The designs of heated floors are constantly being improved, resulting in new types and modifications of these systems. One of these new products is infrared film heated floors, which have their own advantages and disadvantages. Many people, due to a lack of information, consider such floors to be dangerous and even harmful to health. In fact, these systems are as safe as any other, provided they are installed correctly and the rules of use are followed during operation. Some home craftsmen prefer to install film heated floors with their own hands.

General design of infrared floors

The construction of film floors is quite complex, so their design is assembled exclusively in the factory. A special nanostructure based on carbon materials is used as a heating element. With the help of carbon atoms, a hexagonal lattice is formed, which generates infrared radiation, invisible to the human eye.

This lattice is placed between layers of dense polymers. Its elements are connected to each other through copper busbars, which are coated with silver. The strips are located at a distance of 15 mm from each other. Layers of polymer materials provide protection for heating elements from mechanical stress, fire, moisture and other negative factors.

Polymers not only protect, but also transmit infrared radiation well. Thanks to these qualities, it is possible to install electric heated floors under tiles and other types of coverings.

Specifications

Before deciding to use such systems in specific conditions, it is necessary to carefully study their main technical characteristics. Film heated floors are produced in widths from 0.5 to 1.0 m, and the roll length is 50 m. Thickness ranges from 0.2 to 0.4 mm.

One square meter of film consumes power of 25-85 W/h. The heating element is capable of creating an operating temperature of 30-50C on its surface. This is important to know when choosing a warm floor for tiles. Thanks to these parameters, film heated floors often serve as the main heating for apartments or private houses.

Principle of operation

The operating principle of this floor is based on the use of infrared radiation. Such radiation heats not the air space, but directly the objects that surround you. The power of the infrared floor is 220 W. per 1 square meter. We can say that this is a lot. But the floor only consumes this amount of electricity for a few minutes until it warms up to the desired temperature. Then energy consumption stops and the system switches to energy-saving mode. Due to their characteristics, infrared rays do not lead to the formation of convection currents. This material heats the entire room evenly. The air does not dry out with this heating. Also, dust does not rise, which is so disturbing for people suffering from allergic reactions. Due to the safety of this material, heated floors are used in hospitals and children's institutions.

Application

The minimum area that must be covered by the heating system is 70% of the total floor area. However, in places with cold climates in winter, these floors are connected and used only as additional heating. In these situations, they experience increased stress, which they simply cannot cope with.

Sometimes infrared floors serve as emergency heating in case of failure of the central heating system during severe frosts. Film heating, powered from the electrical network, is quite capable of maintaining the temperature level in the room close to comfortable and preventing hypothermia of the people living here.

Infrared systems can be installed not only on floors, but also on other surfaces - ceilings or walls. They are ideal for bathrooms where they only turn on when needed. To do this, electric heated floors are laid under the tiles, after which the tiled floors will be constantly warm, and the air in the room will reach the set temperature.

Temperature controller installation

The presence of thermostats in the heating system is a necessity. This is explained by three reasons:

- Their presence ensures stable maintenance of a comfortable temperature in the room, and it is possible to determine its own temperature level in each room.

- Installation of these devices allows you to obtain significant cost savings on maintaining the required temperature, especially if we are talking about the heating system.

- A thermostat installed in a heating system allows you to smooth out temperature changes that accompany such systems.

Installation of thermostats begins with their selection and purchase. When choosing, you need to know that the temperature regime can be affected by:

- draft;

- the presence of objects that absorb heat, etc.

The thermostat design consists of a sensor and valve that operate without the use of external power sources.

There are two types of thermostats - built-in and external. They differ in the installation method - the first type is installed directly into the wall, the second type is installed on its surface. The distance from the regulator installation site is one meter.

The dimensions of the built-in regulator allow it to be installed in sub-sockets. For installation you will need:

- a hammer drill equipped with a crown and groove drill;

- corrugated sleeve.

Impact on the environment and the human body

The properties of film floors have not yet been fully studied, since they began to be used relatively recently. In this regard, the most contradictory judgments arise regarding these systems. There is an opinion about the beneficial effects of infrared radiation on the human body. Allegedly, it is completely harmless and serves as an effective means for the prevention of many diseases.

However, both supporters and opponents of film floors are wrong. The fact is that the emitted electromagnetic waves have extremely low intensity and do not have any negative effect on humans. Much greater radiation is emitted by heated cable floors used under tiles and with other coatings. However, it is considered completely safe and harmless to health.

With such a low level of radiation, film floors do not have a positive effect on the human body. The positive influence of electromagnetic fields is possible only when the temperatures of the human body and the infrared wave coincide. This state is almost impossible to achieve at home. The uniform heat of a heated room and optimal air humidity are considered more beneficial.

There is a misconception that it is impossible to use an infrared floor in conjunction with laminate or linoleum, which prevents the passage of radiation. Indeed, the rays from the film do not pass through such a floor barrier, but in this case they themselves heat up first, and only then the heat from them enters the room. If other types of flooring are used, the heat directly warms the air and spreads immediately to the entire height.

Procedure for installing and connecting the system

As a rule, the installation of infrared floors is carried out by specialists. Some home craftsmen can install heated floors under tiles with their own hands if they have certain work skills and follow the sequence of operations.

The standard installation scheme includes the following stages of work:

- At the very beginning, a plan is drawn up according to which the film will be laid out. The installation locations of the thermostat and temperature sensor are determined in advance. After this, the thermostat is installed in its place. All this is done before laying other floor elements.

- The base is being prepared. It should be smooth, clean and dry.

- If it is impossible to create a flat surface, chipboard or plywood with a thickness of at least 10 mm is installed on the floor.

- Protective waterproofing device. A film with a thickness of 50 microns or more is best suited for this.

- Laying a thermal insulation layer. Typically, lavsan film or the same metallized and polypropylene coating is used with the film. It is not recommended to use materials with aluminum foil.

- The roll is cut into separate strips along the marked lines. The length of each strip is determined in accordance with the diagram.

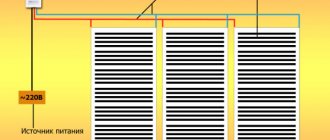

- Installation of film heated floors is carried out on thermal insulation with the tires facing down and fixed with tape. The strips must not be overlapped.

- Special contacts are used to connect elements to each other.

- After installing the temperature sensor, the system is connected to the thermostat, after which the film heated floors are connected to the electrical network.

- At the final stage, the floor covering is laid.

What errors can occur during installation, and what will they lead to?

If the installation is done correctly, there will be no problems when using the infrared heated film floor.

However, sometimes the following mistakes are made:

- Incorrect connection of strips to each other. This is the most common mistake when installing warm strip floors.

- If instead of a parallel connection a serial connection is made, then the heating will not be effective; with other errors, a short circuit may occur.

- Incorrectly cut film during installation. Manufacturers have clearly marked the lines along which the product can be cut. If this is not observed, the electrical circuit will break and the product simply will not perform its function.

- The rough surface was not cleared of debris and dirt. If sharp objects and pieces of dirt remain, they can damage the film, which means breaking the electrical circuit. The warm floor will stop functioning in some area, or entirely.

- The heated floor is not connected through an individual residual current circuit breaker. This error is very serious and may result in fire or electric shock. The automatic switch ensures that the infrared floor is immediately disconnected from the power source in the event of damage to the wiring or short circuit.

- Incorrect temperature sensor location. The thermostat will receive distorted information about the heating temperature, thereby making the adjustment ineffective. The sensor cannot be installed near an open balcony door, where it will be additionally cooled. It will also give a biased temperature if it is exposed to direct sunlight.

The listed mistakes when installing underfloor heating film are made quite often. Therefore, it is better to foresee all these nuances in advance.

Advantages of infrared heated floors

Even in the short time during which film floors have been used, the following positive qualities of these systems have already appeared:

- Simple and convenient installation of film heated floors, no concrete screed. All work can be completed within a few hours. Installing film floors is relatively inexpensive.

- These systems are used with almost any type of floor covering: parquet, laminate, linoleum, carpet. In addition, it is possible to install heated floors under the tiles.

- Due to the insignificant thickness of the film, the thickness of the floor does not increase, and the height of the room does not decrease.

- Rapid heating of the elements and equally rapid completion of heating due to low heating inertia. The rooms are heated evenly, there are no temperature differences in the direction from floor to ceiling.

- Warm electric film flooring is resistant to increased loads on floor coverings typical of public buildings, offices, gyms, etc.

- The air in the room is not allowed to dry out; humidity is maintained at an optimal level. There is an opinion that infrared radiation has an antiallergic effect and eliminates unpleasant odors.

- Film floors can be installed and included in the overall Smart Home system. Their use allows you to reduce energy consumption by up to 30%.

Disadvantages of film systems

Despite a lot of undoubted advantages, infrared systems have certain disadvantages, which sometimes become decisive.

In order to avoid pitfalls, it is necessary to take into account the following features when you need to solve the problem of how to install a heated floor:

- Installation of the system quite often takes longer than expected by the manufacturers. This happens even with the participation of experienced specialists.

- Sometimes the clamps are not tightly connected, which leads to poor contact between individual floor elements. Damaged clamps are no longer suitable and you have to use new contacts.

- The process of laying heated floors must take place on a perfectly flat surface. Even minor distortions lead to its ruptures after the floor covering has already been laid on top.

- Despite the small thickness of the film itself, ultimately the thickness of the heated floor can be up to 35 mm, which is achieved by laying chipboard or plywood, as well as thermal and waterproofing materials along with the floor covering.

- High reliability of the system is possible only if all recommendations and instructions are strictly followed and the work is performed with high quality.

- The declared 20% savings on heating can only be achieved with high-quality insulation of the room and uninterrupted central heating.

The best film heated floors

The modern market for infrared floors is filled with various types of these products from well-known manufacturers. The price of products varies greatly depending on the quality of the film, the configuration of the system, and the popularity of a particular manufacturer. These can be expensive European floors, fully equipped, even with self-regulating systems, or inexpensive products from Chinese companies. In order to determine which is better, you should consider various options.

Q-Term

A Korean company that produces universal film floors that are installed not only in residential but also in public buildings. Q-Term are equipped with carbon heating elements with a power of 130-230 W, so it is quite possible to install a heated floor under the tiles. Rolls are available in widths from 0.5 to 1 meter, which makes installation faster and more convenient. Although the product is quite expensive, it is best suited for installation under a tiled floor.

Caleo

Also a Korean manufacturer. The products are of good quality combined with low cost. Rolls of universal film are 50 cm wide and have a power of 180-220 W. Caleo sometimes develops spontaneous ruptures or deformities.

Calorique

High quality film floors from an American manufacturer. The main advantages of the film are high strength and flexibility, resistance to mechanical stress. This is the best heated floor for tiles. Calorique systems are considered the most durable and reliable, and are very popular, despite their high cost.

HeatPlus

Korean manufacturer producing high-quality infrared film heated floors with carbon heaters. The width of the rolls is in the range of 50-80 cm, and the power of the system is 150-220 W, depending on the modification. High-power products are produced with power consumption of about 400 W. As a rule, they are intended for loggias, open terraces, etc. It is allowed to lay heated floors under the tiles. HeatPlus is equipped with anti-spark protection. The warranty period is at least 15 years.

RexVa

Korean high quality film. Equipped with an anti-spark mesh, it is completely safe to use. Has increased resistance to breakage and tearing. Production of rolls with a width of 0.5; 0.8 and 1 meter. The amount of energy consumption reaches 350 W.

Thermoreg TI 200 thermostat

| Manufacturer: | Thermo |

| Model: | TI 200 |

| View: | electronic thermostat |

| Power: | 3600 W |

| Installation type: | recessed |

to compare old price RUR 3,528 RUR 2,990

Photo Name Price per piece. Quantity Cost

| Thermoreg TI 200 thermostat | 2,990 rub. | <1> | RUB 2,9902,990 |

There are 0 items in the cart worth 0 rub.

← Continue shopping