If you are building a country house or are seriously renovating an existing one, already at the planning stage you need to take care of how the premises will be heated during the cold season.

Correct design of heating systems in private residential construction is a guarantee of winter comfort, rational use of resources and efficient operation of equipment.

In this material we will look at heating systems for a private home, tell you how to choose the best option and show with an example how to properly design a heating system.

Working pressure in the heating system of an apartment building

The page contains information about the working pressure in the heating system of an apartment building: how to control the difference in pipes and radiators, as well as the maximum norm in an autonomous heating system.

For efficient operation of the heating system of a high-rise building, several parameters must simultaneously meet the standard.

Water pressure in the heating system of an apartment building is the main criterion by which they are measured and on which all other components of this rather complex mechanism depend.

Normative references

- GOST 12.1.003−83 SSBT. Noise. General safety requirements.

- GOST 12.1.005−88 SSBT. General sanitary and hygienic requirements for the air in the working area

- GOST 24751–81. Air handling equipment. Nominal cross-sectional dimensions of connections

- GOST 30494–96. Residential and public buildings. Indoor microclimate parameters.

- SNiP 23−01−99*. Construction climatology

- SNiP 23−02−2003. Thermal protection of buildings

- SNiP 23−03−2003. Noise protection.

- SNiP 31−01−2003. Residential multi-apartment buildings. SNiP 31−03−2001 Industrial buildings

- SNiP 41−03−2003. Thermal insulation of equipment and pipelines

- SanPiN 2.2.4.548−96. Hygienic requirements for the microclimate of industrial premises

- SanPiN 2.1.2.1002−00. Sanitary and epidemiological requirements for residential buildings and premises

- NPB 105−03. Determination of categories of premises, buildings and outdoor installations according to explosion and fire hazards

- NPB 239−97. Air ducts. Fire resistance test method

- NPB 241−97. Fire dampers for ventilation systems. Fire resistance test methods

- NPB 250−97. Elevators for transporting fire departments in buildings and structures. General technical requirements

- NPB 253−98. Smoke protection equipment for buildings and structures. Fans. Fire resistance test methods

- PUE. Rules for electrical installations

Types and their meanings

As indicated in the standards and acts for the operation of heating systems, a guaranteed stable pressure in the pipeline allows them to operate as efficiently as possible, providing all apartments with heat, while avoiding unnecessary heat loss.

The working pressure in the heating system of an apartment building combines 3 types:

- Static pressure in the heating of apartment buildings shows how strongly or weakly the coolant presses from the inside onto pipes and radiators. It depends on the height at which the equipment is located.

- Dynamic is the pressure with which water moves through the system.

- The maximum pressure in the heating system of an apartment building (also called “permissible”) indicates what pressure is considered safe for the structure.

There are building codes and regulations (SNiP) that determine whether the pressure in the system is acceptable or exceeds it. If it does not correspond to the accepted indications, this may affect the quality of its work.

Since almost all multi-storey buildings use closed-type heating systems, there are not so many indicators.

The pressure norm in the heating system of an apartment building of any type (Soviet Khrushchev buildings, modern high-rise buildings) is equal to:

- for buildings up to 5 floors - 3-5 atmospheres;

- in nine-story buildings it is 5-7 atm;

- in high-rise buildings from 10 floors - 7-10 atm;

For the heating main, which stretches from the boiler room to the heat consumption systems, the normal pressure is 12 atm.

To equalize the pressure and ensure stable operation of the entire mechanism, a pressure regulator is used in the heating system of an apartment building. This balancing manual valve regulates the amount of coolant with simple turns of the handle, each of which corresponds to a specific water flow. These data are indicated in the instructions supplied with the regulator.

Norms and requirements

Modern apartment buildings can have several types of heating:

- have a central connection from utility companies;

- have your own boiler room and heat source, which further leads to its distribution to the consumer;

- The apartment can have its own independent heating source - gas or electric boiler.

If we are talking about the basic indicator of pressure in a house, such as a “Khrushchev”, then often the pressure level is within 6-9 Atm under ideal conditions. Practice shows that when the resource is exhausted, the efficiency of the heating system drops sharply. At the moment, despite the fact that interfering with the operation of the heating system is strictly prohibited, independent work, repair or replacement of radiators and pipelines, reduction of the nominal diameter of pipes due to rust and deposits - the pressure can drop down to 1-3 atm. Of course, this can be noticed by the temperature of the heating devices, which drops to 30-40 degrees.

Working pressure in the heating system of an apartment building: how to control?

To know whether the pressure in the heating pipes in an apartment building is normal, there are special pressure gauges that can not only indicate deviations, even the most minor ones, but also block the operation of the system.

Since the pressure differs in different sections of the heating main, several such devices need to be installed.

Usually they are mounted:

- at the outlet and inlet of the heating boiler;

- on both sides of the circulation pump;

- on both sides of the filters;

- at points of the system located at different heights (maximum and minimum);

- close to collectors and system branches.

As a rule, in multi-apartment buildings, to facilitate the control of coolant flow, pressure regulators are inserted into the system, which operate on the “before” or “after” principle.

Stage two. Installation of a new pipe

The riser, especially in an apartment building, is a rather complex structure. Before you get started, purchase all the elements of the system.

What will be required at work

To replace a sewer pipe yourself, you will need:

- vertical level;

- plastic pipes ø11 cm;

- liquid soap (it is necessary for easy insertion of pipes into fasteners);

- rubber cuffs;

- silicone sealant;

- clamps;

- tee;

- compensation pipe (in other words, an adapter for connecting cast iron and plastic pipes).

Tools needed for work

Step-by-step instruction

The technology for assembling a new riser is essentially the same as dismantling, only in reverse order.

Step 1. Insert cuffs into both sections of the old pipe.

Installed cuff

Step 2. Then install the adapter on top and the tee on the bottom. Make sure that the joints are as tight as possible, otherwise leaks may occur in the future. To further seal the connections, use silicone sealant.

Compression adapter

Step 3. The new riser must be securely fastened, so the next step is to install the mounting clamps.

Step 3. Next, carry out preliminary installation and fitting of the structure.

Sewer riser assembly

Step 4. Lower the compression adapter into the tee (all connections of this kind require similar adapters). Connect all the pipes in the required places and carry out the final installation of the structure.

Step 5. Attach the new riser using the previously installed clamps.

All that remains is to resume the water supply and check all joints for leaks. As you can see, plugging a sewer pipe and installing a riser is not as complicated a procedure as it might seem at first. Here are some more practical tips regarding installation work.

- If you need to connect plumbing outside the base of the pipe, then the distance at which connections can be made must exceed ten diameters of the main riser.

- Tees with an angle of 90° cannot be used.

- Bends with the same angle cannot be used to connect to horizontal sections of the main line. For this purpose, it is better to take a pair of 45° bends or three 30° bends (depending on specific conditions).

Installed sewer riser

Pressure drops and its regulation

Jumps in coolant pressure in the system are most often indicated by an increase in:

- for severe overheating of water;

- the cross-section of the pipes does not correspond to the standard (smaller than required);

- clogging of pipes and deposits in heating devices;

- presence of air pockets;

- pump performance is higher than required;

- any nodes in the system are blocked.

When decreasing:

- about violation of the integrity of the system and leakage of coolant;

- breakdown or malfunction of the pump;

- may be caused by malfunctions of the safety unit or rupture of the membrane in the expansion tank;

- outflow of coolant from the heating system into the coolant circuit;

- clogging of filters and system pipes.

The pressure drop in the heating system of an apartment building has a bad effect on the performance of its individual components, rendering them inoperable. To avoid such problems, you should use useful devices such as a circulation pump and pressure regulators.

Pipeline requirements

The prescribed standards allow the use of various pipes and pipe fittings that are not prohibited in construction. It is recommended to use products from the same manufacturer and try to avoid direct transitions between polymer and steel pipes.

You cannot lay the pipeline in an uninsulated attic or underground space if the temperature in them can drop below -20 degrees. However, it is permitted to install an expansion tank made of non-combustible materials in the attic.

Pipes must be positioned in such a way that they remain accessible for maintenance and repair. Bricking them into floor and wall structures is permitted only in cases where the operational warranty period exceeds 40 years.

When carrying out hidden installation, it is necessary to provide for the presence of hatches at the connection points. It is recommended to leave polymer pipes open in places where they are not exposed to UV radiation, mechanical damage and other influences. It is impossible to lay lines through partition surfaces without installing non-flammable protective sleeves.

The norm in an autonomous heating system

In the case where autonomous heating is installed in the apartment, the coolant is heated using a boiler , usually of low power. Since the pipeline in a separate apartment is small, it does not require numerous measuring instruments, and normal pressure is considered to be 1.5-2 atmospheres .

During startup and testing of the autonomous system, it is filled with cold water, which, at minimum pressure, gradually warms up, expands and reaches normal. If suddenly in such a design the pressure in the batteries drops, then there is no need to panic, since the reason for this is most often their airiness. It is enough to empty the circuit of excess air, fill it with coolant, and the pressure will automatically reach normal.

To avoid emergency situations when the pressure in the heating radiators of an apartment building rises sharply by at least the permissible 3 atmospheres, you need to install either an expansion tank or a safety valve . If this is not done, the system may depressurize and then it will have to be changed.

In order for the heating system of an apartment building to always have operating pressure, it needs:

- carry out diagnostics;

- clean its elements;

- check the performance of measuring instruments.

Replacing batteries via UC

At the time of an accident (for example, a radiator has leaked), replacing the heating battery lies entirely within the responsibility of the organization, to whose account residents transfer money for maintaining common property and carrying out major repairs. It cannot be said that such a replacement occurs free of charge. Cases of coercion to purchase new devices are not uncommon. It happens that receipts are issued for the cost of work performed.

IMPORTANT! Residents of apartment buildings, regardless of the type of property, do not have to pay anything additional for emergency work. The most unpleasant thing is if the battery replacement process is needed in emergency mode during the heating season. And representatives of the management company will begin to evade their obligations, citing the fact that they have neither time, nor workers, or even radiators themselves

They will remove the old one, install plugs and politely ask you to wait. Moreover, there is no statutory deadline for replacing faulty radiators. In such a situation, it is important to eliminate the cause of the accident. Therefore, in order not to wait for anything, you need to act

And representatives of the management company will begin to evade their obligations, citing the fact that they have neither time, nor workers, or even the radiators themselves. They will remove the old one, install plugs and politely ask you to wait. Moreover, there is no statutory deadline for replacing faulty radiators.

In such a situation, it is important to eliminate the cause of the accident. Therefore, in order not to wait for anything, you need to act

The most unpleasant thing is if the battery replacement process is needed in emergency mode during the heating season. And representatives of the management company will begin to evade their obligations, citing the fact that they have neither time, nor workers, or even the radiators themselves. They will remove the old one, install plugs and politely ask you to wait. Moreover, there is no statutory deadline for replacing faulty radiators.

In such a situation, it is important to eliminate the cause of the accident. Therefore, in order not to wait for anything, you need to act. https://www.youtube.com/embed/GmwS_JMkVcQ

Actions are recorded in writing. All complaints, statements, acts, any other documents accompanying the process must be in 2 copies. First, a contractor is called to draw up a report. Further, the claim, together with the act, is referred to the Criminal Code. The claim must refer to 491 Decree of the Government of the Russian Federation. The 2nd copy must contain the date and signature of the management company employee who accepted the application. This may also take some time. In case of refusal, the Housing Inspectorate, when contacting them, will take control of the situation and the issue will be resolved. We previously wrote about who to complain to about the management company.

Types of pressure in heating pipes

The pressure in the heating pipes allows you to determine how correctly the entire system functions.

Pressure in pipes is usually divided into several types:

- Static (manometric) - physical effect on the walls of the pipeline exerted by the coolant in a calm state. In the summer, when heating systems in houses are not in use, the static pressure can be determined using a pressure gauge.

- Dynamic (working) - water pressure taking into account heating and movement along a closed perimeter. Dynamic pressure is always higher than static pressure due to the expansion of the liquid under the influence of temperature.

- Permissible (maximum) - the maximum possible pressure in the system at which all equipment operates properly.

The prescribed norms and rules regulate what the temperature and humidity indicators in the heating circuit should be.

According to SNiP requirements, the pressure and temperature of hot water in a closed system must be such that the air in the rooms is stably heated to 20-22°C with a relative humidity of 30-45%.

The more floors in the house, the higher the level of static pressure; powerful pumps are used to ensure that the water in the pipes rises evenly to the upper floors.

What should the working pressure be?

Working pressure is the sum of static and dynamic pressure. The safety of the entire heating line depends on its value.

It is important! Normal coolant pressure is a necessary condition for proper and efficient operation of the system. It is necessary to maintain it at the set level so that the temperature in the heated rooms is within the range of acceptable values.

Which SNiPs regulate heating issues?

The federal state enterprise SantekhNIIproekt , with the participation of the Center for Standardization and Standardization Methodology in Construction (FSUE TsNS), developed SNiP 41−01−2003 “Heating, ventilation and air conditioning” to replace the existing SNiP 2.04.05−91. This document was proposed by the Department of Technical Standardization, Standardization and Certification in Construction and Housing and Communal Services of the Gosstroy of Russia. It was adopted on July 26, 2003 and came into force on January 1, 2004.

The provisions of the building codes of this document have legal and technical regulation for heat supply, heating, air conditioning and ventilation systems in the premises of buildings and structures.

The contents of this document begin :

- from introduction;

- Areas of use;

- normative references;

- general links;

Requirements also considered:

- to indoor and outdoor air ;

- heat supply and heating;

- to ventilation, air conditioning and air heating;

- smoke protection in case of fire;

- refrigeration;

- release of air into the atmosphere;

- energy efficiency of buildings;

- power supply and automation;

- space-planning requirements and design solutions;

- water supply and sewerage systems of heating, ventilation and air conditioning.

The appendices discuss all the necessary calculations, coefficients, and permissible deviations from standards for all systems and equipment for them.

Why do pressure changes occur?

Pressure drops in the heating system - in the supply and outlet sections, on the upper and lower floors - arise for various reasons. Errors in design, defective equipment, natural wear and tear, non-compliance of operating conditions with design parameters, mechanical damage - all this leads to a violation of the technical parameters of the system.

The most common causes of fluctuations:

- leaks due to pipe ruptures or depressurization of connections;

- air pockets in various parts of the system;

- boiling of the coolant due to errors in design and operation.

Water leaks can occur due to the natural wear and tear of pipes and equipment, as well as due to a constant increase in operating pressure beyond the permissible parameters for the equipment. For example, residents in one of the apartments replaced standard heating radiators with new ones, without taking into account the design values. Having removed standard cast iron batteries and installed lighter bimetallic ones, after a while the owners discover leaks, because... The water pressure is too high for this type of radiator.

Airing of the system is another common phenomenon in which the oxygen contained in the water forms plugs (as a rule, in the areas where the riser passes to the batteries, in places where pipes turn). A characteristic sign of air pollution is the sound of water in the pipes.

Modern heating systems provide special engineering equipment (air valves, Mayevsky taps) to release air, which makes it easy to eliminate air pollution without the help of housing and communal services workers.

Boiling of the coolant is the most undesirable and dangerous scenario. Occurs for several reasons: due to too much boiler power, design errors, malfunction of the circulation pump, clogged water filters and in too narrow areas of the system.

It is important! Boiling coolant is fraught with water hammer - a sudden surge in pressure, which can lead to an emergency.

Sanitary rules and regulations

These developed requirements (SanPiN for heating) are applied in accordance with Russian legislation. They provide for mandatory standards in terms of epidemiology and sanitation when determining living conditions in residential buildings.

Sanitary rules must be observed when building a house

They, together with the requirements of SNiP, are observed when designing houses, reconstructing buildings, constructing a new one and operating an old multi-storey sector. The implementation of the order is monitored by sanitary and epidemiological authorities.

In accordance with the provisions of legislative documents for the microclimate, air ventilation and heating systems, there are the following requirements:

- The highways regulate the permissible atmosphere in housing.

- They ensure constant and uniform heating of the internal air during the entire heating season without interference, the appearance of odors and the release of harmful components.

- The heating of their surface does not exceed +90°C; areas with temperatures above +75°C are subject to thermal insulation.

- Autonomous boiler houses are created subject to compliance with indoor air hygiene and noise standards.

Natural air outflow through windows and vents is provided in the premises or occurs through ventilation ducts. Flows into neighboring apartments are not allowed. It is allowed to include the exhaust of atmosphere from administrative premises into the general ventilation trunk if there are no harmful components in them.

More information about autonomous heating:

In recent years, construction has been constantly evolving. Modern architectural and planning solutions are aimed at achieving maximum comfort for residents. An important part of the construction of buildings is the arrangement of a reliable heating system, which has a number of requirements.

The rules for the design and installation of heating systems are described in many different SNiPs. You can find out more detailed information in the following versions of documents:

- 2.04.05-91 - describes the fire safety requirements that apply to heating systems, air conditioning and ventilation

- 41-01-2003 – contains environmental, sanitary and fire safety standards for heating systems

Leak test and pressure test

The coolant pressure test is used to test the integrity of a closed circuit in order to detect and repair leaks.

The leak test is called pressure testing, during which water or air is pumped into the system until the pressure on the pressure gauge reaches the maximum permissible value.

In apartment buildings, pressure testing is carried out as part of commissioning work before putting the house into operation, as well as before the start of the new heating season.

The leak test takes place in two stages:

- The pipes are filled with cold water, then the pressure gauges are checked. If the achieved operating pressure parameter remains unchanged for 30 minutes, then the system is considered ready for commissioning. A pressure reduction of no more than 0.06 MPa is allowed during a half-hour test.

- After the cold water is drained, hot water is run into the pipes.

Important! If at the first stage the pressure on the pressure gauge drops below the permissible values, this indicates a leak. In this case, the pipes cannot be filled with hot water and the system cannot be put into operation. You need to find the leak and perform local repairs, and then repeat the leak test again.

Who pays for the stages of work to replace heating radiators in an apartment?

Today in our country there is a document called “MDK 2-04.2004 “Methodological manual for the maintenance and repair of housing stock” (approved by order of the State Construction Committee of the Russian Federation of 2004).”

This Manual clearly states who and in what cases should pay for certain types of work. As for replacing heating units, there are two options: if you decide to replace old (existing) radiators with more modern ones, then this, in accordance with the Manual, is regarded as unscheduled work, which means the consumer will have to pay for the production of such. The same applies to situations from the category “poor heating”, etc. Management companies are obliged to closely monitor the heat supply of the house, which in turn must comply with established standards. Everything else, within acceptable limits, is at the expense of the tenant. And there's nothing you can do about it.

As for replacing emergency or failed radiators, plus eliminating all kinds of leaks and other things, this is the direct responsibility of the management company. Such work should be carried out free of charge. That is why, if you contact the management company, you need to clearly know the reason for the replacement. Very often management companies avoid responsibility, saying that this case is not their responsibility. Or they rush to draw up estimates for paid work. In this case, the owner can file a complaint with the Housing Inspectorate. The complaint should indicate that the responsible persons refuse to fulfill their direct duties. Measures will be taken as soon as possible.

How to deal with pressure changes in an apartment and a private house

Only owners of private houses who have access to working equipment can prevent pressure drops on their own.

In city apartments, residents have virtually no influence on the operation of the system. All they can do is change the pipes and batteries in their apartment by installing Mayevsky taps or air valves with automatic air release.

In a private home, pressure drops can be dealt with using systematic measures:

- regularly checking the indicators of measuring instruments at the supply and discharge sections;

- filling the system with an additional volume of water when the pressure level is insufficient;

- installation of modern engineering equipment - control valves, air vents - providing automatic correction of operating parameters.

Ideally, you need to take care of stable pressure in the system at the design stage. With the correct choice of diameter and length of pipes, boiler and pumping equipment, operational problems should not arise. It is very important to entrust the design and installation of the heating system to professional design engineers.

General provisions

4.1. Buildings and structures must provide :

- compliance with the standards of meteorological conditions and air purity in the serviced premises of residential and public buildings (hereinafter referred to as administrative buildings) in accordance with the current requirements of GOST 3034, SanPiN 2.1.2.1002;

- compliance with the standards of meteorological conditions and air purity in the serviced work areas of production and laboratory premises, the requirements of GOST 12.1.005 (SanPiN);

- compliance with standards for noise and vibration of operating equipment and heat supply systems, heating, air conditioning, as well as noise from external sources (SNiP 23−03). GOST 12.1.003 allows noise of 110 dBA, with impulse noise of 125 dBA for the operation of emergency ventilation systems and smoke protection systems;

- protecting the atmosphere from harmful substances emitted by ventilation;

- maintainability of systems such as ventilation, air conditioning, heating;

- explosion and fire safety systems .

4.2. Materials used in heating and ventilation equipment systems, air ducts, pipelines and thermal insulation structures must be used from those permitted in construction.

4.3. Reconstruction and technical re-equipment of operating enterprises, residential, public and administrative buildings and household buildings allows the use of existing heating, ventilation and air conditioning systems if they meet technical and economic standards.

Central heating system pressure

High pressure in the central heating system of an apartment building is necessary in order to raise the coolant to the upper floors. In high-rise buildings, circulation occurs from top to bottom. Supply is carried out by boiler houses using blowers. These are electric pumps that disperse hot water. The pressure gauge reading on the return flow depends on the height of the building. Knowing what pressure is expected in the heating system of a multi-story building, the appropriate equipment is selected. For a nine-story building, this figure will be approximately three atmospheres. The calculation is based on the fact that one atmosphere raises the flow by ten meters. The ceiling height is approximately 2.75 m. We will also take into account a five-meter gap to the basement and technical floor. Based on this calculation, you can find out what the pressure should be in the heating system of a multi-story building of any height.

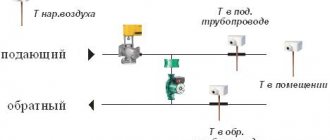

Temperature and pressure distribution in the elevator unit of an apartment building

The central city and housing and communal networks are separated by elevators. An elevator is a unit through which coolant is supplied to the heating system of a high-rise building. It mixes the supply and return flow, depending on the pressure required for heating an apartment building. The elevator design includes a mixing chamber with an adjustable opening. It's called a nozzle. Adjusting the nozzle allows you to change the temperature and pressure in the heating system of a multi-story building. The hot water in the mixing chamber mixes with the water from the return flow and draws it into a new cycle. By changing the size of the nozzle opening, you can reduce or increase the amount of hot water. This will lead to a change in temperature in apartment radiators and a change in pressure. The temperature in the heating system of the house at the entrance is 90 degrees.

Rules for installation work

Work can only begin when all water has been drained from the risers and heating system. To do this, you will need to close the valves in the basement of your house. If you did everything correctly, then when you open the water drain valve in your apartment, you will hear a characteristic noise from the air inside the system and all the remaining coolant will leave the heating system. Now you can start replacing the pipes in the apartment. The installation sequence will be described taking into account the fact that you have chosen a galvanized pipe.

Thread cutting. At the very beginning, we cut the riser using a hacksaw or a small grinder with a metal disc installed. If you are going to replace all the risers along with the heating system, then you cannot do without a preliminary agreement on joint work. The order of cutting threads using a die must be done in the following sequence. First of all, you will need to remove a small chamfer on the pipe so that you can install the die without any problems. If the pipe has been painted, be sure to remove the paint before cutting the thread. Having installed the die in the holder, we begin to slowly scroll it with little effort. It is recommended to make two or three turns forward and then half a turn back. The pipe should be held with a wrench to prevent it from rotating with the die. The thread length must be at least five turns so that the fitting or coupling can be connected to the pipe without problems.

Installation of liners and risers

When working with galvanized pipe, special attention must be paid to sizing. When installing fittings made of brass or cast iron, you should not be too zealous, as this is a very fragile material

You will definitely need to use a winder. This can be a special sanitary linen or polymer material. To prevent it from fading during operation, it is recommended to apply a small layer of silicone sealant, drying oil or paint to the threads. If you plan to install shut-off valves for each heating device, which will allow, if necessary, to replace it without shutting down the entire heating system, then this must be done using a jumper. It is best to use modern ball valves.

Pressure testing of the heating system and its startup. After completing the work, you will need to remove air from the system and check the pressure. How can this be done at home? To do this, you will need to close the valves on the heating devices. Then, closing the water outlet, slowly fill the system to avoid possible water hammer. As soon as the noise of incoming water stops, open the second valve and you can begin inspecting the heating system for possible leaks. Excess air can be vented using a Mayevsky tap on the upper floors.

Thus, if everything is done correctly and consistently, you can replace the heating pipes in the apartment yourself, without the help of a specialist. However, if you still decide to turn to the masters of their craft, we recommend this company!

Causes of pressure drops in the heating of an apartment building

The return pressure in the heating of apartment buildings is lower than the supply. The normal deviation is two bars. In normal operation, boiler rooms supply coolant to the system with a pressure of more than seven bar. The heating system of a high-rise building reaches about six bar. The flow is affected by hydraulic resistance, as well as branches in housing and communal networks. On the return line the pressure gauge will show four bars. The pressure drop in the heating of an apartment building can be caused by:

- air lock;

- leak;

- failure of system elements.

In practice, differences often occur. The water pressure in the heating system of an apartment building largely depends on the internal diameter of the pipes and the temperature of the coolant. Technical marking of nominal diameter - DU. For spills, pipes with a nominal bore of 60–88.5 mm are used, for risers – 26.8–33.5 mm.

Important! The pipes connecting the heating radiators and the riser must be of the same cross-section. Also, the supply and return must be connected to each other up to the battery.

The most important thing is that the apartment is warm. The hotter the water in the radiators, the higher the pressure in the central heating system of an apartment building. The return temperature is also higher. For stable operation of the heating system, the water from the return cycle pipe must be at a fixed temperature.

Plastic water pipes

Sewage pipes made of polymers appeared in apartments only at the turn of the 20th and 21st centuries. It was at this time that an industrial method for the polymerization of organic substances was created, with the help of which the following types of structural polymers were created:

- Polyethylene is the purest type of plastic, suitable for the construction of drinking water pipelines.

- Polypropylene is a plastic with high heat resistance and high ring rigidity.

- Polyvinyl chloride is a material with excellent structural rigidity and an excellent ratio between wall thickness and product diameter, guaranteeing a high level of throughput.

In addition to the above-mentioned types of sewer pipes, water supply systems made of metal-plastic have now appeared, which are a structural material that includes layers of metal (aluminum foil) and plastic (polypropylene, polyethylene).

The properties of fittings and water pipes depend on a number of factors, including parameters of the transported medium, characteristics of the external environment, and others. Of course, the structural materials of the pipes have the greatest influence on the properties of the pipeline system. After all, the ability of pipelines to resist internal and external influences depends only on them.

In this article we will look at the characteristics of all materials used for the production of pipes and touch on their positive and negative qualities.

Elimination of differences

Elevator nozzle design

When the return flow temperature decreases and the pressure in the heating pipes in an apartment building changes, the diameter of the elevator nozzle is adjusted. If necessary, it is drilled out. This procedure must be agreed upon with the company providing the service (CHP or boiler house). Amateur activities should not be allowed. In extreme situations, when the system is at risk of defrosting, the adjustment mechanism can be completely removed from the elevator. In this case, the coolant enters the communications of the house without hindrance. Such manipulations lead to a decrease in pressure in the central heating system and a significant increase in temperature, up to 20 degrees. Such an increase can be dangerous for the heating system of the house and city networks as a whole.

An increase in the temperature of the working medium from the return flow is associated with an increase in the diameter of the nozzle, which leads to a decrease in pressure in the heating of apartment buildings. In order to lower the temperature, it should be reduced. You can't do without welding work here. Then a new hole is drilled with a smaller diameter drill. This will reduce the amount of hot water in the elevator mixing chamber. This manipulation is carried out after stopping the circulation of the coolant. If there is an urgent need, without stopping the system, to reduce the return temperature, the valves are partially closed. But this can have consequences. Metal shut-off valves create a barrier to the coolant. As a result, pressure and friction force increase. This increases wear on the valves. If it reaches a critical level, the damper may break away from the regulator and completely block the flow.

Features of the horizontal pipe laying scheme

Scheme of horizontal heating in a two-story house

In the overwhelming majority, a horizontal two-pipe heating system with bottom wiring is installed in one or two-story private houses. But, in addition, it can be used to connect to centralized heating. A feature of such a system is the horizontal arrangement of the main and return (for two-pipe) lines.

When choosing this piping system, it is necessary to take into account the nuances of connecting to various types of heating.

Central horizontal heating

To draw up an engineering diagram, you should be guided by SNiP 41–01–2003. It states that the horizontal distribution of the heating system must ensure not only proper circulation of the coolant, but also ensure its metering. For this purpose, two risers are installed in apartment buildings - with hot water and for receiving cooled liquid. A calculation of a horizontal two-pipe heating system, which includes the installation of a heat meter, is required. It is installed on the inlet pipe immediately after connecting the pipe to the riser.

In addition, hydraulic resistance in certain sections of the highway is taken into account

This is important, since the horizontal distribution of the heating system will only work effectively if the appropriate coolant pressure is maintained

In most cases, for multi-apartment buildings, a single-pipe horizontal heating system with bottom wiring is installed. Therefore, when choosing the number of sections in radiators, you need to take into account their distance from the central distribution riser. The farther the battery is located, the larger its area should be.

Autonomous horizontal heating

Heating with natural circulation

In a private house or apartment without a connection to the central heating supply, a horizontal heating system with bottom wiring is most often chosen. However, it is necessary to take into account the operating mode - with natural circulation or forced under pressure. In the first case, a vertical riser is installed immediately from the boiler to which the horizontal sections are connected.

The advantages of this arrangement for maintaining a comfortable temperature level include the following:

- Minimum costs for purchasing consumables. In particular, a horizontal single-pipe heating system with natural circulation does not include a circulation pump, a membrane expansion tank and protective fittings - air vents;

- Reliability of operation. Since the pressure in the pipes is equal to atmospheric pressure, the excess temperature is compensated using an expansion tank.

But there are also disadvantages to be noted. The main one is the inertia of the system. Even a well-designed horizontal single-pipe heating system for a two-story house with natural circulation will not be able to quickly heat the premises. This is explained by the fact that the heating network begins to move only after reaching a certain temperature. For houses with a large area (from 150 sq. m.) and with two floors or more, a horizontal heating system with bottom wiring and forced circulation of liquid is recommended.

Heating with forced circulation and horizontal pipes

Unlike the scheme described above, there is no need to make a riser for forced circulation. The coolant pressure in a horizontal two-pipe heating system with bottom wiring is created using a circulation pump. This is reflected in improved performance:

- Quick distribution of hot water throughout the entire line;

- Possibility of adjusting the volume of coolant for each radiator (only for a two-pipe system);

- A smaller area is required for installation since there is no distribution riser.

In turn, horizontal wiring of the heating system can be combined with a collector one. This is relevant for long-distance pipelines. This way you can achieve even distribution of hot water throughout all rooms of the house.

When calculating a horizontal two-pipe heating system, it is necessary to take into account the rotary units; it is in these places that the hydraulic pressure losses are greatest.

Features of autonomous heating

The normal value for a closed circuit is 1.5 -2.0 bar, which is much different from the pressure in the central heating pipes. The reason for the decrease may be:

- depressurization - when a leak or microcracks appear through which water can escape. Visually this may not be noticeable, since a small amount of water has time to evaporate;

- decrease in coolant temperature. The lower the temperature of the water, the less its expansion;

- the presence of autonomous pressure regulators that bleed air. They are installed to remove air pockets. Often leak;

- change in the radius of the pipe diameter. When heated, plastic pipes can change their geometry - they become wider.

Not only the circulation of the coolant, but also the serviceability of the equipment depends on the pressure in the heating system. To prevent a decrease and increase in pressure in any part of the system, an expansion tank is installed. This is a metal container with a rubber membrane inside. The membrane divides the tank into two chambers: with water and air. There is a valve at the top through which air escapes when the pressure is extreme. This can occur due to excessive heating of the liquid. After the water cools and decreases in volume, the pressure in the system will not be enough, because the air has escaped. The volume of the expansion tank is calculated based on the total volume of coolant in the system.

Starting the heating riser

Regardless of how many heating risers there are in the apartment, the operation for starting them always remains the same:

- first the design is pressure tested;

- Next, water is pumped into the radiators and the riser is checked for leaks (for more details: “Start the heating - we start the system according to the rules”).

So, the pressure is checked according to the following algorithm:

A valve opens on the jumper, and its two analogues overlap on the way to the radiator

This allows stress to be removed from some threads while fully testing the remaining threads. The plugs are screwed in or the vents located in the basement are blocked. The valve on the replaced riser opens slightly. It is important to remember that if screw valves are installed, then it is necessary to open only the one that is mounted with an arrow from the filling to the dwellings. You will have to open it this way because if you do it differently, you can tear out the valve. After water stops actively circulating in the area of the slightly open valve, we can assume that the pressure has stabilized

After this, you can open both valves completely. Next, you need to return to the apartment and slowly open the remaining two valves to avoid the consequences of water hammer. After filling the radiator with water, you should inspect all joints for water leaks.

Having completed the pressure procedures, it will be necessary to bleed the air from the radiator and here, as in the previous case, you will need to perform a certain sequence of actions:

- If the house has a bottom bottling, then in the apartment on the floor above you should open the Mayevsky tap, located on the jumper between the risers. After waiting for the water to flow, you should not immediately stop the activity, since the air may not come out immediately and remain in the water as bubbles, so you should wait a little.

- If the riser begins to warm up, then we can safely say that the operation to turn it on is completed.

How to replace a heating riser in an apartment, see the example in the video:

Radiator selection

It is important to choose the optimal radiator for the heating system

The temperature in the house also depends on the efficiency of the radiators. Manufacturers offer batteries from the following materials:

Each material determines the operating pressure of the radiator, its thermal power and heat transfer coefficient. Before purchasing batteries, you should ask the housing office what pressure is in the central heating. In a private house and in a high-rise building, the pressure is different:

- in private up to 3 bar;

- The operating pressure in the heating system of an apartment building is 10 bar.

In addition, you need to take into account periodic reliability checks of the heating system, so-called water hammer.

Pipes and radiators are checked in order to find out what pressure is in the heating in the apartment, to identify blockages, weak points and leaks. To remove dirt from the pipes, you need to close the valve and drain the water. Then dial in the full system and repeat the procedure. The use of special products with high acidity is allowed. This will require equipment. To find a leak or weak point in the heating system of a multi-storey building, you need to increase the pressure to 10 bar. If any connection cannot withstand this load, it should be strengthened or replaced. It is better to detect weak areas as a result of water hammer in the summer. Since it is much more difficult to perform this kind of work in winter. This is due to the short period of time during which the system can defrost.

General provisions

Documents for re-equipment and technical reconstruction use technical and economic justification and provide descriptions of existing heating, ventilation, and cleaning systems. All informative indicators must meet the requirements of SNiP heating systems.

In documents for house reconstruction, all informative indicators must meet certain requirements

The projects provide solutions that provide:

- Compliance with meteorological conditions to ensure the cleanliness of the atmosphere in the serviced area when supplying heat to residential buildings.

- Maintaining the same standards for laboratories, warehouses, production workshops and other premises of various categories.

- Regulation of vibration and noise during the operation of heating systems, air conditioning and ventilation pipelines, smoke protection units (in rooms with such equipment, noise not exceeding 110 dB is allowed, pulse waves should not exceed 125 dB).

- Monitoring the condition and the possibility of repairing systematized pipelines.

- Collection of information about the risk of explosion and fire of pipeline elements, insulation and other structural materials.

In this video about how to install gas in a house:

Pipeline requirements

For the manufacture of ventilation and air ducts, anti-corrosion materials or surface treatment with special protective coatings are used. This is especially true for equipment and pipelines designed to remove air containing aggressive components or operating in such an environment. The components of the lines are made of steel, copper, brass, heat-resistant plastic, fiberglass. The connecting elements are made of similar material.

Heating and ventilation devices, the area of which heats up and causes the ignition of vapors and gases, are insulated. Their operation is permitted if the surface temperature is 20% less than the critical fire indicators. If it is impossible to reduce the temperature to the standard level, pipelines and equipment should not be placed in hazardous areas.

Non-standard sections of pipelines and air ducts are made from materials approved for use in the construction industry. When designing the structures of thermal insulation lines, they are guided by the provisions for heating SNiP 2.04.14-1988. Polymer pipes must have an inner layer of anti-diffusion material.

Insulation against heat loss should be provided where necessary

Insulation against heat loss is provided in those parts of the pipeline where water can freeze. Protection is also done in case of overheating of the pipe walls to prevent burns or the formation of excessive condensation. Use insulating materials with calculated standard thermal conductivity and thickness. At external walls and in unheated rooms, no more than 7% of the energy of the total heat flow of the system should leak away. Water supply and sewerage are laid separately from the heating center and the general heating pipeline.

Design air conditions

In the service areas of residential premises, meteorological conditions are adopted in accordance with the standards of Appendix 1 in the text of SNiP for heating an apartment building (except for special zones, the operating conditions in which are considered by other papers).

Ventilation snip norms

During construction, technical supervision is responsible

on the part of the customer, production supervision on the part of the organization performing the work, and specialists who developed the project as designer’s supervision. For ease of understanding, all regulatory documents for ventilation systems of a multi-storey residential building can be divided into two groups:

A. Mandatory regulatory documents of the Gosstroy of Russia,

The Government of Moscow and the administrations of the constituent entities of the Russian Federation and regulatory documents of the State Fire Service of the Ministry of Emergency Situations of Russia. Basic list.

Rulebooks:

SP 60.13330.2012 “Heating, ventilation and air conditioning. Updated edition"

SNiP 41-01-2003" is fundamental for the development of building air systems. In addition to the basic general requirements, it contains calculation formulas for calculating air and requirements for the thickness of air ducts.

SP 7.13130.2013 “Heating, ventilation and air conditioning. Fire safety requirements” is a standard that reflects the conditions for ensuring fire safety.

SP 54.13330.2016 “Residential multi-apartment buildings. The updated version of SNiP 31-01-2003" does not apply to semi-detached residential buildings, which are subject to the design requirements of individual (private) single-apartment houses.

SP 73.13330.2016 “Internal sanitary systems of buildings. Updated version of SNiP 3.05.01-85.” This code of practice applies to construction work. The necessary stages, installation technology are described, and includes a list of final documentation based on the results of the work.

State standards:

GOST 30494-2011 “Residential and public buildings. Indoor microclimate parameters"

GOST 21.602-2016 “System of design documentation for construction. Rules for the execution of working documentation for heating, ventilation and air conditioning systems

Sanitary norms and rules:

SanPiN 2.1.2.2645-10 “Sanitary and epidemiological requirements for living conditions in residential buildings and premises”

B. Optional

– in them you can find system options, their features and calculations. These recommendations or guidelines are created by engineering communities. They are based on mandatory documents, but cover more broadly the issues of creating a comfortable air environment. Describe a calculation method for determining the required volumes of air based on released pollutants. They provide methods for achieving the most efficient and stable operation of systems.

R NP "AVOK" 5.2-2012 Technical recommendations for organizing air exchange in apartments of residential buildings. STO NP “ABOK” 2.1-2008 “Residential and public buildings. Air exchange standards"

For premises that do not belong to the main functionality of the facility, additional standards apply

, suitable for their purpose.

The above standards reflect all essential issues, including the safety of operation of ventilation systems. And with any intervention in systems after construction, be sure to check their compliance with current specialized standards.

DHW circulation

Circulation in the DHW system can be ensured:

- The pressure difference between the threads of the heating main;

- The difference created by the throttling washer on one thread of the elevator unit. In this case, the DHW is switched on according to the “from supply to supply” or “from return to return” schemes;

- Circulation pump. This method is typical for hot water supply in buildings with a closed heating circuit and for private houses.

Scheme of autonomous hot water supply with recirculation

Free heat from hot water supply

Can heating and cooling be powered from an apartment building's water supply? After all, such a scheme should provide the apartment with free heating and air conditioning, right?

It is quite possible to power the heating radiator in the bathroom from the hot water riser. Moreover: in some pre-war Stalin buildings, this solution was implemented by the builders.

Cast iron radiator in a Stalin bathroom

A caveat: for round-the-clock operation of the heating device, the hot water supply system must be circulating. In a dead-end system, the radiator will heat up only when water is drawn from your apartment or the apartment located higher up the riser.

But it will not be possible to implement an air conditioning system based on a cold water riser. The reason is simple and obvious: all cold water supply systems are dead-end.

Water with a lower temperature compared to the air will flow into the riser only when drawing water, and a fan coil unit connected to the riser will be able to cool the room with any efficiency for no more than an hour a day.

Water heating of industrial premises

If the enterprise will use a water heating system, for its installation it is necessary to build a special boiler room, lay a pipeline system and install heating radiators in the production premises. In addition to the main elements, the system also includes means of ensuring operability, such as shut-off valves, pressure gauges, etc. To maintain the water heating system of industrial premises, it is necessary to constantly maintain special personnel.

According to the principle of its design, water heating of industrial premises can be:

- single-pipe - water temperature control is impossible here, since all heating radiators for industrial premises are installed in series;

- two-pipe - temperature control is permissible and is carried out using thermostats on radiators installed in parallel.

Heat generators for a water heating system are heating boilers. Depending on the type of fuel consumed, they are: gas, liquid fuel, solid fuel, electric, combined. For heating small industrial premises, stoves with a water circuit are used.

You need to choose the type of boiler based on the needs and capabilities of a particular enterprise. For example, the ability to connect to a gas main will be an incentive to purchase a gas boiler. In the absence of natural gas, preference is given to a diesel or improved solid fuel unit. Electric heating boilers for industrial premises are used quite often, but only in small buildings.

At the height of the heating season, failures or accidents may occur in the gas and electricity supply systems, so it is advisable to have an alternative heating unit at the enterprise.

Combination boilers for heating industrial premises are much more expensive, but they are equipped with several types of burners: gas-wood, gas-diesel, and even gas-diesel-electricity.