In the absence of centralized heating, boilers take on the responsibility for heating the home. To accommodate such equipment, it is necessary to prepare a separate room, observing safety requirements and standards.

Agree, at first glance the task looks difficult. However, it is not. Knowing the basics of calculations, rules and design principles, you will be able to plan the room yourself. A typical boiler room diagram for a private house is developed taking into account the specific type of boiler and a list of additional equipment for the heating system.

We will help you understand the issue, describe the features of different boiler rooms, and outline the requirements and rules for their arrangement. Thematic videos clearly demonstrate examples of organizing premises for installing and piping boilers.

Types of boiler houses for the private sector

The requirements for boiler houses are set out in SNiP with the nomenclature designation II-35-76.

Depending on the location of the room with heating equipment installed in it, boiler rooms can be classified into one of the following types:

- built-in;

- free-standing;

- attached.

The dimensions of the room allocated for the boiler room are selected based on the type of fuel and the type of boiler design.

When it is difficult to arrange a special room for a boiler room, there is another option - a mini-boiler room.

It is placed in a container assembled according to the principle of metal structures, which can be placed in the courtyard of the house. All that remains is to connect the mini-boiler room to the communications.

Image gallery

Photo from

Selecting a boiler room by type of placement

Freestanding boiler room

Location of private boiler room

Combustion product removal system

The not very popular popularity of such modules is explained by their rather high cost. If there is a prospect of allocating space for a boiler room in the basement, you can buy the equipment separately. Then the heating system will cost much less.

A mini-boiler room in the courtyard next to the mansion eliminates the need for design work, construction and arrangement of a separate room, and ventilation equipment. The container already contains everything you need for the efficient functioning of the heating system

Finishing

As the requirements of regulatory documentation state, the floor must be leveled and the walls must be covered with a layer of plaster. It is advisable that the lower part of the room be waterproof. This will make it possible to minimize the negative consequences of a possible accident in the heating system.

During finishing work, you can also further increase the thermal insulation/sound insulation properties of the room, which will play the role of a boiler room. For this, it is permissible to use PVC panels or reflective TIM panels.

What is a “smart boiler”

To implement an automation scheme for a private boiler room, you need to invest additional funds. A simple thermostatic valve will cost very little, but programmable systems are many times more expensive.

Constant operation of a conventional boiler in one mode entails a large consumption of electricity and money. Therefore, the cost of purchasing an automation unit quickly pays off during operation.

Automation in a private boiler room guarantees the functioning of the heating system with maximum efficiency, which allows for comfortable conditions for residents living in the house.

By installing automation, the home owner can adjust the heating process according to his needs. Thanks to this, bills for consumed energy resources will be reduced by 2 times.

Controlling the boiler in automatic mode makes it possible to:

- Turn off the boiler in case of an unusual situation. Carry out automatic start or stop of the boiler in the current mode. Depending on the outside temperature, set the heating temperature.

- Manage the heating or water heating branches of a boiler with 1 combustion chamber.

- Regulate the temperature of water or other coolant.

- Make adjustments to the operation of the circulation or recirculation pumps if the heating system in the house is arranged in a closed circuit. In this case, the system cannot function without automation.

The most important element of the heating system is the thermostat. Its function is to regulate the temperature both in a separate room and in the entire house.

There are many types of thermostats - from simple mechanical to weather-compensated. The latter is the most technologically advanced, profitable, but also very expensive.

The heating control system consists of a temperature controller (1), an outside air temperature sensor (2), an actuator (3), a coolant temperature sensor (4), a display for connecting to an external control system (5), a circulation pump (6) , coolant supply (7), consumer circuits (8) (+)

The price of automation depends on the type of boiler used, the presence of heated floors, solar collectors, etc. In order not to spend extra money, you should analyze the features of all schemes and calculate the cost. It is quite difficult to do this yourself, but you can always turn to specialists with this problem.

Reducing the resistance of pipes and circuits

With any wiring diagram or coolant circulation method, it is necessary to reduce the pipeline resistance and ensure optimal fluid movement through the pipes, avoiding both laminar movement and completely turbulent movement.

For systems with natural circulation:

- Any turns and bends along the route are carried out taking into account the minimum permissible turning radius for the type of pipe used.

- Transitions between pipes with different diameters, insertion of risers into the distribution manifold are carried out without narrowing the smaller diameter and, if possible, with a gradual expansion/constriction of the channel.

- In front of shut-off, control valves, radiators or other equipment, a smooth section of pipe should be formed at least 5-6 pipe diameters in order to eliminate unnecessary turbulence and turbulence in the liquid flow.

For a system with forced circulation, the previous tips are not mandatory; it is important that the circuit resistance is less than the pressure generated by the pump. However, if all requirements are met, the load on the pump will decrease and its operating life will accordingly increase. Due to the forced pumping of the coolant, you can use metal-plastic pipes with a small cross-section, a lower two-pipe or one-pipe connection scheme, including packing the pipes into a screed or walls.

Gas boiler room for your home

Gas is an explosive substance, so the requirements for gas boiler houses are very strict. If a boiler with a power of up to 30 kW is sufficient to heat the house, then there is no need for a separate room for the boiler room.

The boiler can be placed in a well-ventilated kitchen on a wall made of non-combustible materials, provided that the volume of the room is at least 15 m ᶾ, the height from floor to ceiling is from 2.5 m, and the floor area is from 6 m².

If there are no walls made of non-combustible materials in the kitchen, then the boiler is installed on a surface plastered and insulated with a special screen

All requirements for gas boiler houses are related to preventing the consequences of possible gas leaks. For this purpose, the window area in the room where gas equipment is installed starts from 0.5 m², and the door width from 0.8 m.

The chimney of such a boiler room must rise above the roof ridge by at least 500 cm and have an additional channel for cleaning. Condensate collectors must be installed on the chimney and ventilation.

When gas enters the boiler, electronic or piezo ignition is turned on. A spark occurs and it ignites the igniter, and from it the main burner, heating the coolant to the set temperature. Next, the automation turns off the burner

If the power of a gas boiler exceeds 30 kW, then a separate building is required for it.

The requirements for a separate boiler room are set out in the building codes:

- the foundation of the boiler room building must be separate from the foundation of the house;

- a certain percentage of sand must be present in the concrete solution used in the construction of the building;

- a separate foundation is placed under the boiler, raising it above the finished floor by 0.2 m;

- under the boiler you need a backing made of flat slate or tiles protruding beyond its limits by 0.1 m along the entire perimeter;

- to drain the coolant in case of an emergency, the boiler room must be equipped with a sewerage system;

- within a radius of 0.7 m around the boiler, the space must be free;

- interior decoration must have a fire resistance rating of 0.75 hours.

There are special regulatory requirements for the boiler itself, since it does not belong to the category of household appliances, but to the category of complex engineering equipment. Gas boilers, like all others used in the domestic sector, must have a certificate certifying that they have passed a safety examination.

Control services will never give permission to put into operation a boiler room with a gas boiler if there is no gas detector in the room.

Ceiling installation

The main requirement for the top floor is that it remains light. This is required in order to ensure safety, since in the event of an explosion it is the upper part of the building that will take the brunt of the destruction. As a result, because of this, the energy will be extinguished due to the destruction of only one ceiling on top, but not by the walls.

In addition, insulation standards must be maintained. To do this, you can use heat-reflecting film, or sheathe gypsum plasterboard/kvl ceilings. The boiler room must be fire resistant, level 0.75 hours and so that the fire does not spread throughout the entire structure. To do this, you need to select the right building materials and use the treatment of parts vulnerable to fire as a safety net.

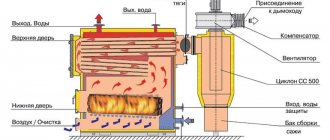

Boiler room with solid fuel boiler

In accordance with the requirements of building codes, solid fuel boilers are installed only in non-residential premises. If the power of the unit is large, the construction of a separate boiler room will be required.

What should the room be like?

There are a number of requirements for placement under a solid fuel boiler:

- the distance between the firebox door and the wall is from 1.2 to 1.5 m;

- the distance from the side walls of the boiler to a wall made of fireproof material or protected by a special screen is at least 1 m;

- the gap between the rear wall of the boiler and the surface of combustible material with a protective screen is at least 0.5 m for boilers with a rear connection;

- ban on superstructures above the boiler room;

- effective supply ventilation , located in the lower part in the form of a gap between the door and the floor or a hole in the wall.

If the wall is made of material that meets fire safety requirements, then it is permissible to attach the pipe located behind the boiler to it using brackets.

In order to operate a CT with parameters of 1x0.8 m at the base with at least a minimum of comfort, you need to install it in a room of 2.8x2.5 m. As the dimensions of the unit increase, the area of the boiler room also increases.

It is necessary to plan the installation of a solid fuel boiler at the stage of building a house in order to allocate space for the chimney in advance

If the boiler room is in the form of an extension, then the correct location for it is a blank wall. The distance to windows and doors in both vertical and horizontal directions must be at least 1 m. If the boiler room is located in the basement, ground floor or first floor, it is necessary to install a door that opens outward.

Equipment for solid fuel boiler house

A functional and well-designed diagram of a boiler room with a solid fuel boiler should include a number of elements:

- Heat generator equipped with appropriate bunkers, fuel chambers, etc.

- TT boiler piping , consisting of a circulation pump, 3-way valve, safety group.

- Chimney.

- water heater for supplying the house with hot water.

- Automation - weather-dependent or in-house.

- Fire extinguishing system.

Coal, peat, and firewood are used as fuel for TT. The diameter of the chimney in a boiler room with a TT unit must be equal to the cross-section of the boiler pipe. The room requires exhaust ventilation, designed so that for every 8 cm² of its area there is 1 kW of boiler power. If the boiler is installed in the basement, this parameter is multiplied by 3.

A steel sheet must be laid around the base of the boiler. It needs to protrude 1 m on each side. The layer of plaster on the walls should be no less than 3 cm thick.

In the chimney itself, which has the same cross-section along its entire length, holes are provided for collecting and removing soot. A mandatory attribute is fire extinguishing equipment.

A high-quality solid fuel boiler is capable of converting any type of solid fuel into thermal energy. This allows you to save money

For 1 kW of TT boiler power there should be about 0.08 m² of glazing area. The maximum permissible area of the boiler room is 8 m². If you plan to load the firebox with coal, then the electrical wiring must be protected from coal dust, because it can explode at a certain concentration.

What documents need to be prepared

To begin adding to the building, you will need to obtain permission to begin construction from the architecture department and local authorities.

To do this, the owner of a residential building will need to provide the following documents:

- Standard application forms can be obtained from the architecture department at your place of residence.

- Documents confirming ownership of the house and land.

- Furnace design with calculations of heat loads, selection of equipment and connection diagrams for heating system pipes.

- Technical specifications from manufacturers of gas, water and electricity services.

- A passport for boiler equipment and a certificate of its compliance with Russian standards.

- Sanitary report on the sanitary safety of the facility for residents.

- Conclusion of the Ministry of Emergency Situations on the fire safety of the facility.

The furnace extension is allowed for the installation of 2 boilers with a total capacity of up to 150 kW.

Advantages of a liquid fuel boiler

Installing an oil-fuel boiler is much easier than a gas or solid-fuel counterpart. You can place it in the house and in the yard.

The main advantage is the absence of the need for approval and obtaining permits. All that is required from the owner of the house is to provide free access for a car with fuel and regularly refuel the boiler.

If there is no gas main near the country house, you can install a unit that runs on diesel fuel in the boiler room. A double-circuit boiler will heat the house and provide residents with warm water

To obtain 10 kW of power, about 1 liter of diesel fuel is consumed, but the exact consumption depends on the quality of the fuel. In the middle zone, with a house area of 200 m², about 5 thousand liters of fuel will be required for the heating season. The chimney must be cleaned periodically.

To install a diesel boiler, an average of 4 m² is required. If supply ventilation is provided by air flow from other rooms of the house, then per 1 kW of boiler power there should be at least 30 cmᶾ of air. With external ventilation this figure decreases to 8 cmᶾ.

Electric boiler for a private boiler room

Of all the models used in a private home, the safest is the electric boiler. It is not necessary to equip a separate boiler room for it. When heating the coolant, no combustion products are released, so ventilation is not needed for it.

Installation of such boilers is simple, they do not create noise during operation, and they are easy to care for. Electric boilers have high efficiency, reaching 99% in some cases. The disadvantage is the high requirements for network power, as well as the dependence on its stable operation.

You can place an electric boiler in any corner of the house, as long as it is convenient. It consumes a lot of electricity and is most often used as an additional heat source

The connection of an electric boiler is carried out according to different schemes: it is connected to heating radiators, and the possibility of installing a cascade is provided in cases where it is necessary to heat a large area.

The piping is carried out according to two schemes - direct and mixing. In the first case, the temperature is controlled using a burner, and in the second, using a servo-driven mixer.