Here you will learn:

- Purpose of heating elements

- Selecting a heating element

- How to connect a heating element with a thermostat

Electric water heating and heating equipment has received great demand among consumers.

It allows you to quickly organize heating and hot water supply with minimal initial costs. Some people even create such equipment on their own, with their own hands. And the heart of any homemade device becomes a heating element with a thermostat. How to choose the right heating element and what to focus on when choosing it? There are quite a lot of parameters:

- Power consumption;

- Sizes and shape;

- Availability of built-in thermostat;

- Availability of corrosion protection.

After reading this review, you will learn how to independently understand heating elements with thermostats and be able to connect them.

Purpose of heating elements

Why do we need heating elements with thermostats? Based on them, autonomous heating systems are designed, boilers and instantaneous water heaters are created. For example, heating elements are mounted directly into batteries, resulting in sections that can operate independently, without a heating boiler. Some models are focused on creating anti-freeze systems - they maintain a low positive temperature, preventing freezing and subsequent rupture of pipes and batteries.

This battery has a built-in heating element with a thermostat, with its help the house is heated.

Storage and instantaneous water heaters are created on the basis of heating elements. Purchasing a boiler is not affordable for every person, so many assemble them themselves using separate components. By installing a heating element with a thermostat into a suitable container, we will get an excellent storage-type water heater - the consumer will only have to equip it with good thermal insulation and connect it to the water supply.

Bulk-type storage water heaters are also created on the basis of heating elements. In fact, it is a container of water that is filled manually. Heating elements are also built into summer shower tanks, ensuring water heating to a given temperature in bad weather.

Heating elements for heating water with a thermostat are necessary not only for creating water heating equipment, but also for repairing it - if the heater fails, we buy a new one and replace it. But before that, you need to understand the issues of choice.

Application

A water heating element with a thermostat is used for various purposes:

- Heating. The device is installed in the battery using a connector. It should not be used for constant heat generation.

- Heating water.

- Water supply to showers, sinks, sinks. For these purposes, the device is installed in a ready-made container.

Experts advise using the equipment for its intended purpose if you want it to last a long time. The rules for its use are usually indicated in the instructions.

Tubular electric water heaters

Heating elements for heating water are usually made of stainless steel if used for food products, or copper for water heaters. Although in areas where the water is hard, stainless steel heating elements must be installed in them, since copper quickly fails due to scale. Heating elements for water heaters are no different in design from others, except that they have increased requirements for tightness and the presence of a thermostat in the package. The shape is straight for vertical heaters, and with an additional bend for horizontal ones, so that the water is heated closer to the bottom. Both ends of the tube are mounted on a brass, carbon or stainless steel flange.

Selection options

The heating element should be 10 cm shorter than the heating radiator.

When choosing an electrical appliance, it is necessary to take into account the technical characteristics of radiators. The main criteria that influence the choice:

- Automatic control. Not all models are equipped with this option, but for convenience it is better to give preference to these.

- Battery Type. To ensure that the thermostat is optimally suited to the heating system, you need to study its technical data sheet.

- Length of the electric heating tube. The optimal parameter is 10 cm shorter than the length of the battery. Thanks to the correct selection, it is possible to heat all sections evenly.

Correctly selected power plays a big role when choosing. Heaters can be installed up to 203 kilowatts.

For aluminum radiators

A heating element for an aluminum radiator with a thermostat is no different from heating elements for cast iron appliances. The differences lie in the material used to make the plug and the shape of the outer part of the housing. The radiator has a 1-inch diameter plug. The plug diameter of standard cast iron batteries is 1.25 inches.

When purchasing a heating element, it is important to read the information on the packaging.

A Question of Choice

Eternal heating elements do not exist today. When heated, the metal gradually becomes thinner at the bending points and sooner or later the filament breaks. Premature failure of heating elements may be associated with overheating; water heating heating elements that are turned on when there is no water in the water heater often burn out in this way.

The correct choice of heating device will allow the device to last for many years without replacing the heating element.

A high price is not always a criterion for the right choice; there are numerous cases where expensive heating elements from a well-known company worked for no more than 6 months.

- It is necessary to check that the seller has documents for the goods being sold. The guarantee that the manufacturer gives for heating elements is also an indirect sign of high quality products. The longer the warranty period, the more reliable the purchased product.

- The correct choice of heating elements cannot be made without selecting the heating element according to power. which is necessary to heat the liquid. If the heating element is less powerful than necessary, then the water will not heat up to the temperature for which the water heater is designed. In the case where the element consumes large electrical power, excessive load on the wiring is possible. Therefore, when replacing this element, it is necessary to select a heating element only of the power for which this water heater is designed.

- When choosing, it is necessary to choose modern power supply shutoff devices. The most advanced thermostats in this regard are those that use electronics to regulate the heating temperature. Devices in which the working element is solid heat elements that expand when heated are outdated and have a limited working life.

- The correct choice is only possible if the device can easily fit in the tank. otherwise, installation of such a heater will not be possible.

- You should be especially careful when choosing a heating element that will be installed directly into the heating radiator. In this case, in addition to the size, an important criterion for choosing an element is the number of the thread on which this device will be installed.

- If you need to replace a burnt heating element. then when going to the store to buy a new element, you should take the burnt one with you and choose exactly the same size and markings.

Types and methods of manufacturing heating elements

Modern devices have heating components that not only have good strength, but are also capable of changing their shape and size under the influence of high temperatures. At the same time, heating elements do not lose their technical characteristics at all. Such electric heating components are used not only in domestic heating devices, but also in industrial devices.

In industrial devices, heating elements must have slightly higher power parameters. Any of these tubular devices, regardless of type, is characterized by a long service life.

There are many types of heating elements

Today, there are two types of heating elements, which are produced by manufacturers of electric heating devices. They, first of all, stand out for their manufacturing method. Some heating devices are produced in large quantities, while others are produced in limited quantities. First of all, manufacturers take into account the interests and needs of their customers. Those heating devices that are produced in small quantities are used mainly in heating installations that have quite specific requirements. Also, similar electric heaters for heating systems are somewhat more expensive.

Tubular type electric heaters

This type is the most common. It is used in most devices that operate from the electrical network. By means of tubular heaters, the coolant is heated according to the principles of convection, thermal conductivity and radiation. Thus, electrical energy is converted into thermal energy.

Tubular type electric heater

This electric heater for heating has the following parameters:

- The tube diameter ranges from 6 to 18.5 mm;

- The length of the heating element ranges from 20 to 600 cm;

- The tube itself can be made of materials such as stainless steel or steel. The tube can be made of titanium, but such heating devices are included in the most expensive category;

- The configuration of the heating device does not have any restrictions;

- Heating element parameters, such as productivity, power, efficiency, are agreed directly with the customer.

Finned Tubular Electric Heaters

TENRs are the same tubular heating elements, but the difference is that they also have ribs. These ribs are located in perpendicular planes to the axis of the heater tube. Such ribs are made of metal tape and attached to the tube using washers and clamping nuts. The device itself is made of material such as structural steel or stainless steel.

Types and types of heating convectors

Finned heating element

This type of electric heaters is used to heat gas or air, which is used to heat a room.

Quite often they are used by electric heating devices such as convectors or thermal curtains. Their area of application is those rooms where heating occurs through heated air masses.

Block electric heaters

Devices such as heating elements are used only if it is necessary to significantly increase the power parameters of a particular heating device. Most often, such devices are installed in those electric heating devices in which bulk material or coolant acts as a coolant.

Electric heater block (TENB)

Its main distinguishing characteristic is its fastening to the heating device. Such fasteners can be of two types: flanged or threaded.

The most popular device today is considered to be an electric heater for heating a house with flange fasteners.

This heating component can be reused for different heating devices. Even if the heating element burns out, it can be replaced with a new one.

Cartridge-type electric heaters

This type of electric heaters is not used as electric heaters for heating a summer house. It is used as a mold part for the manufacture of any products, since they are part of industrial equipment. They are not used in domestic conditions.

Cartridge type electric heater

The main difference between such heaters is the shell made of a material such as stainless steel. The shell of such a heating element is polished to the maximum level.

This is done specifically so that the heater fits into the mold and at the same time there is a minimum gap between the walls and the tube. It fits in quite tightly, you can see this if you look at the standard gap, which does not exceed 0.02 mm.

Ring electric heaters

This type of heating elements is also not used as electric heating elements for heating a house. Its main purpose is to heat injection molding equipment, heat injectors, as well as injection-type nozzle installations.

Types of heating systems

Ring electric heaters

The minimum twist diameter is 8mm and the maximum diameter can be unlimited. This type of heaters is made mainly of a material such as stainless steel.

Electric heaters with thermostat

Electric heating heaters with a thermostat are the most popular today, and their main purpose is to heat liquids. This type of heating element, which has room thermostats for heating, is installed on virtually all household appliances that are used to heat water. The maximum heat temperature generated by electric thermostats for heating is +80 degrees.

Electric heater with thermostat

A heating element with a thermostat for heating is made from nickel-chrome wire. The wire inside the tube of a device that uses an electric thermostat for heating is filled with a special compressed powder. The powder is magnesium oxide. It is characterized by good insulating properties, but, at the same time, stands out for its fairly high thermal conductivity.

Design and types of thermostat

Thermostat is a device for automating the heating process. It serves to regulate the temperature of the liquid. According to the specified parameters, it turns off the power to the heating element when the water has reached the desired temperature, and, accordingly, turns on the heater again when the “degree has dropped.” Based on their design, there are 3 types of such regulators:

- Rod is the first and cheapest option. The operating principle is based on the action of thermal expansion. The key part is a metal rod placed in the liquid along with a tubular heater. As the water heats up, the rod expands and at the moment of the desired temperature and, accordingly, expansion, it activates the thermostat, which turns off the power. At the same time, cooling, the rod decreases in volume and, at a low degree, turns on the control device again, which supplies electricity to the heating element.

More recently, such a thermostat device was the most common, until it became clear that its operation was not so flawless. The paradox is that when cold water is added to the heating tank, the rod, which was previously in the hot liquid, begins to sharply narrow, thereby turning on the heating element for heating in an already heated system.

- The imperfect type of thermostat was replaced by another - capillary. The work is based on the same thermal expansion, only now instead of a rod, the key part is a capillary tube with liquid inside, which, when expanded, exerts pressure on the regulator. The design solves the problem of a false signal when adding cold water. Most modern models of heating elements are equipped with similar regulators, while the rod thermostat remains on the market only as a spare part for older models.

- The third type is, of course, a modern solution - an electronic protective thermostat. Its design includes two sensors: thermal and protective. The first controls the water temperature - performs the main function. The second monitors the possibility of overheating of the tubular heater. The operating principle of the sensors is based on changes in active resistance with temperature changes. Using the dielectric properties of the conductor, such heating elements for heating with a thermostat are able to provide water temperature with high accuracy. The electronic device belongs to the class of advanced models and is far from cheap. When choosing this thermostat as a means of controlling the heating system, it is recommended to rely, first of all, on long-term use. Equipment costs are justified if long-term operation of the heater is expected. Accuracy and functionality allow you to conveniently manage the system and significantly save on energy consumption.

Advantages and disadvantages

You can reduce heating costs by purchasing a heating element with temperature control.

From a tubular-type thermostat, you can create an effective heating system used as additional or main heating.

Main advantages:

- Easy to install. Even an inexperienced person can cope with the task.

- Possibility of automatic control if the system is equipped with additional equipment.

- Acceptable cost of construction.

- Compared to oil radiators, the system is more reliable. The batteries are repairable.

Among the disadvantages, it is worth highlighting the impressive operating costs due to the high cost of electricity. It is possible to reduce consumption, but to do this you will have to additionally purchase an automated control system.

Heating element design

The conductive part of the heating element design is a metal spiral with high resistance, usually a mixture of nickel and chromium. It is this parameter, such as resistivity, that plays a key role in the fundamental operation of the device. According to the laws of physics, the higher the resistance of the metal, the more heat is generated when electric current flows through the wire. The spiral is placed in a metal tube, which is made of stainless material - carbon steel, copper, etc. Heating elements for heating radiators are available in three tube diameters - 13 mm - the most common, 10 and 8 mm are also found. The remaining volume of the tube is filled with a dielectric, which is often magnesium oxide.

Composition of the heating element

The heating element includes the following parts:

- A tube that can be copper, steel, brass, titanium. All types have different performance indicators. You should choose a device that is resistant to corrosion. There must be a protective layer on the walls of the tubes.

- A spiral made of wire that has a high resistivity.

- Filler that does not conduct electric current. Periclase is usually used. The filler serves to separate the coil from the tube.

- The contact rod is an element for connecting the heater to the network.

- The insulators are made of porcelain and are located at the ends of the tubes.

- Tubular shell.

- Sealant.

- Thermal sensor that regulates the water temperature.

Varieties

Heating elements come in different shapes, power and heating medium.

The most popular varieties:

This design is most widespread in water heating devices. The cost of such elements is quite high due to the stainless steel and nichrome used in their production.

These devices, when manufactured with high quality, can last more than 10,000 hours.

finned

The design of the heating element differs little from the tubular one. The only difference is the perpendicularly located stainless steel fins relative to the main heating device. This design allows you to increase the power of the heating element due to a larger heated surface area.

A block of electric heaters that are used in high-power installations, such as electric boilers.

The use of such heating elements allows you not to worry about complete failure of the heating device. In the event that one heating element burns out, the boiler only slightly loses power and continues to function in this state until the time when it is possible to replace the failed heating element without the threat of defrosting the heating system.

Such a heating element is convenient in that it allows you to replace a damaged device even in a water heater filled with liquid in a matter of minutes without depressurizing the tank. Like a cartridge, this element is inserted into a metal shell, which in turn is already in contact with the heated medium.

The cost of such devices is slightly higher due to more precise processing of the heated surface.

Heating element with thermostat

Heaters of this design are used primarily for heating liquids. The thermostat not only allows you to set the required temperature, but also when set to maximum heating does not allow the liquid to boil, eliminating the possibility of such a heater exploding.

Advantages

A water heating element with a thermostat has the following advantages:

- Safety. This applies more to dry heating elements. No short circuit or electric shock possible. This is achieved thanks to a design that does not involve contact with water.

- Long service life - over 15 years. The main thing is to follow the rules of use.

- Economical. This is due to the presence of a temperature sensor that regulates the supply of electricity.

- Easy to install. The heating element must be installed in the water heater, which is fixed on brackets. Then everything is connected to the network. The boiler has all the necessary controls.

- Several thermoelectric heaters can be used in one heater.

- Resistance to mechanical damage.

Heating elements for heating radiators

In radiators, heating elements are installed to maintain the temperature of the coolant during a short-term shutdown of the central heating system or for additional heating of the coolant.

Such additional heating at night can be beneficial if the main source of heat is a boiler using expensive liquid fuel, and a two-tariff electric meter is installed in the house. Heating elements for heating radiators are distinguished by a thin flange and a narrow heating element. They are installed on cast iron and aluminum radiators, can be made in different capacities and differ in the length of the heating element. The delivery set includes a protective casing that protects the heating element from moisture.

Since the tube is plated with chromium and nickel during the manufacturing process, heating elements for radiators are durable and reliable. The capillary thermostat allows you to accurately regulate the heating temperature, and two temperature sensors protect the device from overheating. Modern heating elements have additional functions, for example “Turbo”, when the device operates at maximum power for some time to quickly warm up the room, or “Anti-freeze”, designed to maintain a minimum temperature of 10 ° C for a long time.

Installing a heating element into a radiator is quite simple: remove the plug from the bottom flange of the heating device, screw the heating element into the hole, install the thermostat and connect the power supply to grounding. The passport for the device must indicate the requirements for tightness, if not met, the radiator may become energized, and this is life-threatening. Advantages of installing heating elements in a central heating system:

- protection of the premises from freezing;

- protection of the system from damage in severe frosts;

- efficiency, because all energy is converted into heat;

- pulse operation, which saves energy;

- high accuracy of temperature control;

- additional useful functions;

- reasonable price.

Heating elements for heating batteries and radiators

The devices are designed to warm up the coolant and maintain a given heating mode within a set time. Electric heating elements are installed in any devices filled with liquid, including batteries, boilers, and are used as the main or additional heat source. The power of the device is selected depending on the area of the room, but it is recommended to use the units as a temporary heating source.

Advice! When installing a heater in a stand-alone device, attention is paid to the battery material and the power of the device. For example, you can buy a heating element for a cast iron battery, which is used to heat the basement, utility room or garage.

Thermal electric heaters are convenient to use because they are placed in a battery that is not included in the common line. The radiator is filled with liquid only to the volume of the housing. Experts advise changing the water to technical oil so that when the heater is turned off, the device does not freeze. A battery with a thermal heater has increased power and greater heat transfer, which is beneficial for quickly heating small rooms and country houses.

Advice! If you plan to use an electrical appliance in an apartment, a heating element in the battery is installed on each heating unit, into which water can be poured provided that the system is constantly operating.

Types of devices advantages and disadvantages

Manufacturers offer several types of devices:

- Tubular heaters. Tubular sections are convenient for installation in household heating appliances; transmission is organized by convection or infrared radiation.

- Finned devices. Convenient and practical devices with an increased heat transfer area. The plates are located throughout the entire plane of the device, so the room warms up faster. Finned heaters work best in air-type systems equipped with fans.

- Cartridge devices. These are units with one free end, which dictates the installation rules. The polished steel coating enhances contact with the coolant, the device can be inserted into the hole of the boiler, batteries, fixed to flanges.

Advantages of heaters:

- simplicity, ease of installation;

- you can find devices of low cost;

- reliability;

- maintainability.

There are devices on sale with turbo heating and anti-freezing properties. The circuit can also be equipped with additional devices for automatic startup and shutdown.

Flaws:

Gas heating convectors for home and their design

- Increased maintenance costs. Electric heating elements will increase your electricity bills. Payments can be reduced by creating an automatic start-up and shutdown scheme when the specified temperature parameters are reached.

- Reduced efficiency. Compared to a conventional heating system, batteries provide significantly less heat due to the reduced coolant circulation rate.

Advice! When choosing between oil heaters and electric thermal heaters, the latter will become more profitable, provided that automatic control devices are installed on the batteries with heating elements.

Rules for choosing a heating element for a battery

The main characteristics of devices that you need to pay attention to:

- Power. To heat an apartment with high-quality thermal insulation, an indicator of 20 W/m3 is sufficient; for private buildings with an area of 25-30 m2, a device with a power of 30 W/m3 is suitable; for an old house with insufficient thermal insulation, heating elements for heating radiators with a power of 50 W/m3 are suitable. The devices are produced with operating rates of 800-2000 watts.

- View. To determine the desired shape, material, thickness and cross-section of electric heater plugs, you should first carefully study the characteristics of the battery or buy both devices together. Characteristics and dimensions are indicated in the technical data sheet of the devices.

- Heating tube length. This part must be long to maintain uniform coolant circulation in all sections of the battery. The standard size of the tube length is calculated by the length of the radiator minus 10 cm.

- Manufacturer. Devices from Polish, Italian, and Russian manufacturers have proven themselves well. Manufacturers from the Russian Federation offer products adapted for different regions. Chinese devices should be taken with caution, require certificates and be checked for strength and quality.

Technology for installing a heater in a radiator

To install the heater into the battery, you need to unscrew the radiator plug, insert the heating element, tighten the thread and seal the joint area with a rubber seal. Installation is carried out similarly in any radiators. If you are installing a heating element for heating with a thermostat, you need to pay attention to the installation diagram in the technical data sheet of the product. The manufacturer gives clear recommendations.

On a note! A shut-off valve and bypass must be installed on the battery with heating element. In the absence of shut-off valves, heat will go to neighboring radiators; a bypass reduces the risk of disrupting the circulation of coolant in the heating main throughout the riser.

The device must be screwed on carefully, without applying much force, so that the locknut and heater fasteners do not burst. It is recommended to install a small expansion tank behind the shut-off valve, which is designed for 10% of the volume of the total coolant. This is necessary to discharge excess liquid when it is heated.

Installation and replacement

To carry out installation work, you will need the following tools:

- Phillips and slotted screwdriver;

- pliers;

- spanners;

If the heating element is being replaced, then before installing a new element, dismantling of the failed heating element is carried out.

Before starting this operation, it is necessary to turn off the power to the water heater by removing the plug or turning off the circuit breakers on the central electrical panel if the boiler is connected directly.

Installation is carried out in the following sequence:

- It is necessary to thoroughly wash the tank from the accumulated scale and wipe it with a rag.

- The new heating element is installed in this way. so that the rubber gasket adheres evenly to the surface of the parts being connected. All threaded connections must be tightened to the required torque. When the heating element is installed, electrical wires are connected to it.

- Then the bottom cover is installed and the boiler is filled with water. If there are no leaks, then you can connect the water heater to the electrical network.

If you need to install a heating element in a heating battery, then unscrew the plug at the bottom of the heating device and install the heating element in its place. Then the system is filled with liquid and the heater is connected to a 220 V AC network.

Heating element block with Ariston type thermostat (I)

This device has a built-in thermostat that allows you to adjust the operation of the device to heat the liquid in the range of +20 - 80 degrees. The working surface of this device consists of copper, which promotes maximum efficient heat transfer.

RCT 3.0 KW M6

This device can be used both in factory water heating installations and in self-made water heaters. The heating element body has a hole for installing a thermostat, which is purchased separately.

Cost - 1200 rubles.

TENB-9 stainless steel 220/380V

Heater block for water boiler. On one flange of this device there are 3 elements with a total power of 9 kW. The heating elements are reliably isolated from each other, which allows you to regulate the heating power of the liquid. The heating element is made of stainless steel, this protects the heating element from corrosion and allows the equipment to operate without failure for up to 5 years.

Flaws

A heating element with a thermostat for heating also has disadvantages. But the type of equipment should be taken into account. If the coil burns out, it will not be possible to repair the heating element. With prolonged use, scale appears, which affects heat transfer. Customer reviews confirm the presence of negative aspects of the equipment.

Hard water reduces service life. Dry types of equipment are not considered universal. They are created for specific types of broilers. Therefore, during repairs, it can only be replaced with a similar element. Experts advise using the device correctly, then it will not require repair or replacement.

Heating element with thermostat for heating water

To effectively transform electric current into thermal energy, a heating element is used.

A tubular electric heater is used in modern electric boilers, stoves, electric kettles and other devices that provide electrical heating.

Heat is released due to the glow inside this device of a nichrome filament, which runs exactly in the center of the tube and is reliably isolated from its surface by a layer of dielectric. Ceramics are usually used as an insulating layer, which transfers heat well without passing electric current to the outer surface of the heating element.

What it is?

A heating element is a tubular electric heater. This is the main part of the water heater, with the help of which the required water temperature is maintained in the tank. This element converts electrical energy into thermal energy. As a result, the water is heated by the device to a certain temperature set by the user.

The work is that the thermostat receives electric current at the terminals, passes it through and transmits it to the terminals of the heater. The spiral heats up and transfers heat to the shell of the heating element, which heats the water. The device has a sensor that measures the water temperature. After reaching a certain indicator, the heating element with the thermostat turns off. After cooling down it turns on again. This is how the device works until disconnected from the network. Experts advise purchasing such a device from trusted stores.

Ariston heating element with a thermostat is considered one of the best. The heater contacts are silver-plated, increasing the design current to 25 amperes. This figure in other similar devices is no more than 18. The Ariston heating element with a thermostat quickly heats the water due to good heat transfer. The nichrome spiral has a high stretch coefficient. The devices are easy to install, light in weight and compact in size.

Selecting a heating element

When choosing a heating element, you need to pay attention to some details. Only in this case can you count on a successful purchase, high-quality heating, long service life and compatibility of the selected model with a water heating tank, boiler or radiator.

Shape and size

There are dozens of heating element models available for buyers to choose from. They have different shapes - straight, round, figure-eight or ear-shaped, double, triple and many others. When purchasing, you should focus on the use of the heater. For installation in sections of heating radiators, narrow and straight models are used, since the space inside is quite small. When assembling a storage water heater, you should pay attention to the volume and shape of the tank, and based on this, choose a suitable heating element. In principle, almost any model will fit here.

If you need to replace a heating element in an existing water heater, you need to purchase an identical model - only in this case can you count on the fact that it will fit into the tank itself.

Power

If not everything, then a lot depends on power. For example, this could be the heating rate. If you are assembling a small-volume water heater, the recommended power will be 1.5 kW. The same heating element will be able to heat disproportionately large volumes, but it will do this for a very long time - with a power of 2 kW, heating 100-150 liters of water can take 3.5 - 4 hours (not to a boil, but on average by 40 degrees).

If you equip a water heater or water tank with a powerful 5-7 kW heating element, the water will heat up very quickly. But another problem will arise - the house electrical network will not withstand it. When the power of the connected equipment is above 2 kW, it is necessary to lay a separate line from the electrical panel.

Protection against corrosion and scale

When choosing heating elements for heating water with a thermostat, we recommend paying attention to modern models equipped with scale protection. Recently, models with enamel coating have begun to appear on the market. It is this that protects the heaters from salt deposits. The warranty on such heating elements is 15 years. If you don’t find similar models in the store, then we recommend purchasing stainless steel electric heaters - they are more durable and reliable.

The presence of a thermostat

If you are assembling or repairing a boiler or want to equip a heating element with a heating element, choose a model with a built-in thermostat. It will save on electricity by turning on only when the water temperature drops below a set point. If there is no regulator, you will have to monitor the temperature yourself by turning the heating on or off - this is inconvenient, uneconomical and unsafe.

Installing a heating element: important features

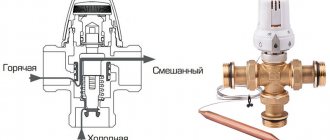

The heating element is installed according to the following scheme: one of the battery plugs is unscrewed, and a heating element is installed in its place using a threaded connection. To ensure the tightness of the joint, a rubber gasket is used.

Mr. Build recommends: it is best to screw in heating elements instead of the bottom plug. There is a logical explanation for this: heated water will rise and cold water will fall, which will ensure efficient operation of the heating element.

This procedure is repeated in each room of the apartment. We remind you that installation is carried out before the start of the heating season.

It is important! Shut-off valves and a bypass must be installed near the radiator to which the electric heater is planned to be connected. If there are no valves, all the heat will go to the neighbors. In the absence of a bypass, the general building heating system will be disrupted.

A few more important points:

- Do not use excessive force during the installation process. There is no need to forcefully tighten the contact nuts and the heating element fasteners themselves. Brittle material may burst.

- It is strongly recommended that after the shut-off valve, install a safety valve or a small expansion tank with a volume equal to 10% of the battery volume. This is due to the fact that when the coolant in a closed system is heated, it expands and increases the pressure in it.