Every person planning to create or update a heating system is interested in which radiators to use for this. The choice is really huge, but if you don’t know the features and key criteria, you can waste your money. Recently, you can increasingly hear about copper heating radiators. What is their advantage? This is what we will try to find out in this article.

- 1 Comparative review of popular models

- 2 Copper radiators

- 3 Main technical characteristics

- 4 Design features of copper batteries

- 5 Main advantages of copper batteries

- 6 Features of device operation

- 7 What to look for when buying?

Pressure (working and test)

The coolant pressure in the heating system is formed by adding the hydrostatic pressure of the liquid inside the system and the hydrodynamic pressure that is formed when the liquid moves through pipelines and heating devices.

This pressure is called working pressure. The operating instructions regulate before starting the heating system after installation, repair, or at the beginning of the heating season, to carry out pressure testing - testing the entire heating system by creating excess pressure in it (this can be done with your own hands). Thus, various malfunctions and leaks in pipelines and radiators are identified.

As is known, in central heating systems, the pressure inside the heating systems is several times higher than in individual or autonomous systems. In multi-storey buildings, the pressure in the networks reaches 10 atmospheres, and in high-rise buildings - up to 20 atmospheres. Therefore, devices must withstand such pressures.

Operating pressure of heating devices (test in brackets) - atmospheres

- cast iron battery – 10 (15);

- steel panel radiator – 9 (13);

- aluminum radiator – 15 (22);

- bimetallic – 20 (25);

- copper - aluminum radiator - 17 (24).

Resistance to water hammer

Another factor that should be taken into account is water hammer, in which the pressure increases abruptly. In this case, the working pressure is exceeded many times

Naturally, in this case, heating devices fail, pipelines are destroyed, and other elements are damaged.

MA radiators

Principle of operation

The temperature in copper radiators quickly rises and warms up the room.

Radiators are the part of the heating system responsible for heat transfer. The liquid circulating in the circuit is heated in the boiler. It flows through the pipeline into the batteries. High water temperature causes the metal to heat up. Copper has high thermal conductivity, an indicator that exceeds the characteristics of steel several times. The operation of radiators is based on physical processes:

- Thermal conductivity is the transfer of energy from heated bodies to colder ones. Pure copper, which is used in the production of batteries, has an indicator of 401 W/(m*K). This is one of the highest values among metals.

- Thermal radiation - hot metal emits infrared waves.

- Convection is the transfer of heat by air flow. Cold air masses pass through the radiator, their temperature rises. The heated flow rises to the ceiling. Heavy cold air takes its place, making the process continuous.

The copper radiator has high efficiency. Its characteristics ensure a rapid increase in room temperature.

Characteristics of copper radiators

Copper radiators are devices made of amazing metal. It does not corrode, prevents the proliferation of microorganisms, and is also not afraid of chemical reactions. Over time, a thin protective layer forms on the surface of the inner walls, which prevents damage to the material, but it is not able to reduce the thermal conductivity and diameter of the product. The surface of the heat exchangers remains smooth, scale does not form on them and no deposits remain.

If we compare copper radiators with products made from other materials, the former are superior to the others in terms of efficiency and thermal conductivity. The latter parameter is 5 times higher compared to steel and cast iron, but it exceeds the performance of popular aluminum by 4 times.

Copper devices have unique performance characteristics, so they can be installed in not only central but also autonomous heating systems. The coolant that circulates inside the system can reach a maximum temperature of 150 °C; as for the operating pressure, it can reach up to 16 atmospheres. It is noteworthy that the radiators described in the article can be used in steam and liquid heating.

Technical and operational characteristics

Copper equipment has unique characteristics, so it can be installed not only in autonomous heating systems, but also in central ones. It is noteworthy that some models of copper heaters can be used for heating with both liquid and steam.

| Technical and operational characteristics | Range of values of existing models |

| Heat output (thermal power), kW | 0,1 — 2,195 |

| Working pressure, bar | 14-16 |

| Test pressure, bar | 20-50 |

| Required volume of coolant in the radiator, l | 0,26-4,81 |

| Maximum operating temperature, °C | 110-150 |

| Heated room area, m2 | 2-23 |

| Weight, kg | 1,6-22,6 |

| Warranty period, years | 20-25 |

| Service life, years | 35-50 |

| Connection type | Side, bottom |

| Thread of holes for connection to heating mains, inches | G ½, ¾ |

Heat transfer from heating radiators Comparison of indicators and calculation methods

Important advantages of copper batteries relative to analogues from other metals

If you do not look at the high price, taking into account the high cost as the main disadvantage, then it must be recognized that copper heating radiators have a number of positive properties. Those who are little interested in the “price of the issue”, but are willing to pay for high quality and durable operation (without additional maintenance), choose heating equipment made of copper.

High heat transfer from copper guarantees quick heating of the room

When producing modern heating equipment, only high-quality copper is used. Impurities in the form of inclusions of other metals - up to 0.1-0.2%. This cleanliness ensures high-quality soldering during installation and minimizes corrosion processes when using any device.

The main advantages of copper heating devices:

adapted to the conditions of urban heating networks and the private sector in terms of total load and internal pressure; with technological installation, they will last 2-3 generations (40-60 years), which is confirmed by the experience of Western construction companies); high heat transfer of copper – a guarantee of rapid heating of the room when heating is started; the good indicator of metal inertia makes it possible to use thermostats after heating and maintain heat in the room for a long time naturally; with small dimensions, they give off the same amount of calories as impressive cast-iron “accordions” with a large weight; even the simplest design (a tube with fins without convection plates) provides rapid heating with a small volume of coolant, which is important in a closed circuit using expensive antifreeze; resistance of the metal to destruction from corrosion, aggressive chemicals and acidity of the heated filler; light weight of heating devices means trouble-free installation on walls made of plasterboard, foam concrete and other porous materials; plasticity of copper – protection from pressure changes and temperature amplitudes; high aesthetic properties - radiators do not require painting and fit organically into any design. Copper radiators have excellent resistance to corrosion damage

Copper radiators have excellent resistance to corrosion damage

A special property of the red-yellow metal is the copper oxide formed on the inner surface, which gradually forms on the inner wall of the radiator. This is a natural protection of products from the destructive effects of fine suspensions and chemical solutions in the coolant.

The main advantages of copper batteries

The products described in this article are considered the most optimal option for any heating system, regardless of whether it is individual or centralized. And if we compare them with other types of radiators, then there are a lot of advantages and unique properties, which can only indicate one thing: copper radiators are one of the most profitable financial investments. And among the many advantages, it is worth highlighting the following.

- High degree of heat transfer. As already noted, pure copper is used in the production process, due to which the heat from the working fluid is transferred to the house fully and without any losses. It turns out that this is an ideal choice for many systems, in particular for a centralized pipeline in apartment buildings, where the liquid temperature, as is known, rarely exceeds 60 degrees.

- Long service life. Copper is resistant to various types of deformation, the action of corrosion inhibitors and other harmful phenomena; Copper batteries can last 15-20 years, and sometimes even 50, without causing any trouble to the user at all.

- Light weight. The copper from which these radiators are made weighs little, and therefore even the largest products with a large number of sections are light in weight. Consequently, there is no excessive load on the walls, and, accordingly, there is no longer a need to use special reinforcing fasteners.

- Low temperature resistance. At sub-zero temperatures of the working fluid, copper products may be slightly deformed, but in no case should they burst. For this reason, the risk of defrosting is practically reduced to zero.

- Economical. In the images in this article you can see for yourself that all copper heating radiators are characterized by a small cross-section. In this regard, little working fluid is required, and the user can save on fuel without any damage to the efficiency of the heating system.

- The maximum permissible temperature of the working fluid in the system is 250 degrees. This is one of the reasons why copper batteries are the best solution for grids. By the way, according to the instructions from the manufacturers, some models are quite capable of functioning at higher temperatures, achieving maximum efficiency.

- Possibility of functioning at high pressure. As noted at the beginning of the article, copper batteries also work well with a pressure of 16 atmospheres. As for the crimping pressure, for these products it can reach 25 atmospheres. It is precisely because of their increased resistance to pressure that radiators can be installed in both individual and centralized networks, and the quality of the working fluid does not play a special role.

Note! Experts recommend installing copper radiators in those heating networks where the working fluid contains a large amount of chlorine salts. After all, if you use, say, traditional steel devices for such a liquid, then in any case problems will arise - up to clogging of the pipeline.

In short, buying a copper radiator is definitely a profitable investment that will soon pay off.

Replacing heating batteries in an apartment

Previously, we talked about how to change the battery in an apartment yourself, in addition to this article, we advise you to read this information, see all the details here

Purpose and design

A side effect of a running engine is the heat that enters the cabin. The released internal energy is a derivative of fuel combustion and friction of parts. To remove thermal energy from very hot components, the power plant is provided with cooling. A component of the latter is heating inside the body. As a result, the amount of thermal energy in the cabin depends on the heating power of the power plant. The heated antifreeze enters the heat exchanger, and the fan, passing air through it, dissipates the energy inside the body.

A tap is provided to regulate the temperature values of the air masses leaving the aerodynamic devices. It is located on the supply line between the power plant and the heating system. The mechanism is represented by conventional shut-off valves with various servos. A set of mechanisms helps regulate the volume of antifreeze passing through the heater.

When the temperature values on the dashboard increase, the mechanism opens, and its closing indicates a decrease in the parameter. The normal functioning of the faucet affects the overall operation of the stove. Failures when the fittings do not completely open the passage for antifreeze lead to the feeling of cold inside the body, the windows do not thaw in frosty weather - it is unsafe to drive.

The values on the street thermometer also play a role. If the stove functions without failures, it will work worse in winter than in spring. In cold weather, the antifreeze does not warm up enough, causing the heating to deteriorate. The thermostat also affects the amount of heat generated: if it does not work correctly, then, regardless of the element, a cold air flow will flow from the aerodynamic devices. Before replacing the heat exchanger, all components of the heating system are checked.

The heater element has much in common with its “big brother” from the cooling unit. And their tasks are similar, only the large one releases heat into the atmosphere, and the small one – into the body. Structurally, both have two tanks that are connected by tubes. Using soldering, plates are attached to them, increasing the cooling area (the larger the part, the greater the heat transfer).

When purchasing, pay attention to this nuance - the number of plates. If you place heat exchangers side by side, you can visually determine the characteristic by the density of heat-dissipating surfaces

Antifreeze inlet and outlet pipes are attached to one of the tanks. On a number of models, during development, designers provided areas for installation on the car.

Attention!

Which heat exchanger has a higher density, the energy output is higher.

Equipment for installing copper radiators

Shut-off valves can also be selected from a similar metal.

One of the factors for the safe operation of a heating system is the installation of shut-off valves.

Mayevsky crane

For normal operation of the water heating system, the batteries must be equipped with a Mayevsky tap. This device serves to remove air accumulated in the pipes. It is installed on the top of the battery. The shut-off valve is opened after starting the system to bleed trapped air and prevent the formation of plugs. After turning the valve one turn, a hissing sound appears, characteristic of air escaping. The tap is kept open until a trickle of water appears.

Shut-off valves

Taps and valves are necessary to regulate the amount of coolant in the batteries, as well as forced drainage. Shut-off valves allow you to shut off the flow of water in the event of a radiator failure. It is made of brass, the connection to the pipe is threaded. Thermostatic valves, depending on the model, require manual adjustment or are automatic.

Bypass

A bypass pipe is installed between the inlet and outlet lines. Its diameter is less than the cross-section of the connected pipes. The jumper allows the coolant to bypass the battery. The element is typical for a single-pipe heating system. A tap can be installed on the bypass, then the movement of water is controlled.

When installing copper radiators, ferrous metal fittings should not be used. To avoid a chemical reaction, all connecting parts must be made of brass.

Homemade radiator: current manufacturing methods and methods for their implementation

Despite the fact that the price of a modern heating battery is not so high, you can do without purchasing such devices, because you can handle their assembly yourself.

In this article we will talk about how and using what materials homemade batteries can be made, which in terms of energy efficiency will be practically not inferior to their factory counterparts.

“Warm baseboard” made of copper pipes

Assessing your capabilities

It is clear that not every person can assemble a homemade oil radiator, since such a design is complex, but making a device through which water will circulate as a coolant is not so difficult.

“Warm floor” - a type of radiator

According to the principle of operation, home-made heating devices also do not differ from factory-made analogues, however, it is not recommended to install these products in centralized systems with high pressure.

Heating register - the basis of homemade structures

Homemade pipe heating radiators are the most common type of homemade heating devices. And this is not surprising, since soldering a sealed system from a pipe is much easier than making a heating device using factory technologies.

Products assembled from a single pipe or combination of pipes are called a register. The register is a sealed system through which one or another coolant circulates. The energy efficiency of the register is determined by the diameter and configuration of the pipes, as well as the material from which they are made.

The practice of assembling radiators with your own hands shows that the most appropriate solution is to use smooth-walled steel pipes with an internal cross-sectional diameter of 32 - 200 mm. In order to achieve maximum heat transfer surface area while maintaining compact dimensions, the device is given the shape of a coil or the register is made sectional.

Tip: In order to make a register, it is not at all necessary to go to a metal depot to purchase new pipes. After all, to carry out the planned work, you can use old pipes that do not have visible defects caused by mechanical deformations or corrosion.

Homemade Device Configuration

Copper tube coil

Homemade heating radiators made of copper or steel can be made in two design options:

- Sectional registers consisting of straight pipes of large diameter with sealed plugs at the ends, connected by pipes with a smaller cross-sectional diameter.

- Serpentine registers with an S-shape or a more complex configuration.

Important: For optimal heat transfer, the coil register configuration should have a distance between adjacent pipes that is 5 cm greater than their diameter. https://www.youtube.com/embed/wlfkSKnOvbM

Let's take a closer look at the design features of the listed configurations:

A sectional register consists of several pipes located horizontally.

The photo shows a sectional register

To circulate the coolant, the horizontal elements of the register are connected to each other by pipes of smaller diameter. As a result, the coolant begins to move along the upper pipe, reaching the connecting pipe, through which it flows into the lower section, and so on.

In the factory version, such structures are made for heating entrances and other auxiliary premises, where the aesthetics of the appearance of the device is not so important.

Operating principle of a sectional register

The inlet and outlet pipes are made threaded. In some cases, to speed up installation work, the pipes are simply welded tightly.

The location of the transition pipes is selected as close as possible to the end of the section. This is done for better coolant circulation and to ensure greater strength of the prefabricated structure.

The optimal materials for self-assembly of sectional registers are galvanized steel pipes with an internal diameter of 76-160 mm. The structure should be welded so that the tightness of the seams is maintained at an operating pressure of up to 13 atm.

Important: The optimal register configuration is one with no more than 3 horizontal sections. Excessive accumulation of sections will lead to a decrease in the efficiency of heated air circulation inside the room

Serpentine registers are structurally similar to the selection analogue. The main difference is that the function of the jumper here is performed by the bend of the main pipe.

Coil welded from steel pipe and fittings

Operating requirements

Although the cost of heating copper is higher than plastic, copper products are resistant to high temperature, overheating, gas diffusion through pipe walls, or mechanical damage.

According to technical and operational characteristics, copper and copper-aluminum radiators can be used both in an autonomous heating system and in a central heating system. It must be remembered that the guarantee of a long service life of any radiator is to build the system from a homogeneous material that is resistant to the most harmful factors, which is almost impossible to implement in an apartment building. The maximum service life of the devices will be possible only if the entire system is made of copper.

However, copper radiators can be used in multi-storey buildings with a central heating system. They are resistant to water hammer and have low demands on the quality of the coolant.

Most models of copper radiators can be used in single-pipe and two-pipe heating systems of open and closed type. They will be effective in systems with forced and natural coolant circulation. Copper radiators are not sensitive to temperature changes and can withstand negative values. Can be installed in rooms with high humidity. Contact of copper with aluminum is unacceptable.

Recommendations for choosing copper heating devices

Copper-aluminum heating radiators are classified as convection-type devices. Cold air sliding from the windows heats up as it passes between the plates or ribs of the batteries, rising with acceleration.

These bimetallic devices are usually more expensive than their aluminum-steel counterparts, but their quality is beyond doubt and they have a longer service life. Most often, it is copper-aluminum batteries that occupy the first places in the ratings.

When purchasing, you should pay attention not only to the cost of the products, but, first of all, to the heat transfer parameters in relation to the volume of air in the room. All important characteristics are indicated in the description of the model or technical data sheet

Copper batteries take first place in the ratings

There are common terms and abbreviations. For example, RB (radiator with side connection), RBD (side diagonal connection method) or RNL (lower side). The highest quality and fastest installation of copper products is ensured by a threaded connection; only specialists undertake soldering.

Copper batteries warm up faster than other types; the volume of coolant circulating in them passes approximately twice as fast with a gravity-fed closed-cycle system. Therefore, they are preferred for the private sector - small room heating units have a higher efficiency than bulky cast-iron batteries or light steel panel-type radiators.

Which battery to choose

The cost of radiators is not the last criterion when purchasing a device. Aluminum batteries are sensitive to the composition of the coolant, have low operating pressure, and are sensitive to water hammer. They are not recommended for installation in apartments with central heating. Aluminum appliances will be the optimal budget solution for a private home. Copper batteries do not have these disadvantages. They are effective and resistant to aggressive influences.

When choosing between copper and aluminum cooling radiators, related factors are taken into account. The non-ferrous metal structure has a small diameter and is more susceptible to corrosion. Aluminum tubes with a cross-section twice as large are less likely to clog and last longer.

Which heater radiator to install on a VAZ 2114

Key advantages of aluminum radiators:

- A radiator made of aluminum will have significantly more side fins. This makes it more convenient and practical.

- The width of all channels in an aluminum radiator is much larger. It is because of this that you can increase the efficiency of supplying warm air at idle.

The main disadvantages of an aluminum radiator:

- The aluminum radiator heats up extremely quickly.

- It is almost impossible to restore an aluminum radiator that has even a small leak.

Key advantages of a copper radiator:

- The copper radiator on the VAZ 2114 heats up for a very long time. It also takes a long time to cool down.

- A radiator made of copper can be easily restored.

Copper radiator of the VAZ 2114 stove and its disadvantages:

- A small number of ribs.

- The channels are too narrow and small. They clog very quickly, which has the most negative effect on warming up. As a result, such a radiator has to be repaired quite often.

- There is practically no heating at idle.

- It is too difficult to find a sufficiently efficient copper radiator. Many of them are made from extremely low-quality material with many different impurities. The heat transfer of such devices is at the lowest level.

Characteristics of copper-aluminum heating devices

Gone are the days of inconvenient and ineffective heat transfer, cast iron batteries. The struggle to save energy and minimize heating costs forces us to insulate our own home, purchase double-glazed windows with reduced heat loss, and use modern heating devices. Thanks to this, in this publication we will analyze the key characteristics of copper-aluminum heating devices.

Copper-aluminum heating devices, which have better convection of warm air, are better suited in appearance to the modern interior style of our residential buildings. Severe shapes and perfect design, the absence of corners with sharp ends and good performance compel us to select this particular type of heating radiator.

The key advantage of copper-aluminum heating devices

The copper tubes through which the coolant moves in the middle of the heating device have a neutral reaction with the copper pipe coil of the boiler for heating. In other words, there is no potential difference leading to electrochemical corrosion, as in heating networks with metal batteries.

The compatibility of copper-aluminum heating devices with different types of adapters, boilers, steel and copper pipes and many types of thermal media allows them to be used everywhere in industrial and residential premises. The durability and duration of trouble-free operation of the heating system becomes significantly greater when using heating devices of this type.

The remarkable heat transfer of copper pipes, on which aluminum plates are mounted vertically, causes air masses to heat up much faster when compared with aluminum heating devices, not to mention cast iron radiators. Convection heat transfer of copper-aluminum batteries reaches 85%, which significantly speeds up the heating of indoor air and saves fuel resources.

The small volume of the heating device makes it possible to quickly heat the aluminum plates to working values. The heat generation power of a typical part with a size of 60×80 cm and a capacity of 0.8 liters is 1400 W, at a coolant temperature of about +70? C.

Comparative characteristics of copper-aluminum heating devices with other heating devices

When comparing copper-aluminum heating devices with other design radiators, we see their definite advantage in many technical specifications. One of the main advantages of bimetal radiators is their integral body, which makes it possible to maintain much higher pressure than other batteries. Radiators of this design have both side and bottom connections, which make it possible to advantageously hide the heating pipes into the floor.

If we take a typical cast iron radiator with 6 sections, a six-section metal, steel radiator with a size of 60×80 cm and a copper-aluminum heating device of similar indicators, we get the following comparative data:

- Cast iron 0.9 MPa 18 liters of liquid 36 kg 600 W.

- Steel 1.0 MPa 1.2 liters of liquid 6.5 kg 800 W.

- Metal 1.5 MPa 1.8 liters of liquid 9.6 kg 1200 W.

- Copper-aluminum 1.5 MPa 0.8 liters of liquid 6.9 kg 1400 W.

As you can see, the use of copper-aluminum heating devices provides savings not only in the amount of heated coolant, but also in high power with relatively similar sizes. The low weight of bimetallic batteries makes it possible to mount them directly on plasterboard walls, which is much cheaper and faster than installing cast iron radiators.

Copper radiators: the best choice for a heating system

Traditional cast iron or steel heating radiators have somewhat lost their position in the market. The reason for this was the rather low operating efficiency and insufficient heat transfer for normal heating of an apartment or house.

In addition, it is not always possible to use such batteries, because heating systems are constantly being improved and their operating parameters are increasing.

The already somewhat outdated batteries made of ferrous metals have been replaced by higher quality, reliable and efficient copper radiators. Such products, installed in the heating system, can practically increase the level of heat transfer several times and reduce the financial costs associated with heating the house.

Copper radiators on the domestic market are presented in a huge range, and therefore it is not a problem to choose the best option for any building.

At the same time, despite the rather high cost (compared to cast iron or even aluminum radiators), heating devices made of copper are becoming increasingly popular every year; they can be found in the heating system of both residential buildings and various offices and trading floors.

Decorative copper radiator

The best known manufacturers and models: characteristics and prices

Alsera 1.045 kW

Copper heating devices from a Russian manufacturer. Certified for sale in Russia. The radiator is designed for side connection.

The diameter of the copper pipes of the device is 28mm, which reduces the possibility of silting. Depending on the geometric parameters of the devices, the heat transfer is 1045 - 2195 W. The devices are sold with or without a wooden casing. Their actual parameters are: width – 830 mm, height – 200 mm, thickness – 110 mm, center distance is 130 mm.

The operating temperature should not exceed 150 °C, and the maximum operating pressure is 16 bar, testing pressure is 50 bar. The manufacturer provides a 25-year guarantee on its radiators and states that the devices will be used for at least 49 years.

Cost: from 16,434 to 39,105 rubles. (depending on configuration)

Low and long heating radiators: detailed analysis More comfortable heating, stylish design and small coolant volume

Regulus-system "REGULLUS" RD2/040

Polskaya is one of the largest manufacturers of copper-aluminum devices. The RD2 type radiator has a bottom connection located in the corner with a built-in thermostat.

REGULUS heaters have a very low thermal inertia and at the same time a large heat exchange surface, which determines their efficiency at low coolant temperatures. They can work in heating systems with flexible settings. Designed for use in both central and autonomous two-pipe heating systems with forced or natural coolant circulation. Suitable for private houses, apartments and office premises.

The height of the devices ranges from 125 to 1,120 mm, and the width - from 400 to 2,000 mm. The heat output of radiators is within the range of 154 - 6,005 W. The center distance is 50 mm. The maximum operating temperature of the coolant is 110 ° C, and the operating pressure is a maximum of 15 bar, pressure testing is 35 bar. The manufacturer provides a 25-year warranty, while the battery life is stated to be at least 40 years.

Cost: from 3,352 to 35,904 rubles.

CLASSICstyle Pomni 1517

Russian-made copper heating radiators for one-pipe and two-pipe systems are suitable for both private houses and apartments or public premises. Can be used in central and autonomous systems with forced and natural coolant circulation. Made from seamless copper pipe with a diameter of 28 mm, which makes the radiator more durable and less sensitive to the quality of the coolant in terms of siltation.

Depending on the geometric parameters of the device, the heat transfer is 1,054 - 2,195 W. The devices are sold with or without a wooden casing. Actual radiator parameters: with casing – 830*420*110 mm; without casing – 830*240*70 mm.

The center distance is 130 mm. The operating temperature should not exceed 150°C, and the maximum operating pressure is 16 bar, testing pressure is 50 bar. The warranty on the device is 25 years, and the service life of the radiator is at least 49 years.

Cost: from 20,120 to 39,500 rubles. (depending on configuration)

The most common mistakes of those who choose a particular radiator model

Some car owners prefer units. It is not worth buying such devices. The fact is that they have practically no heat transfer! The warranty on units from this manufacturer is 12 months, but the efficiency of such radiators is practically zero.

Sometimes car enthusiasts prefer heaters from. These devices are quite efficient. Manufacturer's warranty - 1 year. These radiators help distribute heat evenly throughout the car's interior, but the cost of these units may seem overpriced.

We can also recommend replacing the pump. This unit is responsible for how coolant circulates in the car at idle.

Some experienced motorists also recommend getting rid of all air jams.

Main technical characteristics

In the manufacture of modern copper batteries, exclusively high quality materials are used. Copper must be exclusively in pure form, while the ratio of impurities should be no more than 0.1 percent. It is this ratio of components that ensures the operation of the system at elevated pressure, maximum heat transfer, and also eliminates possible corrosion.

Note! Don’t forget that copper batteries in an apartment/house increases the amount of heat transferred by the working fluid by about 2 times.

Finally, copper itself is a fairly durable and strong metal, and therefore radiators made from it work quite effectively even at a working fluid temperature of 150 degrees and a pressure of 16 atmospheres.

Video - How to choose a radiator?

Types of copper heating batteries and their specifics

In rare houses you can find copper or copper-aluminum batteries. Everyone is accustomed to the old cast iron version and the newer, panel steel and bimetallic (steel plus aluminum) appliances. But all specialized outlets note a growing interest in these samples of red-yellow metal. Although these heating radiators for apartments are used extremely rarely, there are no complaints about them if the thickness of the walls of the device meets all standards.

There are alternative and more convenient ways to quickly warm up rooms, including underfloor heating systems and infrared simulators of fireplaces and paintings. However, of all the variations on the “heating theme” for the private sector, steam heating remains the most common.

Copper heating radiator in designer design

All heating devices, including copper models, are classified:

- conventional radiators (cold air flowing from the windows warms up upon contact with a warm surface);

- thermal convectors (the special shape of the plates promotes faster spread of the heated atmosphere), they are more expensive, but more economical to use.

Copper products may differ not only in quality and wall thickness, but also in model type:

- Tubular radiators with convection plates.

- Copper-aluminum batteries (soft white metal on the outside only).

- Bathroom heated towel rails (justified when all pipes are made of the same metal).

On the heating equipment market there are expensive imported and budget models from domestic manufacturers made of different metals. However, there are no inexpensive copper radiators anywhere, although relatively cheap ones can be found.

Design features of copper batteries

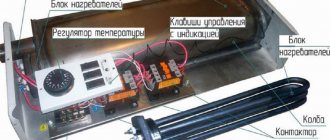

Heating radiators made of copper, as well as those made of other materials, are original elements that differ not only in their composition, but also in their design features. In most cases, copper heating radiators consist of pipes with a working fluid circulating inside and special finned plates.

Do not forget that the number of pipes (as well as their shape or cross-section) varies and depends on the individual characteristics of a particular battery model. Moreover, some of these batteries are even equipped with a special protective casing, which not only decorates the wall product, but also increases its performance. Often, manufacturers offer consumers not just copper batteries, but full-fledged heating devices that have many functions and allow you to control the temperature in order to ensure the most efficient heating of the room. Such properties are made possible thanks to built-in shut-off valves, thermostats and other fittings. Agree, all this is very convenient, which is why, in fact, such radiators are of high value in heating systems.

Note! There are several basic ways to connect copper batteries to risers and heating lines in general. More specifically, there is a threaded connection and soldering, due to which the versatility of the products increases significantly, they become an ideal option for most systems, but installation costs are reduced.

There are several methods of heating using these devices, let’s get acquainted with them.

- Convection is when heat is transferred by air currents and depends on the area/shape of the heating devices.

- Radiation of heat due to the fact that heated bodies are capable of transmitting thermal energy through IR electromagnetic waves.

- Thermal conductivity is the unique ability of heated bodies to transfer part of their heat to other, colder objects. This indicator depends mainly on the characteristics and structure of the metal used in the manufacture of radiators.

Purpose and design

A side effect of a running engine is the heat that enters the cabin. The released internal energy is a derivative of fuel combustion and friction of parts. To remove thermal energy from very hot components, the power plant is provided with cooling. A component of the latter is heating inside the body. As a result, the amount of thermal energy in the cabin depends on the heating power of the power plant. The heated antifreeze enters the heat exchanger, and the fan, passing air through it, dissipates the energy inside the body.

A tap is provided to regulate the temperature values of the air masses leaving the aerodynamic devices. It is located on the supply line between the power plant and the heating system. The mechanism is represented by conventional shut-off valves with various servos. A set of mechanisms helps regulate the volume of antifreeze passing through the heater.

When the temperature values on the dashboard increase, the mechanism opens, and its closing indicates a decrease in the parameter. The normal functioning of the faucet affects the overall operation of the stove. Failures when the fittings do not completely open the passage for antifreeze lead to the feeling of cold inside the body, the windows do not thaw in frosty weather - it is unsafe to drive.

The values on the street thermometer also play a role. If the stove functions without failures, it will work worse in winter than in spring. In cold weather, the antifreeze does not warm up enough, causing the heating to deteriorate. The thermostat also affects the amount of heat generated: if it does not work correctly, then, regardless of the element, a cold air flow will flow from the aerodynamic devices. Before replacing the heat exchanger, all components of the heating system are checked.

The heater element has much in common with its “big brother” from the cooling unit. And their tasks are similar, only the large one releases heat into the atmosphere, and the small one – into the body. Structurally, both have two tanks that are connected by tubes. Using soldering, plates are attached to them, increasing the cooling area (the larger the part, the greater the heat transfer).

When purchasing, pay attention to this nuance - the number of plates. If you place heat exchangers side by side, you can visually determine the characteristic by the density of heat-dissipating surfaces

Antifreeze inlet and outlet pipes are attached to one of the tanks. On a number of models, during development, designers provided areas for installation on the car.

Attention! Which heat exchanger has a higher density, the energy output is higher

Advantages and nuances of use

Type of appliances in the interior of the room.

Instead of arguing which radiator is better - aluminum or copper - we will simply list the main advantages of copper devices. This will allow you to better imagine and understand all the benefits of using these devices.

For convenience, we use the table:

| Advantages | Description |

| High thermal conductivity | Due to accelerated heat transfer, the transfer of thermal energy from the coolant to the surrounding air increases. Accordingly, the efficiency and overall efficiency of the device increases, and it becomes possible to operate on a low-temperature coolant |

| Low thermal inertia | The device heats up within 3 – 5 minutes. This makes it possible to adjust the temperature and use automatic climate control systems. The response to the thermal shut-off valve occurs with a delay of only 30 – 50 seconds |

| Small coolant volume | The battery is heated by a small volume of coolant; 12 - 15 liters are enough to heat a house. This reduces the overall weight of the system and the load on boiler equipment, circulation pumps, and cleaning systems |

| Corrosion resistance | Heat exchangers can last for decades; many manufacturers provide a guarantee of 25 years or more |

| Strength and ductility of tubes | Copper tubes can withstand a working pressure of 16 atmospheres and a working temperature of 150 °C. In addition, due to their plasticity, they are less afraid of water hammer |

| Smooth inner walls | Unlike cast iron and steel, the walls of the devices are not overgrown with mineral deposits, therefore, over time, their cross-sectional area practically does not decrease |

Important! An analysis of the features of copper devices revealed only one significant drawback - the high price. Otherwise, such equipment does not cause any complaints.

It is advisable to use pipes made of the same material.

For those who are interested in purchasing copper convectors, the following nuances of their use will be useful:

- It is advisable to use devices in conjunction with copper or metal-plastic pipes;

- Do not connect copper to galvanized steel and aluminum directly;

- The coolant must be filtered from abrasive particles and impurities;

- Products should only be purchased from licensed distributors to avoid purchasing counterfeits.

The result of direct contact of pipes made of different metals.

Important! The devices are quite expensive, so you should install them yourself only if you are confident in using plumbing tools.

⇡#Design features

Despite the already classic system layout, when a radiator with fans is connected by two hoses to a pump combined with a water block, the Cooler Master Eisberg 240L Prestige even looks different from other serial air coolers.

A large pump with a transparent plastic window, thick wire-braided hoses and, finally, a copper (!) radiator measuring 276x125x30 mm.

The outer diameter of the connecting hoses is 11 mm and their length is 335 mm.

But the main thing is not even the fact that, by increasing the diameter of the hoses, Cooler Master engineers sought to increase the volume and speed of the pumped refrigerant, but the fact that the hoses are not simply pressed, but are fixed with compression fittings.

Together with a special plug on the water block, this will make it easy to disassemble the system, adding additional components to it, or simply refill it.

There is no doubt that the radiator is copper, since it weighs at least twice as much as an aluminum radiator of similar dimensions, and the characteristic orange color of the perforated “comb” between the flat tubes is clearly visible when looking at the radiator at an angle.

There are twelve flat tubes in total. The refrigerant is pumped through them, distributing the heat flow over the copper fins. The thickness of the radiator working fluid is 16 mm, that is, the same as, for example, in the NZXT Kraken X60, but there it is aluminum, and here it is copper!

And the pump of the Cooler Master Eisberg 240L Prestige is special, measuring 65.7x66.0x66.9 mm, with the same hole for filling the refrigerant.

This is a unique development by German Cooler Master engineers with a capacity of 400 liters per hour, that is, at the level of pumps of famous brands. The pump's ceramic bearing should last at least 50,000 hours, or more than five and a half years of continuous operation.

The lifting height of the coolant pump is 2.2 meters, which is also at the level of professional pumps. Proprietary JetStream technology is designed to create optimal coolant pressure and flow rates for improved efficiency. The copper water block itself is microchannel; it is not much different from similar products from other water supply manufacturers.

There is a transparent plastic window on the side of the pump, through which you can see the rotating rotor and the turbulence of the liquid flow.

The rotation speed of the pump rotor at a voltage of 12 V is 3600 rpm, but using the included cable with a resistor, the voltage can be lowered to 9 V with a corresponding reduction in speed to 2900 rpm. Our measured power consumption of the pump was 6.2 W.

The copper base of the water block measuring 56x56 mm is sealed with a protective film with a warning about its mandatory removal before installing the water block.

The contact surface is amazingly processed - well, just a clean mirror.

We also couldn’t make even the slightest complaints or quibbles about its evenness; everything was perfect.

As for the pair of fans, these are the usual 120mm models with a seven-blade impeller, but each of them comes with a 6mm thick soft silicone frame.

These frames are designed to eliminate the transmission of vibrations to the radiator housing and thereby reduce the noise level. In addition, they are quite thick, so that the fans appear to be raised above the radiator. Together with the 8 mm distance from the radiator walls to its “working fluid”, a 14 mm gap is obtained, thanks to which the dead zone under the fan stator practically disappears and the air flow is distributed more evenly across the plates, thereby increasing cooling efficiency.

The rotation speed of the “turntables” is constant - it is 1600 rpm with an air flow of 60.2 CFM and a noise level of 20.5 dBA. These fans do not have PWM control, and our system kit did not include a cable with adapters for 5 and 7 V. Well, this is a minimal loss, since in testing we regulate the fan speed with a special controller. Based on the information on the stator label, the maximum power consumption of each fan should not exceed 1.56 W at a current of 0.13 A.

The fans are secured to the radiator using screws and an L-shaped hex key.

This is what the Cooler Master Eisberg 240L Prestige looks like assembled with fans.

Let's move on to installing the system.

What to look for when purchasing

If your plans include the purchase and installation of copper batteries, then you simply must know about some important points. Let's look at them.

- The main one, which we have already mentioned in passing, is the following: you should not use elements made of different materials within the same network. If the appliances are copper, then the fittings should be so too. And this need is explained not only by the risk of a special electrochemical reaction that can destroy the system, but also by the fact that different materials have different thermal expansion, which appears under the influence of elevated temperatures.

- Make sure that the working fluid is free of abrasive impurities. They can damage the internal cavities of heating devices, because copper is a fairly soft material. In short, be sure to install special filters.

- Connecting fittings must be made of non-ferrous metal - ideally brass.

In addition to all this, try to buy batteries only from trusted sellers. The fact is that there are a large number of counterfeit products on the modern market. So, for example, in the manufacture of a battery, cheap low-quality metal can be used, which is covered with a thin layer of copper on top. What else do you need to know when choosing copper heating radiators? Yes, there are still a few nuances.

- Temperature conditions necessary to maintain comfortable living conditions.

- Total area of heated rooms.

- Condition and number of different types of openings. If required, they can be additionally thermally insulated.

- Dimensions of the room. One of the main parameters in this case is the height of the ceilings.

Note! It is quite obvious that the number of sections in a copper device will be less than in a similar product made of ferrous metals. It is thanks to this that the rather high cost of radiators is compensated

Carry out the installation efficiently; ideally, you should involve a qualified specialist in the work if you need to solder copper elements. Do not skimp on this under any circumstances! Copper is an expensive material, and if you managed to find the money to buy batteries made from it, then do not neglect the quality of work.

As a small conclusion

Copper heating radiators are the best option for both a city apartment and a private house, when compared with similar devices made of ferrous metals. Such products are characterized by high heat transfer, which ensures fast and high-quality heating of the heated room. Despite the high prices, the radiators will pay for themselves in the near future, since energy bills will noticeably decrease. That's all. Good luck and have a warm winter!

In conclusion

The use of metals with high thermal conductivity has long been adopted by manufacturers of heating radiators. This allows you to increase the heating rate of the heating device, and the combination of metals reduces the cost of the battery while maintaining high performance characteristics.

You can even try to create a copper radiator with your own hands; it, of course, will not reach the efficiency of purchased models, but it will look good in the house as an interior decoration.

The video in this article shows the design of a radiator using copper tubes and aluminum fins.

Hello everyone. When I started disassembling the car, my gaze fell on the cooling radiator. To be honest, it didn’t look so hot ((. The radiator was an ordinary aluminum

The engine with this radiator periodically warmed up from being pushed for a long time in traffic jams, even the Niva fans did not save it. After installing a fiberglass hood with a cooling bucket, it became much better, but not as much as I would have liked. After scratching my turnips and weighing up all the pros and cons, I decided to buy a copper radiator. There was no point in going to the spare parts stores, since you couldn’t find such good stuff there during the day. I went to Kuntsevo and ran around with all my friends, but I couldn’t find a copper cooling radiator there either, they said that I had to pick it up from some car. I didn’t bother with the selection, since I had to cut something again, bend it, etc., etc. But this didn’t stop me from looking for a radiator. Sitting at work on Thursday, suffering from idleness, I began to monitor all sorts of sites selling sports spare parts and more. I came across an advertisement for the sale of a copper double-row radiator from a VAZ 2110 at a great price, I called the person and asked where I can pick it up, I agreed with him that I’ll come and pick up the radiator on Saturday. Yesterday, with Andryukha ProDriv3r (many thanks to him for his help), after we picked up the box from the bulkhead, we headed to Sergeev Posad to pick up the radiator. We arrived at our destination, met the person, looked at the goods, I was satisfied with everything, the radiator was new, packed in a box. And we went home in high spirits

The radiator is entirely copper, without any plastic sidewalls like on aluminum; the honeycombs are much larger than those of a conventional radiator. In addition to all this, I purchased a copper radiator for the stove. The old aluminum one will last a long time, again I want to emphasize the copper one without any plastic! The sides will no longer crack.

Here are a couple of photos to compare an aluminum radiator and a copper one.

I think the difference is not only in price, but also in quality. Copper cooling radiator 2500 thousand rubles + copper heater radiator 1100 thousand rubles. With this I say goodbye to you... I completely forgot, can anyone help with the radiator tubes, who can tell me what this thin tube is that is highlighted in the photo? break-in or what? THANK YOU in advance!

Monolithic or sectional?

The outer and inner parts of bimetallic radiators are connected by pouring aluminum into special molds where a steel (copper) core is placed. The operation is performed under high pressure. In this way it can be manufactured as a single monolithic structure,

so is

the sectional team.

Design of a monolithic radiator

In the first case, the heat exchange body is cast over a ready-made welded manifold, resulting in a battery in which there are no potential leak points, due to the lack of joints. Radiators of the second type are assembled from separate sections, fastening horizontal sections of pipes with steel nipples through heat-resistant (up to 200⁰C) sealing rings. The disadvantages of such models are obvious: the installation components are sensitive to the quality of the coolant and pressure surges in the system, which can lead to the appearance of corrosion on the aluminum body and leaks.

However, prefabricated radiators are repairable and allow you to easily replace a failed section, but if there is a problem with monolithic devices, this will be impossible. However, the service life of the latter, according to manufacturers, is up to half a century, and the key to their reliability is the cast structure itself. For comparison: the working pressure of some “monoliths” can reach 100 atm, and for sectional devices it is in the range of 16–35 atm (however, these values are sufficient with a margin for both urban and autonomous heating systems with a standard pressure of about 14 and 10 atm, respectively). The service life of prefabricated radiators is also considerable - 25–30 years.

Non-separable radiators are more expensive than collapsible ones, but for installation in urban heating systems they should be preferred - as they are more durable and better adapted to extreme operating conditions (unstable pressure, water hammer, etc.). As for the ability to reduce or increase the number of sections to adjust the thermal power of the radiator, this is an absolute advantage of sectional models. When purchasing a “monolith”, it is necessary to determine in advance exactly the required power of the device. It will not be difficult to make a choice, since the market offers a wide range of products with different sizes and characteristics.

Black radiator Royal Thermo BILINER 500 Noir Sable, 12 sections. Dimensions 574 x 971 x 87 mm, power 2060 W, weight 22 kg. Price from 9000 rub.

Radiator Rifar Monolit 500, 10 sections. Dimensions 577 x 800 x 100 mm, power 1960 W, weight 21 kg. Price from 8800 rub.

Radiator RADENA BIMETALL CS150, 8 sections. Dimensions 241 x 592 x 120 mm, power 960 W, weight 7 kg. Price from 4400 rub.

Radiator Global Style Extra, 10 sections. Dimensions 566 x 810 x 80 mm, power 1730 W, weight 18.7 kg, antifreeze + water. Price from 8400 rub.

Radiator RIFAR SUPReMO, 14 sections. Dimensions 575 x 1120 x 90 mm, power 2828 W, weight 30.8 kg, water + oil + antifreeze. Price from 13020 rub.

Black radiator Royal Thermo pianoforte, 12 sections. Dimensions 591 x 971 x 100 mm, power 2270 W, weight 26.4 kg, water + oil + antifreeze. Price from 13,320 rub.

Radiator Sira RS Bimetal 500, 6 sections. Dimensions 480 x 572 x 95 mm, power 1194 W, weight 11.52 kg, steam + water + oil + antifreeze. Price from 5300 rub.

Radiator Royal Thermo PianoForte Tower Silver Satin, 22 sections. Dimensions 1760 x 591 x 100 mm, power 3982 W, weight 48.4 kg, water + oil + antifreeze. Price from 5300 rub.

Everything you need to know about copper-aluminum radiators

Bimetallic radiators are made of aluminum with fins, and a steel or copper pipe can act as a heater. Copper is favored by its outstanding thermal conductivity; if for steel this figure is 47 W/m∙K, then for copper it is about 400 W/m∙K. Only silver has greater thermal conductivity (430 W/m∙K).

Comparison of thermal conductivity of different materials

Devices made entirely of copper cost a lot, and the use of aluminum can significantly reduce the cost while maintaining fairly high efficiency. Aluminum has a thermal conductivity exceeding 200 W/m∙K, which is quite enough to quickly heat a room.

Advantages of combining copper and aluminum

Copper-aluminum heating radiators outperform their steel and cast iron counterparts in almost all respects.

The strengths of such radiators include:

- high thermal conductivity, which means greater efficiency with equal surface area;

- Such designs are produced in one piece, that is, aluminum plates are simply put on and soldered onto the copper tube (coil) at the factory. Compared to sectional devices, the risk of leakage is much lower;

Such devices are produced in one piece

Only copper will come into contact with water, and this one is resistant to corrosion. In addition, only purified metal is used for the manufacture of the coil; the proportion of impurities in it does not exceed 0.01%;

High grade copper is used

compared to cast iron radiators, a copper-aluminum analogue of a comparable size will weigh about 4-5 times less, this makes installation easier, and the fastenings can be made not as powerful as for cast iron batteries;

Characteristics of a number of bimetallic radiators

- the inner surface of the copper tube will never be covered with a layer of scale and after 10 years of operation it will remain as smooth as it was when purchased;

- Considering that the device is produced in one piece, it can easily withstand the operating pressure in the heating system (about 8-12 atmospheres). A copper tube can easily withstand a short-term increase in pressure up to 20 atmospheres or higher. This allows the use of copper-aluminum radiators in unstable heating systems.

On the compatibility of copper and other metals

When copper-aluminum heating radiators are used in the heating system, certain restrictions arise regarding the material of the pipelines (supply and discharge). The fact is that copper, in direct contact with some metals, forms a galvanic couple, which leads to rapid destruction of the joint.

Metal compatibility table

Result of joining incompatible metals

Therefore, if a copper-aluminum radiator is nevertheless installed in an apartment, then it is advisable to abandon steel pipes. As an option, you can consider using copper pipes, but it will cost a lot, and the reliability of the connection of copper pipes is not the best. The optimal option is to use a PP reinforced pipeline.

Types of copper-aluminum radiators

The division into types is quite arbitrary, because the design still remains unchanged - the same copper pipe on which the aluminum plates are located.

You can select:

radiators - most often they look like nice panel heaters. The unsightly finned copper tube design is hidden behind a beautiful metal casing. At the top of the casing there are holes that direct warm air into the room;

Copper-aluminum radiator design

convectors - the same design, and the price is comparable.

In the photo - copper-aluminum convector

The main difference between a convector and a radiator is the operating principle. So, for a radiator, infrared radiation (that is, heat) is more typical, and in the case of a convector, air constantly passes through it, that is, air flow movement is observed.

The classification takes into account what percentage of heat transfer is due to infrared radiation and convection. If the share of convection is less than 75%, then the device can be safely classified as a radiator.

Design and device

Copper radiators can be divided into several types:

- tubular products (divided into tubular and tubular-sectional). Tubular - batteries are made of copper pipes through which coolant circulates. They have restrictions on the length of the device. Tubular-sectional – radiator sections are made of copper pipes, which allows you to more accurately select the required battery power;

- copper convectors - are a core made of copper pipe with soldered copper plates. The plates are heated by copper pipes and heat rooms using both radiation and convection. To improve circulation, convectors are placed in a special casing made of wood, steel or aluminum;

- bimetallic – copper-aluminum convectors, which, unlike copper convectors, have vertical aluminum plates connected to a lightweight aluminum body. Externally, they look like flat steel radiators. These devices eliminate contact between aluminum and the coolant, which makes them resistant to corrosion. At the same time, air convection increases due to the larger (compared to copper convectors) area of the plates.

Those same copper convectors, which are also popularly called radiators. It is advisable to install them together with screens or casing.

Conclusions and useful video on the topic

Installation of various models of aluminum batteries is carried out taking into account certain features, but the basic rules for connection and installation are approximately the same.

The entire installation process, from processing the entrance holes to installing on the wall:

Example of assembly using sealant:

Installing an aluminum radiator does not take much time if you have the necessary tools at hand and have the skills to work with metal. But no matter how much experience you have at the time of installation, you must act strictly according to the instructions that come with the new model.

How to calculate the required number of sections?

The general principle is this: 100 W of heat is required per 1 m² of heated area. We calculate the area of the room (S), find out in the radiator passport the specific power of one section (P; on average 120–190 W) and determine the required number of sections (N) using the following formula: N = S × 100 / P Moreover, for rooms with complex configuration, panoramic glazing or, for example, two walls facing the street, correction factors are provided, given, in particular, in special calculators.

In addition, they take into account such factors as the orientation of the room to the cardinal points and relative to the wind rose, climatic features of the area, the quality of insulation of the house, etc. If the calculations cause difficulties, there is always the opportunity to seek help from a sales consultant, the main thing is Before going to the store, take appropriate measurements and be prepared to provide the necessary information about the construction. By the way, there is another, very simple way to find out how many heating sections are needed for a room. It is suitable if you have chosen a model with a standard center distance of 500 mm and a heat output of 180–190 W per section. You need to divide the area (let's say 15 m²) into two. We round the result and get the number 8 - this is how many sections the radiator should have. The adjustment for heat loss through large windows, poor insulation, etc. is conventionally 10%.

Bimetallic radiators are suitable for installation in both centralized and autonomous heating systems. At the same time, in country houses where antifreeze is used as a coolant, it makes sense to use devices with a copper core. This metal completely eliminates the possibility of a chemical reaction with any of the components of the antifreeze liquid

Semi-bimetallic design

There are so-called semi-bimetallic heating radiators. They differ from full-fledged ones in that their core is made on the basis of not one, but two metals at the same time.

For vertical channels in such a device, steel is used, and horizontal channels consist of aluminum, which increases their heat transfer.

Disadvantages of devices

But there is also a minus in this combination: the water used in the central heating system of the apartment contains a large amount of alkalis and can cause corrosion on aluminum parts.

In addition, due to high temperatures, metals change their linear parameters and expand unevenly, so parts of the core can shift, blocking the output of the collector. Such a problem will lead to a malfunction of the radiator, which will not be able to function correctly.

In what rooms are they installed?

Most often, experts recommend installing full-fledged bimetallic radiators in apartments of multi-storey buildings, since their heating system often suffers from pressure surges and poor-quality coolant. Both of these negative factors will quickly destroy the two-component core of a semi-bimetallic battery.

In private homes, the system works stably and homeowners have the opportunity to control the quality of the coolant, so you can save a little and purchase semi-bimetallic products.

Copper is the best metal for radiators

Modern copper radiators for heating are made only from high-quality materials. Copper is used in its pure form, while the amount of impurities should not exceed 0.1%. Thanks to this composition of heating batteries, it is possible to obtain the highest heat transfer, ensure operation of the heating system at high pressure, and eliminate the negative effects of corrosion.

It should be noted that copper radiators installed by yourself in a house or apartment can improve the quality of heat transfer from the coolant by almost 50%. In addition, copper is a strong and durable metal, and therefore heating batteries can operate effectively even at pressures of up to 16 atm. and coolant temperature 150C.

Copper heater core with protective cover

Design features of copper heating radiators

Copper radiators, like heating radiators made from other materials, are original products that differ not only in composition, but also in their design. As a rule, a traditional product consists of copper pipes through which the coolant moves and finned copper plates.

It should be noted that the number of pipes (as well as their cross-section and shape) and fins varies depending on the model of a particular radiator. In addition, some models of heating batteries are equipped with an additional protective casing, which not only decorates the radiator, but also improves performance.

Many manufacturers offer not just copper batteries, but also full-fledged multifunctional heating devices that allow you to regulate the heating temperature and ensure the most efficient heating of rooms. Such qualities are ensured due to the presence on the devices of all kinds of temperature regulators, shut-off valves and other fittings. This is very convenient and increases the value and significance of the radiator in the heating system.

Copper radiator for heating system with wooden casing

Please note! Connecting copper heating radiators to the general system and riser can be done in several basic ways. In particular, we can talk about the use of soldering and threaded connections, which significantly increases the versatility of copper batteries, makes them the best solution for any system, and reduces installation costs .

Benefits of Copper Batteries

A copper heating radiator is an excellent choice for any heating system, both autonomous and centralized. Compared to other types of batteries, copper batteries have a huge number of unique characteristics and advantages, which makes them stand out and make them an excellent choice and a profitable investment.

Among the most significant advantages of copper radiators are:

- Increased level of heat transfer. Thanks to the use of pure copper, the heat from the coolant is transferred fully and without loss to the room. For centralized systems in apartment buildings, where the coolant rarely has a temperature above 50-60C, this will be the best choice,

- Light weight. Copper is a light metal, and therefore even a large radiator with a large number of sections will weigh quite a bit. Thus, the load on the walls is eliminated, there is no need to use specialized reinforced fasteners,

- Economical. As you can see in many photos and videos on the pages of our website, the tubes and cells of copper radiators have a small cross-section. Due to the small amount of coolant, you can significantly save on fuel without reducing the quality of the heating system,

- Ability to work at high pressure. Copper radiators can operate in heating systems with a pressure of 16 atm. The testing pressure for such heaters can be 24-25 atm. Due to their resistance to high pressure, copper radiators can be used without problems in both centralized and autonomous heating. In this case, the type of coolant is not significant,

- The maximum possible coolant temperature in the system is 250C. Thus, it is possible to make copper radiators a universal solution for any heating system. The instructions for some devices allow them to be operated even at higher temperatures, achieving increased efficiency,

- Resistance to low temperatures. Copper radiators can be deformed, but not burst at sub-zero coolant temperatures. Thus, the possibility of defrosting is completely excluded,

Copper convector

- Long service life. Copper's resistance to deformation, the effects of corrosion inhibitors and other negative factors, copper radiators for heating will last 10-20, or even 50 years without causing trouble to the home owner.

Advice: copper radiators are recommended to be installed in heating systems where the coolant (in particular, water) contains a high level of chlorine salts. In the case of traditional steel radiators, problems would certainly arise, including clogging.

By purchasing radiators made of copper, you can guarantee warmth and comfort in your home, apartment or office for a long time. Despite the fact that the initial price of copper radiators is slightly higher than that of steel or cast iron, over time such costs will fully pay off.

Features of using copper radiators

If you plan to install a copper heater radiator in the heating system, it is important to follow some simple installation and operation rules.

For example, radiator manufacturers do not recommend using simultaneous connections of copper batteries and steel (galvanized) pipes along the flow of the coolant. This combination can lead to an electrochemical reaction and destruction of the heating system.

Brass fittings for connecting copper radiators

In cases where copper-steel connections cannot be avoided, it is recommended to use brass fittings. Currently, purchasing such components for heating systems will not be any particular problem, since their range is extremely wide and the cost is affordable.

It is not recommended to install copper radiators in heating systems where even the smallest abrasive particles may be present - they can, over time, “undermine” the inner surface of the radiator and lead to its wear.

Likewise, it is better not to use batteries with coolant that is highly acidic or hard. Some of these problems can be solved by installing special filters.

Review of manufacturers

This segment offers many products from different countries. In the following list they are sorted in descending order of price and quality.

Italy

The Italian company Sira, whose specialists developed bimetallic radiators, has proven itself best in the market of plumbing products for heating systems.

The history of the company goes back more than 50 years of fruitful work, so we can talk about the reliability of the goods produced at its factories located in Italy and China. The technical characteristics of such products are the standard for other manufacturers.

For more than one year, Russian consumers have had the opportunity to evaluate all the advantages of this product, which is also recommended by the Plumbing Research Institute due to the adaptation of batteries to the appropriate operating conditions of the heating system.

Italian designs from the Global Style brand can also boast an excellent heat transfer coefficient (not inferior to semi-bimetallic samples). Whatever product models are chosen, they all have an aesthetic appearance and a long service life.

Compact shapes and high quality make them very popular all over the world. Like the previous manufacturer, Global Style guarantees the durability of its products (at least 20 years). The technical characteristics of Italian batteries correspond to the following parameters:

- thermal power – 100 – 200 W;

- maximum coolant temperature – 135 degrees Celsius;

- working pressure – 20 bar;

- number of sections – from 4 to 10.

Russia

Russian heating batteries are represented by the company Rifar, whose production facilities are located in the Orenburg region. The company launched production in 2002 and today has become a leader in the CIS. The company specializes in semi-bimetal batteries.

The most popular models “Monolith” (a patented new development) and “Rifar Flex” (curved to fit bay windows) meet all the requirements for this type of product. The number of packed sections ranges from 4 to 14 pieces. The domestic manufacturer guarantees uninterrupted operation of its products for up to 25 years.

The main characteristics of the products meet the following indicators:

- thermal power (sectional) – 134 – 196 W;

- hot water temperature – 135 degrees Celsius;

- network pressure – up to 100 bar.

In addition to purchasing serial models, you can individually order batteries at the Russian plant.

South Korea

The South Korean company MARS produces radiators with a copper core and sets their service life to 25 years.

Technical characteristics are stated at the level:

- sectional heat dissipation – 167 W;

- working pressure – 20 bar;

- The maximum coolant temperature is 130 degrees Celsius.

Poland

Polsky also produces bimetallic products with a copper core that can last at least 25 years.

The remaining indicators are as follows:

- coolant pressure – 15 bar;

- coolant temperature – 110 degrees Celsius;

- heat dissipation – 167 W.

Numerous Chinese manufacturers supply the construction market with products that are significantly lower in price than other global companies, but the technical characteristics in this case are much more modest.

In order to determine which batteries are best suited in each individual case, it is necessary to carefully study their technical data provided by the manufacturers and compare them with the existing heating system of the apartment or house.

Installation

If you decide to install copper or bimetallic radiators, then do not forget that the copper parts must be connected either to copper pipes or to compatible metals and adapters. Copper has good contact with nickel, bronze, chromium, and brass. If combined with other metals, an electrochemical reaction may occur, leading to corrosion.

Corrosion at the junction of copper and steel

The most suitable place to install a radiator is under the window opening. As a result of this placement of the batteries, a heat curtain is formed that will cut off the cold air coming from the street. In order to ensure the best possible circulation of heated air, you should maintain a small distance, about 15 centimeters, between the window sill and the device and a distance of 3-5 cm between the wall and the radiator. Installation is carried out using anchors and retaining walls.

Copper is a soft metal. Therefore, in order to protect the device in areas of contact with fasteners, rubber or polymer gaskets should be used that prevent damage and possible leaks.

The connection can be made from the side or bottom.