Complex option

At the same time, the simplest solution in terms of finishing work, and the most difficult in terms of preparation, will be the solution of removing the heater. Preparation will consist mainly of removing the battery completely. Not every home craftsman will be able to cope with this, and in winter, in the absence of a tap that shuts off the water, this simply becomes impossible. If removing the radiator is not a problem for you, then the repair itself is not difficult - the technology for performing all the work will not differ from the rest of the room.

Therefore, there are only two ways to prepare everything here: remove the heating device yourself or call a technician who will first remove it and then, after some time, install it back. You will need to call it twice - for removal and installation, and this will require additional costs. In this regard, finishing the wall with a battery and removing it is one of the most expensive and difficult ways to repair the surface. It is much easier to make repairs without removing anything.

Video description

How to reduce battery heat dissipation

Contact utility companies

Problems in high-rise buildings are resolved by the management company. According to the rules, residents should not directly contact workers servicing the heating network. It is better for the inhabitants of the problem apartment to write a statement to the Criminal Code. If the complaint is not considered, then they further contact Rospotrebnadzor and the housing inspectorate.

The appeal will be investigated if the problem of too high a temperature is observed in other residents. In high-rise buildings, people on the lower floors often suffer from the heat, while those on the upper floors freeze. Utility workers turn up the heating as much as possible, which leads to discomfort.

The management company must carry out balancing. After correction, the temperature of all residents should return to normal. If the weather forecast predicts a sharp cold snap in the coming days, workers may ignore the request.

Pros of a heat reflective screen

The heat-reflecting screen behind the radiator solves two issues:

- increases heat transfer - the main goal,

- reduces heat loss.

All this at minimal cost.

Areas behind heating appliances get hotter than others.

Being an additional insulation, the screen restores their thermal conductivity along with the rest of the wall.

The idea is not new.

It has been tested in practice many times and discussed in specialized literature.

The effectiveness of heat-reflecting screens is indicated by

In their opinion, a heat-reflecting screen behind the radiator can reduce the heat loss of a 0.51-meter thick brick wall by 35%.

Disadvantages of a heat-reflecting screen

Why do you need foil?

The coefficient of reflection of thermal radiation of polished aluminum is higher than that of other metals.

This means that maximum heat will return inside the room.

You should not use screens with a double-sided metal backing.

The layer of foil on the side of the cold wall does not carry a functional load - it simply has nothing to reflect.

Unscrupulous sellers in construction markets deceive customers by talking about new metallized coatings with fantastic characteristics.

These are fairy tales.

Any polished metal refracts heat rays, but the reflection coefficient is negligible and does not affect thermal efficiency.

The cost per square meter of a thermal reflective screen with aluminum foil is more expensive than with a metallized film.

The difference is small - 5-10 rubles.

Pros of a heat reflective screen

This is interesting: What gas pressure should be in the gas pipeline - houses and apartments

Local heating systems

The easiest option for maintaining home heat, which does not require the independent construction of any device, is to purchase a heater. Before purchasing, clearly determine what area you need to heat. The choice of electric heater power depends on this (on average you need at least 1 kW for every 10 m2). It would be nice if the device is equipped with a temperature and power regulator. Various types of heaters are suitable for heating a house - oil radiators, convectors, quartz radiators and fan heaters. An alternative heater can be an electric fireplace, which functions in a similar way.

While maintaining warmth and comfort in your home, do not forget to observe another important condition - ventilation. It is better to replace static ventilation with periodic ventilation: 2-3 minutes every 3-4 hours. This will save much more heat

This will retain much more heat.

Remember that the best warmer is love and care for loved ones. Love each other, create a family hearth, and then there will always be comfort and warmth in your home, regardless of the time of year.

Where can the refrigerator be placed?

When planning to purchase a new refrigeration unit, you need to take care of the location of the device. For a small kitchen, it is recommended to choose a small-sized refrigerator model. It’s better to purchase a separate freezer and refrigerator. In this case, one part can be placed on the work surface, and the other in any free space in the kitchen. But remembering that the refrigerator cannot be located near a heating device, it is prohibited to place it near the oven.

A good option for small kitchens is to purchase built-in appliances, shown in the photo. This will save free space and protect equipment from heating and rapid breakdown.

Built-in refrigerator in the kitchen interior

If the kitchen is very small, and it is not possible to place a refrigerator in this room, you can consider placing large equipment in the pantry or hallway.

Tags thermal insulation

Comments 65

If it’s hard to paste wallpaper behind the battery, you can put such crap, it seems to cover the hole, and you can also feel the “effect”

But I don’t even know, the first time I glued it to my grandmother seems to me to be of little use, although I didn’t actually measure the temperature.

I don’t know about you, but in Moscow every year they go and glue them (in apartments, but I don’t need them) with the same crap, and they glue them on the floors too

Good topic, I enjoyed reading it.

The thermostatic tap is installed incorrectly - it should be horizontal. And cover all the walls with such a screen, then the effect will be))))

Time will put everything in its place, it’s a shame that we throw mud at each other. Why do we have such “ugly” happening on the radio about the fraternal people, what do you have...

p.s. There are plenty of cattle and degenerates everywhere. Those who write “Dill” and “Vata” have probably found themselves and are stuck in their development at the 5th grade level.

On the contrary, I cover all radiators with blankets all winter, the heat is unbearable)))

We have battery-powered regulators and pay according to the meter for heat, so we’re thinking about how we can save money.

Apparently you pay pennies, in my new apartment it was in a corner room of 8.7 sq.m. 2 batteries - one 7 sections, the other 11 - as it turned out, they were building because they were afraid that people would freeze, + a street wall with brick masonry exactly 1 meter high.

The effect is no more than a placebo. The temperature in the room is, roughly speaking, the thermal energy that came from the batteries, minus the thermal energy that went out, through the windows, doors, ventilation, and also through the walls. That is, this way and that - the total will be exactly the same, because the area of the walls leading to the street and the number of other windows remains unchanged. Such Velcro worsens heat exchange with the wall specifically in this place, but, firstly, it’s a drop in the sea compared to the area of all the walls; secondly, the wall in this place will warm up worse, i.e. cooler outside. As a result, the temperature difference will increase and heat transfer will stabilize at the same level. We do not consider the issue of aesthetics.

PS If you want the batteries to heat better, put a fan on them. True, after this your neighbors will start to freeze

Here is Dmitry, thanks for the detailed and clear answer)))

The effect is no more than a placebo. The temperature in the room is, roughly speaking, the thermal energy that came from the batteries, minus the thermal energy that went out, through the windows, doors, ventilation, and also through the walls. That is, this way and that - the total will be exactly the same, because the area of the walls leading to the street and the number of other windows remains unchanged. Such Velcro worsens heat exchange with the wall specifically in this place, but, firstly, it’s a drop in the sea compared to the area of all the walls; secondly, the wall in this place will warm up worse, i.e. cooler outside. As a result, the temperature difference will increase and heat transfer will stabilize at the same level. We do not consider the issue of aesthetics.

PS If you want the batteries to heat better, put a fan on them. True, after this your neighbors will start to freeze

Excellent answer. I’ll just add that such things can be installed in houses made of organic materials (wood, etc.) to reduce the impact of the radiator’s heat on them. And undoubtedly the wall in this place will become colder and at moments when the radiator is not working this cold will get inside the room faster.

On bi-metal batteries they are not particularly needed, because... (even in the photo you can see) their heat exchanger fins are located towards the room and the heat transfer is better than on cast iron, cool air passes from below and, passing through the fins, warm air comes out from above. If you put your hand up, you can feel it. In the case of cast iron, the thing is POSSIBLY edible, because... The cast iron ribs heat the area around them and, accordingly, the wall, but this results in no heat loss in the room. Modern cast iron is of poor quality, as practice has shown... We installed a new (factory-assembled cast iron battery) and after 2 - 2.5 years, 3 ribs at the bottom burst, fortunately not during the heating season, this is for your information. And so I think such things are glued, so to speak, for complacency))) If the wall freezes, then you need to fight the freezing, i.e. insulate the wall, look for “bridges” of cold and arrange. In practice, you will not feel the difference, maybe even when taking temperature measurements or some tests you will see a difference of no more than 2-3%. Usually there are problems with heat in corner apartments of panel houses or external walls, there you just need to insulate and sort out all the joints of walls, floors, and ceilings. In brick houses there are no problems with this and this “device” is of no use))

Principle of operation

To understand the principle of operation of such insulation, consider the main methods of transferring heat from one coating to another:

- thermal conductivity - the ability to conduct heat (solids);

- convection - heat transfer through the air due to different densities of cold and warm air currents;

- radiation - any body with a temperature above zero emits heat waves, which are absorbed by walls and ceilings (surfaces), converted into heat and transferred to the cold external environment. This exchange accounts for about 60-90% of heat loss.

Thus, heat loss is inevitable. It turns out that to create the effect of thermal insulation, it is necessary to minimize heat loss from radiation. But traditional TIMs are not able to protect a building from this type of heat transfer. And the optimal material was found - foil insulation, known for its reflective and low-emissivity properties.

Reflective thermal insulation works across all heat transfer processes: radiation, convection and conduction, inhibiting heat loss.

How to choose a screen for a radiator

Before choosing a screen for a radiator, you need to decide where it will be installed. If it is intended for a nursery, then you can purchase a screen whose surface is covered with drawings, letters, etc. In this case, you can beautifully decorate the interior of the room. Glass screens are completely unsuitable for such rooms, since there is a possibility of them breaking or children getting cuts from the fragments.

However, if the rooms are not warm enough, and it is not clear why the radiators in the apartment do not heat well, then you definitely should not purchase grilles with small, sparse holes, since in this case the warm air will be strongly trapped inside the screen.

Such battery screens are only suitable if the devices get very hot

At the same time, it is important that the material for their manufacture should not be wood or plastic, since they will either deform or emit a specific odor

You also need to consider how beautifully and correctly the screen will fit into the interior of the room. If the room where it will be installed is small, preference should be given to a light-colored product. If you purchase a massive screen, you can later make an additional shelf or stand out of it.

DIY battery screen

If it is not possible to buy a screen for a battery, then you can make it yourself, and there should not be any particular difficulties. To make a screen for the battery, you will need drywall, as it is an excellent material for these purposes.

You will also need a metal profile to assemble the frame (niche). The tools you will need for such work are: a grinder, a screwdriver, a drywall saw and a hammer drill with drills. If a hammer drill is not at hand, then an impact drill can easily replace it.

Before installing the latter (gypsum board), its surface must be impregnated with a polymer emulsion or other suitable mastic. Well, you can read about other ways to hide the battery in the next article.

Do-it-yourself installation of a plasterboard box

In order to close the battery, you need to measure it, and then buy metal profiles and other additional products.

What materials are needed:

- 12 mm plasterboard sheet,

- metal profiles 27x28 and 60x27,

- self-tapping screws for drywall and metal,

- dowel-nails size 6x40,

- construction serpyanka,

- perforated corners.

Tools:

- screwdriver,

- hammer drill,

- metal scissors,

- stationery knife,

- construction stapler,

- pencil,

- roulette,

- building level.

Work order:

Installation of the frame. The profile should be mounted on three adjacent sides: floor, wall, window sill.

- Press the 27x28 metal profile to the base with your hand, drill a hole using a hammer drill in both the profile and the wall.

- Using a screwdriver, screw the dowel-nail into the hole.

- At the bottom of the window sill, a 27x28 metal profile is mounted on self-tapping screws; the length of the screws should not be greater than the thickness of the window sill.

- Next, you can install jumpers made of metal profile 60x27.

Selecting the grid size. This hole must be made slightly smaller than the grid size.

Installation of drywall. Plasterboard sheets can be cut with a utility knife. Screw it in with a screwdriver.

Installation of corners. They must be secured at the corners with a construction stapler, or attached to gypsum plaster.

- Serpyanka should be applied to all seams of the plasterboard box and covered with plaster.

- Before painting or wallpapering, the plasterboard box must be puttied, sanded and coated with primer.

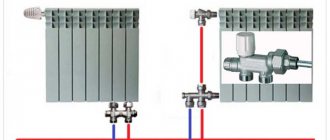

Installing a heat-reflecting screen behind the battery

In the context of constantly rising prices for energy sources, the issue of saving is especially relevant. Heating pipes are usually mounted on walls under windows. In these places, heat loss increases. If the radiator is installed in a niche, the power required for heating is even higher due to the reduced wall thickness. The best solution in this case would be a heat-reflecting screen behind the radiator. It isolates the wall area from the heating device and keeps the house warm.

Operating principle and design features

Various materials are used in the production of heat-reflecting screens. Their main property is a low level of thermal conductivity. First of all, these include:

Porilex can be used for thermal insulation

Also, all screens have a layer of insulation. Sealing is achieved using metallized tape. The thermal conductivity coefficient should not exceed 0.05 W/m*°C. There should be a layer between the foil and the wall that will retain heat. When creating heat-reflecting screens, rolled foam can be used.

Due to its low cost, polyethylene foam is most often used. It is installed with the foil facing the pipes and the insulated side facing the walls. It is best if there is a layer of air under the screen, which will increase heating in the room.

Screens can be used not only as an energy-saving mechanism, but also for thermal protection of furnaces

This is especially important for finishing steam rooms and saunas. The stove is a source of increased fire hazard, so it is important to insulate the walls from excessive overheating

Basalt cardboard is used for thermal protection of furnaces

For such screens, stainless steel and mineralite are used. In accordance with the standards, they are manufactured in several sizes, the edges must be curved at a certain degree, and there must be a natural non-flammable material inside. Usually basalt cardboard is used for this purpose. The heat-reflecting screen is attached behind the stove and on the ceiling. Minerite is installed in two layers. This reduces the distance from the protected surface to the oven.

Front screens in bathhouses began to successfully replace brickwork. In addition, with their help, the temperature rises and adjacent rooms are heated. The thickness of the steel sheet must be at least 0.8mm. A special silicone paint can be used to cover the screens. They are usually assembled from hollow box-shaped elements. There must be a thermal gap between the oven and the screen. Ceramic bushings can be used for fixation.

Aluminum foil is installed under the wooden covering on the walls in the steam room for thermal insulation and increased safety in the room. Next, the lining is installed. The joints between the layers are taped. Aluminum-bitumen tape is used to seal the seams. Convection screens can be used if the temperature of the outer walls of the oven does not exceed 400 o C.

Screens also reduce the effect of wood decomposition in baths and saunas, thanks to protection from wet steam and intense heat. The installation must be carried out strictly opposite the radiation from the stove stones.

Installation features

The screen allows you to retain heat behind the cast iron radiator and pipes. This is where the greatest losses occur. The use of energy-saving installations makes it possible to save up to 10% of heat when heating a room. Thermal resistance increases, the heat from the radiator and pipes remains in the room. During installation, it should be taken into account that the size of the material used must be larger than the radiator.

It is important to pay attention to the location of the battery. If the pipe is in a niche, the thermal insulation layer needs to be thicker

You should also not forget about the type of radiator connection during installation. It can be produced in a one-sided pattern or diagonally. In order to check the material, it is enough to set it on fire - the foil will not melt.

Heat shields for batteries can be attached using a staple gun. In addition to retaining heat, they also protect the walls from moisture penetration. You can install it yourself; you don’t need specialized knowledge; the manufacturer’s instructions are sufficient.

Heat-reflecting screens behind radiators and pipes can be used in residential buildings, country cottages, office and industrial buildings, children's institutions and hospitals. Technically simple installation makes it possible to save energy on heating pipes, protect walls from intense heat in saunas and avoid mold.

Installing films behind radiators - a simple sequence of actions

From a technological point of view, the foil behind the heating battery is installed without any difficulties. You will complete all the work efficiently and quickly if you listen to some advice.

First, don't buy matte metallic material. Use only polished foil.

Second, don't buy double-sided films. One air gap is quite enough to ensure high-quality heat reflection.

Thirdly, leave a gap of about 1.5–2 cm on both sides of the insulator layer. It is necessary to obtain the optimal thermal resistance of the reflector (1.15 sq.m*°C/W).

Prepare liquid nails or standard adhesive used for installing wallpaper, as well as directly reflective foil, and proceed to install it. The procedure is as follows. First, carefully measure the dimensions of the wall areas where you plan to install the screen or niches.

The parameters of the film must correspond to the projection of the heating radiator onto the wall. Add about 10% to the result obtained. In this case, the heat-reflecting potential of the foil will be slightly greater. Some masters say that extra centimeters are not needed.

The effect from them will be insignificant, but the edges of the screen sticking out from behind the radiator will greatly spoil the aesthetics of the room. See for yourself, choose the option that suits you personally.

Then make sure that there is a gap of at least 1.5 cm between the heating device and the film that you will mount. When there is not enough free space, you will have to adjust the radiator suspension to provide the missing centimeters.

Next, remove the radiator. Mark the places where its mounting brackets are located. Dismantle them. Inspect the brick or concrete masonry of the wall surface.

If there are gaps, cracks, or other defects, plaster them (or putty). Level the wall, glue the screen (coat its back side with wallpaper or polymer composition).

Instead of glue, as noted, it is allowed to use liquid nails. In some cases, it is permissible to use staples or small nails to secure the foil (if they fit into the wall material without any problems and are firmly held in it). Carefully return the pendants to their place and install the battery.

Now your home will become warmer!

Additionally, we will give some useful recommendations to home craftsmen who are installing heat-reflecting products for the first time. If during installation of the screen you damage its outer covering, the cut site can be masked with LAMS or LAS films.

They are made of foil and do not reduce the efficiency of heat reflection. Don't try to find screens that are too thick. Practice shows that five centimeters is enough to effectively save heat in the house.

Recommendations for the installation process

- Installing a heat-reflecting screen behind the battery is technologically simple, but will be done faster and better if you take into account the following practical recommendations:

- the maximum effect when using penofol and similar materials is achieved if there is an air gap of 15-20 mm on both sides of the insulating layer. In this case, the thermal resistance of the insulating structure is achieved up to 1.1-1.2 (m∙°C)/W. Installation is carried out on wooden slats, and penofol must be double-sided foil (type B);

- in most cases, to create a reflective screen for batteries, one air gap is enough - between the radiator and the insulating material. Double-sided foiling is not necessary in this case;

- When choosing a reflector, it should be taken into account that the foil must be polished (not matte).

Reflectors for radiators Heating system

» Heating batteries

The heating system includes fasteners, thermostat pipes, an expansion tank, air vents, batteries, collectors, a boiler connection system, and pressure-increasing pumps.

On this page we will try to find and select certain installation components for the desired dacha. Installation of heating a dacha has different elements. All installation elements are very important.

Therefore, the choice of parts of the structure must be done technically correctly.

Reflectors for radiators

Battery reflectors are an energy-saving technology available to any resident of a city apartment. Already now, such brilliant battery reflectors can be seen in Kyiv hospitals, schools and kindergartens.

They return heat from the radiators to the apartments, which is uselessly lost into the wall closest to them.

The foil installed under the battery acts like a thermos - heat is reflected from such surfaces like the sun's rays from a mirror.

The Russian-made material is called “Penofol”, the Ukrainian one is called “Aluf”, there are also a lot of imported reflectors. The basis of the material is aluminum foil, which is attached to a soft foam material with a thickness of 2 to 10 mm.

Head Department of Building Physics and Resource Saving of the Research Institute of Building Structures Gennady Farenyuk told how to best choose a reflector:

— Thanks to Penofol or Alufom, it is possible to save about 5% of room heat (about 1 “extra” degree). Believe me, this is a lot! In 1993, I received a patent specifically for the idea of preserving heat in apartments using this foil material, and now it is installed in several hundred schools as part of an energy saving program.

Ready-made reflectors are not sold in stores, but they are easy to make yourself - you need to buy special material at the market or in a store and cut pieces of suitable size.

“It must be metal foil,” the physicist advised, “it reflects heat better.” Aluminum coating on a lavsan base works much worse. Checking whether it is foil or not is very simple - you need to set the edge of the material on fire with a lighter. If it doesn't melt, it's foil.

The price of a heat reflector depends on the thickness. The material is sold at construction markets and supermarkets.

Removing and preventing the formation of air pockets in the heating system.

One of the main reasons for the deterioration of heating, and sometimes its absence, is the formation of air jams in the heating system of buildings. This causes consumer indignation towards heat supply organizations, sometimes groundless, because At that time, the source of thermal energy was the boiler room, operating in normal mode.

The first reason is that water itself contains dissolved air. If the water heats up, air begins to be released in the form of bubbles that rise to the uppermost sections of the pipelines. It is there that, accumulating, they create air jams.

The second reason is that when the pressure in the heating system decreases or changes, it is partially emptied, and all the resulting voids represent air pockets.

The third reason is that leaks from pipelines also contribute to the “airing” of the system as a whole.

The fourth reason is the repair of the piping system and subsequent assembly. There is no way to avoid the possibility of “airing”.

Practice shows that air most often collects in heating devices installed on the upper floors.

In such cases, at the upper points of the heating system, air is removed through special devices - Mayevsky taps.

Mayevsky crane

When searching for the location of an air lock, tap the pipes and heating devices with a light hammer. Where air pockets are located, the sound becomes stronger and louder.

Air locks can form in places where pipelines are kinked. Therefore, when installing the system, it is necessary to observe the magnitude and direction of the slopes of the distribution pipelines.

Air locks are eliminated by opening the air bleed valves until all air is removed from the system. This method of removing air is repeated several times, especially on contaminated systems.

The news uses materials from the magazine “Miske Gospodarstvo of Ukraine”

Foil insulation BestIzol

BestIzol is a highly reflective heat, steam and sound insulating material made from closed cell polyethylene foam and aluminum foil. The thickness of polyethylene foam, depending on the brand of material, ranges from 2-10 mm, and the thickness of aluminum foil is 7-14 microns.

They produce several modifications of BestIzola:

- BestIzol type A is thermal insulation made of polyethylene foam with one-sided foil coating.

- Type B is thermal insulation that has double-sided foil.

- Type C – thermal insulation with foil on one side, glue with a protective layer of anti-adhesive material is applied on the other side.

BestIzol material is effective for use not only as insulation for residential buildings, but also for thermal insulation of vans, ships, refrigerators, ventilation ducts, and various metal structures.

BestIzol reflective insulation is so light and durable that it can be easily integrated into metal structures by fixing it directly to the frame or framing elements. This avoids the additional costs of constructing temporary structures or gratings to secure the insulation. The additional weight load will be insignificant.

How to solve the problem of noise in an apartment using internal soundproofing of walls? In our article we will tell you all the nuances of this process. What materials to choose for insulating the roof from the inside with foam plastic? Read in this article about the rules for choosing polystyrene foam for various types of roofs.

Criterias of choice

The optimal choice of material for installing a heat-reflecting screen behind a radiator is based on taking into account the distinctive characteristics of insulation materials.

These include:

- type of material: foil, isolon, penofol, foil plastic, Porilex;

- thickness of heat-reflecting fabric;

- density and sound absorption rate;

- thermal conductivity;

- moisture and vapor absorption;

- service life;

- the presence of a self-adhesive base;

- temperature conditions for using the material;

- heat reflectivity;

- manufacturer company;

- cost of material.

Please note: changing the direction of heat flow can help save heating costs.

How to choose the right material for making a heat-reflecting screen?

Thanks to various materials, it is possible to prevent heat loss and ensure high-quality heating of the room. Heat-reflecting screens are made independently. To get the expected result, you need to purchase metal foil; if the material is simply sprayed, it can melt under high temperature. To check this, bring fire to the foil; the material should not melt. The thickness of the selected material should be from 3 millimeters, the joints are covered with special tape on a metallized base. To make the base of such an element, you can use stainless steel, wood, glass or plastic. Plastic is a cheap material, but when heated it can release toxic substances; this should be taken into account when choosing a material. Glass materials can be decorative, that is, with various patterns, they are the most expensive, and at the same time fragile, they can crack under pressure.

Screens made of stainless steel have various advantages:

- they require repair and painting;

- the heat exchange process occurs unhindered;

- the material is environmentally friendly and does not emit toxic substances;

- no deformation occurs when heated.

Screens based on wood are environmentally friendly, have a decorative function, their price depends on the type of material. If you save on material while violating the technology, then the screen elements may crack.

Types of gratings

In addition to its aesthetic functions, a decorative radiator grille must be resistant to long-term temperature loads. This is explained by the duration of the heating season, which lasts about five months.

Currently, gratings are produced from many materials, the most common of which are:

- Glass (transparent, frosted, colored),

- stainless alloy,

Stainless steel grate

- From wood and other lumber,

- MDF - medium density fiberboard,

- Polymers.

As for the cost, the price of plastic grilles is the most affordable.

Important! When purchasing gratings, you need to make sure that they are safe for human health. To do this, ask the seller for a quality certificate

Pay attention to this advice, as there are “handicraft” grilles that are harmful to health

The price of decorative grilles made from MDF will be less than their wooden counterparts.

Grilles made of glass are expensive. They are made from special glass onto which a pattern or ornament is applied. They have advantages in the form of: chemical inertness and beauty. But there is only one drawback, but it is noticeable - poor protective function (possibility of deformation and damage from fragments).

Patterned glass grille

Classification of gratings by design features

- Flat type - good for use in radiator niches,

- Hanging grilles without covers - they are installed on cast iron heating devices under the window sills,

- Hinged grilles with covers - installed on protruding cast iron radiators that protrude under the window sill,

- Box grids are used to cover supply pipes and radiators.

Why use them?

Grilles can be used for the following reasons:

Decorative lattice

- For reasons of beautiful appearance. Thanks to their use, utility networks and structures that previously did not fit into the interior are easily hidden,

- To improve safety, more precisely, to protect against burns. This is a very pressing issue in institutions with large concentrations of children, such as schools, nurseries, kindergartens and others,

Protection of radiators from contamination. In this case, battery care is simple, since there is no access to dust and dirt.

But besides buying a grate in a store, there is another option - making it yourself. Many different manufacturing instructions are freely available on the Internet.

Heat-reflecting screen maximum effect at low costs

In many apartments and residential buildings, heating radiators are mounted under window openings. The section of the wall behind them always heats up the most intensely. Experts say that this part can heat up to 35–40°. Essentially, expensive heat is spent on heating the wall outside the building instead of keeping the temperature in the room as high as possible.

The problem of heat loss can be truly solved in a primitive way - install a heat shield on a section of the wall directly behind the radiator

Even greater heat losses are observed in options when the radiator is installed in a niche. It is thinner than the surface of the walls. This means that cool air enters the rooms in large quantities through it. It is certainly impossible to reconcile with such a state of affairs. No need to. The problem of heat loss can be truly solved in a primitive and elegant way - by installing a heat shield on a section of the wall directly behind the radiator.

The heat-reflecting device we are interested in not only stores heat. Moreover, it protects the batteries from the penetration of dust and moisture particles into them from behind the wall (through small cracks). Visually, factory-made heat-reflecting screens look nice. This allows you to use them to embellish nondescript areas of the wall behind the heating radiators.

Masking of radiators and the laws of heating engineering

The main task of any heating radiator is to heat the room. The goal is achieved by combining or separately using two methods - infrared radiation and convection. Thanks to them, comfortable conditions are formed.

We can feel thermal energy if we place our hand in close proximity to the radiator. Convection ensures air circulation and uniform temperature distribution throughout the room.

The screen for the radiator performs several important functions: it links the device with the design, protects it from damage and settling dust, the combustion of which releases toxins.

It would seem that the task of decorating the radiator was completed successfully, but the room immediately became noticeably colder. This all happened because glass almost completely neutralizes infrared radiation.

An original way to disguise a heating radiator will help to expand the window sill and use the structure as a piece of furniture.

This statement fully applies to blind screens that prevent both long-wave infrared radiation and short-wave convection.

The same can be said about the blind boxes above the top of the radiator - they are an insurmountable barrier to the spread of warm air upward (the convection method does not work). The conclusion suggests itself - the larger the area of the holes in the lining, the smaller the heat loss will be.

Scope of application

Reflective thermal insulation is applicable to all surfaces without dirt and dust, suitable for complex structures with corners, bends and differences. Insulating walls from the outside can achieve maximum effect by creating an air gap of 20 mm on the foil side.

The material is effective for multi-story and single-story frame houses, and it will increase the resistance of the walls without increasing their volume. Installation is carried out end-to-end without overlaps, and the seams are taped with foil tape.

Application from inside

If you want to insulate the room from the inside, then there are two options. The first option is to make 2 air gaps between the external wall and the material, between the insulation and the cladding (for example, drywall). In this case, TIM with double foil is used.

The second option is to create one gap between the external wall and the insulation, for which material foiled on one side is used. The foil is turned indoors.

Roof insulation

Reflective TIMs mounted on the roof provide not only thermal but also vapor insulation. The under-roof space is also protected from moisture.

Reflective film is especially effective when insulating the ceiling of a bathhouse.

Piping and ventilation

Pipes require insulation with double-sided foil. If the pipes have a diameter less than 159 mm, then there is no need to create an air gap between the TIM and the pipe. If the pipes have a larger diameter, then a gap is required. The air gap is arranged as follows:

- The first option is to attach rings made of foil film to the pipe with a distance of 300-400 mm from each other. And on top of the rings the pipe is wrapped with insulation;

- the second option is to lay wooden blocks with a cross-section of 10 by 10 mm or 20 by 20 mm along the pipe, after which insulation is wrapped on top of them.

The joints must be sealed with aluminum tape. Insulating ventilation ducts will eliminate heat loss and provide sound insulation.

Ways to increase heat transfer

From the point of view of releasing the maximum amount of heat into space, it is less effective than a pipe, perhaps a ball. It has an even worse surface to volume ratio.

What did the ancestors do to make these monstrous heating devices warm?

How to increase the heat transfer of a pipe?

Increased infrared radiation from the heating device. Simply painting the register with matte black paint gave a noticeable warming effect in the room. By the way, the current chrome plating of modern bathroom coils looks impressive, but from the point of view of the heat transfer of the device, it is pure idiocy.

The heat transfer of steel pipes can also be increased due to fins welded or otherwise mounted on the outside of the pipe. The final stage of implementation of this method is a convector, a coil of pipe with transverse plates. Of course, in this case, all methods for calculating the heat transfer of a pipe are not applicable - the pipe gives off a smaller portion of the heat in this device.

Comparison of air conditioners when operating for heating

Below are independent results of research and measurements of this coefficient (taking into account defrosting cycles!), which were carried out with some of the highest quality brands of air source heat pumps - Mitsubishi Electric, Panasonic, Gree, Fujitsu. To view, click on the appropriate tab.

Mitsubishi Electric MSZ-FH25VE + Mitsubishi Electric MUZ-FH25VEHZ

Panasonic CS-NE9MKE + CU-NE9MKE

Panasonic CS-HE9LKE + CU-HE9LKE

Gree Hansol 25-A (GWH09TB-S3DNA2D/I) + GWHT09TB-S3DNA1D/O

Mitsubishi Heavy Industries SRK25ZJX + SRK25ZJX-SA

Fujitsu ASYG09LMCB + AOYG09LMCBN

The market leader is Mitsubishi Zubadan. However, you should not believe the marketing and purchase budget models of this brand. They are distinguished from conventional splits mainly by a more powerful compressor. You are unlikely to get normal heating at -25C from them either.

The energy efficiency of real Zubadans, depending on the region of your residence and the average temperature in winter, can be calculated on a convenient online calculator on the Mitsubishi website here.

If COP is not initially indicated anywhere on the device, you can calculate it yourself. To do this, divide the thermal power, which is written on the device nameplate, by the consumed electrical power.

How to choose the power of the air conditioner according to the area of the room, read a separate article.

Glass screen

If wooden screens are well suited for traditional and rustic styles, and metal ones for industrial ones, then glass ones look great in modern interiors, such as high-tech. minimalism, fusion, pop art. It all depends on the decorative processing of the glass.

In principle, you can order self-adhesive film with large format printing for a glass screen. You can also make a design on a matte or transparent surface using sandblasting or paste for chemical etching of glass.

If you don’t want to bother with decorative processing, then glass with a matte surface or painted in bulk is available for sale - you just need to order the desired size, and you can process the edge yourself. The only condition is that the glass must be tempered.

The simplest option for installing a screen is to point-mount the glass to the wall in four places. To do this, use special fittings with remote fastening.

But there is one drawback - you need to drill holes in tempered glass, and this is difficult to do at home.

Therefore, it is better to use a cold-rolled thin-walled pipe as the supporting structure of the screen. It (and fastenings for it and glass) are sold in stores that sell everything necessary for making furniture. As a rule, such pipes and fasteners are made chrome, but you can order them to be painted in any shade from the RAL palette. The screen stands are attached to the floor.

As an additional support for the racks, two remote adjustable fasteners of a closed type (with a plug for the pipe) can be attached to the wall. The glass is secured between the posts using clamps.

Important Features

By choosing modern material, the owner of the premises receives certain advantages. They are largely due to the high characteristics of the insulator itself.

Gaps between the film can be sealed with aluminum tape

When using this solution during the cold season, heat loss is eliminated. In summer, there is no excess thermal energy in the rooms of the building. As a result, a small amount of resources has to be spent on maintaining an optimal microclimate. Reflective insulation works on the principle of a thermos, preventing the penetration of thermal energy along a given vector.

One of the features of foil insulation is its complete waterproofness. This statement is especially true for models made from polyethylene foam. Aluminum foil is not subject to combustion. Therefore, the use of such a layer together with foam plastic or foamed polyethylene provides increased fire safety.

Read also: about non-flammable fireproof insulation.

In terms of physical parameters, reflective insulation has the same properties as the base layer. The material that is created on the basis of foamed polyethylene has the smallest thickness. Models made from mineral wool with the addition of a layer of foil are thicker.

How reflective insulation behaves in fire:

Advantages and disadvantages

Any material used in the construction industry becomes popular if it has a set of unique positive qualities that are in demand among consumers. In the case of reflective type insulation, there is no shortage of them.

Experts highlight the following advantages:

- The material meets hygienic standards, since the main components in its production are polyethylene and foil.

- This solution is able to reflect up to 97% of thermal energy.

- Polyethylene foam, which contains air bubbles in its structure, allows for additional thermal resistance.

- High fireproof properties. Experts classify the material as highly flammable.

- Rolls of reflective insulation are lightweight and compact in size. Therefore, there are no problems with storage, they are convenient to transport.

- When using material to insulate surfaces, heating costs are reduced. The cost savings for the owner of the structure are much higher than with other solutions.

The main disadvantage of reflective insulation is its softness. After installation, finishing work is not carried out using plaster and ordinary wallpaper. Another disadvantage is that easy fastening is only possible when using materials with an adhesive backing.

Other models must be installed using a suitable fastening compound. When a material is nailed to a surface, it reduces its thermal insulation properties. When insulating facade walls, it can only be used as an additional layer, acting as a protection against moisture and reflecting heat.

Convective beam calculation

The thermal calculation of the boiler is carried out in order to determine the volume of thermal energy that the beam is capable of absorbing in order to prevent overheating of the boiler heating surfaces and exceeding the operating parameters of the steam. It is performed by drawing up a heat balance for this heating surface and a heat transfer equation.

Moreover, the second calculation is performed to compare heat indicators. The calculation will be considered reliable in the case when, when comparing two results, the discrepancy in the calculations will not be more than 5%.

Algorithm for calculating CP:

- Using reference data or drawings of the steam boiler, the structural dimensions of the convection shaft of the flue and the gas window are specified.

- The temperature and enthalpy of the gases at the entrance of the first convective beam are taken according to the calculation data of the screen pipes at the exit from the furnace.

- The temperature of the heating medium is taken from the table of saturated steam at the operating pressure of the steam boiler.

- Initially, the first control point is calculated, then the second one is calculated in the same way.

- In the initial calculation of the convective heating surface, 2 temperature parameters at the outlet of the flue are initially taken: 700 C and 400 C.

- Both calculation options are carried out synchronously.

- After performing the calculations, the real temperature of the flue gases downstream of the flue is determined graphically by the amount of heat transfer calculated using the heat balance and heat transfer coefficients at previously accepted temperatures.

Convective heating surfaces of steam boilers play an important role in the process of steam generation. They affect the efficiency of the boiler as a whole, increase its efficiency and reduce thermal emissions into the atmosphere from flue gases.