Innovative technologies and the use of the latest materials have radically changed the approach to home heating in winter. But along with modern equipment, designs that have served humanity for many years still remain relevant. We are talking about a heating radiator made of cast iron. Let's look at what the MC 140 500 is, a cast iron radiator whose characteristics have changed little over many years of operation.

Cast iron heater Source makler.md

A little history

Let's start with an interesting fact. The fact is that one of the first cast-iron radiators still successfully heats one of the halls of the Imperial Court Chapel in St. Petersburg. It was made in 1857 in the workshop of Franz Karlovich San Galli.

Of course, the device was restored over a period of more than a century and a half. But the very fact that it still works great says a lot. And, of course, the design features were not changed. They are the same as the inventor came up with them.

San Galli developed its “hot box” for 4 years. The result was a horizontal structure made of a thick cast-iron pipe, densely covered with flat vertical disks. The design consisted of several levels. And the size of cast iron radiators of that time was impressive.

The inventor arrived in Russia from Poland. Having learned iron casting skills at the St. Petersburg Machine-Building Plant, he decided to open his own workshop. But sinks, fireplaces and beds were of little interest to residents on the Neva. And in order not to end up on the street, the Polish German had to come up with something original.

Mansion San Galli Source opengorod.rf

At that time, a heating system using hot water had already been developed. But it used steel pipes in the form of a coil, which the insidious heat carrier dealt with in a short time. A material was needed that could resist water aggression for a long time. And it became cast iron.

Long-lasting heating batteries quickly gained popularity in the cold northern capital. Orders poured in, and the developer set up widespread production. Franz Karlovich did not make a secret of the discovery and cordially shared the manufacturing technology with everyone.

Europe immediately paid attention to the new product. And specialists from neighboring northern countries flocked to the inventor. It must be said that they not only successfully applied the innovation in their homeland, but also improved it. As early as 1872, Nelson Bundy adopted a vertical design that is still reflected in modern radiators today.

Antique cast iron heater Source teplo-24.ru

And in 1895, a well-known American company launched the production of the first cast billets. The power of one section of a cast-iron radiator compared to a steel pipe was so great that batteries of the required size were assembled from individual elements. American Radiators was also the first to use cast iron construction for steam heating. Because the material turned out to be super strong and could easily withstand high pressure.

Comments

January 26, 2016

Author: Andrey

I still disagree a little, of course this radiator is good, but nowadays there are other radiators of a more modern type that are lighter, more comfortable and visually pleasing. In addition, the heat transfer of cast iron is lower than that of aluminum; by the way, for me, the best ones are bimetallic.

Answer

03 February 2016

Author: Vadim

Andrey, there is nothing better than cast iron. Excellent price/quality ratio, and the most important thing is durability, painted and like new. About aluminum ones, I can say that not everything is so good, yes, they are light and beautiful, but with our water quality, the radiator is very susceptible to corrosion and heat transfer is significantly reduced. And bimetallic ones are very expensive. So the best choice is cast iron. Just because they are heavy, it’s not a big deal if you hang them up and forget them, and then when they start leaking you can turn them into metal.

Answer

April 02, 2016

Author: Christina

I agree that cast iron radiators are a thing of the past, and no one has installed them for a long time, they are heavy and do not look aesthetically pleasing, although they keep the heat longer.

Answer

Advantages and disadvantages of cast iron structures

It is believed that cast iron began to be smelted in China as early as the fifth century BC. The properties of the material turned out to be so unique that it has found wide application in all spheres of life. And in order to take a place in heating our homes, cast iron had to wait several thousand years. The corresponding technologies have not yet appeared.

Advantages

The advantages of a cast iron heating radiator are more than enough:

- The material is highly durable. Manufacturers provide a guarantee for their products for a period of 25 to 50 years. But it is often positioned that a cast iron battery can last at least a century.

Working heaters in an old mansion Source artteplo23.ru

- The radiator walls can withstand very high pressure - up to 12 units.

- Coolant heated to +130 °C can be used.

- The power of the cast iron radiator section is higher than that of its steel counterparts.

- Cast iron has very good rust resistance. This parameter can be explained by one circumstance. Rust is still growing in the structure. But it is considered “dry”. This layer further protects the material from the effects of normal corrosion.

- Cast iron is not afraid of dirt inside the structure. And wide channels cannot be clogged with any debris.

- The heat capacity of cast iron is high enough to retain heat long after the hot water supply to the system is turned off. After an hour, the battery will still retain 30% of the original heat. Steel can only hold 15%.

- In addition to the convective method of heating air, cast iron can radiate heat using the infrared method.

- Modern designs are collapsible. Therefore, you can select the required number of segments purely individually. And replacing a broken unit is much easier.

Increasing battery segments Source 1-teplodom.ru

- The dimensions of cast iron heating radiators produced today are quite compact. They easily fit into any room design.

- The cost of structures remains affordable for all segments of the population for many years.

- If you properly sort out and thoroughly rinse a previously used product, you can give a cast-iron battery a second life.

But some advantages can also play a negative role. For example, wide channels in a section require a lot of coolant to fill. True, this can hardly be called a serious drawback.

See also: Catalog of companies that specialize in home insulation

Disadvantages of a cast iron battery

Many people note that at the very beginning the boiler needs to work under serious load and without pauses. The high heat capacity of cast iron is to blame for this. And the system needs to overcome the inertia of heat. And this requires a lot of energy. But this begins to be compensated already at the stage of switching on the automation. Since the material retains heat longer, the pauses between turning on the boiler increase.

Antique radiator Source prom.st

There are also very serious disadvantages. Despite its high hardness and strength, cast iron remains a brittle and non-plastic material. An accurate and strong blow is enough to split the product. It is also afraid of sudden temperature changes.

This is considered unlikely, but there were precedents. If you immediately run cold water into a battery heated to maximum, the walls of the product will crack. This can also happen if the coolant inside the battery freezes.

The second serious drawback is the significant mass. Even 1 section of the MC 140 radiator reaches 7.5 kg. Only two physically healthy men can lift a ten-segment battery. And if the coolant remains inside the system, then dismantling becomes very difficult.

Therefore, installation requires reinforced fastenings in the form of powerful hooks, or better yet, brackets. But they may also be powerless if the partition turns out to be flimsy. Therefore, before attaching the structure to the wall, the strength of the latter is checked.

Mounting brackets Source prom.st

There are often cases when, due to the impossibility of installation on a weak partition, cast iron radiators MS-140-500, the technical characteristics of which do not play a role in this case, have to be installed directly on the floor. In this case, special stands are used. But there are structures (of considerable length) in which legs are already provided on the outer elements.

Radiators are generally sold only with a primer outer coating. Therefore, fine-tuning to the aesthetic component is carried out independently. There are consumers for whom such an operation is considered difficult. In addition, it needs to be updated regularly. Preferably once every five years.

But even here manufacturers meet even such wishes halfway. And today’s market provides cast iron products with multi-layer painting. Naturally, their price is much higher. They also produce castings with antique decorative patterns. Such things are even considered exclusive.

Imported designs

Special mention should be made about Western-made cast iron radiators. They have one peculiarity. Heater sections are smelted much smaller than domestic ones. But they generate just as much heat as our larger cells.

European cast iron construction Source prom.st

The cast iron used for production is almost the same. But the technologies are strikingly different. Over the hill they require large investments. But the inner surface of the battery is smooth. Therefore, the coolant literally slides along it without experiencing resistance. This allows more water to pass through the radiator. And increased circulation means absorbing excess heat and increasing the power of the battery.

A striking example is Czech-made cast iron radiators. With compact dimensions, the power of one segment reaches 0.14 kW. But it only holds 0.8 liters of coolant. Even the best domestically produced samples with the same volume cannot generate more heat than 0.102 kW.

Old style radiators

Old-style cast iron batteries do not have the most attractive appearance. However, this does not mean that their installation will spoil the interior of the room. Today it is fashionable to cover radiators with decorative grilles, boxes and screens. Their level of heat transfer is reduced, but outwardly everything looks much more aesthetically pleasing.

Decorative screen for battery

Compared to radiators manufactured in Soviet times, modern batteries have a reduced distance between sections, which makes them neater.

Modern cast iron radiator

The main advantage of old-style radiators is their affordable price. The cheapest devices are manufactured in Russia. Batteries produced in other countries (for example, Belarus) are a little more expensive, but in addition to price, they differ in size.

Old-style cast iron batteries are unpretentious in operation. If the apartment owner does not dislike their appearance, he can simply paint them to match the color of the walls.

Cast iron radiators of the old type are called “MS”. After the name there are numbers separated by a dash. The first number indicates the depth of the sections, and the second - the distance between them (for example, MS-140M-500, MS-110-500).

Cast iron radiator MS-140M-500

When choosing a cast iron radiator, you must take into account the depth of its section. First you need to measure the depth of the window sill. After all, if the battery is located in a niche under the window opening, then it should not stick out from under the window sill. Firstly, this can ruin the entire appearance, and secondly, the radiator will interfere with approaching the window. For example, the MS-110 model produced by the Santekhlit plant has a small depth of sections, only 11 cm. Such a battery will easily fit under any modern plastic window sill.

Cast iron radiator MS-110

Which radiators are better - domestic or imported? In Western countries, heating systems are of higher quality and cleaner, therefore cast iron batteries manufactured by Western developers, when working with domestic coolants, can quickly fail. Dirt (rust, various chemical elements) accumulates inside the batteries, narrowing the opening for the passage of hot water. As a result, their thermal efficiency decreases and they may stop heating the room.

Features of MS-140 brand batteries

Today, cast iron heaters with four, seven and ten sections are produced for sale in specialized stores. But since the design is collapsible, it is possible to assemble a radiator with any number of segments.

MS 140 Source prom.st

Let's look at the markings that MS-140-500 cast iron radiators have: technical characteristics of the last two digits and letter designations. The number 140 shows the depth of the segment in millimeters. And the number 500 (mm) indicates the distance between the axles. Another value found is 0.9. It indicates the allowed water pressure. And at the very end of the marking you can find a number indicating the number of cells in the battery. And most often the documents contain the following marking: MS-140-500-0.9-7.

There have been disputes over the letters MC for years. There are several decryption options. Someone is talking about cities. For example, that the first products were produced at one of the factories in Moscow. But there are only two acceptable versions. "Modified Standard" and "Multi-Sectional". The latter is more plausible.

In addition to sections with a depth of 140 mm, segments with smaller dimensions are also produced - 110 and 90 millimeters. There are also models with different heights between the axles. Just 300 mm. Such designs are more compact, but they have much less heat transfer.

You can also find such an article - MS 140 108 or 98. The last numbers indicate the gap between the nipples of the cells in millimeters.

MS-140-500 Source prom.st

The following companies produce cast iron batteries of the MC 140 series:

- Boiler and radiator plant in Nizhny Tagil (Russia).

- Heating equipment plant in Minsk (Belarus).

- Foundry and mechanical plant in Lugansk in Ukraine.

- Enterprises of OJSC Santekhlit, covering the Bryansk region of Russia.

- in Novosibirsk (Russia).

All enterprises operate in accordance with the regulations of their countries, and their products are certified ISO 9001:2008.

Main characteristics

MS-140M-500 is a cast iron radiator, the characteristics of which must be carefully studied before purchasing the product. This equipment is a convection-type device that has elliptical or round sections. The radiator releases approximately 25% of the heat flow transmitted by the coolant into the room. The remaining 75% is transmitted by convection.

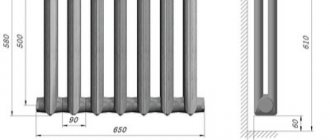

On sale today you can find sectional cast iron radiators, the construction depth of which is 90 and 140 mm. If we are talking about the MS-140M brand, then we can say about it that the distance between sections is 300 or 500 mm. One section has a heat transfer surface of 0.208 m2. One section holds 1.45 liters and weighs 6.7 kg.

MS-140M-500 - a cast iron radiator, the characteristics of which may be useful to you, is equipment whose specific metal consumption is 42 kg/kW. Experts are sometimes also interested in the linear heat density of the flow; it is 1.48 kW/m. One section has a power of 160 W. For Russia, such devices are traditional today. Their main advantage is their ability to be used in open systems.

Technical standards for a cast iron heater

The performance of the entire heating system largely depends on the quality of the coolant. Water in the post-Soviet space leaves much to be desired. The concentration of aggressive chemical elements in it is so high that sometimes it can even corrode metals.

Therefore, consumers choose the cast iron radiator MC 140, the technical characteristics of which allow them to ignore this problem. And all because the battery material is not susceptible to chemical reagents. It is also not afraid of corrosion and is extremely resistant to abrasion.

MS-140-300 Source prom.st

The power of cast iron heating radiators and their technical characteristics are indicated in the table:

| Model | Center height in mm | Section width in mm | Depth in mm | Height in mm | Thermal power in W | Volume in liters | Weight in kg |

| MS 140 500 | 500 | 93 | 140 | 588 | 160 | 1,45 | 7,1 |

| MS 140 300 | 300 | 93 | 140 | 388 | 120 | 1,11 | 6,1 |

| MS 110 500 | 500 | 82 | 110 | 588 | 105 | 0,85 | 5,6 |

| MS 110 300 | 300 | 82 | 110 | 381 | 79 | 0,63 | 4,5 |

| MS 90 500 | 500 | 76 | 90 | 581 | 115 | 1 | 4,5 |

Radiator segments are cast from so-called gray cast iron. Moreover, there are a couple of channels for coolant inside. And for the latter they use water. But it can be heated up to +130 degrees Celsius. Almost turning into steam. And no design made of other materials can afford this. The maximum possible liquid temperature in stainless steel batteries rises only to +110 °C.

The MC 140 radiator segments are fastened to each other with nipples. They are also made from cast iron. But sometimes steel is used in accordance with GOST 1050. For sealing, rubber is used that can withstand heating up to +150 °C. The nipple hole is made with a G11/4 thread.

Nipple for cast iron battery Source sowetkin.ru

Among the additional technical characteristics of the cast iron heating radiator MC 140, it should be noted that the chemical activity of the metal is quite low. This allows you not to worry about the quality of the coolant. And normal water circulation cannot be prevented by hydraulic resistance. Because it's small.

Since, in addition to standard models, manufacturers also produce decorative (antique) ones, the height of the cast-iron battery differs somewhat, both up and down. Naturally, the size will affect the heat in the room. After all, the heating area of the standard section is 0.19 m2. If the parameters are higher, then the heat transfer increases.

Indicators influencing the calculation of the number of sections

When choosing a radiator for a particular room, you need to take into account technical features. For example, the calculation will be different for a corner and non-corner room, for a room with different ceiling heights and different window sizes, etc. The most important parameters that are taken into account when determining the required radiator power are:

- the area of your premises;

- floor;

- ceiling height (above or below three meters);

- location (corner or non-corner room, room in a private house);.

- will the radiator be the main heating device;

- There is a fireplace and air conditioning in the room.

There are other important features that need to be taken into account. How many windows are there in the room? What size are they, and what kind of windows are they (wooden; double-glazed windows for 1, 2 or 3 glasses)? Was additional insulation of the walls done and what kind of insulation (internal, external)? In a private house, what matters is the presence of an attic and how insulated it is - and so on.

Cast iron radiators Conner (China)

According to SNIP, 41 W of thermal energy is required per 1 cubic meter of space. You can take into account not the volume, but the area of the room. For a 10 sq.m standard room with one door and one window, one door and an outer wall, the following heat output of the radiator will be required:

- 1 kW for a room with one window and an outer wall;

- 1.2 kW if it has one window and two external walls (corner room);

- 1.3 kW for corner rooms with two windows.

In reality, one kilowatt of thermal energy heats:

- In houses made of brick with a wall thickness of one and a half to two bricks, or made of timber and log houses (window and door area up to 15%; insulation of walls, roof and attic) - 20-25 sq. m

- In corner rooms with walls made of timber or brick of at least one brick (area of windows and doors up to 25%; insulation) - 14-18 sq. m

- In the premises of panel houses with internal cladding and a thermally insulated roof (as well as in the rooms of an insulated dacha) - 8-12 sq. m

- In a “living trailer” (wooden or panel house with minimal insulation) – 5-7 sq. m.

Calculation of the power of a cast iron battery

There is a misconception that the greater the power of 1 section of a cast iron radiator, the better. In fact, it is necessary to take into account the comfort of staying in the room. After all, few people know that when air is heated, oxygen is burned from it.

This will lead to the fact that over time a person’s breathing will begin to become difficult. In addition, the atmosphere is constantly drying out. Losing normal humidity will also not lead to anything good. The mucous membranes will dry out and no longer retain harmful microbes.

Multi-section cast iron heaters Source simpalsmedia.com

Excessive heat will actually cause large temperature fluctuations in the room. Because you will have to ventilate it more often. And after the body warms up under the influence of excess heat, the effect of drafts on it can be detrimental.

Therefore, it is especially important to correctly calculate the required power of a cast iron radiator for each individual room. There are various ways to do this. Let's look at each of them, from simple to complex.

The simplest calculation

General recommendations state that for every square meter in a room there should be an average of 100 W of heat. Therefore, measure the length and width of the walls of the room. Then the indicators are multiplied. And the found size of the room is again multiplied by 100.

For example, the area of the room turned out to be 12 m2. This means that 1200 W of heat is needed to heat it. If you plan to purchase a standard model MS-140-500, then you need to find out the power of one section. Its parameter is 160 W. Now it remains to find out how many segments the battery should have. To do this, divide 1200 by 160. And the resulting result is always rounded up. And since the final figure is 7.5, for such a room you need to purchase a radiator with eight segments.

Battery with eight sections Source cast-radiators.ru

More accurate calculations

But it is better to look not for the area of the room, but for its volume. Therefore, you need to multiply three parameters - length, width and height. Since standard ceilings in apartments are 2.5 meters, we get a room volume of 30 cubic meters.

Next you need to know a special coefficient depending on the type of structure:

- for a brick building – 0.034 kW/m;

- in panel houses - 0.041 kW/m.

The volume is multiplied by a coefficient. And if the room is located in a panel high-rise building, then 1.23 kW will be needed to warm it up. Dividing by the power of the standard battery section and rounding up, we get a radiator with eight segments. In a brick house you will need a battery with only six sections.

Difficult, but the most accurate way

In this case, many factors must be taken into account:

- square;

- volume;

- ceiling height;

- presence and number of windows;

- location of the room relative to the building;

- way to connect a battery to a heating system.

First you need to find how much heat is needed to heat the room. It is best to use the more accurate previous method. Next, the final figure is adjusted according to all the conditions in which the premises are located.

Corner apartment in the house Source repair161.ru

And each has its own coefficient:

- corner room - 1.8;

- the presence of a large window or a pair of small ones – 1.8;

- presence of double glazing – 0.8;

- bottom battery connection – 1.1;

- For the ceiling coefficient, you need to divide the height of the room by three.

Let's assume that the dimensions of the room are the same, and the listed factors are all present. The ceiling coefficient for a room 2.5 meters high will be 0.8. If the house is panel, then the required heat when adjusted will be within 2.8 kW. To meet this need, you will need a battery with eighteen segments. You can place two radiators in the room, each with 9 sections. For a brick house you will need 14 segments.

We remind you that for the calculations we took a room with an area of 12 m2 with ceilings of 2.5 meters. The room has a corner location and has two standard windows equipped with European double-glazed windows. And the power of one segment was taken from the MS-140-500 battery.

Calculation of the number of sections

Accurately determining the number of sections in a heating battery is a long process.

You need to take into account the region, the material of the walls, what kind of windows and doors there are, how many windows are in the room, what their area is, whether the room below is warm or cold, etc. If you need an exact calculation method, look here, but you can roughly calculate based on the area of the room. It is believed that on average 100 W of heat is required to heat 1 m2 of area. Knowing the area of your room, determine how much heat will be needed: multiply the area by 100 W. Then divide by the thermal power of the selected radiator model. For example, in a room of 12 m2 we will install MS-140M-500-0.9 from the Bryansk plant. Thermal power of the section is 160 W. Calculation:

- Total heat required is 12m2 * 100 W = 1200 W

- How many sections are needed 1200 W / 160 W = 7.5 pcs. We round (always up - it’s better if it’s warmer) and we get 8 pieces.

Connection options for cast iron batteries

There are four ways to connect radiators to the heating system:

- Diagonal. Suitable for batteries with a large number of sections. The upper fitting is connected to the supply on one side of the radiator, and the lower one is mounted on the return on the other. The sequential connection principle implies that the coolant will circulate only due to the pressure in the system. And to remove airiness, Mayevsky taps are installed.

- Lower. Used when the system is located below floor level. The most aesthetic method, since communications are not visually visible.

- One-sided. Both supply and return are connected from the side, on one side of the battery. This method guarantees very high heat transfer. Even if the pipe connections are confused. In this case, the power may decrease by only 10%.

- Parallel. In this case, the supply and return pipes are connected by a separate jumper, with a shut-off valve installed between them. The battery is connected to the pipes on one side. If you install shut-off valves at each inlet, the radiator can be easily dismantled for repairs, and the system continues to operate.

When connecting by any of the methods, it is necessary to provide a place for carrying out maintenance work. This will allow servicing the system without dismantling and temporary shutdowns.

terms of Use

The radiator is used in water/steam heating systems with any type of boiler, in which the coolant is ordinary water, without specific requirements for its quality.

Installation should only be carried out in a heating network that is designed, installed and operated in accordance with regulatory documentation adopted by government industry organizations.

For Russia, such a regulatory act is the rules SP 60.13330.2012 or 73.13330.2012.

Features of installation of cast iron structures

There are certain rules that will ensure better system performance if they are strictly followed. It is also necessary to adhere to the established sequence of work. By following the recommendations of specialists, you can increase the guarantee that your heating equipment will last for many years.

Help for selecting battery sizes

Experts say that to provide the most effective protection from the cold, the radiator should occupy at least 70% of the width of the window opening. In this case, you can avoid cold areas on the sides of the battery. And this will eliminate condensation on the window and the appearance of dampness.

Rules for the location of the radiator, relative to the floor, walls and window sill:

- It is necessary to mark the middle of the window opening with extreme accuracy. From this point, segments are laid to the right and left. They are taken knowing the size of the cast iron battery in order to accurately position the fastening elements.

- To reduce the lower cold zone, the radiator should be located from the floor at a distance of 8 to 14 cm.

- The convention will not be violated if you leave 10 to 12 cm from the radiator to the windowsill.

- The heater's thermal output will increase if it is placed 3-5 cm from the wall.

Mounting the battery on the wall Source ytimg.com

Knowing these parameters, it will be much easier to choose a cast-iron structure of the optimal size. But you should know that literally every manufacturer has its own recommendations for installing products. Therefore, it is a good idea to read the instructions supplied with the radiator.

Preparatory work

Before installing the device, you must carefully examine the walls. The method of fastening them will depend on what material they are made of. Since it is not possible to properly strengthen a weak wall, you will have to think about a system of stands on the floor in order to install a heavy radiator on them.

This step will be necessary if the partition is wooden and made of plasterboard. If the surface is monolithic, then you just need to prepare it. If possible, it is leveled and a heat-reflecting shield is glued on top. This will increase the heating power.

The future location of the radiator should be with a minimum slope towards the return line. This will ensure free and proper circulation of coolant. If you mix up the slope, air pockets will form, which will not allow hot water to move through the system.

Controlling the correct slope Source remont-system.ru

Installation of brackets

Correct installation of fasteners is the key to good performance. It would be a good idea to try on the radiator in place before installing the fasteners. This will help you maintain the correct slope. And since the weight of the structure is considerable, you need to prepare a layout. A lightweight cardboard imitation will allow you to accurately mark the locations for fastenings.

Sequential steps for installing brackets:

- Using a radiator model, points on the wall are marked.

- Holes of the required diameter are drilled.

- Plastic dowels or wooden plugs are installed.

- Brackets are driven into the prepared holes.

- The fastenings are fixed with concrete mortar.

- After complete hardening, the strength must be checked.

To install a cast iron radiator, four brackets are enough. Two are located at the top of the structure and two at the bottom. When building up sections, fasteners are added.

Radiator connection diagrams Source teplosale.ru

Step-by-step installation steps

To connect the battery to the heating system, you must do the following:

- Hang the radiator on the brackets.

- The upper battery collector must be equipped with an adapter with an installed air vent.

- Free collectors are provided with plugs. If they do not fit in diameter, then they are installed through adapters.

- Shut-off valves are installed at the inlet and outlet of the battery. It will help quickly eliminate coolant leaks in the event of an accident. And it will provide convenient repairs without dismantling the system.

- Adjustable fittings in the form of manual or automatic thermostats are installed at the request of the homeowner.

- By choosing one of four connection schemes, inlet and outlet pipes are connected to the battery. The connection can be threaded, crimped or welded.

- After this, the radiator is pressurized.

To avoid water hammer, it is necessary to fill the system with coolant as slowly as possible, gradually opening the taps to full speed. At this stage, it is better not to remove the protective film from the product. This operation is left for later, when painting of the battery is completed.

Pressure testing of heating Source x-teplo.ru

Decoration

The easiest way to complete the heating system is to paint the radiator. To do this, select a durable palette of colors that will look harmonious in the overall interior. If desired, you can apply patterns or ornaments to the surface.

For those who think that cast iron radiators look too barracks-like, it is recommended to hide them behind decorative screens. Just don't use a blind shield. Otherwise, the circulation of heated air will be disrupted. It is best to install a wooden grate. Or use a screen with many holes.

Basic characteristics of a classic radiator

A standard cast iron battery consists of 4-10 separate sections. Its size depends on the choice of thermal conditions in the room and the architectural features of the house.

Despite the difficulties that arise when installing a heavy cast iron heating radiator, this is not considered the main problem. The main task is to correctly install the battery. To implement it, it is not enough to know only the mass of the product; the following points must be taken into account:

- Distance between axles. Standard models can have 350 or 500 mm. Batteries with a large height are characterized by proportional dimensions between the axes.

- Depth. Standard sizes 92, 99, 110 mm.

- Section width. The sizes are in a slightly larger range - 35 - 60 mm.

- Section volume. This is the amount of coolant that is necessary to completely fill the radiator element. The volume depends on the size of the section. Average values range from 1 to 4 liters.

An important problem with installing a classic cast-iron battery is that it is only intended for wall mounting. At the same time, most modern houses are made of porous materials

such as aerated concrete, foam concrete, as well as SIP panels with foam filling. These walls require special fastening of a complex structure with multi-point fixation, which is unlikely to be to your liking.

User reviews and recommendations

Aluminum or bimetallic batteries for home heating cope with their functions much more efficiently. But their service life is not long. And many users do not want to spend large sums for a short period of time. Therefore, cast iron radiators with good power of 1 section still remain relevant.

People are mistaken when they talk about the negative side of using large amounts of coolant. The opinion that this will cause severe heat loss is erroneous. In fact, a larger mass of hot water will provide even better heat transfer.

This factor remains decisive when the heating system boiler turns off for any reason. A large amount of coolant in the battery allows it to remain hot for a long time. Whereas other systems immediately begin to cool down. And after a short time the radiators in them become cold.

Pressure testing of a cast iron battery Source 1c-bitrix-cdn.ru

Experience shows that the material of the battery also contributes to heat retention. Cast iron in this case is at the highest altitude. Leaks are very rare in such products. And if they happen, then there is a high probability that, due to “dry” rust, the microcracks themselves will become slagged.

Users recommend not leaving any window without batteries. It is in this area that the largest heat leaks from the room occur. A radiator under the window sill compensates for heat loss. It will also be a guarantee that no matter what the winter, your home will remain warm.

Qualities and characteristics

The described heating devices are designed to transfer thermal energy from the heating system to the premises of public, residential, industrial and other buildings. They are designed for coolant temperatures up to +130 degrees and operating (excess) pressure of the medium up to 0.9 MPa. Products are manufactured in accordance with GOST No. 31311/2005, as well as TU No. 4935/005/00288372/05.

Advantages of cast iron batteries

- High degree of corrosion resistance. This quality of cast iron is explained by the fact that during operation “dry rust” grows on its surface. It protects the material from corrosion.

- Cast iron has good wear resistance. Dirt and debris inside the system do not harm it.

- Excellent level of thermal inertia. Cast iron batteries, 60 minutes after turning off the heating, retain about 30 percent of the heat. For steel analogues, this parameter is only 15 percent.

- Very long service life. A high-quality device can last about 100 years. Manufacturers guarantee 15/25 years of trouble-free service.

The thermal photo shows that part of the battery is clogged with debris, which means it needs to be cleaned.

- Large cross-section of the internal space of the sections. Thanks to this, the batteries only need to be cleaned once every few years.

- The price of such heating devices is relatively low.

Briefly about the main thing

When installing a heating system at home, many owners think about saving money. But at the same time, none of them wants to stay in a cold apartment when the frost outside the window increases. Therefore, the choice of heating radiator is of utmost importance.

A large number of people whose home heating system uses hot water focus on the classic cast iron radiator MS-140-500 (or 300). Over many years of operation in different conditions, the design has proven itself only on the positive side.

Due to its good flow capacity, the heater segment has excellent thermal output. And the material has special properties that allow it to retain and release heat for a long time, when the boiler no longer heats the water. At the same time, the design is not at all afraid of corrosion.

Despite its excellent advantages over radiators made from other materials, a cast iron battery has one significant disadvantage. Its mass is very large. Therefore, installation is only possible on a sufficiently strong wall. But if there is none, then you can always use special stands or legs and install the radiator directly on the floor. System performance will not be affected by this.

Device Specifications

Cast iron radiators of this type have the following technical characteristics:

- The service life of cast iron radiators of the MS 140 brand is at least 50 years.

- The coolant temperature can reach +130 degrees.

- Warranty period - 2 years.

- Working pressure - 9 atmospheres. And the maximum test pressure applied to radiators of this type is 15 atmospheres.

- The inlet diameter is 1 ¼ inches.

- The material of the intersection gaskets is high-temperature resistant rubber.

- The heat output of one section is 175 W.

- Sections and plugs are made of gray cast iron grade SCh-10.

- Cast iron radiators can withstand pressures up to 15 bar when performing pressure testing.

- The number of channels in 1 section is 2 pcs.

- Country of origin: Russia.

In the factory configuration, MC 140 radiators can consist of 4 or 7 sections. These types of devices are supplied without brackets, so do not forget about this element when purchasing.

Formulas for calculating heater power for various rooms

The formula for calculating the heater power depends on the ceiling height. For rooms with a ceiling height of 3 m, calculations are carried out according to the formula

- S – total area of the room;

- ∆T – heat transfer of a separate section of the battery;

- h – ceiling height.

These simple formulas will help you accurately calculate the required number of sections of the heating device. Before entering data into the formula, determine the real heat transfer of the section using the formulas given earlier! This calculation is suitable for an average incoming coolant temperature of 70˚ C. For other indicators, it is necessary to take into account the correction factor.

Let us give examples of calculations. Let's imagine that a room or non-residential premises has dimensions of 3 x 4 m, the ceiling height is 2.7 m (standard ceiling height in Soviet-built city apartments). Let's determine the volume of the room:

- 3 x 4 x 2.7 = 32.4 cubic meters.

Now let’s calculate the thermal power required for heating: multiply the volume of the room by the indicator required to heat one cubic meter of air: