a layer of soot, as this will negatively affect its function.

A set of tools that will be needed when descaling heat exchangers:

- scrapers;

- metal brushes;

- plastic brushes;

- power tool with attachments.

Stages of work:

- disconnect the unit from fuel supply;

- remove the heat exchanger;

- The device is cleaned with the above tools;

- the coil is installed in the unit.

Important. When working with the heat exchanger, do not use tools with sharp edges. If the surface of the device is damaged, it will further cause corrosion.

One of the reasons for contamination of the heat exchanger (scale formation inside the device) is the circulation of low-quality coolant through the water circuit. A clogged coil blocks the free circulation of the circuit, and this has an extremely negative effect on the performance of the system.

Practice shows that the best way to remove scale is to use chemical reagents.

Cleaning a gas boiler from scale can be done using the following means:

- adipic acid;

- sulfanilic acid;

- finished drugs.

The acid must be handled very carefully, taking into account the material from which the heat exchanger is made.

Important. To choose a way to flush a heating boiler at home and choose the right chemical, you need to focus on the degree of contamination of the heat exchanger.

Cleanable nodes

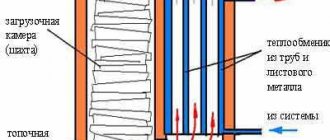

Gas boiler installation.

(Click to enlarge) This type of equipment has the following components that need to be cleaned periodically:

- igniter;

- burner with nozzles;

- gas filter;

- heat exchanger;

- firebox;

- chimney.

It is worth noting that cleaning each component of a gas boiler has its own specifics, which we will dwell on in more detail.

Igniter

When the igniter is functioning normally, its flame should look like a cone with a blue tint.

If the flame turns yellowish, this means that the burner is dirty. The cleaning procedure occurs in the following sequence:

- shut off the gas supply to the boiler;

- unscrew the igniter;

- Clean thoroughly using a wire brush;

- perform purging;

- Reinstall the cleaned igniter.

Burner with nozzles

This part is the main one in the design of wall-mounted and floor-standing gas boilers, since it is intended directly for supplying fuel.

The sequence for cleaning the burner with nozzles is as follows:

- the gas supply valve closes;

- the burner is removed from its installation location;

- the location of the nozzle is noted, and then it is carefully unscrewed;

- You need to carefully clean the nozzle with a brush;

- the burner is cleaned with a brush, and its hole is purged using available pumping equipment;

- the nozzle is inserted into the burner according to the mark;

- the burner is installed in place.

Expert advice: cleaning the burner with nozzles should be done once a year, preferably before the heating season.

Gas filter

This device is designed to purify incoming gas from various types of contaminants and impurities.

Therefore, it is very important to regularly clean the filter from accumulated clogging.

Heat exchanger

It is worth knowing that the main purpose of the heat exchanger of a double-circuit boiler is how much water will be heated and at what speed.

It is also necessary to understand that this element of the boiler unit can become clogged both inside and outside.

The outer part of the heat exchanger becomes contaminated with soot, which negatively affects its functioning. This boiler unit can be cleaned of soot mechanically, in other words, cleaning is done with your own hands.

To do this you will need the following set of tools:

- scrapers;

- metal brush;

- various shapes of brushes;

- power tool with cleaning attachments.

The cleaning procedure is as follows:

- gas supply and power supply from the boiler is turned off;

- the heat exchanger is carefully removed;

- cleaning is carried out using convenient tools;

- the device is installed again in its place.

An important point: try to use a tool for cleaning that does not have sharp edges. Otherwise, you may cause damage to the heat exchanger, which may cause corrosion of the product in the future.

The cause of contamination of the inside of the device may be poor-quality coolant, due to which scale settles on the walls. (By the way, you can read about cleaning a heating boiler from scale here).

As a result, the throughput of the heat exchanger decreases, which generally affects the functioning of the entire gas boiler. The most optimal way to clean the inside is to flush the gas boiler heat exchanger using chemicals.

In some cases, contamination causes equipment to fade. You can read about other causes of flame problems here:

Among the reagents that are used to clean the internal walls, the following products can be distinguished:

- adipic acid;

- sulfamic acid solution;

- special gel.

Specialist's note: the choice of reagent for flushing should depend only on the degree of contamination of the heat exchanger.

To carry out a full range of work on cleaning the internal walls from scale, special washing equipment is used, which is called a booster.

The booster consists of the following elements:

- circulation pump;

- reagent container;

- electric heater.

The principle of cleaning the heat exchanger using a flushing device such as a booster is as follows:

- to improve cleaning properties, the reagent is heated in a container;

- Using a pump, the solution is supplied under pressure directly to the heat exchanger.

As a result of the circulation of the chemical, the scale lags behind the internal walls and comes out along with the waste solution.

Experts advise: using a booster, you can clean not only the circuit of hot water boilers, but also the pipes of the entire heating system.

To the question of how often to clean the heat exchanger, we can answer that cleaning is carried out as it gets dirty, but not less than once a year.

You can learn more about calculating boiler power in this article:

An effective way to descale

To carry out the highest quality cleaning of equipment, you can use a modern device - a booster. It will effectively solve the problem of how to flush a gas boiler from limescale.

What does the booster include:

- circulation pump;

- container for loading reagents;

- electric heating part.

The booster functions as follows:

- the reagent is heated in a special container (in order to increase its cleaning properties);

- the circulation pump pumps the heated reagent into the coil;

- chemicals circulate through the heat exchanger and clean the walls;

- the spent reagent with dirt pours out.

Advice. The booster will also help out in cases where you need to clean not only the heat exchanger, but also the pipes of the entire system, or heating radiators.

The heat exchanger must be cleaned regularly, at least once a year. However, this procedure can be repeated more often if the quality of the coolant is very low. If ordinary tap water is poured into the system, then it is very simple to determine this: observe how quickly scale forms on the kettle. Hard water “suffers” from this deficiency.

Boilers of any model can suffer from scale. How to clean a Baxi boiler at home if there is no way to understand its structure? In this case, the best solution is to contact gas boiler specialists.

Soot removal

Despite the fact that gas is a fairly clean fuel, soot accumulates in the combustion chamber and in the chimney over time. Soot is a product of the combustion of organic compounds. If too much of it appears on the walls, the draft will disappear and the boiler will not be able to work productively. In this regard, it is necessary to periodically clean the combustion chamber, chimney and other elements of the boiler.

You can get rid of it using friable abrasives. If a small layer has formed on the walls of the boiler, you can deal with it with soda and a hard sponge. To clean the walls of the boiler you will need a brush, scraper and rags.

Having carried out all the work on cleaning the elements of a gas boiler, you can expect an increase in its efficiency.

We pay attention to the firebox and chimney duct

Natural gas differs from solid and liquid fuels in that it is a pure fuel product. However, not so much that there are no combustion products, which during the operation of the boiler accumulate on the inner surface of the combustion part and inside the chimney duct.

There are many devices that are used to clean chimney ducts from soot: these are brushes, brushes of various configurations and sizes. You can buy them in stores or take old brushes intended for household needs.

Basic cleaning methods

The heat exchanger is cleaned in the following ways:

- mechanical;

- using chemical reagents;

- hydrodynamic;

- electric discharge.

Mechanical

The mechanical method involves manual cleaning using various auxiliary tools. This is the simplest and cheapest method that does not require the owners to spend money and time. However, its effectiveness leaves much to be desired. Mechanical cleaning does not provide a 100% guarantee that the problem will be corrected.

What you will need

To mechanically clean the heat exchanger you will need to prepare:

Refrain from using tools that have sharp edges. They can damage heating system components.

How to clean

We remove the part needed for cleaning and carefully treat its surface with a brush. To clean the internal surfaces of the part, use a brush or vacuum cleaner.

Using chemically active substances

Chemical cleaning is much more effective than mechanical cleaning, due to the removal of blockages in hard-to-reach places that cannot be reached with a regular brush. Advantages of the method:

- reagents cost money;

- chemicals are harmful to the human body and must be used extremely carefully;

- requires specific equipment, which you will have to purchase in a store or do it yourself.