Solid fuel boilers are a popular type of boiler equipment. They are widely used for autonomous heating in facilities where it is not possible to use models running on natural gas. Modern equipment of this class is capable of providing high-quality heating and at the same time is inexpensive, convenient and easy to operate. For maximum heating efficiency, it is important to have an idea of how to properly heat a solid fuel boiler.

The firing of a pyrolysis boiler has some peculiarities. A few wood chips and a sheet of paper are placed in the combustion (screw) hole, and firewood mixed with coal is placed in the loading door - most often it is located above the combustion door. A sheet of paper is set on fire, after which the fire is directed towards the fuel with a stream of air, starting the combustion process. For normal operation of the boiler, a constant supply and normal circulation of air is necessary.

How to properly heat a solid fuel boiler with wood, tips on how to heat a boiler with wood

It would seem, what does it mean to “properly” heat a boiler with wood?

What's so complicated about it, throw your firewood into the firebox before the coals cool down, and the whole process. It turns out that it's not that simple. How efficiently a boiler operates does not primarily depend on its design. First of all, the result of its work, as well as its efficiency, depends on the quality of the fuel used. Not only the type of wood is important, but also whether it is dry or damp, and the condition of the valves and chokes.

The nuances of operating solid fuel boilers will be discussed in the article.

How does a solid fuel wood boiler work?

The boiler works as follows:

- As a result of the combustion of wood in the firebox, a certain amount of heat is released, different for different species.

- The heat is used to heat the water tank located above the firebox.

- Water circulates through a pipeline from the tank to the heating radiators and back in a closed circuit. Circulation can be either natural (when the pipes are located at a slight slope) or forced, through a circulation pump.

- Combustion products are discharged through a chimney to the street. In order for the draft to be normal, the vertical part of the chimney is made three or more meters high.

- The combustion intensity is regulated using the firebox and chimney dampers.

Important!

The heating unit is equipped with a safety system for emergency pressure relief in case of overheating. If this is not done, the boiler becomes dangerous to operate.

How to heat a solid fuel boiler with wood

Before you start heating, you need to properly make the kindling, but if you ignore it, smoke may begin to seep into your home. Different types of wood are better suited for different stages of the process; the size of the wood also matters in this case.

Which firewood to choose

It is recommended to burn with well-dried wood, and its varieties are worth dwelling on separately.

Birch gives a lot of heat, burns for a long time, but during the combustion process it leaves a large amount of tar on the walls of the chimney.

Alder produces one and a half times less heat than birch, but leaves virtually no soot. Well suited for kindling as it ignites easily.

Aspen also does not produce soot and produces little heat; it is also advisable to use it as kindling.

Pine burns hot, but contains a lot of resin and produces a large amount of soot. Spruce firewood burns hotter than pine firewood, while producing less soot.

Poplar, releasing a lot of heat, burns out very quickly.

Apple and pear produce a lot of heat, good coals, but knotty and difficult to prick.

Oak, ash and beech are dense and hard, and are difficult to chip. When burned, they release a lot of heat and produce little soot. Rarely found on sale.

Taking into account the above properties, firewood is selected both for kindling and for directly heating the boiler.

Correct sequence of actions

The process begins with cleaning the ash pan and subsequent kindling. This stage can take about an hour. The purpose of kindling is to warm up the firebox and chimney to create sufficient draft. The complexity and duration of the process is determined by the shape of the chimney and the presence of horizontal sections in it.

Crumpled paper, bark, and small wood chips are used as kindling. Then thin logs are placed. After they are ignited, add wood little by little until the firebox is half loaded.

The vent and chimney dampers are opened wide during the kindling process to ensure good air flow. It is also recommended to open the windows in the room to increase the flow of fresh air.

After the flame burns well, close the dampers halfway.

After sufficient heating, full fillings begin, and the rate of their burning is determined by the type of wood and the position of the dampers.

On a note!

To automate the adjustment process, thermostatic draft regulators and fans with controllers equipped with a temperature sensor are used. These devices can significantly simplify temperature control and increase boiler efficiency.

Features of working with a wood-burning boiler

Unlike devices running on liquid fuel or gas, wood-burning boilers do not release heat into the room evenly, this is due to the peculiarity of the combustion process. In the middle of the process, significantly more heat is released than at the beginning and end. The dampers on the vent and on the chimney help more or less equalize the amount of heat produced.

Remove soot promptly

Soot needs to be removed not only when the chimney is clogged and there is no draft, but regularly. Soot not only impairs chimney draft, but also serves as thermal insulation. It covers the internal walls of the heating device and the heat exchanger, which reduces their heat transfer. If soot is removed in a timely manner, the volume of wood burned can be reduced without loss of heating power.

Obvious, but worth remembering: the firewood must be dry. Wet wood does not ignite well, goes out quickly and emits 2-2.5 times less heat than dry wood.

How to light a boiler

The most difficult thing in cycling is not to ride, but to start and finish the movement. It’s the same in the operation of a boiler - the most difficult thing is to light it. Do not expect that lighting the boiler will take you little time: you will have to allocate about an hour for this procedure.

Firing a wood-burning boiler is a responsible task

The beginning of the firebox is removing the ash and preparing the boiler for operation. After the ash pan and combustion chamber are cleaned, you can proceed to kindling.

Warming up the boiler firebox and chimney

For your own comfort and proper startup of the boiler, you need to warm up its firebox and chimney. If the heating device is not equipped with a forced smoke removal system, in order for the fuel to start burning, it is necessary to create draft. The formation of thrust is based on Archimedes' law: heated gases become lighter and tend to “float”. For their movement and removal, heating devices that burn fuel are equipped with a chimney.

Boiler diagram. Photo from the site www.viessmann.ru/

The design of the boiler is such that the path for smoke is difficult: in its path there is a heat exchanger and a complex convective surface, which reduces the speed of movement of combustion products. And the chimney pipe is usually located horizontally, which also makes it difficult for smoke to move. Therefore, if the boiler is not heated up, combustion products look for the easiest way. And most often the smoke begins to seep into the room.

In some cases, the vertical part of the chimney is equipped with a firebox (a small firebox used to warm up the chimney) with a door, by opening which you can burn a small amount of flammable fuel (for example, paper) directly in the chimney itself. When used, the heating element warms up the inside of the chimney duct.

If this possibility is not provided, then kindling is placed in the firebox - crumpled paper, birch bark - something highly flammable. On top of the kindling are chips and splinters, then logs of small thickness. The combustion chamber must be filled with firewood to no more than half the calculated volume.

At the moment of kindling, you need to open the chimney damper and the blower valve, ensuring the flow of air for combustion.

There is advice before starting the fire to open the window in the boiler room, if there is one: do not forget that the physical and chemical process of combustion requires oxygen.

How to properly heat a boiler with wood

To burn a kilogram of wood, about 5 cubic meters of air are required. If the air flow into the boiler furnace is from the boiler room, then it is necessary to arrange supply ventilation - especially if the boiler room does not have windows or they are sealed (with double-glazed windows).

After laying the logs, the kindling is ignited. When a stable combustion appears, the firebox door must be closed and the filling should be allowed to burn out.

Output to design power

As soon as the combustion chamber and chimney have warmed up sufficiently, you can proceed to the main stage of boiler operation. To do this, repeat the kindling process using well-burning materials. Now the main load of firewood is already complete, in order to fill the combustion chamber, according to the instructions for the device.

After the fuel has ignited, the boiler will reach its design capacity after some time. Now the combustion process will occur independently for some time. How long depends on the volume of the combustion chamber and the operating principle of the boiler. After the stack of firewood burns out, you will need to make a new one.

A properly functioning boiler is a source of heat and comfort in a country house

Important! When lighting, do not use lighter fluid or flammable gasoline, diesel fuel, etc.

Proper stacking of firewood

Typically, firewood is set on fire like this: they build a pyramid of logs, put paper and wood chips in the center and set it on fire. First, the wood chips flare up, and over time, the firewood itself. The disadvantage of this method is that you do not control the combustion. The firewood ignites all at once and entirely, burning unevenly and quickly. When some of the logs burn out, you throw in new ones, which will also quickly flare up and burn.

The burning time of firewood can be increased by changing the way it is placed in the firebox. For example:

- Lay the first bottom row of firewood.

- Place the second row on top, shifted to the right or left by 5-10cm to form a ledge. Place the third and subsequent rows on top.

- Place paper or wood chips near the edge with the ledge and set them on fire.

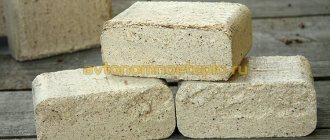

Laying using fuel briquettes as an example. The briquettes do not ignite entirely, but burn evenly: the flame gradually moves from left to right. A stack of firewood burns for a long time and produces a sufficient amount of heat.

- Do not place firewood close to each other. Leave a small gap between them for air movement.

- The denser and drier the wood, the more evenly it burns and the easier it is to ignite.

Tips for more efficient heating

If before refueling the boiler has recently been operating, and the chimney has excellent draft and has not yet lost its high temperature, it is enough to close the doors and, after turning on the control, record the desired temperature. After some time, you can remove the control unit and check whether the previously added part of the coal has ignited. If so, then it’s time to add additional combustion material. In this case, there is no need to close the slots in the front part of the grille.

Rice. 2 Automatic coal boiler

If the chimney is not preheated, after setting the paper on fire, the lower door of the ash pan must be opened

Next, without turning on the fan, it is important to give the device some time to warm up using natural draft. After the combustion intensifies, its thrust will increase significantly, noticing this, you can close the door tightly and activate the control unit by turning it on

When the chimney has not been used for a very long time, or it is new, it is worth warming it up well before lighting it. To do this, it is enough to set fire to the paper while inspecting the chimney until the draft in the boiler increases.

Close the valve in a timely manner

The stronger the draft, the faster the wood burns. But if there is not enough air, they burn poorly and form a lot of soot. Balance is important so that the minimum amount of air necessary for combustion reaches the firewood.

- Before ignition, open the heater damper to the maximum to ensure good draft for igniting the wood.

- When the wood starts to burn, begin to gradually close the valve. If the firewood starts to go out, open the valve slightly and increase the draft. Over time, you will find the optimal valve position.

The drier and denser the wood, the less air is required to burn it.

What coal is best to heat a boiler?

The manufacturer initially carries out thermal calculations and adapts the design of the combustion chamber and heat exchanger to the specific type of fuel. Therefore, in order to increase the efficiency of a household boiler, it is enough to use coal of the grade and fraction specified in the operating instructions.

What brand of coal to burn?

Coal contains carbon and non-combustible impurities, which form ash and slag after combustion. The ratio between carbon and impurities depends on the type of fuel chosen. Coal has (depending on the brand) different degrees of moisture, loose or hard structure, and age of formation.

To effectively heat a coal boiler, you need to have a good understanding of the characteristics that distinguish this or that type of fuel:

- Lingite – this type of fuel has a loose structure and a large percentage of ash residue. Lingite is used in industrial power plants. This type of fuel is not suitable for heating a house.

Hard coal – has a calorific value of 5500 kcal/kg. The percentage of carbon is at least 75%. Ash content from 2 to 4%. Most classic-type household boilers are heated with coal. For gas generator type equipment, not suitable due to humidity above 20%.

Brown coal – calorific value is only 3000 kcal/hour. When burned, a large amount of ash residue and coking substances are formed. Humidity is at 50%. Brown coal is not recommended for heating domestic boilers, due to the rapid clogging of the chimney and heat exchanger.

Anthracite – the humidity threshold is within 7%. It has high specific heat values, equal to 9000 kcal/hour. The share of ash carried away by gases from the coal boiler is no more than 7%. Manufacturers of heating equipment recommend heating gas-generating boilers with Anthracite. Coal is divided into several grades according to size: fist, nut, seed.

Is it possible to burn with coal briquettes?

Coal briquettes are made by pressing small fractions (dust). Special organic or mineral compounds are used as a binding element. The latter greatly increase the ash content of the fuel, but are cheaper. The most popular are coal briquettes, in which coal tar acts as a binder.

Heating with compressed coal has the following advantages:

- Easy to install in the combustion chamber.

- Good flammability.

- High calorific values, identical to anthracite.

- Easy storage and transportation - briquettes have a regular geometric shape, so they are easier to store and take up less space.

The only disadvantage of compressed coal is its high cost, which is approximately one third higher than the price of lump raw materials. The advantage is the ability to fire the boiler on coal, without contamination by combustion products.

How to burn with coal dust

The safest and most effective method of burning dust is considered to be using a special burner device.

Is it possible to burn with charcoal?

With all these advantages, charcoal has one serious drawback. The cost of a kilogram of purchased charcoal will cost almost 2 times more than the cost of hard coal. You can somewhat reduce the cost of raw materials by establishing its independent production. To obtain 1 ton of charcoal, you will need to burn about 10 m³ of wood.

Coal

Coal is a traditional raw material for solid fuel boilers. It burns for a long time and has good heat transfer, but only if it is correctly placed in the combustion chamber, properly ignited and subsequently maintained.

Coal selection

To increase the efficiency of the boiler and extend its service life, it is necessary to take into account the manufacturer’s recommendations for choosing the grade of coal. Usually the name of the brand and its fraction are indicated in the technical data sheet of the device. Each grade has a different ratio of carbon and impurities, different humidity, structure, strength and age of formation.

The most popular types of coal for solid fuel boilers:

- Coal. The heat transfer of the fuel is 5500 kcal/kg. The average percentage of carbon and ash is 75%/3%. Suitable for igniting most classic boiler models.

- Anthracite. Specific heat indicators are 9000 kcal/hour. The percentage of carbon is no more than 7%. The disadvantage of this variety is difficulty in ignition and extremely high combustion temperature.

The most popular and convenient for ignition is long-flame coal. This universal fuel for all types of boilers ignites quickly, burns for a long time and releases a large amount of energy.

Brown coal and lingite can be found on sale. However, these varieties are recommended for use only on an industrial scale due to the large amount of ash residue and high humidity levels.

How to fire a boiler with coal

The solid fuel installation consists of two main chambers: the upper one is used to store fuel, and the lower one (ash pan) is used to collect ash and slag. As the fuel burns in the main chamber, the combustion products gradually fall into the ash pan, from where they are removed manually.

The supply of oxygen to the firebox is regulated using the ash pan damper - the draft necessary for stable combustion of the fuel is formed in the chamber.

Before starting melting, it is necessary to prepare the installation for operation. To do this, solid combustion products are removed from the ash pan, the walls of the combustion chamber are wiped and the chimney channels are cleaned.

As soon as the preparatory work is completed, you can begin loading fuel and igniting.

- Place dry paper on the grid of the main chamber. It is recommended to crumple it up first - this way it will light faster.

- Place wood chips and brushwood evenly on top in the shape of a well or hut.

- Light a match and bring it to the paper from different sides - the paper will burn evenly, involving wood chips in the process.

- Close the firebox door and open the ash pan valve to allow oxygen to enter. At this stage, you will have to monitor the combustion process of the wood chips. You can adjust the intensity using the ash pan (ash pan) door.

- As soon as the wood chips burn completely, pour a small layer of fine coal on top. Its amount should not exceed a third of the combustion chamber.

- After loading the first batch of coal, close the door again to achieve maximum combustion temperature. This usually takes about

- When the first layer of fuel completely engulfs the flame, add the remaining coal to the upper border of the door. It is recommended to stir the burning coal slightly beforehand.

- Close the blower door halfway. If there is strong smoking, leave a small crack.

More intense combustion can be ensured by closing the chimney outlet damper halfway.

As combustion proceeds, fuel is added in small portions to the main chamber, each time closing the ash pan damper. You should not put in a large amount of coal at once - this will lead to the fuel solidifying on the grate and its premature deterioration.

Adjusting the temperature of a solid fuel boiler

The efficiency of a heating system depends on a uniform temperature supply. And if in gas and liquid fuel boilers this issue is resolved by continuous fuel supply, then in solid fuel boilers there is no such possibility. And the solid fuel itself, when burned, releases its temperature unevenly: at the beginning and end of combustion, the portions of firewood are smaller, in the middle of the process – more.

A system for regulating the intensity of fuel combustion, that is, the supply of air necessary for combustion, helps to partially solve this problem.

Thermostatic draft regulator

The boiler doors have seals, so air enters under the grates through the lower damper. The opening amount of this blower flap is controlled by a thermostatic draft regulator.

Thermostatic draft regulator. Photo from cotlix.com

The required temperature is set on it, and the regulator itself is mechanically (by a chain) connected to the blower door. If the temperature is insufficient, the regulator slightly opens the blower door; if it is too high, it closes it.

You need to understand that a solid fuel boiler is a very inert device, and the draft regulator controls the combustion process with a large error. Therefore, the entire heating system must be designed taking this feature into account.

Fan and controller

A smoother adjustment of the combustion process is possible using a fan that pumps a specified amount of air into the firebox. The number of revolutions of the device blades is regulated by a controller that takes into account the readings of the temperature sensor and the value of the temperature set by the user.

Shiber

A damper is a damper on a chimney, otherwise called a throttle. The damper is installed after the boiler and blocks the chimney channel. Whether it needs to be installed or not depends on the equipment model. Some types of boilers are equipped with a damper as standard; in other cases, manufacturers may recommend installing an additional damper in the chimney.

The damper allows you to increase the efficiency of the heating device by partially blocking the chimney and reducing the rate of removal of heated combustion products. How much to open or close the damper can only be determined experimentally, because it depends on the outside air temperature, humidity, atmospheric pressure, wind direction and strength.

Properly selected heating equipment, and most importantly, its effective use, will bring warmth into the house, and the owners will only need to supplement it with home comfort.

How to use solid fuel units correctly

Coal boiler operation

The operating principle of a solid fuel boiler is known, and the issue of choosing the type of coal has been resolved. All that remains is to learn how to properly light the stove. There are several simple rules that everyone who chooses the described installations for organizing heating of a country house must learn.

Remember! First, the stove must be prepared for lighting, then fuel must be correctly loaded into it. During its combustion, the installation must be closely monitored, removing combustion products in a timely manner.

Let's look at all these points in more detail.

Preparing the stove for lighting

If the stove in a country house is used occasionally, before starting its operation, for safety reasons, it is necessary to exclude the presence of cracks inside the masonry.

Why are they dangerous? Through them, combustion products and carbon monoxide can enter the room, which must be removed outside using drafts. If such a defect is discovered, it must be eliminated before kindling by covering the cracks with a mixture of clay and sand. Otherwise, when heated, the cracks may increase in size even more. And this will lead to dangerous situations.

When inspecting the stove from the outside, we remove flammable objects away from it and clean it inside. We remove the ash and slag with a shovel, freeing the internal compartment. It is advisable to wipe the inner walls of the firebox with a dry cloth. If this is not done, then during kindling the dust will begin to burn, filling the room with an unpleasant odor.

The coal stove needs to be lit several times a day. The duration of one fire should not exceed two hours. For loading, it is better to use well-dried medium-fraction coal.

Note! Wet fuel produces steam when burned. It forms condensation, which settles inside the chimney

Mixing with soot, condensate forms coke, which gradually clogs the chimney passage, narrowing it. And this leads to problems with traction.

Do not use household waste or flammable liquids such as gasoline or kerosene to ignite coal. Do not leave the stove unattended while it is burning. This rule must be observed especially strictly if there are small children or animals in the house.

How to properly melt coal?

Laying solid fuel boilers

The stove must be lit as follows:

First, we place sheets of newspaper or any other dry paper on the bottom of the firebox. On top of it we place a layer of small wood chips. And on them we stack small firewood, for example, birch logs. To make them burn faster, they need to be folded in the form of a well or a small hut. Set fire to the paper. We close the oven door and open the ash pan. Using it, it is easy to control the intensity of fuel combustion. The stronger the air flow, the faster the stack of firewood burns out. After the firewood has completely burned out and only a pile of smoldering ash remains, you need to lay a 15-centimeter layer of fine coal directly on it.

Note! When opening the door to load fuel, be sure to close the vent. When the 15-centimeter layer of coal burns well, we place larger coal directly on it and build a pillow 60 cm high

It is useful to stir the burnt fuel thoroughly beforehand, which will improve air circulation and prevent caking of the coal mass. Coal can be placed by opening the firebox door

When the 15-centimeter layer of coal burns out well, we place larger coal directly on it and build a cushion 60 cm high. It is useful to stir the burnt fuel thoroughly beforehand, which will improve air circulation and prevent caking of the coal mass. Coal can be placed by opening the firebox door.

Note! Low-quality solid fuel tends to coke. Therefore, experienced stove makers advise laying a layer of coal with layers of firewood.

Such a multi-layer cake will allow the unit to burn well and give off the maximum amount of heat.

To properly light the stove, it is better to do this - open the ash pan and let the paper with the wood chips burn out using natural circulation. This will allow the chimney to warm up well. As the fuel burns, the draft will increase, so you then need to close the ash pan and turn on the fan.

Preparing the stove for lighting

If the boiler is used infrequently, before starting operation, it is necessary to conduct a visual inspection of the masonry to exclude the presence of cracks. Carbon monoxide can penetrate through the holes, which normally should leave the firebox through the chimney. If such cracks are found, be sure to eliminate them using a heat-resistant mixture of clay and sand. Otherwise, during heating, the hole may expand, with a subsequent increase in the risk of rupture of the furnace or boiler.

When conducting an external inspection, it is imperative to remove from the direct accessibility area all objects that could ignite if struck by a spark. Then, you need to completely remove the ash and slag. Then, wipe the walls of the firebox with a rag to prevent the spread of unpleasant odors from combustion products.

a3e6d0a551d2f8605c1c1a74133e1cf1.jpe eadc92b0b05f10f9edb881dd73312c8d.jpe

It is advisable to light the coal boiler several times a day. The duration of one such process should not exceed 2 hours. Load dry coal in small sizes. If the fuel is wet, steam may form, which will subsequently settle on the walls of the chimney, leading to a narrowing of the clearance. As a result, traction will drop significantly.

Working with a long-burning boiler

The question of how to heat a long-burning solid fuel boiler is multivariate, since the boiler can heat both by combustion and by layer. This feature allows you to significantly increase the operating time of the unit with just one load.

Loading and lighting the device is quite simple:

- Firewood is placed upward in the firebox;

- chips and paper are added through the loading door;

- the paper is set on fire, you must wait until the wood chips ignite;

- when the door is closed, you can turn on the control unit.

If all the steps have been performed correctly, the top layer will gradually begin to flare up; while the unit is operating, the entire filling will burn through from top to bottom.

In some cases, when the entire system has not fully warmed up, a small amount of barely visible condensation may appear on the walls of the heat exchanger. Sometimes this liquid can leak out of the hatches, forming small puddles on the floor. Mostly this situation is temporary. A boiler that has proper circulation will no longer produce condensation after heating the system.

Immediately after turning on the control system, it is better to leave the solid fuel device in operating mode with a high temperature. In this case, the room and the unit itself will warm up faster, after which the temperature can be reduced.

Do not allow wood to burn too high

There are three wood burning modes: low, high and optimal.

When the mode is reduced, the firewood does not burn completely and produces a lot of soot. If it is higher, you waste firewood: part of the heat flies away through the chimney, since the heat exchanger and the room do not have time to remove it completely. This occurs in two cases: you use too much wood or supply too much air. It is necessary to reduce the volume of the bookmark or draft.

The best option is when the wood burns in the optimal mode: not weakly and not strongly. The easiest way to determine the combustion mode is to use a combustion indicator, which shows the current mode in real time. If the temperature of the flue gases is more than 320 degrees, then the firewood burns at high speed.

The combustion indicator determines the flue gas temperature and combustion mode in real time

Heating water supply boiler room

Heating installation

LLC DESIGN PRESTIGE > https://resant.ru/

Telephone

We provide installation services for heating and water supply systems for private country houses, dachas, and organizations. We supply equipment for work at discounts.

Heating: > https://resant.ru/otoplenie-doma.html

Installation, design, service repair. Heating by type: autonomous, water, private, wood, individual, gas, natural.

Water supply: > https://resant.ru/vodosnabzhenie-doma.html

Boiler room: > https://resant.ru/kotelnaya-doma.html

For private homes and industrial enterprises. We will install the boiler, distribution modules for heating circuits, and install automation elements for temperature control.

We carry out all work on a turnkey basis. LLC DESIGN PRESTIGE

How to properly light a boiler

How to clean soot from a coal boiler

The composition of soot includes a non-combustible residue that turns into slag during the combustion process. An additional problem is that under the influence of high temperatures, low-quality coal leads to increased formation of condensation, an acid that can corrode the metal of the heat exchanger.

Boiler cleaning is carried out in several stages:

- It is necessary to remove the ash from the ash pan, a chamber located immediately under the firebox and which is a spacious box closed with a sealed door. The ash pan is removed and the ashes are poured out.

- Cleaning of slag is carried out with a special tool, the appearance of which resembles a curved awl. Sludge is removed around the perimeter of the heat exchanger and from the grate.

In addition to regular boiler cleaning, measures are taken to prevent increased soot formation. The main reason why the heat exchanger becomes clogged with soot is insufficient combustion temperature of the fuel. Layer-by-layer stacking of firewood mixed with coal can solve the problem of increased soot formation.

How to clean the chimney pipe of a coal boiler

Proper operation of heating equipment includes measures to reduce soot formation in the chimney during boiler operation, as well as regular maintenance and cleaning of pipes. SNiP stipulates the need to carry out routine maintenance at least twice a year.

Pipe cleaning is carried out in the following ways:

Mechanical cleaning method - proper cleaning of chimneys is carried out using a special brush. Flexible plastic rods are mounted on the rod. If necessary, the brush can be extended using flexible bars that can be connected. Cleaning is carried out from the roof. Soot is removed through special inspection wells. The largest layers of soot accumulate on the bends and adapters of the chimney

During cleaning, they receive the most attention. Cleaning chemicals are available as fuel additives. It is enough to place the bag in burning coal to effectively clean the chimney

Chemicals are used as preventive measures and cannot completely replace the need for mechanical cleaning. Reducing soot emissions from coal combustion. Preventing the appearance of soot is the best measure to combat deposits on the walls of the chimney. As a preventative measure, several methods are used. A soot trap is installed, the required coal combustion temperature is ensured, the chimney design is changed and a deflector is installed to improve draft characteristics.

All of the above measures are aimed at maintaining the performance of both the boiler itself and the chimney. Acidic condensate leads to rapid burnout of the heat exchanger and chimney.

Proper operation of a coal boiler includes: proper choice of fuel, kindling and maintaining combustion in the chamber, preventing increased soot formation and regular maintenance of the heating unit and chimney.

Choosing fuel for a solid fuel boiler

Many users of solid fuel boilers are very careful when choosing fuel. This is not at all surprising, since the quality operation of the unit depends on this product. Moreover, it needs to be purchased in large quantities, not only because of the cold climate, but also because the long-burning device requires refilling with large quantities of raw materials.

The following types of gas stations are considered the most popular today:

Not knowing what is the best way to heat a solid fuel boiler, you should pay attention to briquettes and pellets, which are easy to use and have a long burning time. But when using them, there is also a significant disadvantage - the high price, which is derived from the difficulty of manufacturing these products

But heating with coal is beneficial from all sides - its combustible effect is quite long, and during combustion it does not emit any harmful substances. The low price of the material is no less pleasing.

Rice. 3 Cleaning a solid fuel boiler

The method of loading firewood as an attachment to this product is extremely popular for the reason that after the firewood is burned, black fuel continues to act for a long time, increasing the time before a new refueling is required. Although none of the heating methods can be called correct, each user chooses the option that suits them.

Fuel briquettes

In its composition, this type of fuel is similar to pellets, but looks somewhat different: briquettes are larger and can be not only cylindrical, but also of any other regular shape. The starting raw materials are the same wood chips, sawdust, and shavings. Organic residues of plant crops grown in agriculture are also widely used.

Fuel briquettes have the same advantages and disadvantages as pellets. The main difference still comes from the size: briquettes are not suitable for automatic loading, so they are placed in the firebox manually. Products with an aesthetic appearance have gained popularity among owners of fireplaces and decorative stoves due to the almost complete absence of smoke during combustion.

Periodic boiler cleaning

After learning how to fire a coal boiler, you need to learn how to clean it. These actions will help prolong the performance and neat appearance of the unit. During the smoldering process of coal at high temperatures, the device leaves a minimal amount of waste, which is dumped into the ash pit. The amount of waste is practically invisible; it becomes visible only after prolonged use of the device.

The entire combustion process takes place on a grate. But over time, the time comes when the solid fuel boiler needs to be cleaned. Such cleanup activities are not considered particularly time- or financially expensive.

These products are thrown directly onto hot coals, resulting in the formation of acrid smoke, which will remove all the toxins inside the boiler and chimney. In this case, the operation of the device can not be interrupted. In addition, the walls of the device can be cleaned with a brush and a wire brush, which are usually included when purchasing the equipment.

The heating device is the warmth in the house

Many settlements today have not yet been gasified. Therefore, residents of such villages have to look for an alternative to gas equipment. The best solution in this case is to heat a country or private house with a solid fuel boiler.

It is becoming increasingly popular not only due to its ability to work on wood or coal, but also due to its complete autonomy.

After all, a solid fuel boiler does not require either gas or electricity. It can only operate on wood, while maintaining a comfortable room temperature. However, such devices are available in various modifications, and in order to make the right choice, you need to at least briefly get to know each of them.

How to calculate coal consumption

Coal consumption in a solid fuel boiler depends on many factors. Costs are affected by:

- Heated area.

- Amount of heat loss.

- Ambient temperature.

Exact costs can only be calculated after the end of the heating season. Moreover, depending on the winter, the average consumption of coal for heating can vary from 8 to 15 tons (for a building of 200 m²).

If you make average calculations based on actual operating experience, you can obtain the following data:

- Costs for September – October will be 1 bucket per day.

- Fuel consumption rates in a coal boiler from November to February will increase to 10 buckets per day.

- In March and April, you will need to burn 1-2 buckets per day.

Calculating the coal consumption for a 20 kW boiler, using the above data, will show that the costs during the heating season will be 580 buckets or 10-10.5 tons.