Before the start of the winter season, many new owners of private houses are thinking about which boiler to choose in order to keep the house warm and cozy in cold weather.

For many owners of country houses that are heated with gas, the solution to this issue lies only in choosing a boiler that uses gas as the main type of fuel.

The purchased equipment must comply with the following principles:

- productivity;

- efficiency;

- reliability;

- safety.

Cast iron gas boilers correspond to these characteristics, both according to the conclusions of experts and according to statements from buyers.

Features of cast iron boilers

For many decades, heating equipment made of cast iron has served and continues to function properly, since it was used mainly as a heating circuit. The popular use of cast iron is based on the fact that the material is very reliable and very durable.

A cast iron boiler fits into almost any heating circuit, and it is designed to allow the most common and cheapest coolant to circulate inside it, namely water. And at the same time, cast iron, as a material, is capable of withstanding quite critical loads, namely:

- strong pressure drops in the circuit;

- fluctuations that may accompany fuel supply;

- incorrect draft in the operation of the chimney due to bad weather conditions.

The cast iron gas boiler in the product line of many manufacturers is sold with a good warranty period. This suggests that the manufacturer himself is confident in the durability of the product. For example, boilers made of steel are sold with a guarantee for a period of 12-14 years, and the same boilers, but using cast iron instead of steel, are given a guarantee of 38-56 years. If the buyer wants to clarify the exact period covered by the warranty, then it is necessary to determine the manufacturer and model.

There are, of course, some points that affect the time it takes for a boiler to operate under any individual conditions:

- it is necessary to carry out installation that complies with all correct standards;

- regular boiler maintenance by a technician;

- good compatibility with all components of the system.

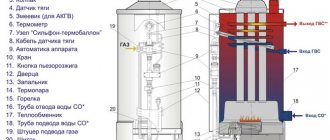

An example of a retro boiler - AGV-80 and modifications

AGV-80, the photo of which is shown above, belongs to the old type of heating boilers. It has one circuit (heating water for domestic needs). Production of the model began in 1939 at the Zhukovsky Machine-Building Plant. The reason for this was the mass gasification in the USSR and the use of gas for heating domestic premises.

The boiler is a cylinder on three legs, in the upper part of which there is a chimney pipe. The cylindrical tank is made of steel, sealed, with a volume of 80 l. Inside the tank is a flame tube, under the mouth of which an atmospheric burner is installed. To reduce the speed of heated gases escaping into the pipe and increase the degree of heating of the tank walls, a turbulator is mounted inside the pipe. The efficiency of the device reaches 80%.

Equipment:

- thermometer;

- traction fuse.

When the pressure drops or the maximum water temperature reaches, these devices allow you to shut off the gas supply.

The design of this boiler served as the basis for the company's developers to produce improved models AOGV (for CO) and AKGV (with two circuits), the efficiency of which is up to 89%.

In addition to a similar design, the new generation gas boilers include:

- coil (for supplying water for household needs);

- the flame tube is divided into sections, each of which contains a turbulator;

- traction sensor;

- air regulator;

- automatic start;

- automation unit for regulating boiler operation and temperature.

Construction of the AVG-80 boiler

Specifications

Cast iron gas boilers are the most popular heating units, which, according to their technical characteristics, are most suitable for use in buildings intended for permanent residence.

The operating principle of all cast iron boilers operating on gas is built as follows: heat is released, which owes its appearance to the fact that the fuel is burned and the air is heated. In short, the next stage of work occurs, that is, when fuel such as gas enters the combustion chamber, it burns and transfers all the heat to the coolant.

Then the coolant, which circulates through the system in a closed loop, is supplied to the batteries and the room heats up - the batteries begin to give off heat.

The technical characteristics of gas boilers with a cast iron heat exchanger differ in that:

- such a device does not require constant operation, since the heat exchanger retains heat well, and the temperature sensor, detecting temperature fluctuations, does not perform manipulations that will start the boiler;

- One of the main parameters that dominates the technical characteristics is the durability of this type of material, even though the conditions may be extreme.

Flame and draft sensors

Flame and draft sensors work on this principle. The draft sensor reacts to deteriorating smoke draft and transmits an impulse to the control system. It is located in the smoke hood. Equipped with a plate made of an alloy of two metals: iron and nickel. When draft deteriorates, flue gases accumulate and heat the plate. It becomes deformed, the contacts open, and the flow of fuel into the combustion chamber stops. When the temperature decreases, the plate returns to its normal state.

The temperature sensor works on the same principle. When the water in the boiler heats above the set temperature, the lever mechanism is activated and the temperature regulator valve closes. The gas supply stops and the burners go out.

When the water cools, the sensor bellows contracts, the lever mechanism is activated, the temperature regulator valve opens, gas begins to flow, and the burners light up.

Options for cast iron gas boilers

Cast iron gas boilers for heating a private house differ in the following parameters:

- Burners. According to the type to which the burners themselves belong:

- atmospheric burners;

- or with fans;

- Burners can also be used that use the principle of forced, that is, artificial, air pressurization, which causes a total pressure of all supplied fuel.

- They also differ in the type used in the installation of the thermal structure:

- floor;

- wall-mounted

- According to the method used to remove residues and combustion products in the form of smoke. Turbocharged ones are used, but a prerequisite for use is the availability of electricity. Or chimneys.

- General functionality: either those that operate in one circuit, that is, capable of heating only the room, or dual-circuit, heating not only the room, but also water intended for a variety of home uses.

And also a gas cast iron heating boiler has a main difference from analogues made of steel; it has a prefabricated and sectional design. The assembly of such a unit occurs exclusively by hand.

The technical characteristics also include the following points:

- Thermal engineering data are very different from other materials - after cast iron heats up, it gives off heat for a long time;

- quite resistant to acids and aggressive environments;

- if any parts of the exchanger are damaged, they can easily be replaced due to the fact that the structure is prefabricated;

- cast iron is capable of withstanding strong thermal shocks without deformation of surfaces, that is, it can withstand heating that reaches 300 C. It is important to note: cast iron does not burn out;

- The minimum period for which a boiler can be used is approximately 25 years, but usually the service life of such boilers is about 35 years.

You might be interested in >> How to properly clean a heat exchanger from scale

Therefore, the user can absolutely calmly choose for himself exactly the boiler option that appeals to him most in terms of all its qualities.

Gas savings on boilers KST-16 and KChM

If anyone is interested, I’ll tell you how to remake the boiler burner to save gas. It takes a couple of hours to work on the material and one and a half meters of pipe. There’s no photo since I won’t disassemble the boiler already, but you can understand everything with your fingers, there’s no need to remake the boiler or drain the water. ghie in advance Forgiveness if I created a topic that no one needs or if I came up with a bicycle. So the continuation is only at the request of the working people.

Gas savings on boilers KST-16 and KChM

Even very interesting

Gas savings on boilers KST-16 and KChM

Saving gas on boilers KST-16 and KChM I overcame laziness and filmed the burner on a webcam, in my opinion everything is clear, the holes are in increments

12mm d3mm, frame size 265 by 265, length of pipes 75mm, half-inch tube, drilling from the igniter goes as if in a spiral with a transition to the outer wall. The burner is inserted into the boiler diagonally, then turned and inserted. The middle nozzle is plugged with a threaded screw due to this and less consumption with better heating of the boiler walls. I would like to warn you, firstly, about safety when handling gas, and secondly, the sizes of the boilers and doors are different, but the principle is clear, the burner is located 15-20mm from the walls, the flame heats the water jacket and does not fly out into the pipe. And even the first 10 igniter holes on each side d2mm.

Attached images

Consumption has decreased by 25%, I’m also thinking of putting 3-4 partitions in the boiler on spacer pins so that the gases move in a zigzag pattern. I also wanted to weld a package of pipes into the boiler, but then I’ll lose the opportunity to return to using coal, but in life anything can happen.

Saving gas on boilers KST-16 and KChM We have a boiler KS-T-16. Will the walls burn out from the directed flame? Although it shouldn't if there is water there. Right? I also want to do the same as you. And the gas workers won't mind?

Post edited by Turbulizer: 26 November 2011 – 15:18

Saving gas on KST-16 and KChM boilers In order to save gas in these boilers without loss of power, it is not necessary to remodel the burner. It is enough to make a type of labyrinth above the burner. Place three sheets of metal so that the combustion products move like a snake. And in your case, a drop in power is inevitable, although if your boiler is selected with a large power reserve in relation to the area of the house, then this loss can be neglected.

Post edited by papaLis: 26 November 2011 – 15:19

Saving gas on boilers KST-16 and KChM The problem with these boilers is this. that the flue gases, without having time to transfer the heat of combustion of the fuel to the walls of the heat exchanger, fly out into the smoke channel. By modernizing the combustion process in these boilers, it is necessary to increase the residence time of flue gases in the combustion space. The labyrinth just meets this task. Gas workers don’t care what’s inside the boiler, in the sense of a labyrinth, etc., but altering the burner is already an unauthorized intervention, and since during registration the boiler brand, type of burner and safety automatics are recorded in the documents, then when checking once a year, gas workers having discovered tampering with the boiler have the right to shut it down gas tap at the inlet

Post edited by papaLis: 26 November 2011 – 15:28

Saving gas on the KST-16 and KChM boilers I didn’t inform the gas workers; for more than ten years, none of them realized that there was something wrong with the burner. both thermal and mechanical are higher. A labyrinth without altering the burner will not allow you to save much, do not forget the middle nozzle is plugged in my case.

Post edited by sanek66: 26 November 2011 – 15:37

Gas savings on boilers KST-16 and KChM

Looks like the gas workers are klutzes. But you only achieved savings due to the fact that there are fewer holes in the burner, and the burner missing in the middle does not heat the middle of the combustion volume.

Gas savings on boilers KST-16 and KChM

There is no need to heat the middle of the combustion volume. It is better to line it with refractory bricks, thereby directing the gases to the walls.

Gas savings on boilers KST-16 and KChM

As an experienced gas worker, I kindly ask you not to get involved in the operation of gas equipment, too often you see shell-shocked and fried Kulibins. The nozzle directed to the center of the combustion chamber is designed to smoothly ignite the gas-air mixture from the igniter in the volume of the combustion chamber. On boilers with the main burner completely extinguished, this nozzle should under no circumstances be turned off.

Gas savings on boilers KST-16 and KChM

In general, all this was started due to the fact that when standard burners were burning during the day, the coolant temperature barely reached 70 degrees, and on the street -28 (which is rare for our area) and a small child in the house. Having rebuilt the burner in just a couple of hours, the coolant temperature rose to 90, and after another half an hour it completely started to boil (the thermostat was set to maximum for the factory burner). At the beginning there was a struggle for heat, savings turned out to be a by-product. And from the igniter this burner ignites no less reliably than the factory one. I won’t argue with that This is because gas requires an extremely careful attitude; making mischief is not appropriate here.

Gas savings on boilers KST-16 and KChM

Hello, I want to ask a question. Boiler KChM Kaunas, 4 sections. burner subk 3rd 16, like 19 kW, brick house, 2 floors 10 by 10.. the boiler worked on coal for 15 years and natural gas was supplied. THE QUESTION is whether to close the bottom of the boiler furnace or not. Is a flexible connection possible from the pipe to the burner?, the supply pipe is on the right and can no longer be moved, the entrance to the burner is on the left. and if possible, an approximate diagram of a combustion gas flow cutoff and the material from which it is best to make it. If you play with refractory bricks and fold this cutter inside the boiler, then how much you can reduce the combustion volume, how will the refractory brick behave in the firebox if you simply fold it without mortar. On the left, 10 cm away, there is a second KChM, IS IT POSSIBLE to use its smoke channel as a supply ventilation, the technical conditions prescribe it. The burner is new but manufactured in 2006. Will there be any problems with the expiration date?

The operating principle of such a boiler

The principle of direct operation is similar to boilers made from other materials or differs very slightly. To ensure the operation of such installations, conventional standard components are used.

The components of such a node are:

- burner;

- a pump that circulates the coolant;

- combustion chamber;

- heat exchanger

The boiler works because the supplied fuel, that is, gas, is burned in the combustion chamber and all the heat is supplied to the coolant coil. In cast iron boilers, the main element is the cast iron coil, which is responsible for ensuring that the coolant is heated evenly.

The positive principles of operation of cast iron gas boilers include:

- good corrosion resistance;

- wave-like heat transfer;

- good adaptation to severe thermal overloads;

- long service life;

- control maintenance is kept to a minimum.

But there are also disadvantages:

- significant weight;

- quite plastic, and therefore sensitive to loads that are produced mechanically;

- During critical thermal shocks, microcracks form.

Basic elements of automation

The main elements of automation for a gas boiler are:

- thermostat;

- shut-off valve;

- traction sensor;

- flame sensor;

- igniter tube;

- igniter;

- burners.

Let's try to clearly explain how automation for a gas boiler works, breaking it down into its main elements and talking about their functions.

The gas passes through a gas purification filter. Next it goes to the solenoid valve, which regulates the fuel supply to the burner. Temperature and draft sensors are located next to the valve, monitoring the indicators and signaling if they exceed acceptable standards. Also, the automation kit for gas boilers includes a thermostat with a bellows and a rod, designed to set the desired temperature. A special button is used to adjust the indicators. When the water is heated to the temperature set by the user, the thermostat is activated, the gas supply to the burner is stopped, while the igniter continues to operate. When the water cools by 10-15 degrees, the gas supply is resumed. The burner lights up from the igniter. The automation is started manually.

How to properly install equipment

You can install such equipment either independently or with the help of boiler installation specialists. The only condition that cannot be violated is to include the boiler in the gas system itself, because such work will have to be entrusted to a specialist. Moreover, such people must have special permits and certificates. If the homeowner violates this provision, then first of all, he will be disconnected from the system, and secondly, a very large fine will be imposed. But in order to independently connect a cast-iron gas boiler, you will still need construction skills.

Cast iron boilers have an impressive weight, so if you buy a mounted boiler, then an impressive frame must be mounted under it. Such equipment must be installed in the boiler room.

And such technical premises have special requirements:

- The ceiling height in the boiler room must be at least 3 meters, and the room must be at least 4 square meters. meters. These parameters are suitable for an average-capacity boiler, but the larger the boiler, the more space there should be around. Usually such things are recommended by the manufacturer themselves;

- the presence of at least a single window, because there must be air flow. The door opening must be 80 cm wide and the gap between the floor and the door leaf must be at least 35 mm;

- the distance to electrical and gas installations or appliances must be at least 3.5 meters;

- On the floor, in the place where the cast iron boiler is planned to be installed, a cement screed is poured, and this place is reinforced with a steel plate. It is important to remember that the steel sheet must be located under the entire surface of the bottom of the heating installation, and also protrude 3-4 cm beyond its front side;

- With materials that have fire-resistant qualities, it is necessary to strengthen the entire part of the wall where the chimney pipe will pass.

You may be interested in >> What to do if the boiler blows out in the wind

The main document when independently preparing a boiler for mounting it into the system should be an accompanying document in the form of instructions developed by the manufacturer.

Such a document gives parameters and regulates the procedure for connecting the boiler to the main pipeline, to the chimney system, as well as to the return and supply systems.

Popular Russian manufacturers of heating equipment

When choosing heating equipment at an affordable price, it is reasonable to proceed from considerations of individual needs, focusing not only on the brand. In general, floor-standing reviews of Russian gas heating boilers are increasingly positive, perhaps this is due to a decrease in purchasing power, or maybe our compatriots have begun to trust local manufacturers more and have given themselves the opportunity to evaluate Russian equipment.

Domestic gas boilers have a number of advantages for Russian buyers:

- reasonable price;

- good service base;

- optimal efficiency.

Among the disadvantages of Russian boilers are:

- large weight and dimensions;

- inability to regulate temperatures;

- often outdated design.

Zhukovsky Machine-Building Plant

The plant has been producing heating equipment for more than 40 years. The company presents boilers of three series (types) on the market: Economy, Universal and Comfort. Depending on the type, Zhukovsky gas boilers are equipped with imported automation or the development of our own engineers. The automation disconnects/connects the burner, monitoring the temperature in the heating system, monitors the readings of safety sensors and turns off the gas supply to the boiler if a potentially dangerous situation occurs. All ZhMZ models do not require connection to the electrical network. Among them there are both double-circuit (AKGV) and single-circuit models (AOGV).

Floor-standing gas boilers ZHMZ of the Economy series are equipped with an atmospheric burner, equipped with emergency draft sensors, are easy to set up, and have high efficiency. However, these models do not provide protection against overheating, which requires a more accurate calculation of power when purchasing a boiler, as well as periodic manual ignition of the igniter in cases where the protection is triggered. In addition, economy-type devices require a mandatory annual maintenance procedure before the start of the season.

But the price for Zhukovsky gas floor heating boilers is so attractive that these minor inconveniences can be ignored. In addition, the listed service features apply only to Economy series boilers. The automation of the Universal and Comfort models is more advanced (made in Italy and Germany, respectively). These models do not require maintenance, are reliable and unpretentious.

Price is one of the main advantages of Zhukovsky heating devices, but not the only one. In addition to their low cost, they have high efficiency (80 - 92%), a high degree of reliability and have a long service life. The standards of the plant, which, by the way, also produces special-purpose aviation equipment, lead to confidence in the durability and long service life of the heating equipment produced here. If you need a Russian-made floor-standing gas boiler whose price is minimal and whose operation is stable, perhaps you should take a closer look at Zhukov’s models.

Borinskoe

Like Zhukovsky, this plant has been producing heating equipment for quite a long time - more than 20 years. The company produces single-circuit and double-circuit boilers with the usual markings AOGV and AKGV, as well as boilers of its own design of the ISHMA series. All of them are equipped with imported automatic equipment, almost all models are energy independent, have a relatively modern design and low price.

The reviews for Borino gas boilers are quite good; they speak especially warmly about the ISHMA series models - they are additionally equipped with gas pressure sensors, providing the devices with an increased level of equipment automation and helping to reduce specific gas consumption by about 15-20%. An important advantage of Borin heating devices is the durability of the budget AOGV and AKGV series due to a reliable cast iron heat exchanger. True, this affects the cost.

For comparison, the heat exchangers of ZhMZ boilers are made of steel, so they are cheaper. Due to the cast iron elements, some models of Borino boilers are also heavy.

For those who are looking for floor-mounted Russian gas heating boilers, which are particularly durable, it is worth considering models from Borinskoye OJSC.

In general, if you compare boilers by heat exchanger material, you should take into account some comparative characteristics of cast iron and steel models.

Steel heat exchangers:

- cheaper than cast iron;

- easier to transport and install;

- They last a little less than cast iron.

Modern steel grades, when properly used, provide a service life of up to 30 years.

Cast iron heat exchangers:

- have a longer service life compared to steel;

- characterized by a higher heat capacity, which ensures slower cooling;

- more expensive than steel ones;

- more demanding to transport than steel ones (cast iron is a more fragile material).

It should be borne in mind that prices for floor-standing gas boilers made in Russia partly depend on the material of the heat exchanger.

If you need to buy a single-circuit floor-standing gas boiler that would look attractive, you should also consider Borinsky’s proposals. The boilers are coated with polymer enamel, which gives them an attractive appearance: they will fit well into a modern interior and will look quite impressive. But there are also disadvantages: increased sensitivity to fuel quality and susceptibility to corrosion.

In general, Borinsky’s heating equipment is perhaps even the most reliable domestic gas floor heating boilers, the prices of which are significantly lower than similar offers on the foreign market. All models of Borinsky boilers are ideally suited for operation in Russia and are characterized by high efficiency, up to 90%.

"Signal"

The Engel heating equipment plant “Signal” has recently been gaining popularity. His gas boiler Signal KOV-10ST and other models are collecting good reviews, given the optimal price/quality ratio, however, installation of Signal boilers can be difficult due to divergent connector standards. Reviews for this Signal gas boiler are generally positive, as for other models of the manufacturer. They attract mainly due to their low price.

There are single- and double-circuit models on the market, the automation is imported, and they are moderately capricious in operation.

For many who decide to buy a floor-standing gas boiler, price often becomes the main selection criterion, but the Russian market offers such a variety of heating equipment made in Russia and the CIS at a relatively equal and affordable price that it is possible to choose a model that matches requirements for all key parameters.

Many became interested in the small-sized and attractively designed Pechkin boilers (Taganrog), choosing as the main argument that, for example, the Pechkin KSG-10 gas boiler is small in size and equipped with an autonomous continuous water heating system. And someone chooses a Hephaestus floor-standing gas boiler, which has an original water-tube heat exchanger design based on the “Russian stove” principle, which ensures quick and efficient heating of the entire heating system.

You can buy a ThermoBar gas boiler (Ukraine) with a multi-section atmospheric burner, which ensures clean combustion products, silent operation and avoids the accumulation of soot in the combustion chamber even during long-term operation of the device. You can read about other popular Ukrainian-made gas boilers here. In addition to the manufacturers mentioned above, the Lemax and Rostovgazapparat enterprises have steadily occupied their niches.

Lemax

The offers of the Taganrog enterprise Lemax will be of interest to those who cannot decide on the type of boiler heating: Lemax offers solid fuel heating devices that can be easily converted to gas. The company offers gas boilers in three types, both single-circuit and double-circuit, the distinctive features of most of which are a special coating of the steel heat exchanger that protects the boiler from corrosion. There are models with cast iron heat exchangers. All boilers are equipped with imported components, have high efficiency, and are energy independent.

Rostovgazapparat

Rostov equipment is valued for its design feature, which allows complete combustion of fuel. Heat exchangers at this enterprise are made of steel, cast iron and copper. The boilers are equipped with high-quality imported automation.

Quietness, environmental friendliness, design, dimensions - any of these parameters can become a decisive argument when choosing. The main thing is that domestic manufacturers have learned to create heating equipment that is affordable and capable of competing with the foreign market.

Selection of coolant

For cast iron gas boilers, the following coolants are mainly used:

- distilled water;

- antifreeze.

Cast iron, according to its characteristics, cannot enter into any reaction with a liquid that does not freeze. The sections of the device are mounted so tightly that leaks are excluded even after antifreeze is introduced into the system.

The user, when choosing the media that will circulate along the circuit, should focus on the following characteristics:

- by heating time - in this case, water has a lower density than antifreeze. Therefore, the water warms up faster. Warming up time takes from 15 to 40 minutes. It all depends on the quality of the coolant;

- but the antifreeze gives off heat much longer, because due to its physical properties it cools more slowly than water.

Therefore, the coolant is selected based on the principle for which the heating system will be used in the future: for permanent operation or for temporary heating of premises.

Operating principle

The operation of a single-circuit floor-standing gas boiler consists of flow-through heating of the coolant using thermal energy obtained from fuel combustion.

The liquid enters the heat exchanger, receives the maximum possible heating for a given operating mode and enters a three-way valve . This is a unit where the hot coolant is mixed in a given proportion with the colder return flow.

The more return is added, the lower the temperature of the liquid entering the heating circuit. This is how the room heating mode is adjusted. The coolant moves under the action of a circulation pump, and the air supply and smoke removal are controlled by a turbofan.

The operation of all components is under continuous monitoring of a self-diagnosis system - a network of sensors installed on important components and parts of the boiler.

If abnormal situations occur or any elements fail, the sensors signal to the electronic control board, which immediately generates an error signal.

Some types of malfunctions cause immediate shutdown and blocking of the boiler for safety purposes; the control unit simply notifies the user about minor malfunctions.

What are the features when operating such a boiler?

Typically, few problems arise with cast iron boilers during operation. But still, there are some features, the observance of which will extend the life of the unit:

- In half of the cases, the reasons for the need to change the boiler much earlier than due are mechanical damage to the device during transportation. Cast iron is quite fragile and ductile, so if during transportation of the boiler it is dropped or struck in any way, the heat exchanger may fail. Therefore, when the boiler arrives on site, it is necessary to pour liquid into the coolant to make sure that there is no leak;

- sudden temperature changes can lead to the formation of microcracks over time, so it is necessary to add a mixing unit to the system during installation;

- A prerequisite for good operation is proper site preparation.

If the user handles the heating system carefully, the installation can last much longer than planned by the manufacturer.

Advantages and disadvantages

The advantages of floor-standing single-circuit boilers include::

- simplicity, absence of unnecessary components and parts;

- reliability, stability;

- high power, ability to heat large areas;

- the presence of powerful and efficient heat exchangers with a high heat transfer coefficient;

- the floor mounting method simplifies the installation and connection of the unit;

- management of single-circuit models is simple and accessible to all users;

- There is a large selection of designs that allow you to obtain the most suitable type of boiler for the given conditions.

The disadvantages of floor-standing single-circuit boilers are:

- lack of independent ability to supply hot water;

- the specifics of the work require the allocation of a special room - a boiler room, equipped with window and door openings;

- atmospheric or non-volatile models are connected to the central common house chimney, which determines the location of their installation;

- increased power automatically means increased fuel consumption.

What principles should you follow when choosing a boiler?

When choosing a boiler, a person must first of all be guided by the advantages or disadvantages of a particular model. Therefore, it is worth taking a closer look at what advantages or disadvantages cast iron gas boilers have:

- Cast iron heating devices are much more expensive than similar units made of steel. But this cost is justified by the fact that a cast iron device will last 15 years longer than a steel one;

- If a steel heat exchanger breaks down in a steel boiler, then any technical part cannot be repaired, because it is impossible to seal the seams by welding. But a cast iron unit can be repaired quite easily, because it is assembled in sections and any of the component parts can be replaced;

- if the user has some welding skills, then you can quite easily repair the boiler yourself, as well as increase the volume of the existing cast iron boiler by attaching sections;

- cast iron is difficult to corrode and is also inert to the effects of any acids, so any antifreeze can be safely poured into the circuit;

- Cast iron has much better thermal characteristics than steel.

There are not many disadvantages to such heating systems:

- high cost, due to the fact that cast iron is more expensive than steel, but this is offset by a long service life;

- heavy weight, it is quite difficult to install such a boiler alone;

- mandatory filling of the slab under the boiler itself.

Despite the fact that cast iron boilers are less popular than steel ones, the homeowner should still think about what to do better. Win a small amount on the difference in the cost of boilers at once, or still buy yourself a good unit so that it will serve for many years and also help save on fuel.

Types of valves

The gas valve is responsible for regulating the gas flow, its distribution and shutting off. The valve has a hole for the passage of gas (the so-called seat), closed by a piston or disk.

Depending on the number of inputs and operating positions, there are one-way, two-way and three-way valves, as well as modulating ones:

- a one-way valve is either open or closed;

- two-way is equipped with one input and two outputs. The start is smoother due to opening through an intermediate position;

- three-way valves are installed on boilers with two-stage power;

- With the help of modulating valves the power can be adjusted smoothly.

Accordingly, gas burners (types of gas burners for heating boilers) with automation for heating boilers come with single-stage, two-stage or modulated power control.

Installation Tips

The rules for installing equipment are simple:

- Before starting work, carefully read the instructions for the unit.

- When installing an AGV, organize a separate room for it, since this type of equipment takes air from the room.

- Provide good ventilation.

- Equip a chimney. It must be no less than the diameter of the pipe (minimum length - 5 m, horizontal section - up to 3 m).

- Clean the device through a special hatch. Since the chimney runs outside the house, debris and condensation collect in it, causing the structure to fail.

- When installing the boiler, leave a free space in front of it within a radius of 1 m, the distance to the nearest wall is at least 2 m.

The walls and floor in the room where the AGV is located are finished with non-combustible materials. If it is not possible to carry out such work, then use a special screen made of basalt cardboard or asbestos sheets.

The connection of the AGV to the gas supply system must be carried out by professionals. Basically, these are representatives of a company that has the appropriate license.

The best Russian floor-standing single-circuit boilers

Let's look at the most popular models of Russian floor-standing gas boilers:

Lemax Premium-20

Products of the plant of the same name from Taganrog. A non-volatile floor-standing boiler with a power of 20 kW is capable of heating a house of 200 square meters. m.

Its main characteristics:

- Efficiency - 90%;

- coolant temperature (max) - 90°;

- heating system pressure (max) - 3 Bar;

- fuel consumption - 2.4 m3/hour;

- dimensions - 556x961x470 mm;

- weight - 78 kg.

The high demand for Lemax boilers indicates the demand and positive attitude of users towards domestic heating units.

Rating of TOP 10 best models

| Place | Name | Price |

| TOP 5 best Russian floor-standing single-circuit boilers | ||

| 1 | Lemax Premium-20 | 25 000 ₽ |

| 2 | Lemax Premium-12.5 | 21 000 ₽ |

| 3 | Lemax Leader-35 | 53 000 ₽ |

| 4 | ZhMZ AOGV-17.4-3 Comfort N | 21 000 ₽ |

| 5 | Rostovgazoapparat AOGV | 20 000 ₽ |

| TOP 5 best foreign floor-standing single-circuit boilers | ||

| 1 | Protherm Wolf 16 KSO | 19 000 ₽ |

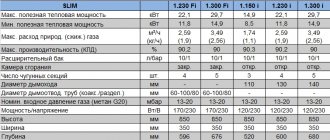

| 2 | BAXI SLIM 1.230 iN | 55 000 ₽ |

| 3 | MORA-TOP SA 20 G | 30 000 ₽ |

| 4 | MORA-TOP SA 60 | 25 000 ₽ |

| 5 | Protherm Bear 40 KLOM | 57 000 ₽ |