Until recently, the primitive wood stove was the main source of heat in many settlements that did not have centralized heating. But progress does not stand still and today stoves are becoming a thing of the past, and their place is taken by solid fuel boiler equipment with high efficiency and the ability to automate the entire heating process.

Various designs of this type make it possible to select equipment for a small country house, a cottage with several floors or an industrial premises, and the choice of fuel type, taking into account local conditions, makes it possible to significantly reduce the cost of heat.

Application options

The highest popularity of this type of equipment is in remote areas with poor infrastructure, and in areas where there is a possibility of connecting to a gas pipe, not all consumers prefer gas, since the cost of connection is high, and it is not always possible to fulfill all the requirements for the premises.

Solid fuel boilers can serve as the main or backup source of heat; in some cases, this type of equipment allows not only to obtain cheap thermal energy, but also to significantly save on the disposal of industrial waste, for example, in woodworking enterprises. Therefore, the Ural Boiler Equipment Plant produces various options for heating equipment so that you can choose the right option for yourself.

In addition to the industrial and residential areas, the use of this heating option is very important for agriculture, both due to the lack of an alternative and due to the presence of a large amount of waste that can be used for heating. Among the main advantages are:

- relatively low price;

- various fuel material options;

- availability of non-volatile models;

- environmental friendliness and safety;

- no special requirements and easy installation.

Not only the listed advantages are the advantages of solid fuel boilers; in modern models, the efficiency can exceed 80%, which is comparable to gas analogues or liquid fuel equipment.

As in every “barrel of honey” of positive qualities there must be a “fly in the ointment” in the form of disadvantages, and these units have them:

- the need for additional fuel storage space;

- the tendency of some models (usually the cheapest) to accumulate soot, which requires frequent cleaning of the chimney;

- manual fuel loading mode in most models;

- low, at 70%, efficiency for long-burning boilers;

- impossibility of using a coaxial type chimney in the chimney system.

Main varieties

The type of heating equipment determines its operational properties, parameters, and maintenance requirements. The dimensions and area of application of the equipment depend on the design.

Classic wood-burning for heating a private house

The most common option, characterized by simplicity of design, energy independence, and the ability to work with all types of fuel. For thermoregulation, a mechanical drive and a damper are used.

The classic wood-burning boiler has a simple design.

With extra traction

For more complete combustion of fuel, it is necessary to force air into the furnace or equip the unit with a smoke exhauster (an exhaust for combustion products that enhances draft). This increases productivity and reduces fuel consumption.

Pyrolysis

Gas generator models have 2 combustion chambers: for solid fuel and the combustible gas released at the first stage. This design ensures environmental friendliness, energy efficiency of the installation, and increases its efficiency to 95%. You can use fuel of any fraction, provided its humidity is controlled.

The pyrolysis boiler has 2 combustion chambers.

Long burning

The equipment is equipped with water-cooled grates, a smoke removal system with convection channels, a control unit and a fan for air supply. The boilers are distinguished by 90-95% efficiency, battery life up to 48 hours, and the absence of complex electronics, which increases the reliability of the units.

Auto

The fuel supply is automated, carried out using a screw conveyor or a pneumatic conveyor from an external bunker in which it is stored in large volumes. Complex electronics are used to control the temperature of the coolant. Remote control function available.

An automatic boiler is one of the most convenient units to use.

What to burn, from sawdust to anthracite

Materials of plant origin are used as fuel for this type of boiler, even peat and coal are essentially plants that existed many thousands or millions of years ago.

Firewood

Firewood is a classic solid fuel; its use dates back as many years as people have been familiar with fire. Firewood from various types of wood is used for boilers; the efficiency of the heating system and its uninterrupted operation largely depend on the type of wood and humidity. As for humidity, it is clear that the lower it is, the higher the heat transfer, since energy is not spent on moisture evaporation, and the properties of various types of wood when used as fuel deserve more careful consideration.

The most suitable option is considered to be deciduous trees, among which the record holders for heat transfer are: oak, beech, hornbeam and ash; birch is not far behind, but if there is insufficient air supply to the combustion site, birch begins to release tar, which is deposited on the walls of the smoke removal system.

Hazel, ash, yew, pear and apple have proven themselves well; they split easily and burn hot, but elm and cherry emit a lot of smoke when burning. Poplar and linden, familiar to city dwellers, are not the most suitable option for a firebox; they burn well, but quickly burn out and spark strongly during the combustion process; aspen and alder are a completely different matter, which not only do not emit soot, but contribute to its burning on the walls of the chimney .

Coniferous trees are characterized by the presence of resins in the composition of the wood, which is ultimately deposited on the inner surface of the pipe; the process of deposition of resin and soot is especially relevant for boilers in which the combustion process occurs at a not very high temperature. The heat transfer of conifers is noticeably lower than that of deciduous trees.

Briquettes

This type of fuel is made from wood chips, shavings, peat, as well as agricultural waste - sunflower husks, straw, etc. Briquettes are produced by pressing, the binder is ligin - a natural mixture of aromatic polymers, no synthetic materials are used in production, so they deservedly considered a clean fuel.

Briquettes are produced in the form of a cylinder or parallelepiped; cylindrical products from some manufacturers have an internal hole along the entire length. Briquettes are not susceptible to fungal attack, have a high calorific value and are very convenient to use, as they have a low ash content of no more than 3%.

Pellets

Pellets are a granular type of fuel that greatly facilitates the task of automating solid fuel heating devices. The material for production is waste from woodworking and agricultural production - sawdust, bark, wood chips, shavings, flax waste, sunflower husks, etc. The material is processed into flour and pressed into cylinders under high pressure, the diameter of the pellets is 5–8 mm, and the length is not exceeds 40 mm. As in the case of briquettes, the binding material is a natural component – ligin.

Criterias of choice

Modern boilers differ in many ways, and when choosing, you should start from several basic criteria. Despite their heavy weight and large dimensions, such installations continue to be in demand. This is primarily due to their availability.

Fuel type

When purchasing a unit, you need to choose what type of fuel it will operate on. Modern devices operate on ordinary wood, peat, various types of coal, and so on.

The choice of a certain type of raw material affects heat transfer, operating time from one load and operating comfort. If wood is used, then preference should be given to deciduous and soft-leaved species.

Fuel should be stored in a ventilated area. For this purpose, a separate closed place is allocated, where precipitation does not fall. Some types of wood do not burn well, while others may not even be laid dry. Each breed has its own calorific value.

Recently, installations operating on briquettes - pressed waste wood or peat - have been in great demand. These are environmentally friendly resources that do not produce a spark during a fire. Briquettes should also be stored in a place protected from precipitation.

Advantages of pellet boilers:

- environmental friendliness;

- no waste remains;

- availability;

- high thermal conductivity.

Pellets are pressed material of plant origin. Their characteristics are similar to coal, which is not so common now, as it releases sediment and sulfur during combustion. For its storage, certain conditions should also be provided: protection from rain and snow, humidity not more than 75%.

Weight

Steel products are inferior in weight to cast iron by about 17%. This means their cost will be lower. Plus, they are easier to install. Cast iron models are more durable and reliable, but their installation often requires a special foundation. Steel analogues withstand temperature better, but if they start to rust, they cannot be repaired.

When choosing a material, you should proceed from the climate zone in which the equipment will be operated. If the temperature does not “jump”, then it is better to give preference to a cast iron product.

Power

Power is the key parameter by which the unit is selected.

There are 2 simple formulas:

- 1 kW of power is needed to heat 10 m2 of room area, provided that the ceiling is no higher than 3 meters. Thus, in order to heat a house measuring 200 m2, the installation power must be at least 20 kW.

- Not only the volume of the room is taken into account, but also the quality of thermal insulation. To express its degree, it is recommended to use simple coefficients. If the house is poorly insulated or has large window openings, the coefficient will be 60. When installing high-quality thermal insulation, it will be 40. The formula is not complicated. As an example, let's take a room without insulation with an area of 200 m2 with a ceiling height of 2.5 m. The calculation looks like this: 200 × 2.5 × 60 = 30,000 W (36 kW).

The second formula is more accurate, since it takes into account energy savings.

Loading chamber volume

Once the required power of the equipment is known, you should decide on the dimensions of the boiler, namely the volume of the firebox. This determines how quickly the unit will heat the room.

To determine the useful volume, you should make 1 load of fuel and understand what heating power is obtained during its combustion. The reloading interval is also taken into account. The material from which the firebox is made also plays a certain role. In steel models the ratio will be as follows - from 1.6 to 2.6 l/kW, in cast iron - from 1.1 to 1.4 l/kW.

Efficiency

This is an indicator of effectiveness.

It all depends on the type of boiler:

- standard - up to 76%;

- universal - up to 82%;

- pyrolysis - up to 85%;

- pellet - up to 95%.

As can be seen from the list, pellet equipment will have the best efficiency. However, given this feature, you need to understand that fuel burns differently. Wood can be burned longer than pellets, which means there will be more heat, albeit with less intensity.

Models whose efficiency is higher ultimately leave less ash, which means they are easier to clean.

Types of boilers, their advantages and disadvantages

Modern technologies have made it possible to develop and produce several types of solid fuel boilers with a higher coefficient of sub-ice action, let's look at them in more detail.

Classic boilers

All solid fuel boilers can be divided into two types - single-circuit and double-circuit.

The presence of an additional circuit makes it possible to provide a residential or industrial building with hot water. There are two types of structures for heating water - flow-through and storage; the flow-through system is made in the form of a coil or pipe system, and storage is a built-in container (boiler) in which there is always a certain supply of hot water. The advantages of a dual-circuit system are the compactness of the unit and ease of operation, but it is more expensive than its single-circuit counterpart and requires a minimum content of mineral impurities in the water, which cause deposits on the walls of the pipes.

When using a single-circuit boiler, providing hot water is only possible with the purchase of additional equipment - an indirect heating boiler. The advantages of this unit are low cost, high efficiency, and the ability to install a cast iron heat exchanger. Disadvantages include the need for additional space when installing a hot water supply system and the cost of a boiler.

Gas generator (pyrolysis) boilers

Among all solid fuel units, models using the pyrolysis process are the most efficient devices, their efficiency reaches 90%. The process is based on the principle of high-temperature decomposition of organic fuel. Combustion occurs in several stages: first, the fuel is heated with limited access to oxygen, heating causes the release of pyrolysis gases, which are burned in a separate chamber, and gaseous waste, having passed through an additional heat exchanger, is removed through the chimney.

Advantages:

- Efficiency 90%;

- minimal amount of ash and soot formation;

- laying firewood for 8-12 hours;

- minimum waste in the form of ash;

- reduced emissions of harmful smoke into the atmosphere.

Due to the high temperature in the combustion chamber, maximum heat transfer is achieved. The fuel used for this type of boiler is coal, wood chips, briquettes, pellets and firewood. It is very important for the efficient operation of the equipment to use fuel with minimal humidity. Strict requirements for humidity characteristics of no more than 20%, the high price of units and volatility are the main negative qualities of these devices, but nevertheless, the purchase of a pyrolysis boiler is justified, since it allows you to save on the amount of fuel, which is required significantly less than for classical models. You can read more about this type of boiler here .

Features of long-burning boilers

The main disadvantage of solid fuel thermal units is the need to constantly monitor the presence of fuel in the combustion zone. The design of long-burning heat generators, such as TT Energy boilers, allows the firebox to be loaded for a period from 12 hours to 5 days , depending on the type of fuel and the volume of the combustion chamber.

How to install correctly

Before you begin installing such equipment, you must familiarize yourself with the basic rules. The duration and safety of the installation depends on their compliance. You need to be careful at every step, otherwise the device will not be able to perform its task effectively.

Required tools and materials

To create a competent heating system, you need to have not only special tools, but also skills. We are talking about any boilers, not just long-burning ones. For this reason, if experience is not enough, it is recommended to contact specialists.

Before installing the system, all necessary calculations are prepared and the parameters of the boiler room where the equipment will be installed are taken into account. Next, pipes are laid out, connecting elements are secured, and so on.

The list of necessary tools includes:

- soldering iron for plastic pipes;

- welding machine;

- pipe cutters.

If the unit is installed at home, it must be covered with a protective cover. To do this, a frame made of metal structures covered with sandwich panels is installed. You can also use profiled sheets, but with insulation.

Preparatory work and protection of the premises

Inexpensive models of solid fuel boilers are installed directly on the floor. Due to their low weight, they do not exert serious loads on the base. If a unit with a power of more than 50 kW is selected, it should be installed on a concrete foundation. Soil or compacted crushed stone bedding is used as support. The foundation should be made 80–100 mm above the screed, and they should not be connected.

The furnace room must have natural exhaust ventilation. Usually this is a shaft in the wall. It runs parallel to the chimney, but only has a smaller cross-section. If it is not there, a transfer grille is installed in the outer wall, located under the ceiling.

The hood is needed for:

- creating a vacuum in the firebox, which will allow the system to “take” air from other rooms for high-quality combustion;

- removal of products formed after fuel combustion and accidentally found in the room.

Often boiler rooms are not equipped with a sewer outlet, although it can be useful, because the system, like the water jacket of the unit, must be periodically emptied.

Harness

The classic scheme, which allows the device to operate effectively, consists of two elements: a safety group and a mixing unit. The basis is a three-way valve with a thermal head and a temperature sensor.

The safety group is installed directly at the outlet of the boiler supply pipe. Its task is to automatically relieve pressure in the network if it rises above a set value. The system also contains a safety valve that releases air from the coolant, as well as an automatic air vent that controls the pressure.

Please note that there should be no shut-off valves in the pipeline section between the unit and the safety group.

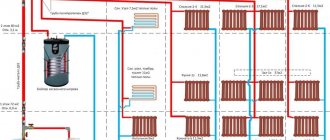

The most common connection schemes:

- Open system. It is considered the simplest and works on the principle of natural circulation of water, without consuming electricity.

- Closed system. Since it operates under pressure, an expansion tank with a membrane is added to it. This allows atmospheric air not to come into contact with the coolant. Its advantage is that when laying main pipes there is no need to create slopes. Thanks to the circulation pump in the system, the circuit can consist of a large number of pipe turns. The only drawback is that it requires an electrical connection.

- Through the distribution comb. This element comes in several types: it has 2, 3 or 4 connection outlets. The collector's job is to distribute water evenly throughout the system. In this case, adjustment of a separate circuit is available.

- Connection via heat accumulator. In this case, hot water from the boiler flows to the insulated battery housing. It accumulates excess thermal energy, which is subsequently transferred to the system. After all the fuel has burned, the heating will operate from the storage tank. In a word, the device takes away excess energy, which makes the entire system more economical.

There are many connection diagrams and drawings. Each user decides on this issue at the heating system design stage.

Chimney connection

In private houses, as a rule, there is a chimney shaft where the pipe exits through the roof. If it is not there or is already in use, you will have to create a new chimney. For this purpose, a double-walled version with insulation, made of metal, is suitable. It is lightweight, the elements are easily connected to each other according to the type of sections. Turns and branches are made using special tees and bends.

When installing a chimney, you need to be careful, since each boiler model requires certain parameters. If you violate the requirements, difficulties may arise: draft will deteriorate, condensation will begin to form, air pockets will appear in the chimney, and so on.

To avoid this, follow these rules:

- To determine the final height of the chimney in each specific case, it is recommended to contact specialists. They take into account nearby objects and the characteristics of the climatic zone.

- Depending on the power of the equipment, a certain chimney diameter and draft level are selected.

- The pipe leading outside the building must be insulated.

- If the chimney is diverted into a brick chimney, it is lined (a metal liner is installed).

These tips will help you properly organize a smoke removal system from the room.

Connection to the heating system

During operation of the boiler, there is always a possibility that the coolant will simply overheat. This is especially common when the equipment is operating at maximum power. This is explained by the inertia of fuel combustion; in a word, this process cannot be stopped quickly. Due to heating, the risk of vaporization increases, which leads to increased pressure in the system.

To avoid this, a safety valve should be used when connecting. It is adjusted to a specific value, depending on the critical pressure specified in the boiler passport.

The next step is the competent organization of a small coolant circulation circuit. This will prevent cold water from entering the system.

Automation

Modern solid fuel boilers are equipped with a whole range of automatic devices that minimize human participation in servicing the operating unit. The scope of automatic regulation includes the following functions:

- compliance with the temperature regime in the system;

- control of pumps in the main and auxiliary (admixture circuit) circuits;

- maintaining the set temperature of hot water supply;

- control of coolant flows using a three-way valve.

If there is an automation unit , a person only needs to set the required temperature and load fuel, then the combustion process is controlled automatically according to the specified settings by controlling the supply of oxygen to the firebox . If heating is carried out using a pellet unit, then the fuel is loaded automatically.

Operating principle of three-way valve

If there is a three-way valve, the system works on the principle of mixing hot water from the boiler into the main flow when the temperature drops below the set one. This principle allows you to heat only the required amount of water. It can be supplied either directly from the boiler or from a buffer tank. At the same time, it can be heated by alternative sources, for example, a solar collector.

How to build a solid fuel boiler for a country house or cottage without the help of a specialist

The simplest unit can be made independently if you have basic welding skills.

The classic version includes the following elements:

- combustion chamber;

- heat exchanger;

- draft regulator;

- grate;

- chimney.

The battery life of the device depends on the size of the loading hopper and its capacity.

Required tools and materials

After designing a solid fuel boiler installation, specifications and drawings are drawn up.

To manufacture the unit you will need:

- welding machine;

- electric drill;

- angle grinder;

- set of screwdrivers, keys;

- pliers;

- hammer;

- square

To make a boiler, a welding machine is required.

For the frame you need a corner made of heat-resistant steel 50 x 50, steel pipes for a heat exchanger with a diameter of 32‑50 mm or a finished cast iron coil, dismantled from a previously used unit. To manufacture the drive, you need rolled stainless steel sheets. The minimum metal thickness for the boiler is 5 mm, for grates - 7 mm.

Step-by-step instruction

To complete the task, you will need welding skills, taking into account the characteristics of the selected metal and the welding machine used. Basic operations are performed in the following sequence:

- Manufacturing of a two-layer rigid body with a combustion chamber based on a frame made of angle iron. Sand is poured between the layers of rolled metal to prevent deformation of the sheets when heated.

- Preparing openings for the ash pan and loading hopper on the front wall according to the markings. To increase the accuracy of the operation, craftsmen recommend making holes with a diameter of 3-4 mm in the corners with a drill.

- Manufacturing a heat exchanger from water supply steel pipes by welding using bends.

- Assembly of unit components. Performed at the installation site in accordance with the project.

After a test run of the assembled installation, if necessary, identified shortcomings are eliminated and adjustments are made to the design.

Buffer tank (heat accumulator)

If we exclude devices operating on granular fuel, then solid fuel boilers are characterized by uneven operation; the increase and decrease in temperature in the furnace are cyclical. In order to smooth out temperature fluctuations in the heating system, a heat accumulator (buffer tank) is used. The design is a sealed tank with a heat-insulating layer, most often cylindrical in shape.

Two or more pairs of coils (heat exchangers) are embedded in this tank, through which heated coolant from the boiler enters the tank and is distributed throughout the heating system. This scheme allows excess energy at the peak of combustion to be accumulated in a heat accumulator, so that later, when the fuel burns out, heated water can be used to maintain the set temperature. You can read more about them here.

Pros of installations

Solid fuel boilers allow you to save money - their operation costs 3-4 times less than electric ones and 2-3 times more affordable than gas ones. Other advantages:

- durability;

- cheapness;

- variability of energy resources, affordable prices for them (firewood, peat, briquettes, coal, manure, coke, anthracite, etc.);

- quick, simple installation;

- minimum requirements for a boiler station.

The downside is that equipment maintenance requires a special approach. You must carefully study how to heat a solid fuel boiler, choose a safe room for it, and arrange a chimney. With electrical installations there is much less hassle (but they are noticeably more expensive).

Choosing a boiler for a private home, which one is better

Boiler power calculation table

The main argument when choosing a heating device is the correspondence of its power to the heated area.

An average calculation assumes that 1 kW is needed per 10 m2 , and the resulting result is multiplied by a correction factor, which is equal to 1.2. For example, for an area of 100 m2 you need a boiler with a capacity of 10 x 1.2 = 12 kW, but this is an inaccurate calculation; in order to choose the best option, the results of a house inspection must be taken into account - the thermal insulation of the enclosing structures, as well as climatic conditions.

The choice of model depends on the financial capabilities of the future owner and on the intended heating mode. For a seasonal stay at a summer cottage, it is absolutely not necessary to purchase expensive systems with automatic control; you can get by with the classic low-budget option. It’s another matter if the boiler will heat a cottage or house for permanent residence, in which case comfort comes to the fore.

If it is possible to purchase granular fuel (pellets), the optimal choice would be a pellet boiler; this option will provide the owner with the opportunity to fully automate the home heating process.

The use of pyrolysis devices is justified by the availability of fuel with minimal moisture content. The choice of these heat generators will significantly reduce the cost of purchasing coal or firewood due to the high efficiency of pyrolysis models.

Piping the boiler with a water heating circuit

Energy efficiency and safety of the boiler room are problems that can be solved when choosing the correct connection diagram for the unit to the pipeline. At the same time, the location of process equipment (pumps, valves, air vents, measuring instruments) affects the accuracy of parameter control and the correct operation of protection devices.

Gravity type system

Depending on the design, the circuits are open or closed. The first option involves installing an expander in the attic, the second - a membrane tank located at the level of the boiler with the mandatory equipping of the system with a safety group.

The gravity-type system operates thanks to the circulation of water.

With natural circulation

No pressure equipment is provided. The movement of the coolant is ensured by the location of the boiler at the lower level of the building. The minimum slope angle observed when laying pipelines is 0.5°. The speed of water movement in the system is 0.1-0.25 m/s.

With forced

The liquid circulates in the circuit under the action of a pump located on the return line. It is selected according to the pressure and volume of the pumped coolant based on the heated area and circuit configuration. It is possible to use an open or closed circuit.

Popular manufacturers and their offers

There are quite a few companies that produce solid fuel boilers, among them there are several of the most popular. Our rating of the best boilers of 2022.

Buderus Logano

A German manufacturer with almost 300 years of experience, his contribution to the development of the production of heating devices can hardly be overestimated. The boilers produced by this company are deservedly considered one of the best on the world market. The company uses only high-quality materials in production, so Buderus Logano boilers are durable and reliable.

Price: 100,000 -109,000 rubles.

| Advantages | Flaws |

| High quality design, manufacturer's warranty up to 20 years | High price |

| Reliable automation | |

| Ease of installation |

Stropuva

This Baltic brand has been known in Russia since 2008, Stropuva units are reliable and have an impressive fuel chamber volume, they can work on one load for up to 5 days, if coal is used, for firewood this limit is limited to 30 hours.

Price: 52,000 - 65,000 rubles.

| Advantages | Flaws |

| High efficiency, minimum 90% | Heavy weight of the unit |

| Economical consumption | Lack of built-in automation |

Protherm

The Czech company Protherm has been present on the Russian market since 2011, during which time the company's products have gained wide popularity due to such qualities as reliability, ease of installation and maintenance, as well as the energy independence of heating devices of this brand.

Price: 52,000 - 60,000 rubles.

| Advantages | Flaws |

| Not expensive | Manual ignition |

| Efficiency up to 90% | Small firebox |

| Built-in automation |

Zota

Who, if not the Siberians, knows what cold is? The Krasnoyarsk enterprise Zota is known for its combined models of boilers. The versatility of the equipment allows you to use different types of fuel - gas, wood, coal or diesel fuel; with such a set of options it is impossible to be left without heat, even in hard-to-reach areas.

Price: 34,000 - 40,000 rubles.

| Advantages | Flaws |

| Built-in automation | Low efficiency, 70% |

| Low price | |

| Built-in electric heater |

Teplodar

A characteristic name for the products of a Russian company, which fully justifies it. Teplodar boilers are distinguished by their versatility; it is always possible to replace wood or coal with pellets or gas; this does not require replacing the unit; it is enough to install the appropriate burner. This brand produces many different models, both expensive and budget.

Price: 30,000 - 90,000 rubles.

| Advantages | Flaws |

| Large selection of models by type and fuel | Additional equipment must be purchased separately |

| Built-in heating element |

Teplodar Kupper

This product from the Teplodar plant allows the owner not to think about problems with purchasing fuel - any will do. The unique design of the Kupper brand is the basis for the efficient operation of the equipment; its efficiency is one of the highest among analogues.

Cooper Pro

Another successful development of the Teplodar company is long-burning boilers Kupper Pro, the entire line of this series has an efficient heat exchanger and a water-cooled grate, the units are equipped with an additional door, there are now three of them on the front side.

Don

Another Russian representative on the market of solid fuel boilers, Don heat generators are produced in Rostov. They have earned their popularity due to their versatility and reliability; the manufacturer uses high-quality boiler steel for production.

Siberia

The NMK plant from Novosibirsk specializes in the production of inexpensive budget models, but despite the reasonable price, Siberia brand units are very efficient, high efficiency is ensured by a grate made of pipes and beams at the flue gas outlet, also filled with coolant.

In conclusion, a few video reviews

Indeed, solid fuel equipment can be installed without worrying about poor infrastructure or distance from large populated areas. You can always choose a model that will provide heat and hot water to residential or industrial premises in the most unfavorable conditions.

Solid fuel boiler. What is the efficiency?

Wood heating? What are boiler sellers silent about?

Features of coal combustion

Let's look at how to properly heat a solid fuel boiler with coal. For kindling, wood chips approximately 5 cm thick are used, which must be laid out on paper. You need to put 3-4 logs with a diameter of 10-15 cm on top of the wood chips. After this, you need to set fire to the paper and close the firebox door, as well as cover the ash pan. In this case, the draft must be sufficient to ignite the firewood. If the boiler is equipped with a slide valve, then it is only slightly opened when lighting. If there is a thermostat, then it should be set to a temperature of 70-80 °C.

Coal can be added after 15-20 minutes of intense burning of the logs, when the chimney and the boiler itself are already sufficiently warm. In this case, you need to reduce the temperature set on the thermostat and fully open the gate valve. Before throwing coal, be sure to close the ash pit. The first layer of coal is laid with a thickness of 5-6 cm. After it burns out, a second layer with a thickness of about 15-20 cm is laid. Further layings also have this thickness.

It is also important what kind of coal to heat a solid fuel boiler. When using fine-grained fuel (up to 5 cm), it should be moistened by adding about a liter of water to a bucket of coal. The optimal fuel is large anthracite of a fraction of 6 cm. It does not require wetting. Water is added only if it is necessary to prevent overheating of the boiler.

Forced circulation system

A system with forced circulation of coolant using a circulation pump does not have these disadvantages. Such piping of a solid fuel boiler allows you to ignore the hydraulic resistance of the system and use control valves to maintain optimal temperature conditions. Negative aspects also include possible power outages, which will cause the circulation pump to stop and the boiler to overheat. To avoid such troubles, you should equip your solid fuel boiler with a built-in emergency heat exchanger.

Important! It should not be overlooked that excessive regulation can lead to overheating of the boiler.

Figure 8: Forced circulation heating system

Natural circulation system

If you have chosen a system with natural circulation, it is necessary to minimize all hydraulic resistance in the path of the coolant, minimize all corner and elbow elements and ensure that the diameter of the pipeline is maximum. Systems with natural coolant circulation are good due to the simplicity of their design and independence from the power supply, but their disadvantages include relatively high fuel consumption and the difficulty of maintaining optimal thermal conditions in a heated room.

Figure 7: Natural circulation heating system

How to make your boiler work more efficiently

All types of boiler units have optimal load parameters in which they operate most of the time. When operating the equipment, you must comply with the following requirements:

- supply and exhaust modes of the ventilation system;

- control of combustion intensity and complete use of fuel;

- assessing the condition of surfaces that heat up during fuel combustion;

- regularly clean external and internal surfaces, heat exchanger, chimney;

- load the combustion chamber with fuel that meets the manufacturer’s requirements.

Compliance with these points guarantees the operation of the boiler with the parameters guaranteed by the manufacturer.

Expert advice: Proper loading of fuel ensures uniform combustion and more complete combustion.

For greater boiler efficiency, you can install an additional heat exchanger-economizer that operates on flue gases.

Theory of coal combustion.

When coal is heated, moisture is first released from it, which evaporates and is removed in the form of steam into the chimney.

As the temperature rises, the coal begins to release gaseous volatile components (pyrolysis), which, when burned, heat the coal. After their separation, a solid residue remains, coke, consisting of carbon and ash. The released gases, quickly burning, provide approximately 10% of the heat from the entire temperature balance.

Thus, the main heat release comes from the carbon located in the solid residue of coal.

The air supplied for coal combustion is divided into primary and secondary.

- Primary air is supplied through the grate into the combustion chamber, where coal coking occurs.

- And at the exit of coke oven gas from the combustion chamber, for its complete combustion, secondary air must be supplied.

For the most efficient combustion of fuel, it is necessary to control this process, i.e. regulate the intensity of combustion of both coal and coke oven gas.