Double-circuit gas appliances make our lives more comfortable and enjoyable. They are quite practical to use, suitable for heating country houses and small apartments. They are used for heating industrial or warehouse buildings with an area of no more than 500 sq.m.

The advantages of Ariston boilers are that in addition to heating buildings in winter, they heat water used in everyday life all year round. This is quite convenient and does not require the installation of additional equipment.

About company

The Ariston brand is the brainchild of Vittorio Merloni. His father, Aristide, founded a small business back in the 30s of the last century. Today this enterprise has become the largest industrial giant, uniting several large companies. The Merloni Elettrodomestici concern was renamed Indesit Company in 2005, which includes several brands, including Ariston. The company ranks 3rd in the world in terms of sales of household appliances.

Advantages and disadvantages

Italian boilers are able to operate uninterruptedly even at a pressure of 5 mBar and at a temperature of minus 52 °C. They are equipped with two mechanical filters that purify the water. The developers took into account almost all the dangers for gas equipment in high-risk environments.

Each model is equipped with a self-diagnosis system that simplifies their operation and maintenance. Security systems prevent emergency situations by stopping the operation of the device in a timely manner. Self-diagnosis is periodically repeated - if the parameters return to normal, the device will start without human help. Ariston advantages:

- Absolute safety – despite explosive fuel.

- High efficiency. After the combustion of gas, almost no combustion products remain - all the heating is used for heating.

Minuses:

- Floor-standing equipment should be placed in a separate room.

- To eliminate pressure surges, it is necessary to install an additional adjustment unit.

If the boiler pressure is low

If the question arises why the pressure in the heating boiler drops, the problem may be with the safety valve. Once the valve has been actuated, either automatically by increasing pressure or manually, it may not close completely. Since the valve would have to be replaced if it continues to leak, there is no harm in operating it manually again now.

Turning the red cap will release the inner valve from the seat, allowing system water to enter. If you turn it further, it will slam shut and fall back into place. You can repeat this by increasing the boiler pressure as needed. If the pressure still does not hold, the valve needs to be replaced.

If it is still not clear why the water pressure in the boiler drops, most likely the leak is under the floor. If the floors are solid or can't be lifted, this is a big problem, but there are leak detection companies that specialize in finding them.

What do Ariston products have in common?

Traditional gas heaters are produced in nine lines - each of them contains a different number of modifications - from 2 to 7. The lines represent single-circuit and double-circuit versions. Some have a wide range of capacities, others consist of 2-3 options. All traditional Ariston models are distinguished by the following features:

• Automatic control. All modifications have the “auto” function - the intelligent unit itself selects the optimal modes, taking into account changing conditions.

• Can work with a conventional or coaxial chimney.

• Russified control panel. Its logic is intuitive – you don’t even need instructions to understand it.

• Burner material – stainless steel. Its power is modulated taking into account the specified mode. This solution saves gas.

• Self-diagnosis.

• Hydraulic devices are made of high-strength composite materials.

• Expansion capacity – 8 l.

• Automatic removal of air from the heating system.

• Protective systems – against blocking, scale, freezing.

• The double-circuit device has a copper heat exchanger - the primary one, and a stainless steel one - the secondary one, for heating domestic water.

• In 2-circuit versions, a “summer” mode is provided - operation only on DHW.

• Condensate container.

• Temperature sensors – 2-4 pieces, depending on the series.

• High-quality sound insulation. Almost silent operation.

• Includes instruction manual. All documentation is presented in Russian.

• Warranty – 2 years. For condensing versions – 3 years.

• Average dimensions 70x42x60 cm - this is slightly larger than those of competitors.

The models of each line have distinctive design and technical solutions. Models may also differ in functionality, dimensions, and design.

Removing air pockets in the system

It's better to start with batteries. To remove air pockets, a Mayevsky tap is usually installed on them. We open it and wait for the water to run. Did you run? Let's close. Such manipulations must be done with each heating device separately.

How to start a boiler with your own hands photo

After the air is removed from the batteries, the pressure in the system will decrease and the pressure gauge needle will drop. At this stage of work, the solution to the question of how to start the boiler involves re-filling the system with liquid.

Now, the most difficult thing is that starting gas boilers requires bleeding air from the circulation pump. To do this, the boiler needs to be disassembled a little. We remove the front cover and look for a cylindrical object with a shiny lid in the middle, which has a slot for a screwdriver. After we have found it, we put the boiler into operation - we supply it with electrical power and set the water heating controls to the operating position.

Relieving air from the circulation pump when starting the boiler photo

The circulation pump will immediately turn on - you will hear a faint hum and loud gurgling and many incomprehensible sounds. This is fine. As long as the pump is aired, it will be so. Take a screwdriver and slowly unscrew the cap in the middle of the pump - as soon as water starts seeping out from under it, screw it back. After two or three such manipulations, the air will come out completely, the strange sounds will subside, the electric ignition will work and start working. Check the pressure again and add water to the system if necessary.

Basically, that's it. While the system is warming up, you can begin to study the instructions in detail (if, of course, you have not already done so) and start debugging the system that involves starting the boiler. Everything is simple here - the batteries closest to the boiler need to be screwed on, and the ones farther away need to be turned on to their full potential. This debugging is carried out using control valves installed on the supply connection pipe to the heating radiator.

What are they?

By installation method:

- Wall-mounted - it is compact, has a copper heat exchanger (less often - steel). Complete with strapping elements. Mounted on a flat wall. Mounted models are more sensitive to unstable gas and water supply parameters.

- Floor-standing devices are more powerful, heavier and larger in size. They need a fairly large area. They are mounted on the floor - on a stand. Manufacturing material – cast iron. Power – up to 64,000 W. This heating output is enough to heat an area of up to 500 square meters.

By number of circuits:

- Single-circuit - they work only to heat the room.

- Double-circuit - they heat the house and heat water for domestic use.

By type of combustion chamber and thrust:

- Open firebox (natural draft) - air for combustion comes from the room. Such a device is atmospheric.

- Closed chamber (forced draft) - the operating principle is based on forced ventilation. This is a turbocharged version.

Choice

Modern heating equipment can use natural gas, electricity or solid fuel. Installation of heating boilers requires compliance with special requirements for installation and operation.

Gas boilers

Heating systems with gas units are popular for use in a private home. Natural gas is an inexpensive and efficient fuel. Of course, this is only possible for those regions where there are main gas pipelines and supplying gas to the house does not cause any difficulties.

At the same time, we must not forget that gas is a highly dangerous environment due to its explosiveness. When choosing gas installations, you need to remember the following differences:

- manufacturer and price segment;

- power consumption;

- number of circuits - single-circuit and double-circuit models;

- type of installation (floor or wall);

- method of cleaning exhaust gases.

Wall-mounted gas installations are very popular - they are easy to install and small in size.

The equipment of such a unit includes a burner, expansion tank, circulation pump (one or more), pressure gauge and thermometer, heat exchanger, exhaust gas removal circuit (natural or forced). For safety, the equipment is equipped with special sensors.

Electric boilers

The main advantage of these compact boilers over units operating on other types of fuel is the complete absence of waste during operation (including the absence of combustion products). It is believed that this is the most environmentally (and aesthetically) clean type of heating in a private home. But, at the same time, perhaps the most expensive. Boilers can be installed on the floor or on the wall. Depending on the type of heating, such settings are:

The design of heating element boilers is quite simple. Several heating elements are placed in a container with distilled water or ethylene glycol-based antifreeze liquid. Depending on the set heating temperature, either all heating elements work, or only part of them. This design is very primitive and is partly considered obsolete.

The operating principle of an induction boiler is based on electromagnetic induction. To put it simply, a core is placed in a dielectric pipe, which is heated by the current of an electric coil around the pipe. The core heats the water that flows through the pipe.

The principle of operation of the electrode unit uses a law of physics based on the heating of water due to resistance when an electric current is passed through it. The water must have a special concentration of salts. These devices are safer than the previous two, since if water leaks from the heating tank, the unit automatically stops working.

Solid fuel boilers

Now this equipment is used to heat houses where natural gas heating is not possible. Such boilers operate on various types of solid fuel, but the main type is traditionally firewood. Heating equipment of this type is very similar to a stove, but at the same time meets all safety standards and modern quality requirements for similar installations.

The boilers have in their design a combustion chamber, a heat exchanger, a loading hopper, a chimney, nozzles, a control unit and a hot gas exhaust chamber. Installation of boilers is carried out only on the foundation. They have quite large overall dimensions and weight.

How to choose?

To choose gas equipment for heating a private house or apartment, you cannot act intuitively - you need to calculate heat loss. For the calculation, the condition is taken that for 10 sq.m. area (height up to 3 m) should account for 1000 W. But this is only an approximate calculation. It is not recommended to select an option without a reserve, so that the device does not have to function at the maximum of its resources. It is also necessary to take into account the degree of insulation of the house.

More accurate calculations are ordered from construction and design companies. The cost of such services depends on the region and ranges from 2,000-7,000 rubles. Calculation errors can provoke:

• uneven distribution of heat throughout the rooms;

• lack of hot water.

Operation and Maintenance

You should find out from the instructions what the pressure in the expansion tank should be - since during operation it may decrease. It is recommended to monitor your blood pressure once a year. Periodically you should:

• check the filters and clean them if necessary;

• clean heat exchangers - this is especially important for hard water;

• change the corresponding gaskets.

The above activities, as well as installation, configuration and first start-up, are the task of the service technicians. The owner only needs to conclude an appropriate service agreement and follow the manufacturer’s recommendations regarding the operation of the device. A specialist should be called twice a year - you cannot start the heating season without an inspection. At the end of the season, you also need to invite a service worker.

Design features of the gas boiler Baxi baxi, Navien, Ariston

In any case, it will be useful to become familiar with the equipment of this class and the features of modern models. This knowledge will help you choose the right equipment and avoid making mistakes during operation.

In household boilers Baxi (baxi), Navien and Ariston, gas, diesel and solid fuel are burned to heat water, and electric heating elements are used. To more fully utilize the potential of energy resources, heat exchangers are being improved. They make long ducts of complex shapes to ensure that the liquid remains in the working area for a long time.

The current trend is compactness. Manufacturers offer gas boilers with square bodies of relatively small thickness. Some models, due to their aesthetic characteristics, deserve to be placed in a prominent place.

The next feature is the introduction of automated control systems. They control the combustion process, change operating modes taking into account the readings of temperature sensors on the street and in individual rooms. If the equipment overheats, it turns off without user intervention.

It is necessary to carefully consider situations when the Baxi gas boiler does not heat the water. This happens, for example, when the supply of energy resources is cut off. It is not difficult to carry out an appropriate check even without special professional training.

Circulation pumps, valves, and other typical components and assemblies rarely fail. Their designs are designed for many years of operation without mandatory maintenance. Electronic circuits have no moving parts at all. Their breakdowns occur due to defects. Subject to the rules established by the manufacturer, the service life of modern gas heating boilers is more than 10 years.

Voltage surges in the power supply network can damage the electrical part of the equipment. To eliminate such influences, an external stabilizer is installed. It will be useful to check the grounding system. This completes the set of preventive measures for this group of problems.

It is much more difficult to provide protection against the most common cause of breakdowns of gas boilers - scale.

It is this that will be studied in detail in this article. When heated, calcium and magnesium salts are converted to a solid state. It is these impurities that clog narrow technological openings in heat exchangers. They also form a porous structure on the surface of electric heating elements. If normal heat dissipation is significantly disrupted, their housings are damaged.

To prevent the formation of scale and lime inside the boiler, it is advisable to install non-chemical filters (water converters), magnetic and electromagnetic, which will ensure a long “life” of your boiler and an uninterrupted supply of hot water, as well as protect the heating circuit.

Ariston series

The manufacturer offers three series, each of which has several modifications.

Egis

For those who like to save. Double-circuit models are compact and have increased efficiency. There are filters and an anti-scale function, intelligent control and frost protection. Allowed to operate at temperatures down to -50° C. Popular versions:

• Egis Plus 24 CF - open firebox.

• Egis Plus 24 FF – closed chamber.

The line is represented by one power - 24 kW. Specifications:

• Dimensions – 40x77x31.5 cm.

• Weight – 30 kg.

• Combustion efficiency. 24 CF has the second one. 24 FF is third.

• Efficiency for 24 CF is 92%, for 24 FF – 94%.

• Hot water capacity – 9.7 l/min.

You will have to pay 20,000-30,000 rubles.

Clas

Larger and more powerful than Egis. They also have everything for uninterrupted operation - frost protection, filters, auto-tuning, fuel consumption control. This series has an 8 liter expansion tank to heat water. Modifications:

• Clas Evo. AUTO and INFO PLUS functions. The power of the device with a closed chamber is 24 and 28 kW, with an open chamber – only 24 kW. Productivity – 9.9 and 10.2 l/min, respectively. Power consumption – 88.5 kW.

• Clas B – you can connect a boiler.

• Clas Premium – condensing boiler.

• Clas Premium Evo – with PLUS, INFO and AUTO functions.

• CLAS EVO SYSTEM - there is automation that responds to the weather and copper heat exchangers. Versions with closed (FF) and open (CF) firebox. Power range – 16-32 kW. The former have an efficiency of 93%, the latter – up to 90%.

• CLAS SYSTEM – single-circuit versions. Mounted option. 16,000-32,000 W.

• CLAS and BS II – heating and hot water supply. Economy class.

Approximate price – 25,000-32,000 rubles.

Genus

Representatives of this series are the most functional wall-mounted versions with two circuits. There is a fan, an LCD screen, a remote control, and a weekly programmer. Modifications:

- Genus Evo. Open/closed firebox (turbo). Heating capacity 24-30 kW.

- Genus Premium. Condensing boiler. Increased efficiency – 105%. 24-35 kW. Remote control. Self-diagnosis.

Hotpoint-Ariston Cares X 15 FF

Wall-mounted 2-circuit option. Approximate cost: 27,000 rubles. Expansion tank 8 l. Turbocharged. Protection against overheating, flame failure and lack of draft. Weight – 30 kg. Dimensions (HxWxD) 77x40x31.5 cm.

UNO 24 MFFI R

Wall-mounted unit "UNO" with instantaneous water heater. Compact - 40x70x25 cm. Closed firebox. 24,300 W – heating output. Electric ignition. Protective systems - gas control, anti-freeze, heating limitation. There is a water filter. Weight – 29 kg.

Hotpoint-Ariston BS II 15 FF

Attachment with two circuits. Heating capacity – 15,000 W. turbocharged type. Heats an area up to 180 square meters. m. Weight – 30 kg. Efficiency - 91%. Power consumption – 106 W. Estimated price – 23,000 – 32,000 rubles.

The most common Ariston boiler error codes and troubleshooting methods

To quickly understand what happened to the heating device and why the double-circuit gas boiler does not heat hot water, it is worth familiarizing yourself with the list of Ariston boiler errors, grouped by component. In some cases, correcting errors and troubleshooting an Ariston gas boiler can be done independently, including by replacing parts.

Error 101 gas boiler Ariston 24, interpretation

The list of error codes starts with 101. If such a code is displayed on the equalizer (display) of the Ariston-24 device, this indicates overheating of the coolant. The failure occurs due to:

- increased pressure in the area of the gas valve;

- insufficient speed of water movement (this problem arises due to blockages in the filter, scale, pump breakdown);

- temperature sensor failure.

Read more: Why does a gas boiler go out? Main reasons

Error 103, 104, 105, 107. What should I do?

Error 104, 103, 105 or 107 appears when the H2O flow is incorrect, there is an obstacle in the flow of the coolant, or as a result of deterioration in pressure. Disrupted water movement is caused by air accumulation inside the device.

There is a simple solution: for a 24 kW double-circuit boiler - hold down “Mode” for ten seconds; for Ariston Uno - hold “Reset” for about six seconds.

After these steps, the pumping apparatus will operate for five minutes, pumping out air without ignition. After the procedure, it is worth assessing the pressure level. The normal value is 1.2 Bar avigeneric.com.

Error 108, how to fix it

Error 108 is caused by weak pressure in the heat exchanger, tank, pipes, mountings on the gas boiler, or the reasons indicated in the previous paragraph. Error code 108 means that it is worth inspecting the tank and other spare parts for leaks, and make sure that the membrane part in the expansion tank is in good condition.

109

Error 109 in Ariston indicates increased pressure (more than 3 Bar). To eliminate such a nuisance, you need to bleed the air (using a Mayevsky valve). The second cause of the 109th breakdown may be a broken heat exchanger that mixes water of different temperatures.

302

Such a failure indicates a breakdown in communication between the display and the control board. Error 302 is caused by disconnection/oxidation of contacts. Do-it-yourself repair of an Ariston gas boiler is accomplished by stripping and connecting the contacts.

Error 304

Code 304 is a broken electronic board. You should find a place that sells spare parts for Ariston gas boilers and purchase a replacement part.

Error 501, what it means and how to fix it

Error 501 means that the device does not start due to lack of ignition flame. The heating unit can be turned on by correcting the following causes of failure:

- lack of gas (you need to make sure it is present, open the gas valve);

- control board failure;

- violation of the electrode connection with the ignition control module;

- breakdown of the ionization electrode (it is necessary to clean the contacts, check the correct placement of the comb: a distance of eight millimeters must be maintained between the parts);

- reduction in the power of the smooth ignition system;

- leakage of electric current (remove the breakdown in the electrical network: the voltage should be 10 V).

The boiler does not ignite, the display shows error 607

If an Ariston double-circuit gas boiler shows the numbers 607, the contacts of the fan relay have stuck together and it simply worked before ignition.

Error Sp1

Sp1 or 5p1 reflects failed ignition. At the same time, 5p2 indicates a repeated unsuccessful attempt to light the wick. Causes:

- poor air flow;

- oxidized ionization electrodes;

- low gas pressure (it is difficult to immediately say why the pressure drops, so detailed diagnostics will be required).

Sp3, 5p3

If the wall-mounted gas boiler Ariston 24 gives one of the indicated designations (error sp3 or 5p3), there may be a problem with the flame. Eliminating the error of flame separation from an Ariston gas boiler is associated with cleaning the chimney. It is too clogged with dust and soot or is not arranged correctly, so the fire is immediately blown out or the so-called flame separation occurs.

Error 025

When the boiler shows error 025 constantly (it can also look like this: “e25”), this indicates that the maximum permissible temperature of the boiler has been exceeded (see the paragraph about the 101st error).

What to do if 6p2 lights up on the display

A light on the display showing error 6p2 or 6p1 tells the user that the room with the unit is not properly ventilated: either it is not ventilated enough or combustion products are not removed.

Launch and operation

Commissioning and commissioning work is carried out by company representatives - service employees. Failure to comply with this requirement will result in a denial of warranty. The user only needs to read the instructions to understand how to use the device. It is important to follow operating rules and perform seasonal maintenance in a timely manner. When a malfunction occurs, an error code appears on the display indicating the cause of the problem or the problem that has arisen. Complete with gas equipment - instructions, passport and connection diagram.

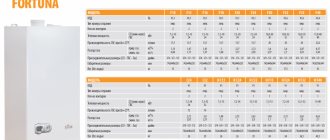

Specifications

Almost all gas boilers from the Ariston brand have a power of 15 to 30 kW. Thus, each client will be able to select the necessary indicators for the size of their apartment or house. It is also worth noting other distinctive characteristics of such gas equipment:

at maximum efficiency, boilers have a high level of efficiency; all wall-mounted boilers have Russian instructions and symbols on the equipment itself, so citizens do not have problems with operating the unit; most models from this manufacturer are able to cope perfectly with water in the system and low pressure; Particular attention to this equipment should be given to those people in whose homes voltage surges often occur. Ariston boilers cope with such network surges without any problems; All models are very easy to operate. To start using the boiler, you don’t need to study the instructions for a long time; all operating features are intuitive and accessible even to those who are installing such a unit for the first time.

To start using the boiler, you don’t need to study the instructions for a long time; all operating features are intuitive and accessible even to those who are installing such a unit for the first time.

In some cases, the boiler cannot simultaneously heat water and provide sufficient heating of the room; this applies to budget models. In this case, a person needs to think about installing an additional boiler.

How to secure?

When installing, you need to consider the following points:

- Anchor bolts are used for fastening. Install on any wall - solid or load-bearing. Wall material – brick, aerated concrete blocks, reinforced concrete slabs.

- Pipe connections are carried out according to the instructions. The data sheet describes in detail the purpose of all pins. Shut-off valves are installed directly in front of the apparatus. Cleaning filters and a pressure relief valve are installed at the water supply point.

- Most Ariston models are equipped with a coaxial chimney - exhaust gases are removed through a hole in the wall.

- Additionally, the equipment is equipped with a circulation pump.

- Control unit – regulation of the temperature of hot water and coolant.

- Ariston models are non-volatile, so the instructions require the mandatory installation of a UPS.

Distinctive abilities

According to reviews of Ariston gas wall-mounted double-circuit boilers, they have 4 distinctive features that are useful for their owners:

- All models of this company are equipped with automatic protection systems.

- The presence of a water pump, which is necessary for constant circulation of water through the pipes.

- Possibility to choose a model with an expansion tank. With its help, pressure will be automatically adjusted inside the heating system.

- Ariston equips its equipment with various types of ignition. It can be automatic, which will make life much easier for the owner of a particular boiler. Otherwise, every time the unit starts, the person will need to press a special button.

You might be interested >> Gas double-circuit boiler Buderus