The device for drying hygiene items and removing excess moisture in the bathroom is simple to design and install. In order to install it, you do not need fundamental knowledge in the field of engineering communications construction.

However, you should clearly know how to connect a heated towel rail. After all, the result of your own efforts or the work of hired plumbers should please you for many years, do you agree?

In the article we presented, all options for installing a substation and possible complications during its connection are discussed in detail. Verified and systematized information will be a reliable help for home craftsmen who want to do the work themselves, or who want to control the actions of workers.

We have outlined in detail the specifics of connecting an important household appliance in old and new bathroom layouts. The problems of private home owners have not been left unattended. The information we offer has been tested in practice, supported by visual materials and video instructions.

Connection diagram in an apartment building

The purpose of constructing the far-from-perfect “Khrushchev” buildings was mainly for ideological reasons - in this way it was possible to achieve the resettlement of barracks and communal apartments. To heat newly built residential areas, exclusively centralized heating was used. As a rule, in the bathroom the radiator was combined with a heated towel rail. This approach had both strengths and weaknesses.

- The heated towel rail provided additional heating for the room.

- It was turned on only in the winter, in parallel with the heating. When it got warm, the device turned off.

- Cumbersome design.

- You had to pay extra to use it.

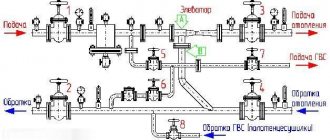

This scheme for connecting the heated towel rail to the heating system provided for the presence of an additional pipeline in the basement. As a result, we had to sacrifice an elevator and a garbage chute.

Two options were used for connecting the heated towel rail to the heating circuit and placing it in the home:

- In separate bathrooms

. In this case, the installation site was the adjacent wall between the toilet and the bathroom. From the basement, the supply pipe was led into the apartment on the first floor. Then, having passed the entire entrance, through the apartment on the last 5th floor, she found herself in the next apartment. Having passed through all the floors, the pipe descended back to the basement. Shut-off valves in the apartments were not used in any form: only the basement sections of the supply and return pipes were equipped with valves. - In adjacent bathrooms

. Here the heated towel rail was placed on the wall near the washbasin. It is important to understand that this connection method was considered the most difficult due to the inconvenience of the combined room.

The most common series of “Khrushchev” buildings, where heated towel rails were connected not with hot water supply, but with the heating system, are:

- 1-434С – years of construction 1958-1964.

- 1-434 – years of construction 1958-1967.

- 1-335 – years of construction 1963-1967.

What rules and regulations require installing a heated towel rail?

What are heated towel rails for? Is it really not possible to dry towels by hanging them on the loggia, in the bathroom or in the kitchen?

Everything is very simple. The heated towel rail provides additional heating of the air in the bathroom, bringing the temperature to a comfortable level. This is especially true when we get out of the bathroom wet.

The temperature that does not allow you to feel discomfort at this moment was determined experimentally and is prescribed in SanPiN 2.1.2.2645-10, paragraph 4.1. which reads as follows: “Heating and ventilation systems must ensure acceptable microclimate and indoor air conditions. The optimal and permissible microclimate parameters in the premises of residential buildings are given in Appendix 2 to these sanitary rules.”

Below is a table from the specified Appendix 2:

As you can see, the acceptable temperature in the bathroom is from 17 to 26 degrees. There is almost always 17 degrees in a living room and in this case there is no need to install a heated towel rail. But it is quite difficult to ensure an optimal temperature of 23°C without additional heating in a bathroom where there are no heating radiators.

How to connect a heated towel rail in a private house

In the 60s, private houses were not provided with hot water from central mains. Basically, autonomous systems were used based on wood-burning boilers of the “Titan” type, which required preliminary kindling.

The reasons why such a hot water supply scheme could not be equipped with a heated towel rail are as follows:

- Design features. The tap was inserted directly into the body of the device, so there was simply no pipe for drying clothes.

- Temporary restrictions on the operation of the heating device. One portion of firewood could only provide heating of water in the tank.

The installation of a water heated towel rail became possible only after water heating began to be used in the private sector:

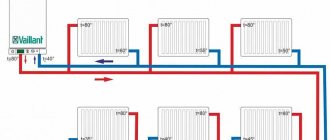

- In the old scheme of how to connect a heated towel rail to the heating system, direct connection to the heating boiler was used.

- Currently, a heated towel rail in a private household is part of a general scheme, which, in addition to it, also includes radiators and a heated floor system.

Recommendations for installation work

The efficiency of a heated towel rail depends on its correct installation. To avoid future problems with the operation of the device, it is recommended to take into account the following recommendations during the installation process:

- The diameter of the pipeline should not exceed the cross-section of the heated towel rail itself. Compliance with this requirement helps prevent an increase in pressure in narrowing areas.

- Installation of adapters in the presence of different sections of pipelines and pipes is allowed if the diameter of the towel dryer is smaller than the pipes. Violation of this installation procedure can cause a significant increase in pressure in the device, which will lead to an emergency.

- To remove air from the device, ensure normal operating process, as well as the possibility of repair, it is recommended to install a bypass. In order not to disrupt the good circulation of the coolant, shut-off valves should not be installed on the jumper.

- A distance of 4 centimeters must be maintained from the wall surface to the heated towel rail. If the diameter of the device pipes exceeds 25 millimeters, then it should be increased to 7 centimeters.

- The location of the bottom of the dryer from the floor should be 90 centimeters. The optimal height is considered to be 120 centimeters.

Experts recommend using materials of the same origin when installing a heated towel rail. The combination of different metals can lead to the process of structural destruction. Teflon gaskets will help eliminate problems with corrosion at joints.

The method of installing a heated towel rail in a private home depends on the type of device chosen and the complexity of its design. Taking into account all the installation requirements, you can connect the towel dryer yourself.

Reinstallation and maintenance

With the advent of modern technologies, the question of whether it is possible to connect a heated towel rail to heating in Khrushchev apartments has disappeared. Most often this is solved by dismantling the old heated towel rail and installing an electric one. To implement this solution, there is one serious condition: the remaining residents of the entrance must carry out a similar reinstallation in their apartments. Otherwise, you will have to straighten the pipe to ensure water supply to neighboring dwellings.

In addition, the relevant authorities must issue permission to carry out dismantling work: unauthorized reconstruction of heating circuits can entail serious fines. Much fewer problems arise when connecting a side-switched heated towel rail to a hot water supply.

DHW and circulation

Let's start with a small lyrical digression.

The hot water supply system in an apartment building can be a dead-end and circulation system. In the first case, water moves through a single bottling and dead-end risers only when it flows through one of the plumbing fixtures.

Elevator in a house with dead-end hot water supply

In the absence of water supply, bottlings and risers gradually cool down due to inevitable heat loss.

This feature of a dead-end system has three practical consequences:

- If there is no hot water supply for a long time (for example, in the morning), it has to be drained for a long time until a comfortable temperature is obtained;

- Due to heat loss, the water temperature in apartments far from the elevator unit can drop to 55°C and below;

Set of rules for designing building engineering systems

- By definition, a heated towel rail with hot water supply cannot be hot around the clock: in the absence of water supply, it will cool down.

All these problems have been successfully solved in recirculating systems. How are they different from dead-end ones?

- There are two hot water dispensers throughout the house;

Two hot pours indicate recirculating water supply

- The risers are connected to them one by one. The number of risers connected to the bottling stations does not necessarily have to be the same: often there is one return riser for three supply risers;

- On the top floor or (less often) in the attic, the risers are combined by jumpers equipped with Mayevsky taps or automatic air vents to remove air pockets;

Jumper connection diagram for risers

- The pressure difference between bottlings, depending on the heat supply scheme used and the hot water supply scheme, is ensured by the pressure difference between the supply and return of the heating main, throttling washers in the elevator unit or circulation pumps.

Elevator unit with additional hot water inlets for its recirculation

As a result, we get two extremely pleasant features of the system - instant heating of water when the tap is opened, regardless of the location of the apartment within the house, and round-the-clock operation of heated towel rails.

Of course, if they are connected correctly. Which brings us close to the next question: how to properly connect heated towel rails to hot water supply?

Stainless steel heated towel rail

The easiest way to solve the problem is how to connect a heated towel rail to heating by replacing the old element with a more modern stainless steel product.

This solution has a number of advantages:

- There is no need to rebuild the heating system.

- The heating level of such a device is much higher.

- The device has high decorative characteristics.

- Very little materials are wasted.

However, the fact that the heated towel rail can only heat during the heating season is a serious drawback.

Where to connect and where to hang

You can connect a water heated towel rail to both the hot water riser and the heating system. If both of these options are available, DHW is usually chosen

There are three reasons for this: there is less hassle with permission to connect, you can connect at any time of the year (agree with the management company to turn off the riser and that’s it) and, most importantly, such a heated towel rail heats up all year round

If there is no hot water supply in the house, you will have to connect to the heating riser. This requires permission from the Criminal Code and a project. Buy a heated towel rail (preferably a simple design), go to the housing office with its passport (copy), write an application. If permission is given, order the project (you will also need a copy of the passport with connecting dimensions). Then, according to the project, you do it yourself or hire performers (plumbers from the housing office, as an option). Call representatives of the Housing Office for acceptance.

To ensure that the “towel” always warms up without problems, all connections are straight, without arcs or pockets

When determining where to install the heated towel rail, questions may still arise about what height it should be hung. If you have a choice, it is most convenient to place it so that it is at head level and below. This is if you install a U-shaped or snake. If we are talking about “ladders” of great height, the top bar is placed at the level of the heat of the raised hand (approximately 190-200 cm).

When choosing a location for installing a heated towel rail, you must also take into account the distance from the riser. In principle, the closer to the riser, the better - the greater the chance that it will work. But, it can be attributed to a meter or so only if the following conditions are met:

- low hydraulic resistance of the heated towel rail (simple shape and cross-section 1″ or 3/4″),

- sufficient pressure (2 atm or more)

- drain pipes of normal diameter (one step smaller than the riser).

At the same time, be sure to follow other connection rules. Then there will be chances that such a “remote” device will work normally.

A clear example of connecting to a heating system

For clarity, you can look at an example of how to properly connect a heated towel rail to heating in an apartment.

The operating procedure is as follows:

- Scope of work. We are talking about replacing an old heated towel rail with a more modern stainless steel product, without changing the heating circuit of the house.

- Dismantling. To remove the old device, you can simply cut it off with a grinder. After this, the thread is cut on the pipe, for which you will need a hand clamp.

- Installation of a stainless steel heated towel rail. On the surface of the wall you need to make preliminary markings for the placement of the device. A hammer drill is used to drill mounting holes.

- Pre-fixation. Using a ruler and pencil, mark the location of the polypropylene pipe at 0.5 inches.

- Pipe welding. Using a soldering iron, a new connection to the heated towel rail is created. A ball valve is also being installed. If ceramic tiles have not yet been laid, it is recommended to install a stainless coil after finishing work is completed.

As a result, we managed to achieve:

- Unchangeable heating system. Constructive changes were kept to a minimum. Only the replacement of the heated towel rail and the additional installation of two taps were carried out. The presence of these elements makes it possible to quickly shut off the water supply in case of leaks.

- The bathroom has become much more attractive. The bulky pipe was replaced by a beautiful stainless “snake”. There are a sufficient number of design options on sale, so choosing the most suitable solution for a specific bathroom design usually does not cause problems.

- The presence of forced ventilation will allow the towels to dry in a short period of time.

Thanks to this description of how to connect a heated towel rail to a two-pipe heating system, if you have the appropriate skills, it is quite possible to independently implement this procedure. It is best to plan the work in the summer: then you will not have to block the entire riser of the circuit.

When choosing a scheme for connecting a water heated towel rail to hot water, two conditions must be met. First, under no circumstances should the device interfere with or block the circulation in the riser. It’s unlikely that your neighbors will be happy if, by turning off your heated towel rail, you cut off everyone’s hot water. The second condition is that there must be good circulation in the dryer itself. Therefore, the connection diagram for a heated towel rail is selected depending on its shape.

About design - it is recommended to approach its choice from a rational point of view

The heated towel rails offered by the retail chain have a fairly diverse design - from ultra-modern to classic. It's easy to find one that matches your bathroom design, finished in polished brass or chrome, finished in antique bronze or brushed nickel, antique gold, etc.

Models from some major manufacturers, such as the Italian Cordivari heated towel rails, have a design ranging from the most familiar and simple ladder to an exclusive, author’s solution, bold and unexpected, which allows you to use the device for drying towels as a design element.

You can also pay attention to more functional models, equipped with shelves or a hook for a robe. Of course, if such functions are really necessary, and a larger heated towel rail will not clutter up an already small bathroom. The second point concerns finances - by abandoning a multifunctional device, you can save a considerable amount.

You can purchase a device with substantial dimensions if the bathroom area allows its placement and if you require:

- drying several towels at the same time,

- obtaining additional heating of the room.

General principle

Connecting a water heated towel rail to a hot water or heating riser is no different. All schemes are identical. The only difference is seasonality. There is almost always hot water supply (if there is one at all), heating is only available in the cold season.

The water heated towel rail is connected by separate pipes: the connection diagram for the heated towel rail in general, without considering particulars

In any case, the heated towel rail is connected through special and separate connections. It does not consume water/coolant, it only takes away some of the heat. Therefore, DHW consumption may not be counted. Heating is an issue. This is essentially a heating device. So it can be considered as a radiator.

The best heated towel rail - what should be the material used to make it?

The following materials are usually used in the manufacture of heated towel rails:

- stainless steel - the thickness of a high-quality radiator made of this metal should be about 2-2.5 mm, their cost is quite high, cheaper stainless heated towel rails do not have a long service life;

- brass and copper - they are characterized by good heat transfer; the condition for their use in centralized water supply and heating systems is galvanization of the inner surface of the pipes;

- steel is the most durable material with a long service life, which can be guaranteed by the presence of an anti-corrosion coating on the inner surface of the pipes.

We connect a classic heated towel rail (snake) to the hot water riser

The first heated towel rails in bathrooms were simply made from a piece of bent pipe and were part of a riser. Not the most aesthetic option, but effective and does not interfere with circulation. Later, instead of the ugly pipe, they began to insert a ready-made “towel” (pictured on the right).

The old pipe version and its correct replacement

One can argue about the aesthetics of such a replacement, but everything was done correctly. The device is part of the riser, has the same diameter, and does not affect circulation. It heats up great. This solution also has disadvantages:

- in case of damage/need for replacement, the entire riser must be closed;

- There is no way to regulate the temperature.

Convectors with forced convection Klima TKV

TKV floor convectors operate on the principle of forced ventilation, i.e. the air flow is increased using a fan. Designed for primary and secondary heating of premises where it is necessary to use devices with high thermal power. Thermal power depending on the size of the convector is from 0.4 kW to 8 kW. In convectors with forced convection “Klima TKV”, air movement is provided by a built-in tangential fan. Cold air accumulating near the floor is sucked in by a fan and, heated as it passes through the heat exchanger, enters the room. Forced air circulation and its increased volume involved in movement contributes to the rapid and uniform heating of your room. Compared to heating devices operating on the principle of free convection, the Klima convector significantly increases overall comfort.

Technical characteristics of Klima TKV:

- Convector heights: 82, 105, 140 mm

- Convector length: from 800 to 5000 mm

- Convector depth: 200, 300, 400 mm

- Working pressure: 10 atm.

- Maximum pressure: 25 atm.

- Maximum coolant temperature: 100°C

- The heat exchanger material for built-in convectors IMP Klima is made of copper pipes 16×1.0 mm, on which ribbed aluminum plates 83×50 mm are located

- Connection to water pipes is made using a connecting nut with internal thread R ½"

- The tangential fan of built-in convectors IMP Klima TKV consists of a low-power single-phase motor (220 V, 33 W, max 0.25 A) with propellers on both sides of the motor.

- The fan is protected by a protective mesh, which prevents mechanical damage

- Thermal power is indicated for temperature conditions of 90/70/20°C (convector operating mode - NORM)

- Certificate of conformity: ROSS SI.AB28.B06253

Operating principle of Klima TKV convectors Each convector is equipped with one or more tangential fans (their number depends both on the length of the convector and on the specific model - it is necessary to specify when ordering), which force air from the room directly onto the heat exchanger, where the air is heated and exited directly on the window. This ensures better heating of the glass, which prevents the formation of icing and condensation on them.

The fans can operate in three modes: minimum, medium and maximum speed, depending on the required power, and they can also be turned off. To control the operation of fans depending on the room temperature, it is necessary to additionally install a wall-mounted room thermostat Hidria 09T or 037. One thermostat can simultaneously control several fans or convectors, if they are located in the same room - the complete set must be specified when placing an order.

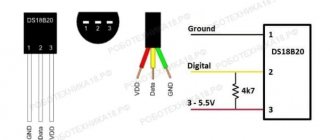

Ladder connection diagrams

When connecting a water heated towel rail with a ladder, a bypass is required. Bypass with or without narrowing depends on the circuit and direction of coolant supply. The diameter of the supply pipes can be the same as on the riser or one step smaller. It is selected depending on the chosen scheme. Please note that for normal operation the following conditions must be met:

- pipes must be at least 25 mm in internal cross-section (more is possible, less can cause poor performance or complete inoperability);

- fittings (angles, bends, taps) are selected so that the pipe clearance remains the same;

- branch pipes are smooth, without depressions or humps;

- the connection points are on the same axis.

When connecting a water heater dryer, you must use high-quality (fluoroplastic) gaskets that can withstand high temperatures for a long time

In addition, when laying hidden (in grooves), installation in thermal insulation is highly desirable. The best choice is foam shell, but any other insulation suitable for installation inside the wall will do. Even if the pipe is simply laid in corrugation, this is already a plus. This shell is a compensator for thermal expansion of pipes and reduces the likelihood of electrocorrosion. By insulating the supply pipes, any connection diagram for a heated towel rail will work more stably.

Side outlets: heated towel rail connection diagram

Ladder towels often have a side connection. Moreover, they can be connected not only on the right or left, but also diagonally. Both types of connection - direct lateral and diagonal - are effective regardless of the direction of water supply; the heated towel rail can be located at a considerable distance from the riser ( but not more than 4.5 meters ).

Please note that the pipes from the riser run at an angle (from 3 to 30 mm per meter of pipe). If the length of the supply pipes is no more than 2 meters, the slope does not need to be made. For longer distances, slope is a prerequisite for normal circulation.

In order to be able to turn off the water at any time, shut-off valves are installed. When choosing them, make sure that they do not narrow the lumen of the pipe. Ball valves are ideal for this.

Scheme of direct and diagonal connection of a ladder-type water heated towel rail

Both the direct and diagonal connection schemes have an unbiased and unabridged bypass. This is where it should be for normal operation. If water is supplied from below, the bypass (the section of pipe between the outlets) must be of the same diameter and must not be offset. When serving from above, you can narrow it one step. In any case, the layer pipes must be perfectly straight, without depressions or humps. Pay special attention to the connections with the branches - they must be in the same plane. Only under such conditions will the heated towel rail connection circuit work properly.

Possible side connection options

It is not always possible to convert outlets from the riser to fit a new heated towel rail. In this case, two other schemes can be implemented. They operate at normal system pressure and are not overly complex in design.

Options for side connection of a water heated towel rail

When choosing corners and other fittings, pay attention to ensure that they do not narrow the clearance. In these schemes this can be critical. There are also restrictions on the distance from the riser. This connection works normally with branch lengths of up to 2.5 meters. One more point: the scheme on the right only works with top feed.

Bottom connection: working diagrams

The bottom connection itself is less efficient - water circulates worse. With this type of installation, a device for bleeding air (Mayevsky valve or automatic air vent) is installed on one of the racks at the very top. This connection has one advantage: you can run pipes not along the walls (in grooves or openly), but in the floor or down along the walls (under the bathroom, for example). So the connection diagram for the heated towel rail must be selected and executed very carefully.

Working diagram for connecting a heated towel rail with bottom outlets

There are three well-working options for the bottom connection of a heated towel rail. In any of them, the bottom outlet must be lower than the level of the bottom outlets on the dryer. This guarantees functionality with any delivery method. Also note that in the diagram with an offset and narrowed bypass (center and right figure), the upper outlet should be slightly below the connection point. This guarantees functionality even with bottom feed. If the water supply comes from above, you can make layering higher.

Acceptable options for the bottom connection of a heated towel rail

For the operation of the circuit, a bias towards the heated towel rail is also observed (this is not noticeable in the pictures). Slope - from 3 mm to 3 cm per meter. The more complex/larger the structure, the greater the slope (the more, the better). These schemes operate with branch lengths of no more than 450 cm.

Heated towel rail connection diagrams with errors (non-working or unstable options)

We also give non-working options for connecting heated towel rails. With this installation, they will only work if a circulation pump is installed in the supply. But such a low-power, reliable and quiet pump is very difficult to find.

There may be other errors. But the most typical ones are presented. Let's look at them in more detail. The first two schemes (see figure below) are with artificially created rises. Any “humps” block circulation. Air accumulates at the highest points, which blocks the movement of water. In order not to redo the connection, you can try to install an air vent at the highest point (preferably an automatic one). In theory, this could help. In practice, it depends on how high the “humps” are raised and whether the pressure is able to overcome them. There may be a situation with “periodic” work. When the water flow in the riser is low, the heated towel rail is warm, but when the water flow is high, it does not heat up.

You cannot connect a heated towel rail this way.

In the next two diagrams there is another error - the lower outlet is above the connection point. Such schemes can work, but unstably (at low flow rates they heat up, at high water consumption they do not). It is impossible to predict the exact height at which they become inoperable, since it depends on the type and diameter of the pipes, pressure, water flow in the riser, etc.

The last scheme is an offset and narrowed bypass with a side connection. With this connection method, usually only the heated towel rail rack, which is closer to the riser, is warm. It’s just that the circulation usually goes through the bypass - up, and down - through the first rack. The crossbars are heated unevenly. They are slightly warm closer to this “warm” counter and cold at the far one.

Installation types

Heated towel rails can be divided into three groups according to the type of installation:

- floor-standing, most often - these are water models,

- wall-mounted, they can be electric or water,

- portable, powered by electricity, easily moved around the bathroom or transferred to other rooms.

Installation of models connected to the hot water supply of the house is carried out to the walls or floor. If the bathroom is small, then the best option would be to install a wall-mounted model; a ladder heated towel rail, for example, will not take up much more space than a towel rack. You can choose the appropriate model: electric or water type.

When choosing wall-mounted models, special attention should be paid if the wall on which you plan to install it has different levels, in particular if it is half tiled. The model should be selected with the expectation that it will be placed above or below the cladding boundary; it may be possible to find one that can be installed on a wall with a level difference.

There is nothing special to say about installing a portable device; a person who has no idea about construction or installation tools can plug it into a power outlet.

Grounding a water heated towel rail

The phenomenon of electrocorrosion causes the pipe walls to become thinner. And so much so that over time they begin to “drip”, or even leak. Brass and copper products especially suffer from this. Stainless steel also wears thin, although much more slowly.

It is impossible to get rid of stray currents, since we are surrounded by magnetic fields, which provoke their occurrence. And connecting with plastic pipes does not completely solve the problem - currents are induced in the metal body of the heated towel rail. It is possible to neutralize the influence of these currents. You just need to ground the heated towel rail.

How to ground a water heated towel rail

To do this, screw/weld/solder an insulated wire (cross-section of at least 2.5 mm²) to the metal part of the heated towel rail. Connect its other end to the grounding block, grounding bus. Since grounding has low resistance, current will flow through the conductor and not through the pipes.

The device for drying hygiene items and removing excess moisture in the bathroom is simple to design and install. In order to install it, you do not need fundamental knowledge in the field of engineering communications construction.

However, you should clearly know how to connect a heated towel rail. After all, the result of your own efforts or the work of hired plumbers should please you for many years, do you agree?

In the article we presented, all options for installing a substation and possible complications during its connection are discussed in detail. Verified and systematized information will be a reliable help for home craftsmen who want to do the work themselves, or who want to control the actions of workers.

We have outlined in detail the specifics of connecting an important household appliance in old and new bathroom layouts. The problems of private home owners have not been left unattended. The information we offer has been tested in practice, supported by visual materials and video instructions.

Heated towel rail against mold and mildew

As you can see, one of the functions of a heated towel rail is to maintain a temperature that is comfortable for taking a bath or shower. But it also has one more important function, much more important, but not prescribed in SanPiNs and SNiPs. This is to ensure stable ventilation and reduce humidity in the bathroom.

The bathroom differs from all other rooms in the house by its specific microclimate. This is where we take a shower, enjoy a hot bath, perform daily hygiene procedures and wash clothes. Water vapor accumulating in the bathroom air creates high humidity, which can be fatal not only for the building materials used in finishing, but also for our health.

Under the influence of humidity in the absence of reliable ventilation in the corners, behind false ceilings, under baseboards and behind false walls made of plasterboard, mold and mildew may soon appear, which not only spoil the appearance of the room, but also destroy building materials in the process of their vital activity - the plaster cracks and crumbles, cracks appear, the air is filled with a heavy smell of mold, and fungal spores that multiply in the warm, humid air of the bathroom can become a health hazard, causing lung diseases.

It would seem - what does a heated towel rail have to do with it? And the heated towel rail is here because it allows you to quickly dry the air in the room, preventing the appearance of fungus and mold.

In addition, warmer air with a lower density rushes into the exhaust openings of the ventilation system, providing reliable draft and allowing moist air to be quickly removed from the bathroom.

Specifics of installing a heated towel rail

The general principle of connecting any type of heated towel rail remains unchanged: water is supplied at one end, and it flows out at the other. Installation of a substation requires mandatory consideration of points dictated by the installation features.

When connected to a hot water or central heating system, it becomes part of the pipeline. If the connection is made incorrectly, then the problems that arise will affect not only the individual apartment, but also all the others located along this riser.

To avoid electrolytic corrosion, it is recommended to use parts made of the same material. The exception is plastic pipes; plumbing fixtures made of any material will fit them.

For our water supply system, it is better to choose a heated towel rail manufactured by domestic manufacturers and that complies with regulatory documents. You need to be careful with imported models - most of them are designed for different standards.

A ladder-shaped heated towel rail is connected to the pipeline using several methods - vertical, diagonal, lateral. The main thing is to maintain an interaxial distance of 50 cm.

When connecting to an existing system, you need to take into account its parameters. The distance from the riser to the newly installed unit should not exceed 200 cm, otherwise significant heat loss cannot be avoided.

Ideally, the pipes of the system and the heated towel rail are the same in diameter, but if they still differ, then the connection is made through adapters.

The pipes of the device may be larger in diameter than the pipes of the existing circuit, but in no case smaller. This will prevent the creation of excess hydraulic pressure and ensure normal coolant circulation in the system.

A selection of photos will familiarize you with the features of connecting a substation to hot water systems:

To ensure that the device, if necessary, can be easily dismantled and moved to another wall, detachable couplings with American-type internal threads must be used to connect it to the riser. It is necessary to strive to reduce the number of adapters, because... Leaks may form at the places where they are installed.

The joints should be sealed with special compounds or winding, and you should not save on this. Connections with regular metric threads are sealed with flax winding. It is better to seal tapered threads using FUM tape. Tightening should be carried out with a slightly noticeable tension; excessive force is unacceptable.

When selecting taps and fittings, inquire about their electrochemical compatibility so that they do not create a galvanic couple upon contact. A connection made of steel and brass has this property. Rapid corrosion occurs and the unit becomes unusable.

If the plumbing fixture is part of the riser, then no shutoff devices can be installed on it. To make it possible to turn off the heated towel rail without shutting off the entire riser, it is necessary to include a bypass in the system - a jumper connecting the outlets from the riser towards the device.

Ball valves are installed after this jumper. When the connection pipes are embedded in the riser, it itself acts as a bypass.

General understanding of the operation of a heated towel rail

There are several types of such devices. The vast majority of them are designed to operate when connected to a pipeline through which heated liquid circulates. There are quite a few electric models on sale these days that only require a connection to the power supply. This is, so to speak, a “free-standing” category of heated towel rails, the installation of which does not require compliance with special requirements - it is only important to comply with electrical safety rules. By and large, installing such a device is not much different from connecting, say, a lamp or a heating convector.

The variety of heated towel rails is extremely large, both in terms of external design and operating principle.

The most “problematic” ones were and still are heated towel rails based on the water operating principle – it is with their installation that the greatest number of questions arise. The following discussion will be mainly devoted to devices of this type.

Combined type heated towel rails are subject to general rules when connected to pipework

Let’s immediately say that you can purchase a combined type model, which will work thanks to the circulation of hot water, but can, if necessary, switch to electric heating. However, connecting such heated towel rails to pipe circuits is subject to general rules, so we will not put them in a separate category.

How to understand the variety of heated towel rails?

The offered range of such devices is extremely wide, which can even be a dead end when choosing. A special publication on our portal will help in this matter - . ”

So, for normal operation of a heated towel rail, a flow of heated liquid through it is necessary. In multi-storey buildings, where hot water supply was organized on the principle of constant water circulation, this device, as a rule, was just an ordinary loop of a hot riser pipe, most often on the downward part of the “ring”, that is, with a flow directed from top to bottom. This meant that consumers received hot water at the required temperature, regardless of the floor of residence, and when the flow returned, additional heat was taken from heated towel rails.

From an early age, everyone is familiar with the heated towel rails found in most city apartments. Essentially - a loop on the return riser of hot water supply

Please note that the pipe forming the loop (one in U-type heated towel rails, or two in M-type) has the same diameter as the one on the riser itself, or even larger. This is a requirement to ensure normal circulation in the local DHW circuit, without interference or excessive hydraulic resistance.

It is clear that such heated towel rails now very often do not satisfy the owners in terms of their appearance. A decision is made to replace them with more modern ones that are most suitable in terms of their aesthetic qualities to the interior created in the bathroom. And this is where the “miracles” begin. Incompetent intervention by home craftsmen or even “poor plumbers” (of which, unfortunately, there are quite a few) leads to the fact that, at best, the heated towel rail does not work at all or heats up unevenly (this is especially true for “ladder” type devices). And in the worst case, the functioning of the hot water supply system throughout the entrance riser is disrupted, which entails administrative measures and, of course, aggravation of relations with all neighbors.

The fact is that ill-conceived decisions, most often based on the desire to hide the supply pipes or purchase a device of an original shape, without taking into account the peculiarities of its connection, lead to an imbalance in the hydraulic balance in the system. Therefore, later in the article we will offer options for connecting heated towel rails, from which you can choose the most suitable one. In addition, attention will be paid to controversial schemes that are obviously unworkable, or even completely prohibited for implementation.

One more disclaimer before moving on to the diagrams. In the future, we will talk more about installing a heated towel rail in the hot water supply system. The fact is that in private houses or apartments where autonomous heating is organized, these devices are often an integral part of the heating system. On the one hand, it seems convenient, but on the other, in the summer, when heating the house is not needed, the device becomes “incapacitated.”

One of the universal options for organizing autonomous heating and hot water supply, with the inclusion of a heated towel rail in the overall scheme

Another option is to connect the heated towel rail to an autonomous hot water supply system equipped with an indirect heating boiler with an automated circulation circuit.

The schemes in both versions of autonomous systems can be very diverse, complex, but subject to slightly different rules. Therefore, this question will also be “bracketed”, since it relates to another section, more related to heating systems.

Prices for heated towel rails

Heated towel rails

Connecting the substation to hot water supply or central heating

Connecting a heated towel rail to the risers of central networks can be done in different ways.

The tactics of work depend on the modification of the coil:

- Top connection . Water enters from above, and the return is located below.

- Bottom connection . The coolant enters on one side and exits on the other.

- Diagonally . Inlet from above, outlet from below on the opposite side.

- At the bottom of the device in the center.

Regardless of where the substation is connected - to the GSV system or to the central heating riser, similar schemes are used.

Installation of a heated towel rail in a riser

To install a heated towel rail in a bathroom located in an apartment in a multi-storey building, you need to turn off the hot water on the riser. The task is made easier if the unit can be dismantled by simply unscrewing the nuts connecting it to the common pipe. The main thing is that the connecting pipes of the new device have similar dimensions.

When an old-style device is welded to the hot water riser, it is more difficult to disconnect it. The best solution is to connect the heated towel rail with your own hands and replace the riser, either partially or completely. The second option is preferable. Pieces of old pipe left in ceilings pose a potential hazard.

The riser along with the old unit is cut out using a grinder, then the pipe threads are cut from the neighbors above and below, a new riser is connected and taken out to your room.

The use of polypropylene pipes with the same diameter is preferable to steel ones. They are cheaper, lighter, do not corrode, are resistant to high temperatures, and durable.

There is a large selection of fittings for PPS pipes, which are welded into the riser in order to switch to threads and connect a heated towel rail.

A special soldering iron is used for soldering. Many people install a box to hide the wiring behind it without changing the connection diagram.

Self-installation of a simple configuration PS

The dryer is assembled, shut-off valves are installed on the supply line using detachable connections, then they are tried on a pre-marked place on the wall, horizontal and vertical are checked, and the brackets for fastening the PS are fixed.

Causes of breakdowns and troubleshooting methods for electric heated towel rails

Electric heated towel rails (often called design radiators) have a sufficient margin of reliability, but, like any other equipment, they can fail due to exhaustion, internal defects, overheating or power surges in the network.

Depending on the design, there are two types of electric design radiators - solid-filled and liquid. Heat transfer in the former is ensured by graphite and other compounds, while the latter operate by heating specially prepared water, antifreeze or a mixture of mineral oils. Solid-filled design radiators can use either a traditional spiral or tubular electric heater, or a heating film or cable. Liquid “towels” are built using traditional “dry” or conventional heating elements.

You can learn more about choosing and connecting electric heated towel rails from this article: https://aqua-rmnt.com/santehnika/polotencesushitel/elektricheskij-polotencesushitel-dlya-vannoj.html

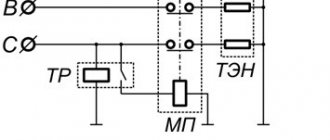

Design and installation diagram of an electric heated towel rail

In order to find the cause of the breakdown of an electric heated towel rail, you will need a multimeter, a set of screwdrivers and an adjustable wrench. The search begins with checking the integrity of the electrical circuit, gradually moving towards the power elements:

- check the presence of mains voltage in the outlet;

- “ring” the power cord with a multimeter - its resistance should not exceed 1-2 Ohms;

- when the substation is connected to the network, the voltage at the terminals of its heater is measured.

If the multimeter shows the presence of 220 V, then this is indirect evidence of failure of the heating element; To check the electric heater, use a multimeter turned on in resistance measurement mode. An infinitely large value indicates an internal break. The resistance of a working heating element should not exceed several tens of ohms. - if there is no supply voltage at the heater terminals, check the serviceability of the contact group or the thermostat relay - the cause of the malfunction can be either burnt contacts or a poor electrical connection;

- if an electronic rather than a mechanical thermostat is used to control the temperature of the heated towel rail, then the reason for the lack of voltage on the heating element is more difficult to find. First of all, you should check the output relay or power semiconductors - powerful transistors, thyristors or triacs of the output stage. If they are in good working order, other components of the circuit are checked. If you do not have experience in repairing electronic devices, then it is better to entrust such work to a specialist.

All you need to diagnose and repair an electric heated towel rail is a multimeter, an adjustable wrench and a set of screwdrivers

Replacing the heating element in a heated towel rail is easy. If the type of device is unknown, then before disassembling it, the coil should be turned over so that the working fluid does not leak out. Then use an adjustable wrench to unscrew the nut on its flange, dismantle and replace the heater. Don't forget to check if there is any current leakage on the design radiator body. To do this, one multimeter probe is connected to the metal surface of the heated towel rail, and the other touches the heating element terminals in turn - the device should show an infinitely high resistance.

Burnout of the heating element is the main cause of failure of electric heated towel rails

Before assembling the heater, the level of the working fluid should be replenished (if there were leaks or some of the oil leaked out during operation), leaving room for thermal expansion. After this, check the integrity of the sealing gaskets and, if necessary, replace them with new ones. Next, with a force sufficient to ensure tightness, tighten the flange nut and check the performance of the heater in various modes.

Connecting a heated towel rail in a country house

The conditions of a private home are more favorable for installing a dryer. With an autonomous supply system, the water here is cleaner. You can buy imported PS that is afraid of sediment accumulation.

Usually in such a house a fairly large room is allocated for a bath, which expands the boundaries of the choice of unit in terms of size and shape. And connection work does not require permission from neighbors.

The connection diagram itself is similar to that used in an apartment building. It must be remembered that the device should be connected exclusively along the flow of water. For line lengths up to 50 cm, place the pipes horizontally; for larger lines, make a slope along the entire length.

Maintain the distance between the wall and the water pipe. If the pipeline diameter is 4-5 cm, choose a distance from 5 to 5.5 cm. When the diameter is less than 2.3 cm, this gap is reduced to 3.5 cm.

Considering the temperature deformations to which hot pipes are subject, it is impossible to fasten the PS to the supports by welding; the fastening must be free.

How to choose a coil?

Installing a heated towel rail with your own hands is a routine operation that even an inexperienced technician can handle. Before starting installation, it is important to correctly determine the appropriate device model. When choosing, you need to consider the following characteristics of the device:

- Connection points. There are heated towel rails with vertical, horizontal and universal connections. The choice of model depends on where the entry points into the heating system or connection to the riser are located.

- Form. Various models of coils can have one or several turns of pipe; devices in the form of a ladder are also very popular, with plenty of space for drying clothes.

"Ladder" form - Distance between insertion points. This is a very important parameter, which is selected in accordance with the distance between the points of entry into the central heating system. If these two distances do not match, you have to use adapters, which reduce the reliability and tightness of the system.

- Material. When purchasing a device, you need to pay attention to the fact that it is made of corrosion-resistant material that is not afraid of constant contact with water. Stainless steel models are considered the best. The external coating can be chrome or paint depending on the style of the bathroom. Copper coil

Please note that to successfully install a coil in a bathroom, you must accurately determine the appropriate model. Maximum attention should be paid to the diameter of the heated towel rail pipes and the distance between the connection points. If these parameters do not correspond to the connection location, you will have to use adapters for connection, which often cause leaks.

Typical mistakes of independent craftsmen

When, with a side or bottom connection, the lower outlet is located above the extreme point of the PS, a stagnation zone is formed between the bottom of the device and the connection point of the lower outlet.

This is a consequence of the fact that the cooled liquid, having dropped down, cannot get back into the riser due to the pressure on it from a column of hot water with a lower specific gravity. As long as the permissible height difference between the bottom outlet and the bottom of the heated towel rail is not exceeded, the device works, and after that the circulation in it stops.

Circulation will also stop if there is a bend formed by the upper pipe. The only way to make such a scheme work is by inserting a Mayevsky tap to periodically bleed off the accumulated air. Sometimes a loop is made in the upper pipe, laying it behind the ceiling trim, and the lower pipe is walled into the floor.

Air will accumulate at the top, and the cooled water in the unit will be blocked in the lower loop located in the floor. The movement of the coolant will stop completely.

Installation diagram of a structure with bottom connection

The connection diagram consists of several stages.

At what height should I hang it?

The dimensions of the product are determined depending on the area of the room. When choosing an installation location, the distance from the riser is also taken into account. It is recommended to install it directly next to it. The height of the ladder heated towel rail (upper installation point) is 1.9 - 2.0 m.

Photo 2. Dikron L water heated towel rail with side connection and stainless steel shelf.

Removing old equipment

This process will require turning off the water. For this purpose, contact your utility service. If the previous device was fixed to the pipe using a thread, then you can simply unscrew it. If difficulties arise with this, then a grinder is used.

How to properly connect a ladder to a riser?

Couplings suitable for the size of the pipes are fixed to the heating system. The lower outlet pipe is mounted below the level of the body of the device itself. The supply of heated water is connected to one of the pipelines, and its outflow to the other.

Attention! Supply pipelines must be thermally insulated

Installation of taps

A Mayevsky tap is installed in one of the vertical pipes to remove excess air. Shut-off valves are installed on the supply pipeline with detachable connections.

Wall Mount

To begin with, places for future fastenings are marked, walls are laid for laying pipes.

Then the correct fixation of the heated towel rail is checked by applying a special building level. Brackets are fixed to the wall.

Initially, a bypass is installed. One ball valve is attached to it, and the other two are at the connection points of the heated towel rail.

Important! It is necessary to leave a gap from the lined wall to the staircase. The device is connected to the valves using fittings

All joints are tightly sealed with flax or FUM tape

The device is connected to the valves using fittings. All joints are tightly sealed with flax or FUM tape.

Features of use

A warm floor from a heated towel rail in a bathroom is, rather, not commonplace, but an exception to the rule. However, such a heating system still exists, and therefore deserves attention.

Let us remind you that this water heating system will directly depend on how the centralized communications network functions. And, for example, a pressure drop in the general system or a deterioration in the quality of the coolant will affect the permeability of the water circuit.

How to install a warm water floor in an apartment using a heat exchanger. You can read about this in this article.

Don't forget about possible emergency situations. If a pipe ruptures due to a water hammer, the resulting leak will need to be repaired immediately. It will be necessary to remove both the tiles and repair the screed area. It is even possible that in an accident you will flood your neighbors.

Remember that a hot towel dryer can be your problem. If there is no thermostat, it will be difficult to achieve the optimal temperature in the bathroom. A floor that is too hot can dry out a small bath space too much. After all, instability of hot water supply in apartment buildings is not a rare phenomenon. In some cases, a collector and thermal control sensor can help, but then, naturally, the heating system will require large financial investments.

You can read about the types of thermostats for heated floors.

A warm floor in a bathroom is, of course, comfort and warmth, which is so lacking in the cold season. Connecting the system to a heated towel rail is one of the options for creating these favorable conditions.

You can install underfloor heating from a heated towel rail yourself, but only if you have the appropriate skills. If you have no experience, rely on the skills of qualified workers.